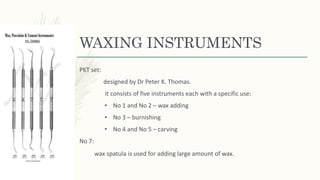

The document details the wax pattern process used in dental restorations, highlighting both direct and indirect techniques for creating patterns on prepared teeth. Key requirements for ideal wax properties, construction methods for various types of restorations such as crowns and retainers, and specific instruments used in waxing procedures are discussed. The text emphasizes the importance of achieving accurate margins and minimizing distortion during the wax fabrication process.