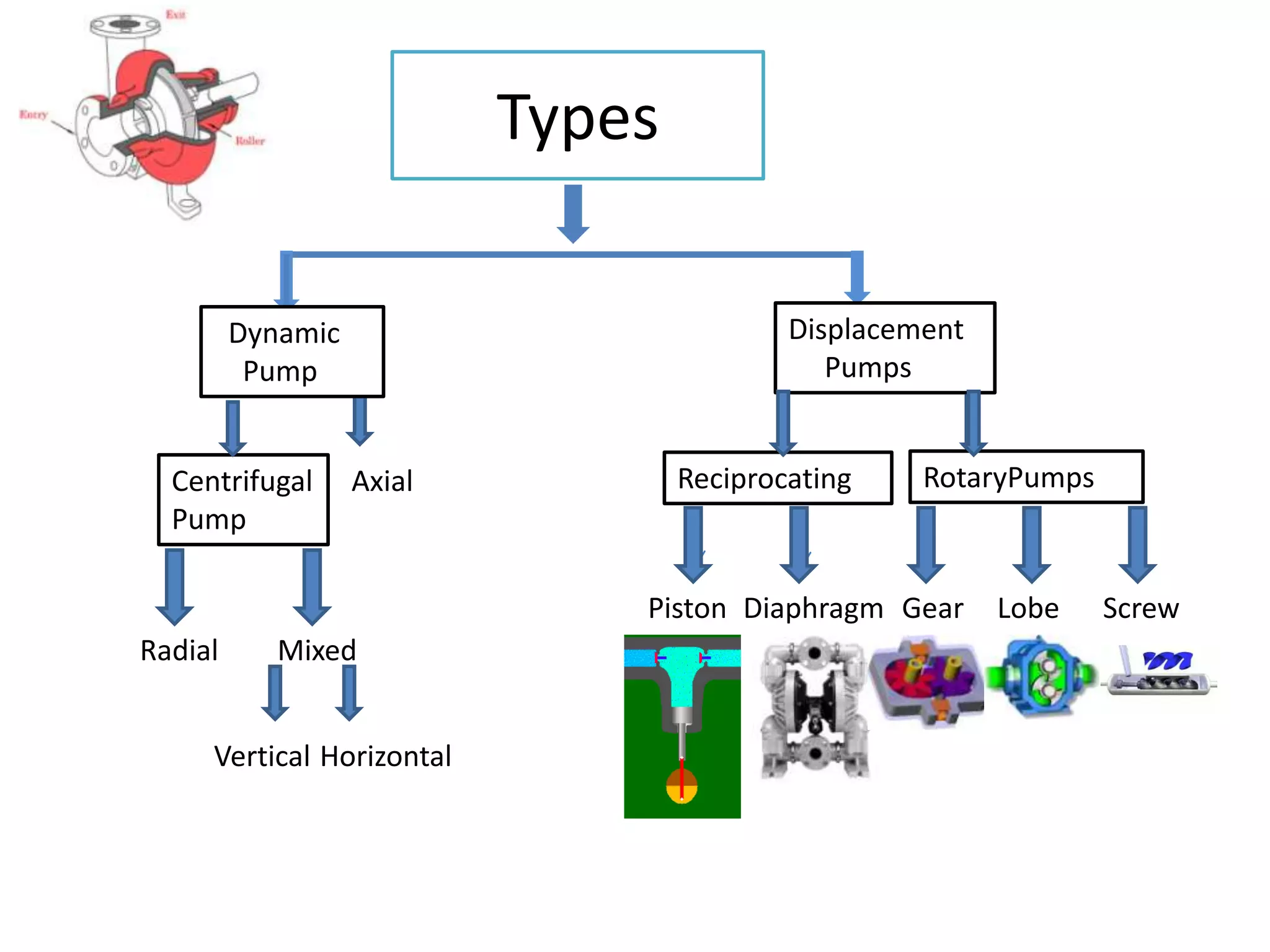

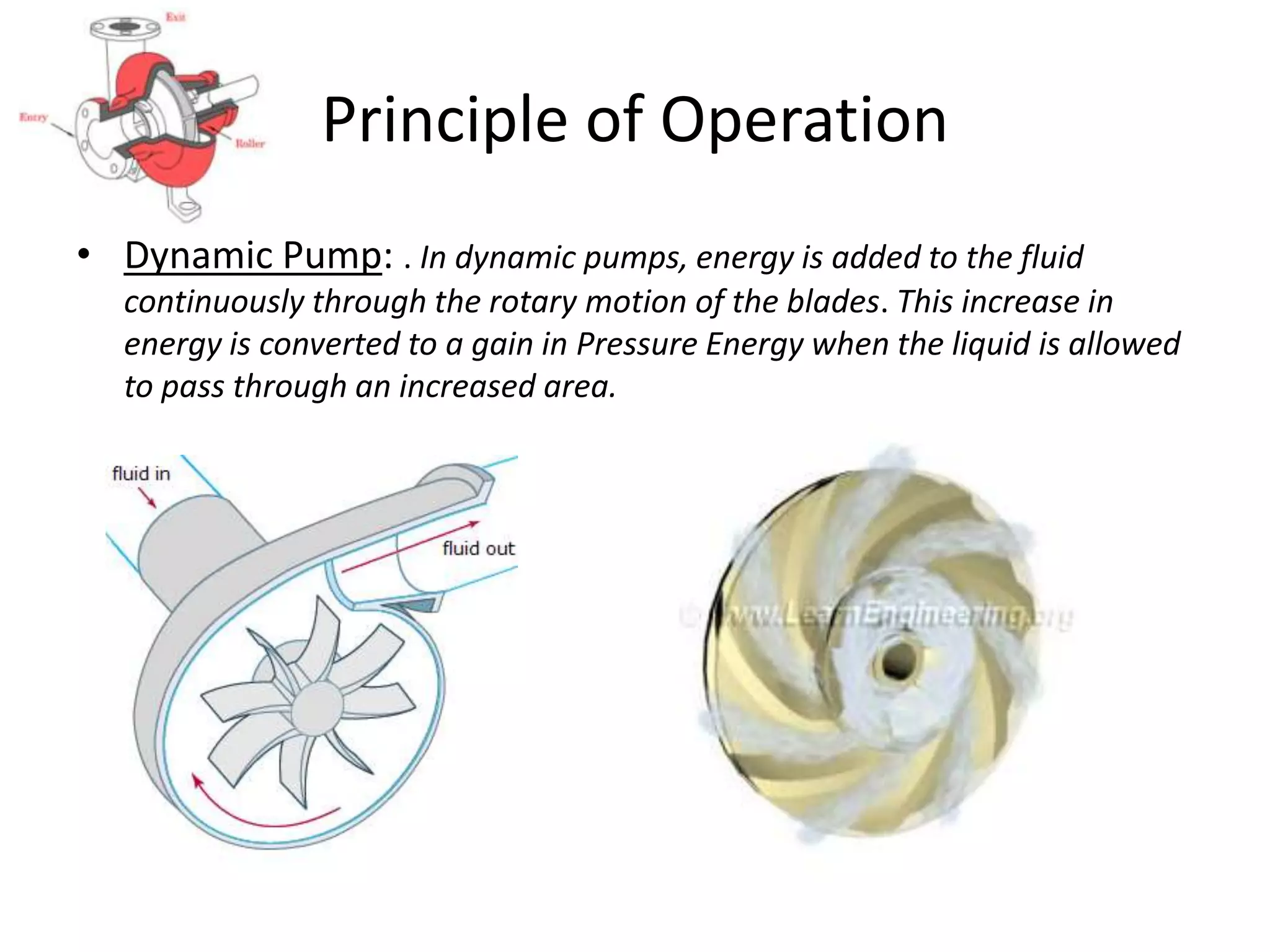

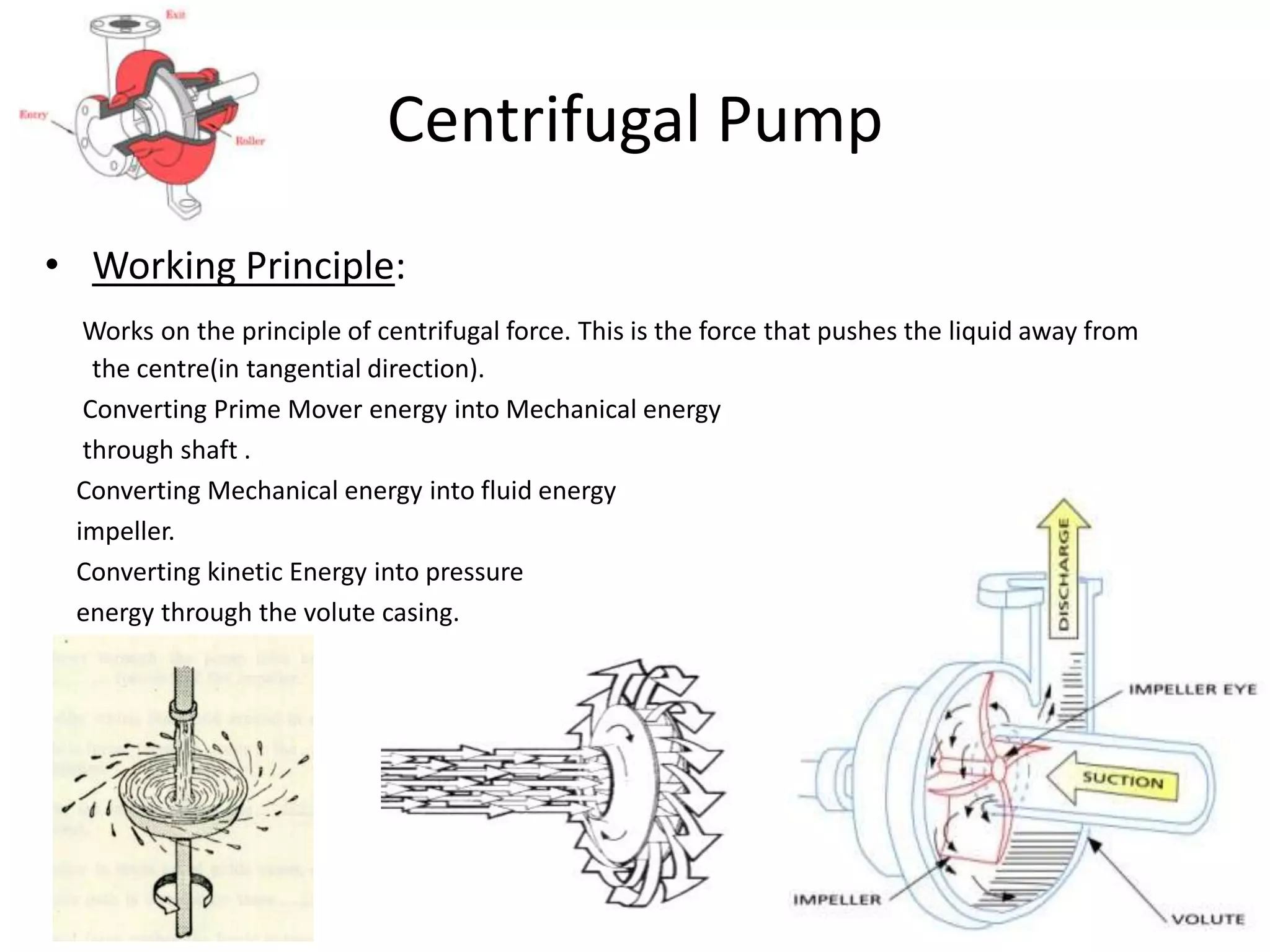

