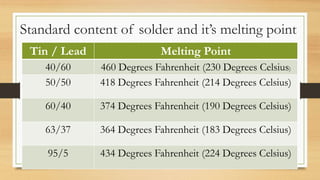

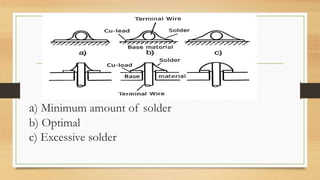

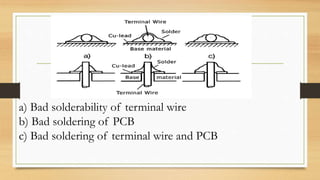

The document provides information about soldering, including how it is done, the materials used, and tips for ensuring reliable solder connections. Soldering involves heating metal parts and applying flux and solder to join them metallurgically and form strong electrical and mechanical bonds. Common solder alloys are tin-lead with melting points between 180-460 degrees Fahrenheit. Proper soldering technique and using the correct amount of solder and flux are important to make reliable connections.