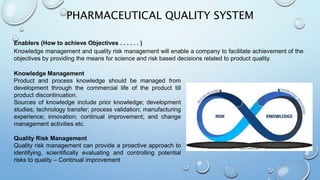

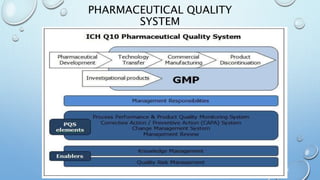

The document outlines the principles and responsibilities of a Pharmaceutical Quality System (PQS), emphasizing the need for senior management commitment and participation across various departments to ensure product safety and quality. It highlights the interrelation of quality management concepts such as quality assurance, good manufacturing practice, and quality risk management, and the need for a well-documented system to achieve continuous improvement in product quality. Additionally, it discusses the role of knowledge management and quality risk management in maintaining an effective PQS and meeting regulatory requirements.