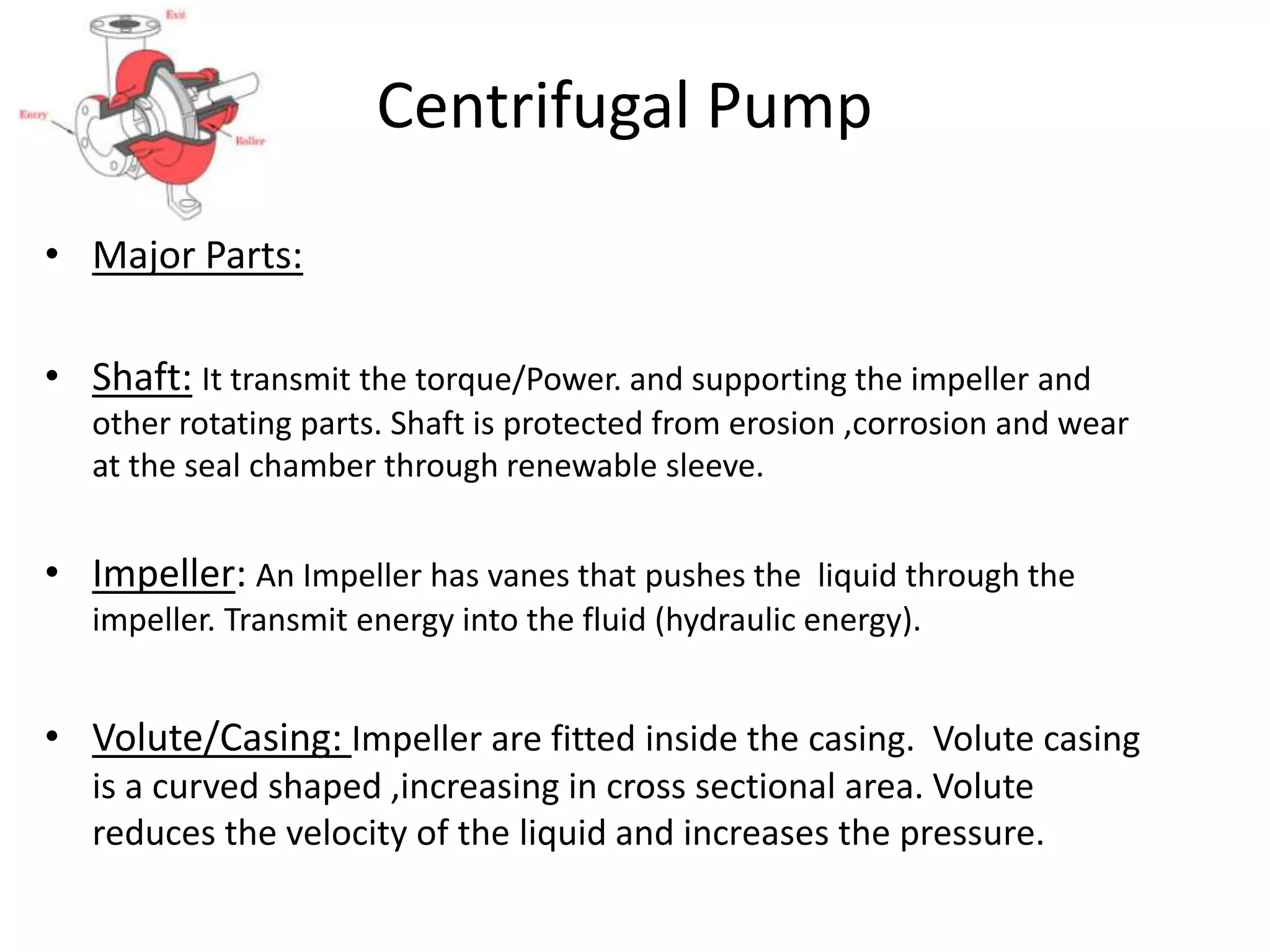

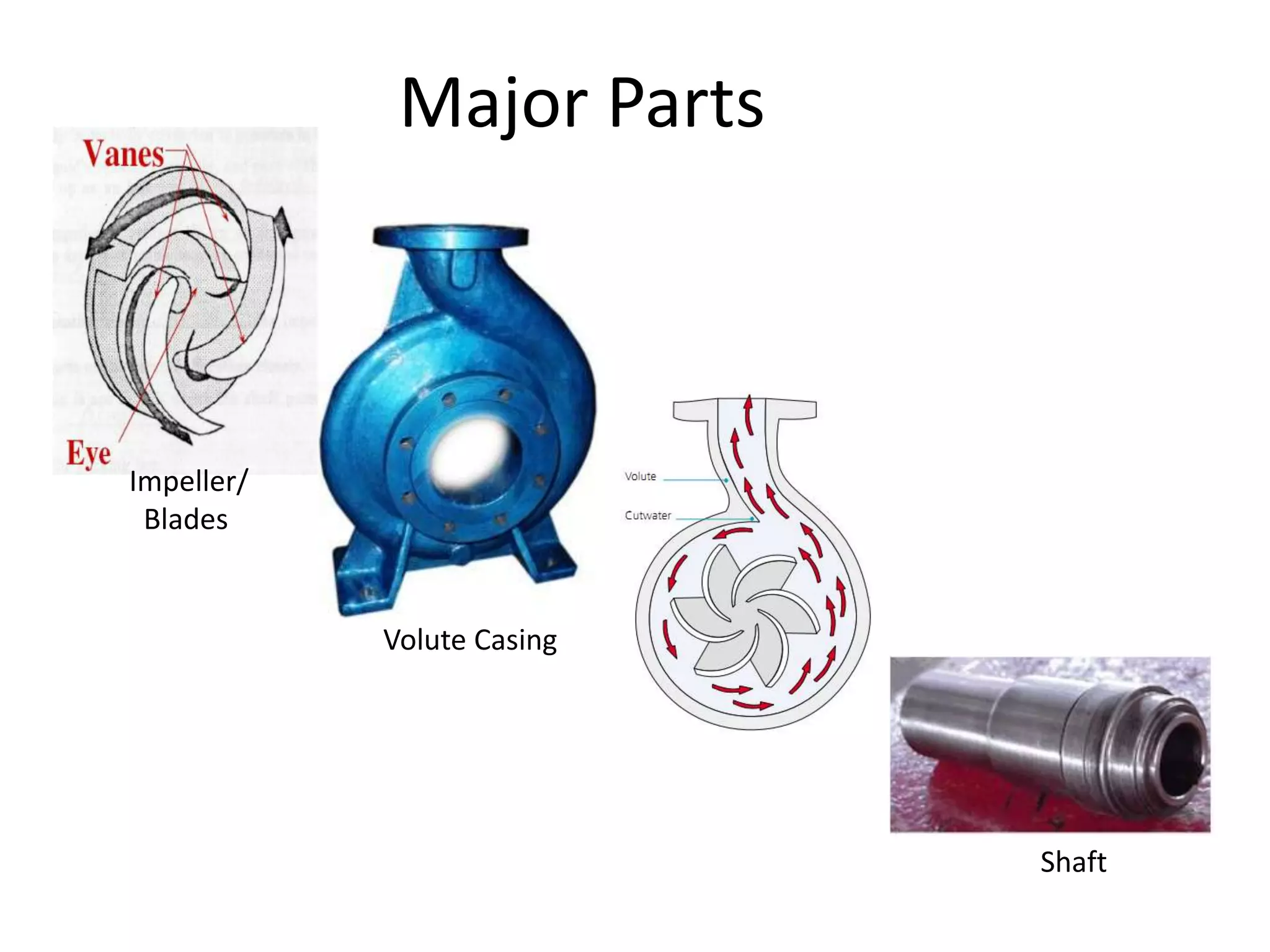

