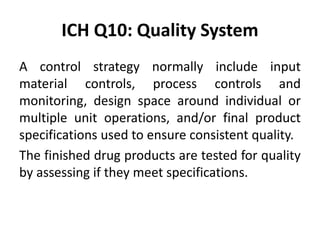

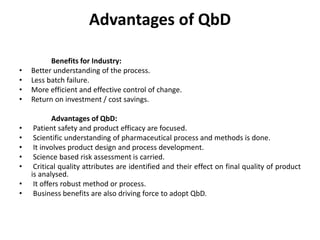

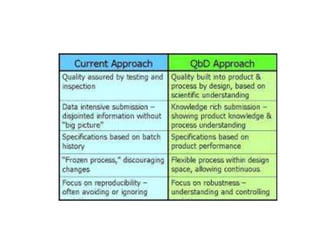

The document discusses Quality by Design (QbD), which is a systematic approach to pharmaceutical development that begins with predefined objectives and emphasizes product and process understanding and control based on sound science and quality risk management. It defines key QbD elements like Quality Target Product Profile, Critical Quality Attributes, Design Space, and Control Strategy. QbD aims to ensure final drug quality and has benefits like increased understanding, efficiency, and patient safety.

![Regulatory Control Guidelines Emphasising QbD: The

QbD approach which is based on scientific and

methodical product development was included in the

quality guidelines of ICH from 2005 onwards.

This approach includes, ICH

Q8: Pharmaceutical Development,

Q9: Quality Risk Management, and

Q10: Pharmaceutical Quality System guidelines.

The pharmaceutical products quality was also emphasised

in Process Analytical Technology [PAT] guidelines for new

pharmaceutical product development and quality.](https://image.slidesharecdn.com/qualitybydesignqbd-190202063119/85/Quality-by-design-QbD-8-320.jpg)

![ICH Q8: Pharmaceutical

Development:

It discusses the various element of Quality by

Design.

• Define the Quality Target Product Profile

• Identify the Quality Attributes

• Perform a Risk [Assessment] Analysis

• Determine the Critical Quality Attributes and

Critical Process Parameter

• Determine the Design Space

• Identify a Control Strategy](https://image.slidesharecdn.com/qualitybydesignqbd-190202063119/85/Quality-by-design-QbD-11-320.jpg)

![1. Quality Target Product Profile [QTPP]:

QTPP is “Prospective summary of the quality

characteristics of a drug product that ideally will be

achieved to ensure the desired quality, taking into

account safety and efficacy of the drug product”.

It is the quality characteristics that the drug product

should possess in order to reproducibly deliver the

therapeutic benefit promised in the label.

2. Quality Attributes: Once QTPP has identified, the next

step is to identify the relevant CQAs. A critical quality

attribute as defined by ICH is a physical, chemical,

biological, or microbiological characteristic that should be

within an appropriate limit, range, or distribution to

ensure the desired product quality.](https://image.slidesharecdn.com/qualitybydesignqbd-190202063119/85/Quality-by-design-QbD-12-320.jpg)

![For Drug Substance [Chemical] For Drug Product [Tablet]

Appearance

Particle size

Morphic forms

Water content

Residual solvents

Organic impurities

Inorganic impurities

Heavy metals

Residue on ignition

Assay

Appearance

Identification

Hardness

Uniformity of dosage

Physical form

Dissolution

Degradation products

Water content

Assay](https://image.slidesharecdn.com/qualitybydesignqbd-190202063119/85/Quality-by-design-QbD-13-320.jpg)

![ICH Q9: Quality Risk Management

[QRM]](https://image.slidesharecdn.com/qualitybydesignqbd-190202063119/85/Quality-by-design-QbD-14-320.jpg)