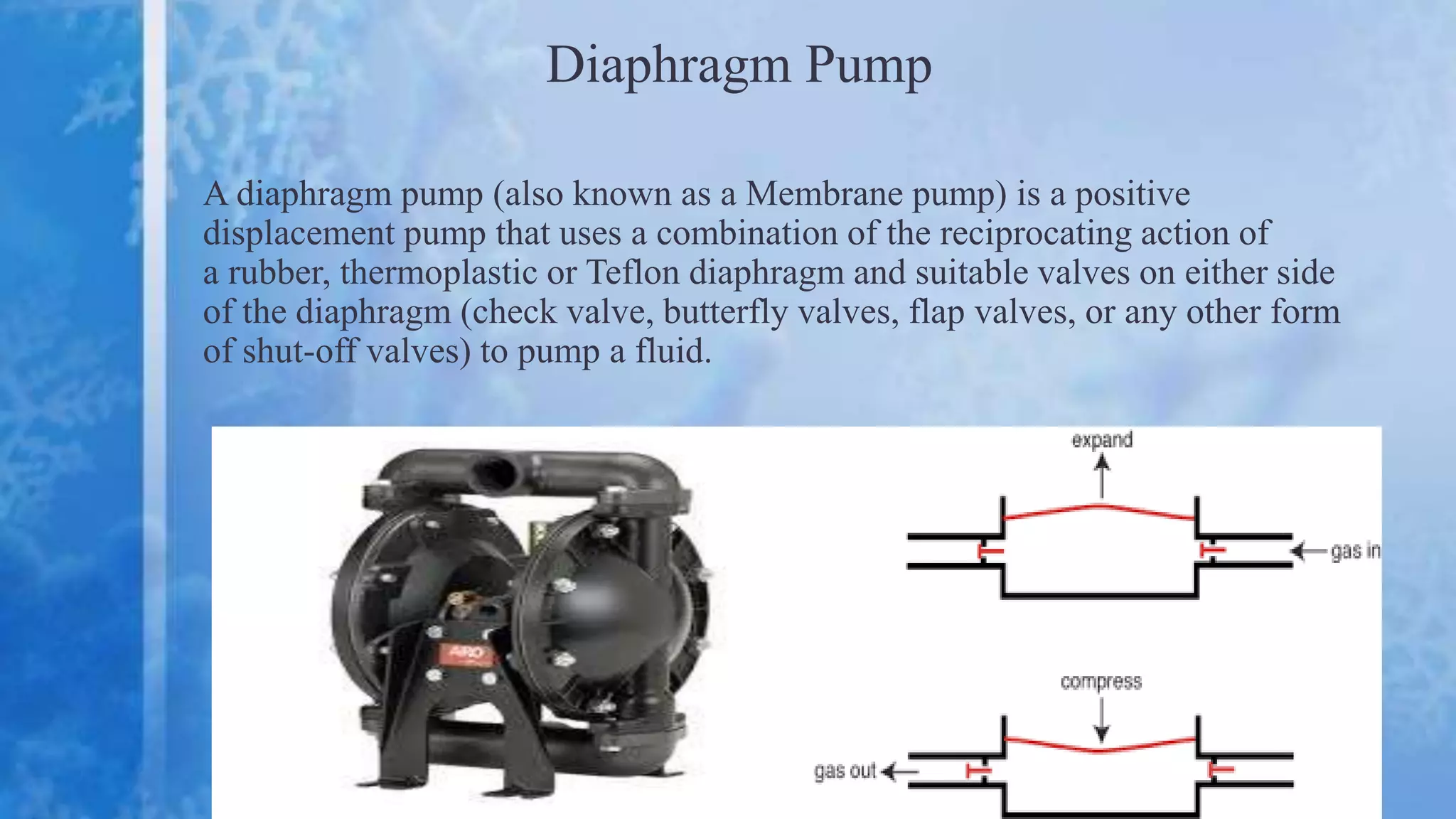

The document is a seminar presentation on various types of pumps, explaining their mechanisms, classifications, and applications. It details positive displacement pumps, including diaphragm and centrifugal pumps, highlighting their operational principles, advantages, and common issues like cavitation and overheating. The presentation concludes with a list of applications for different types of pumps, emphasizing their importance in fluid movement across various industries.