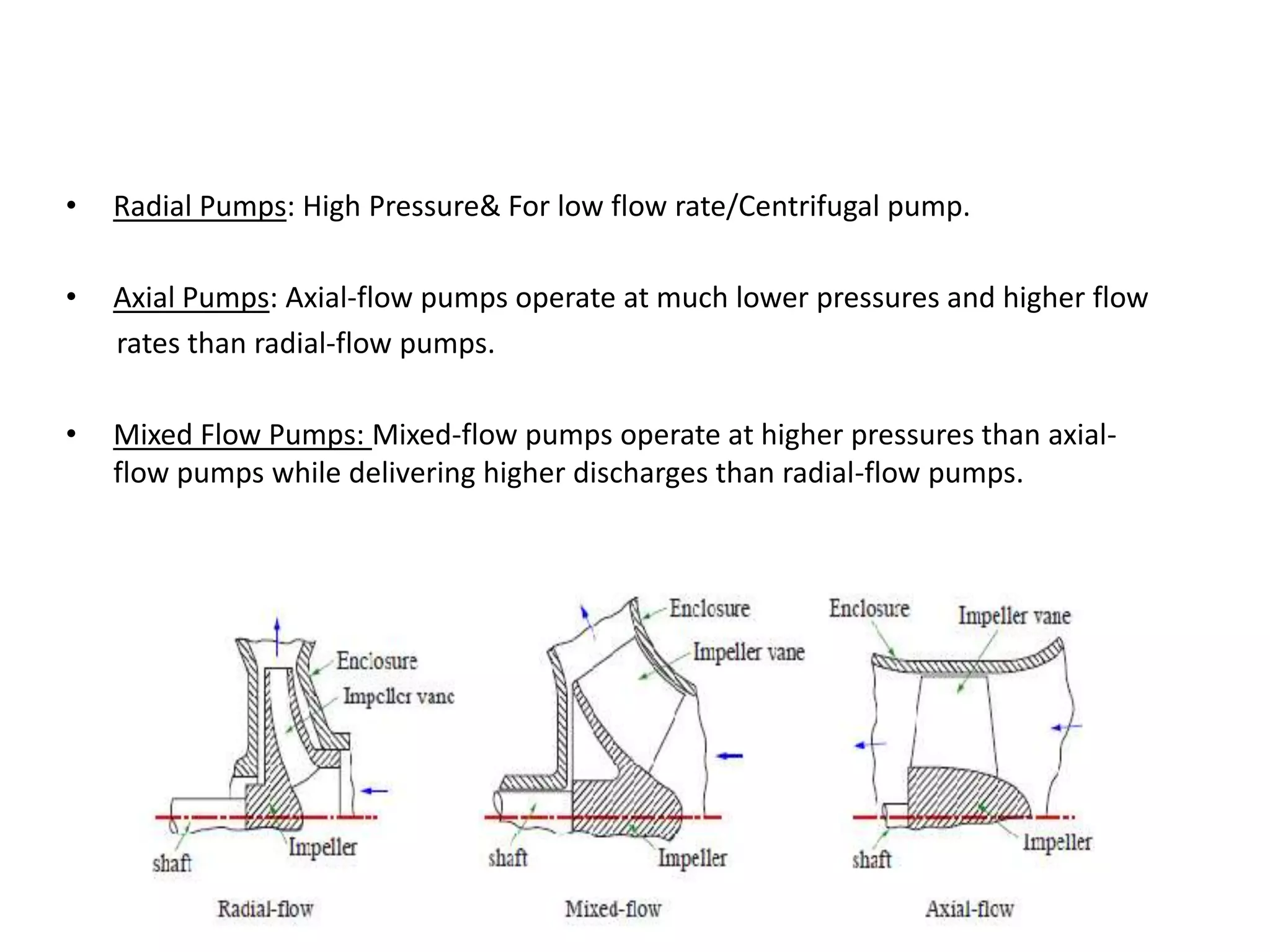

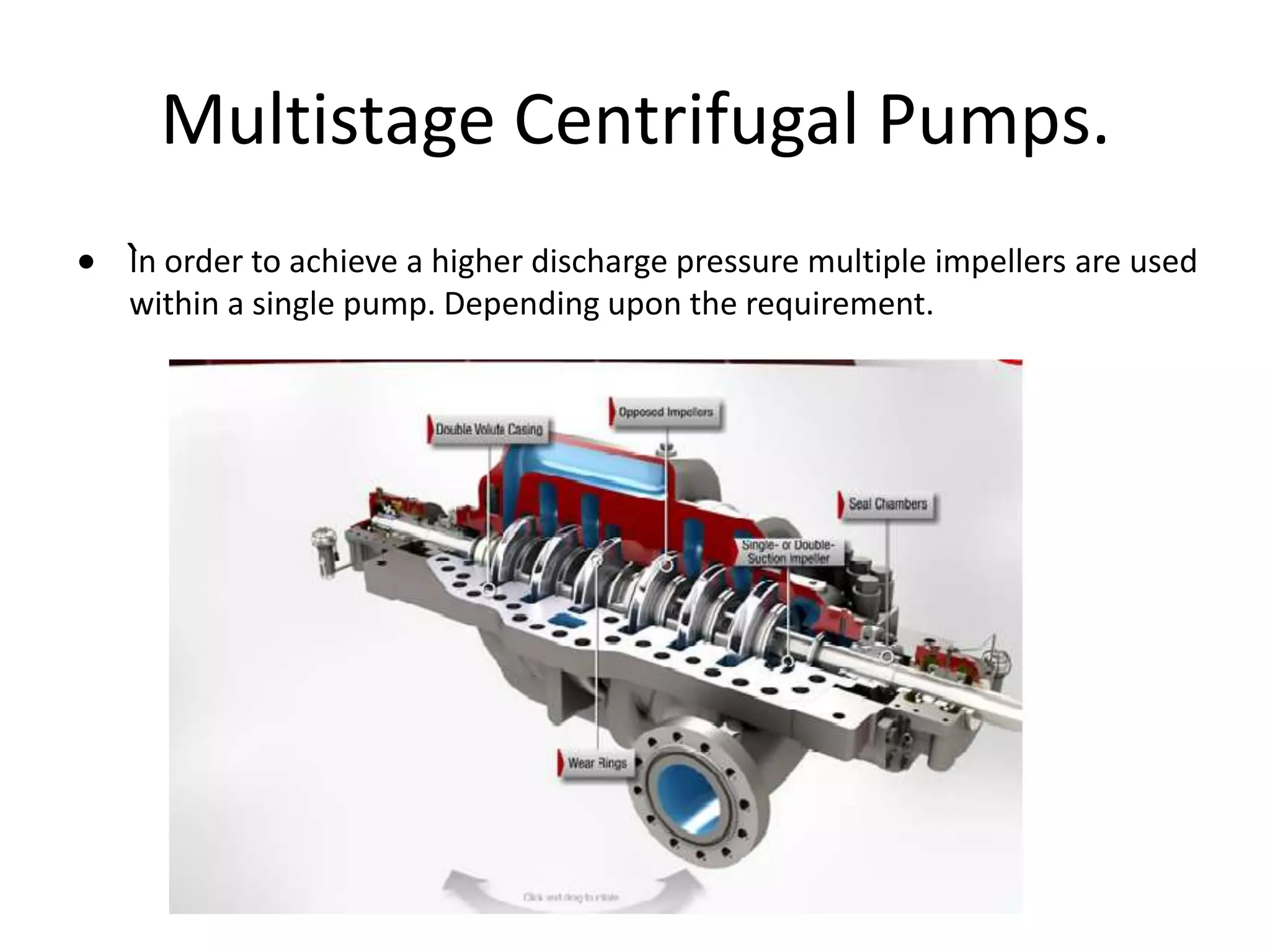

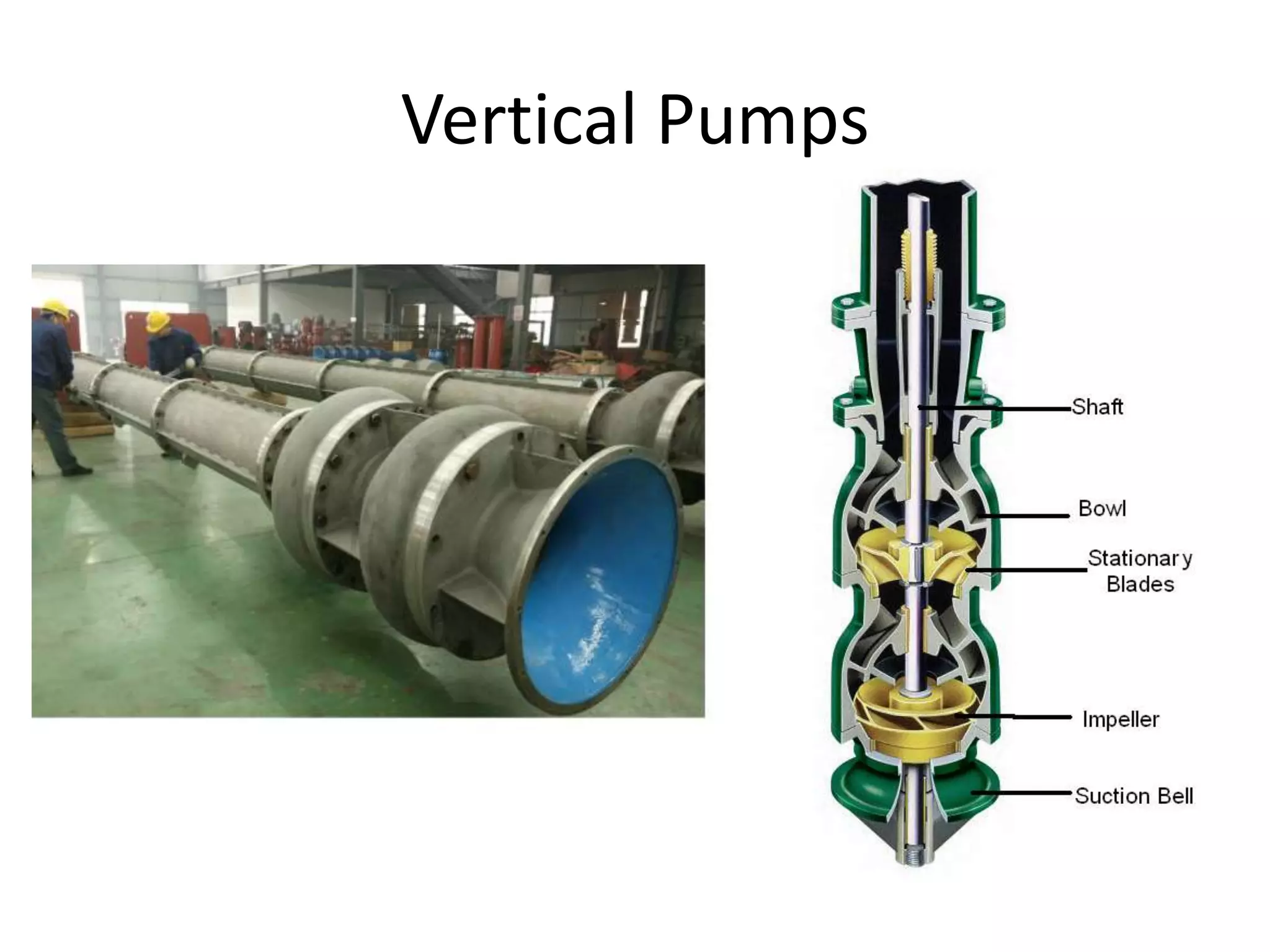

