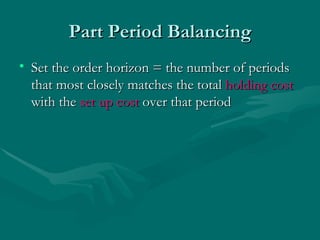

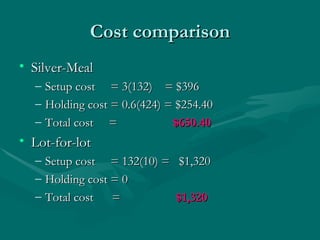

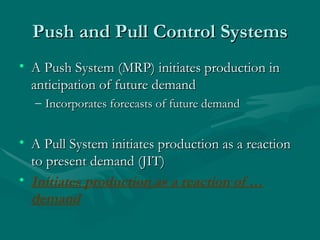

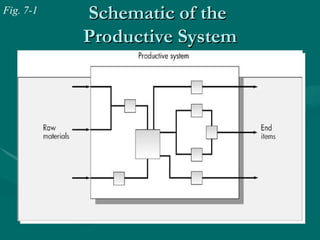

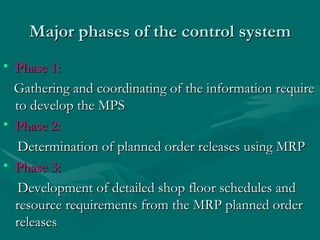

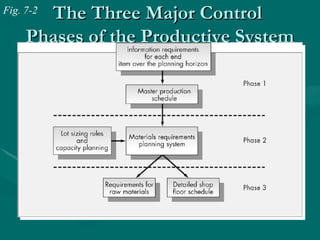

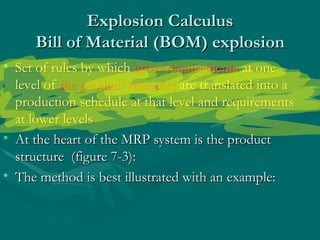

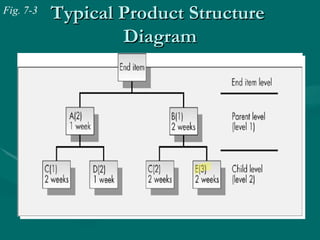

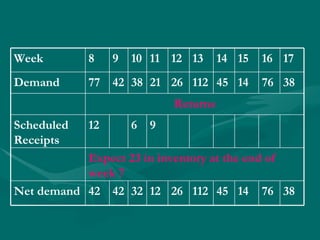

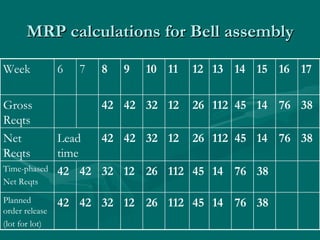

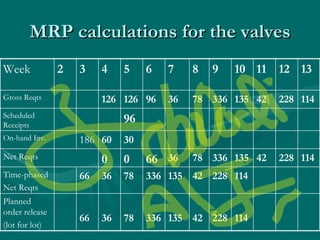

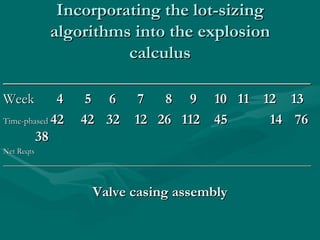

The document discusses push and pull production control systems. A push system like MRP initiates production based on forecasts, while a pull system like JIT initiates production based on current demand. MRP involves gathering demand data, determining planned order releases using explosion calculus, and developing shop floor schedules. Lot sizing algorithms aim to balance setup and holding costs. Capacity constraints and improvement steps can further optimize production planning.

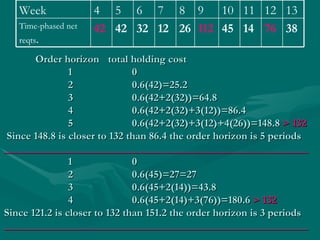

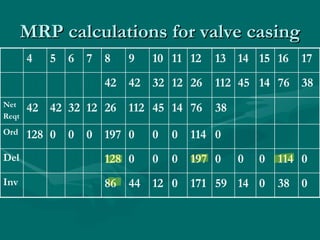

![Starting in week 4 C(1)=132 C(2)=[132+0.6(42)]/2=78.6 C(3)=[132+0.6(42+2(32))]/3=65.2 C(4)=[132+0.6(42+2(32)+3(12))]/4=54.3 C(5)=[132+0.6(42+2(32)+3(12)+4(26))]/5=55.92 y 4 = 42+42+32+12=128 38 76 14 45 112 26 12 32 42 42 Time-phased net reqts . 13 12 11 10 9 8 7 6 5 4 Week](https://image.slidesharecdn.com/pushandpullproductionsystems-chap7-ppt-100210005527-phpapp01/85/Push-And-Pull-Production-Systems-Chap7-Ppt-20-320.jpg)

![Starting in week 8: C(1)=132 C(2)=[132+0.6(112)]/2=99.6 C(3)=[112+0.6(112+2(45))]/3=84.4 C(4)=[112+0.6(112+2(45)+3(14))]/4=69.6 C(5)=[112+0.6(112+2(45)+3(14)+4(76))]/5=92.16 y 8 = 26+112+45+14=197 38 76 14 45 112 26 12 32 42 42 Time-phased net reqts. 13 12 11 10 9 8 7 6 5 4 Week](https://image.slidesharecdn.com/pushandpullproductionsystems-chap7-ppt-100210005527-phpapp01/85/Push-And-Pull-Production-Systems-Chap7-Ppt-21-320.jpg)

![Starting in week 12: C(1)=132 C(2)=[132+0.6(38)]/2=77.4 y 12 = 76+38=114 Week 4 5 6 7 8 9 10 11 12 13 Pon 128 0 0 0 197 0 0 0 114 0 38 76 14 45 112 26 12 32 42 42 Time-phased net reqts. 13 12 11 10 9 8 7 6 5 4 Week](https://image.slidesharecdn.com/pushandpullproductionsystems-chap7-ppt-100210005527-phpapp01/85/Push-And-Pull-Production-Systems-Chap7-Ppt-22-320.jpg)