This document provides information about air compressors, including:

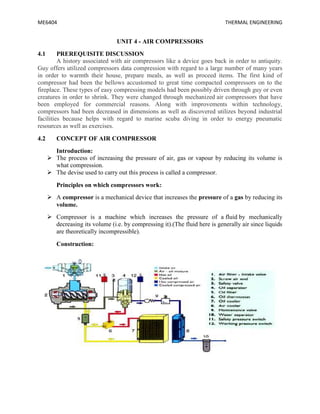

- It discusses the history and principles of air compressors. Compressors increase pressure by reducing gas volume.

- Air compressors have many important applications and account for 10% of global energy use in industry. They are essential for manufacturing processes.

- Compressors are classified as either positive displacement or dynamic. Positive displacement compressors include reciprocating and rotary vane compressors.

- Multistage compression improves efficiency by compressing air in multiple stages separated by intercoolers. This reduces temperature and improves volumetric efficiency.

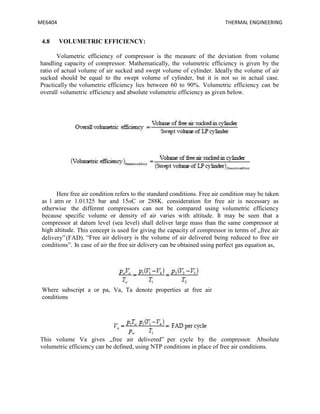

- Technical details are provided on reciprocating compressor operation and factors that affect volumetric efficiency.