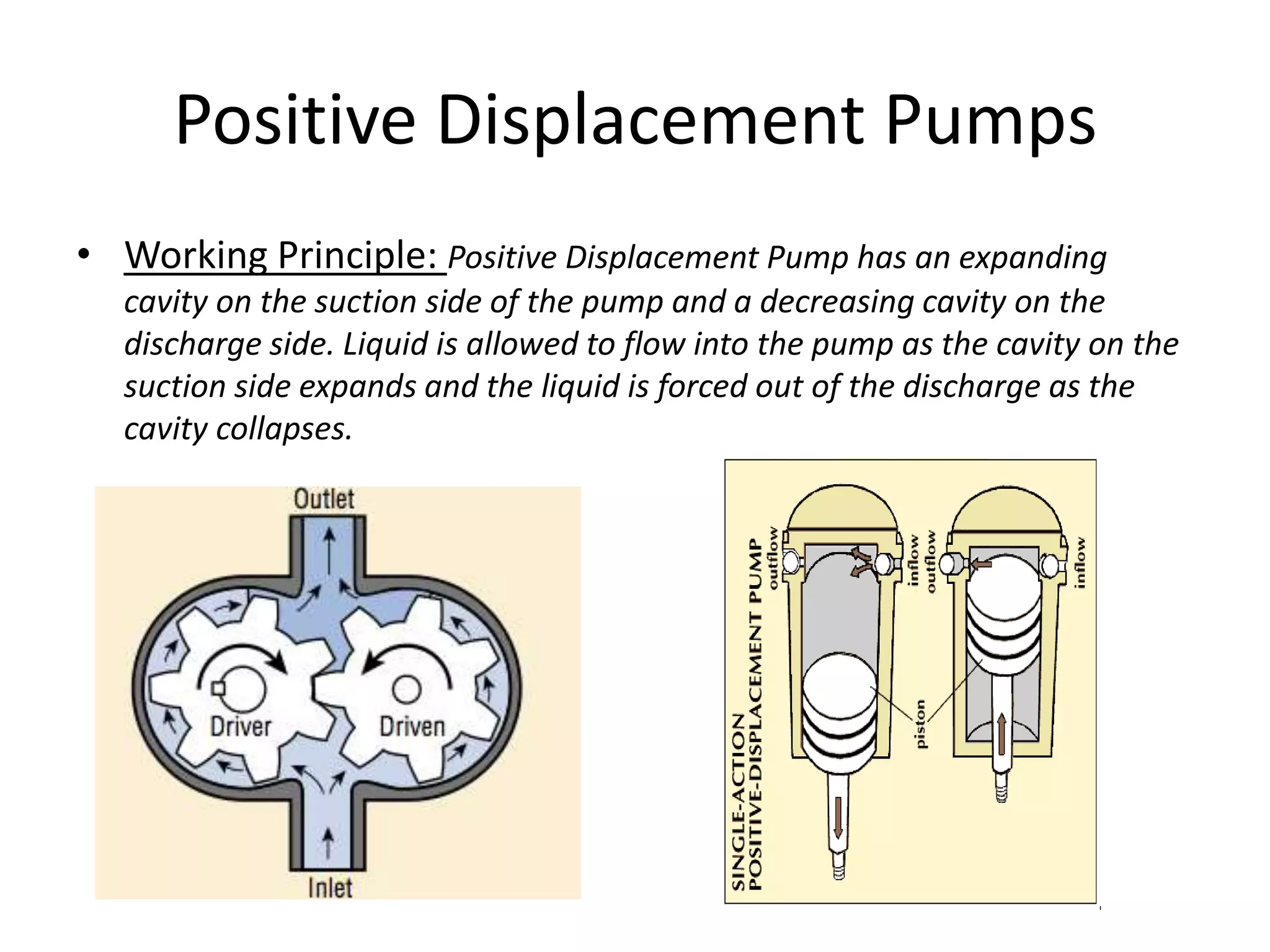

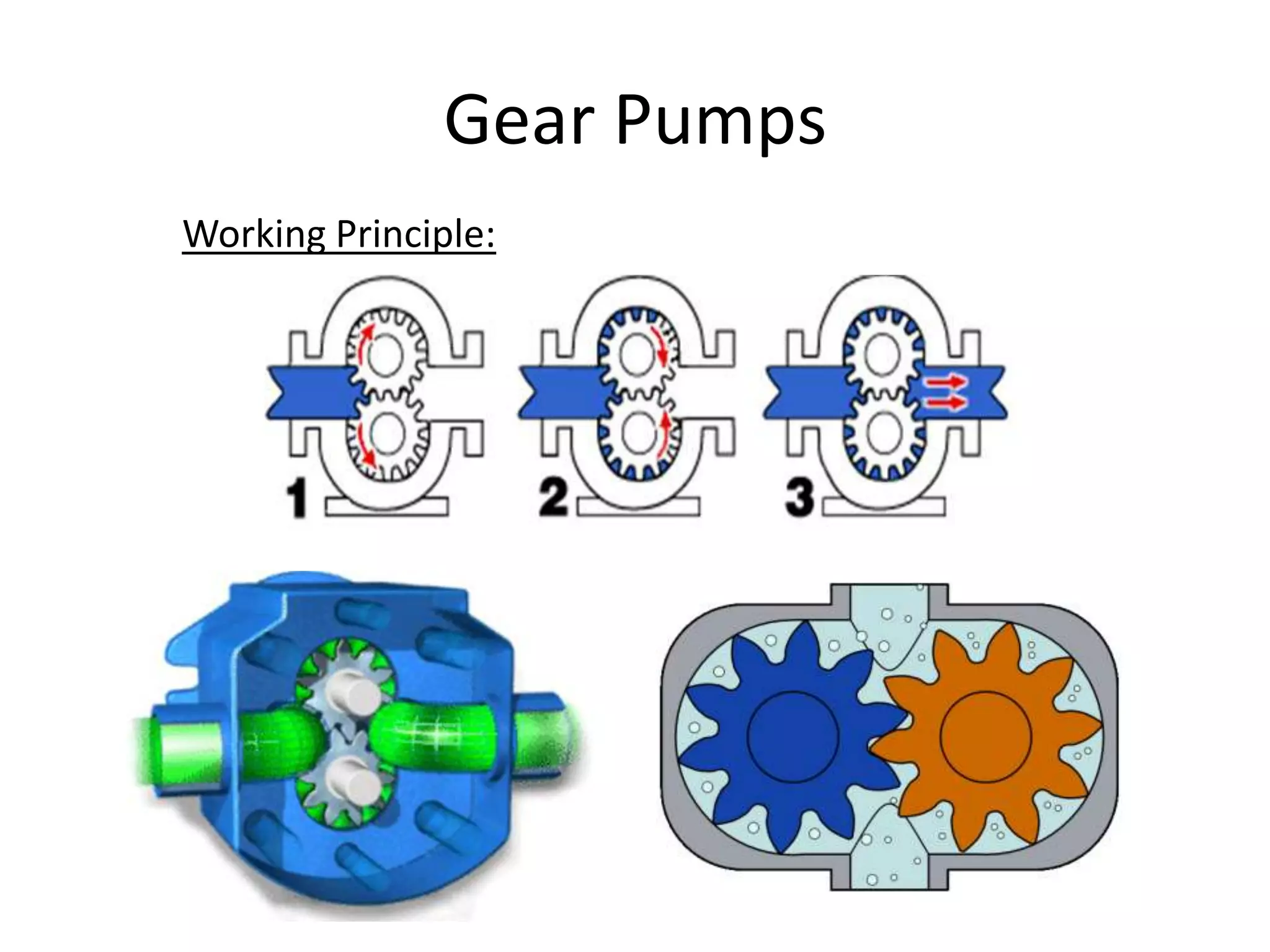

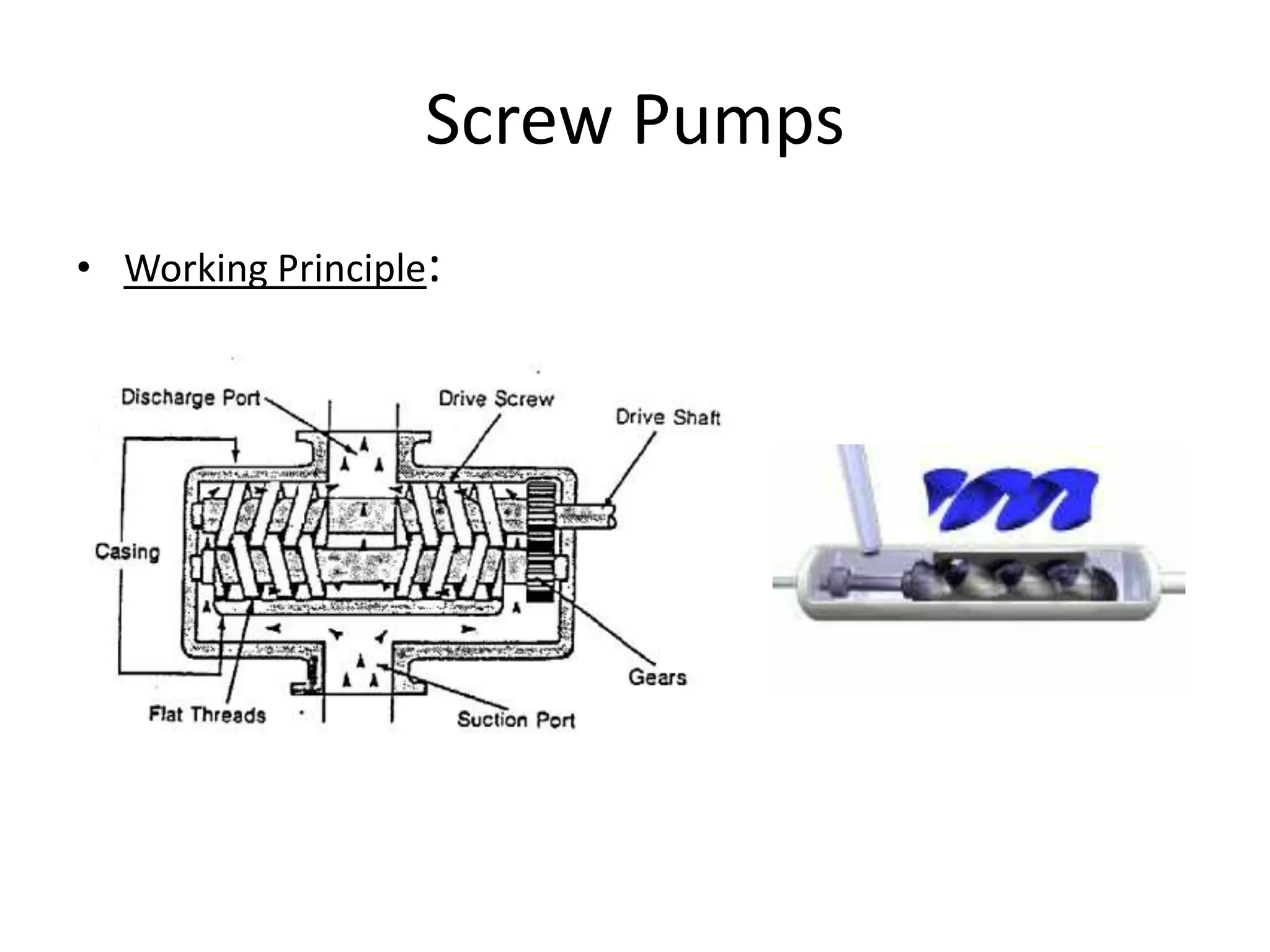

