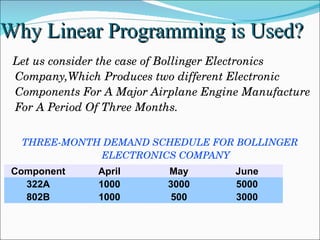

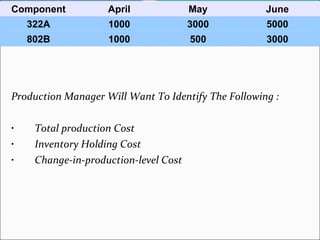

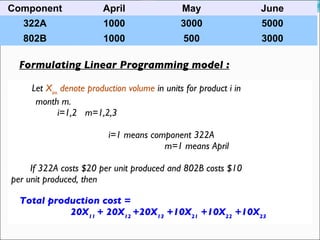

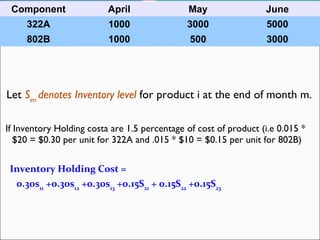

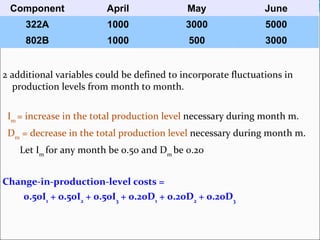

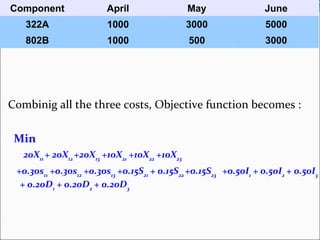

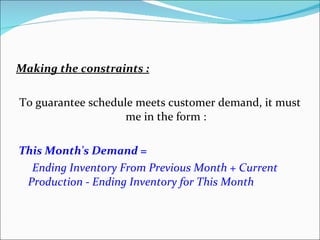

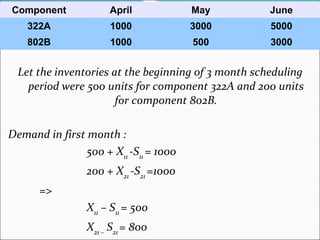

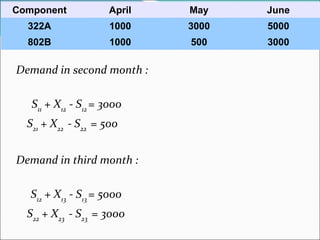

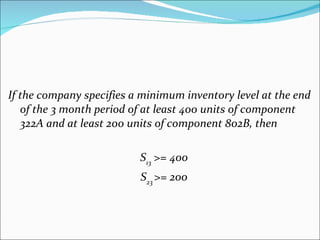

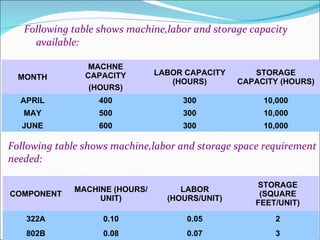

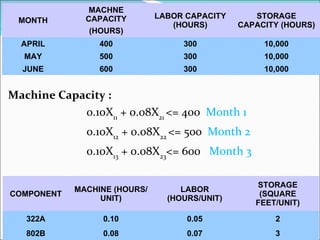

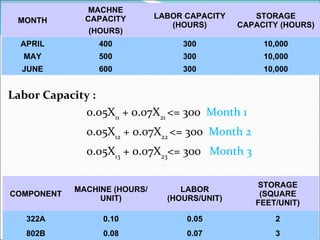

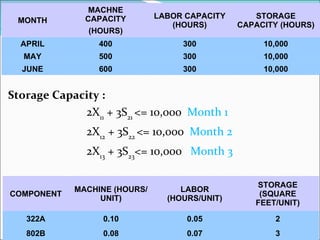

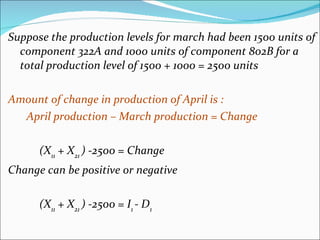

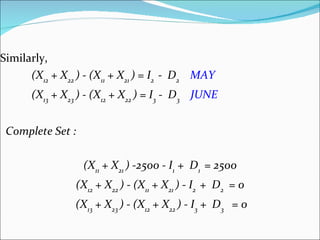

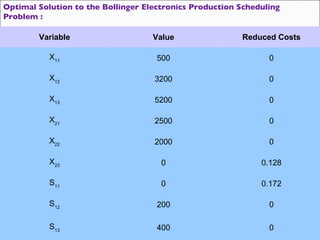

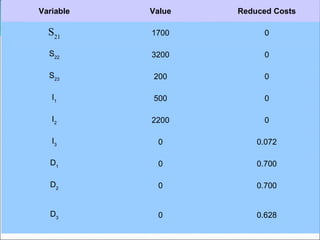

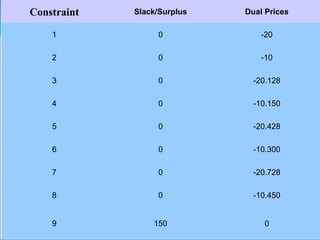

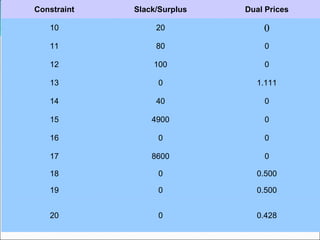

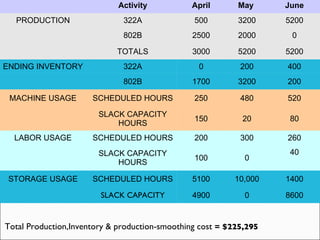

The document describes a linear programming model to optimize a 3-month production schedule for two electronic components produced by Bollinger Electronics. The objective is to minimize total production, inventory, and changeover costs subject to machine, labor, storage and demand constraints. The optimal solution schedules maximum production in months 1 and 2 to minimize costs while meeting all demands and capacity limits. Linear programming is useful for efficiently solving complex multi-period production scheduling problems.