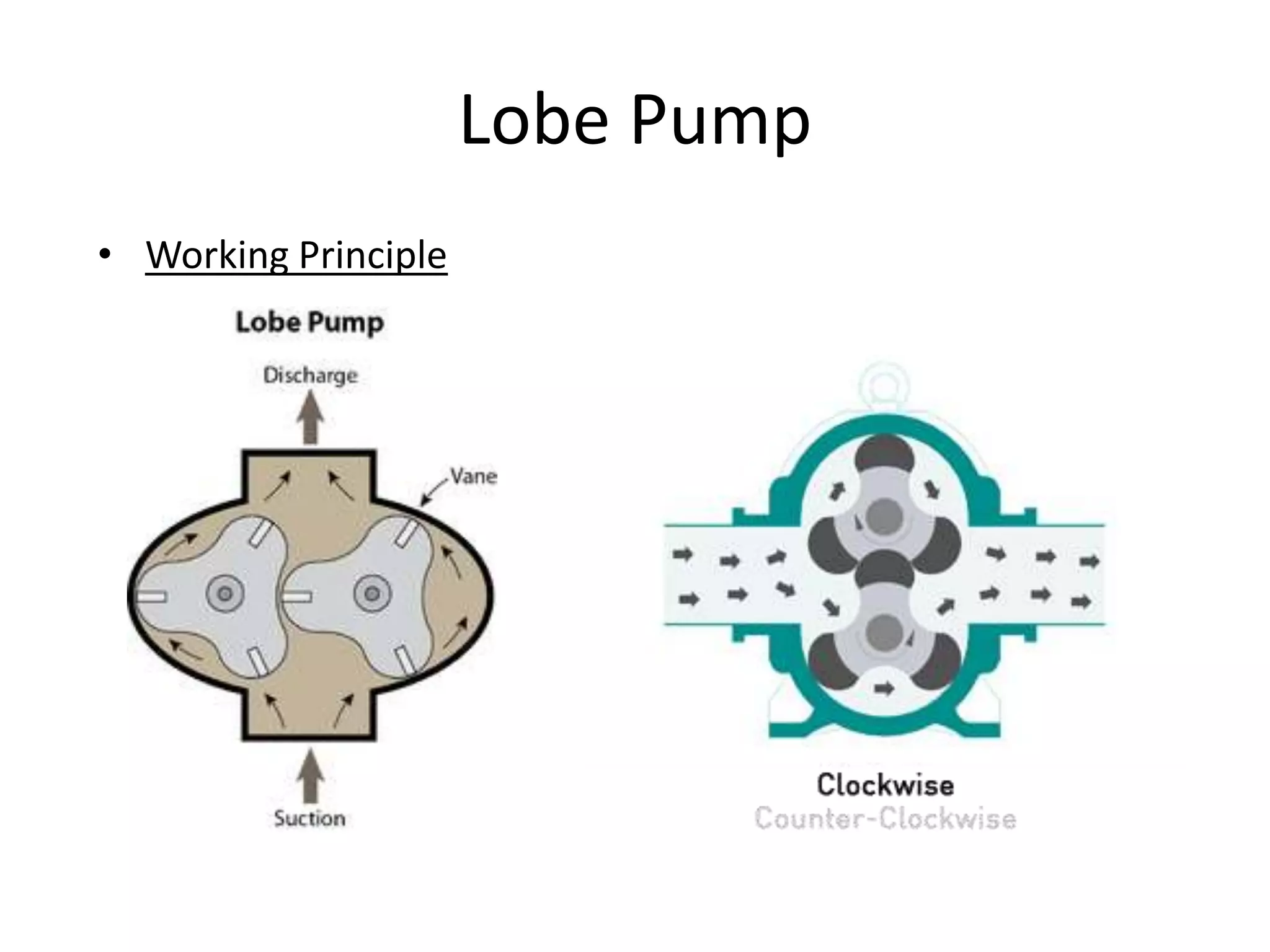

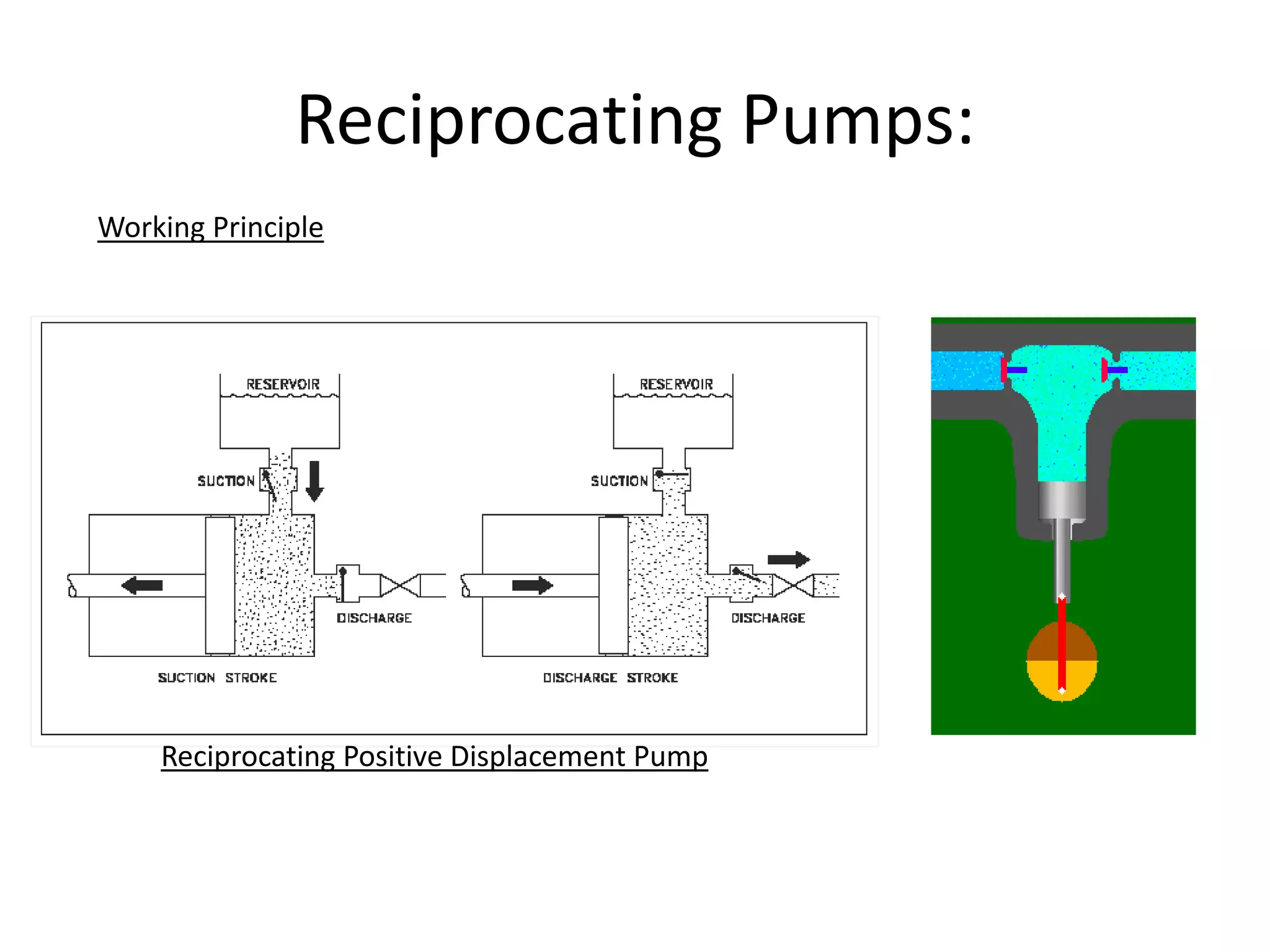

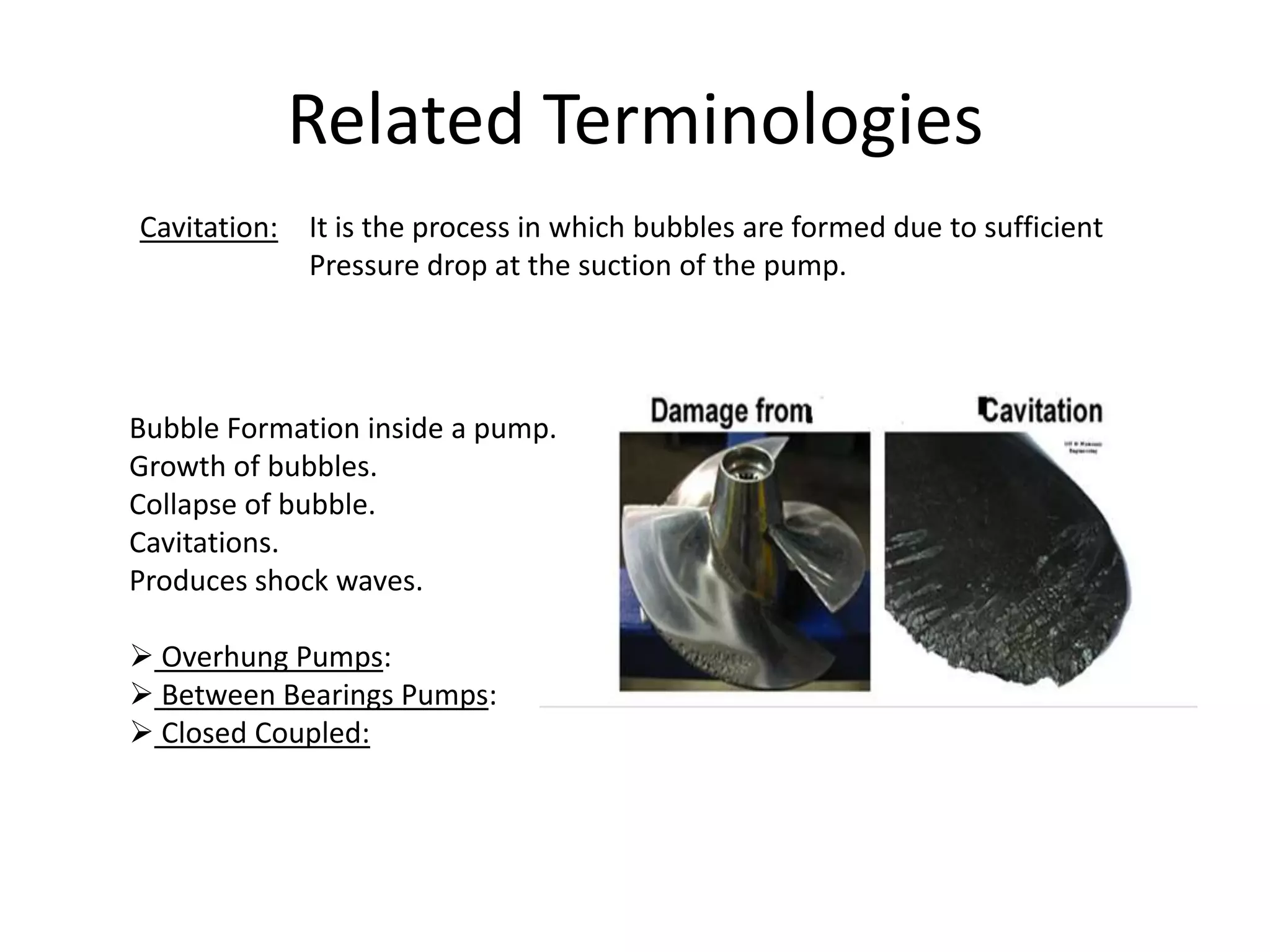

This document provides an overview of pumps, including their definitions, types, operating principles, and major components. It explains the differences between centrifugal and positive displacement pumps, their uses, and the importance of priming. Key terms such as volumetric flow rate, total head, and cavitation are also defined.