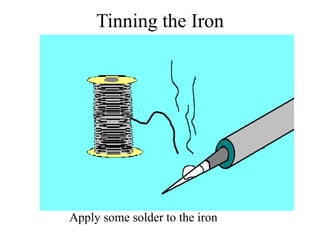

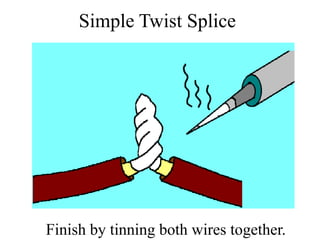

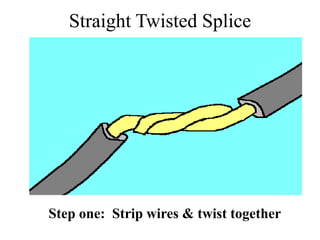

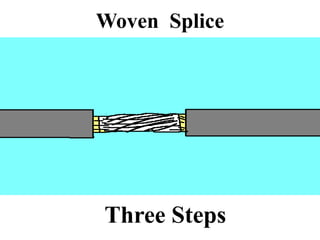

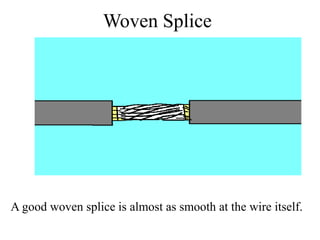

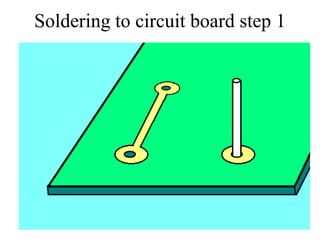

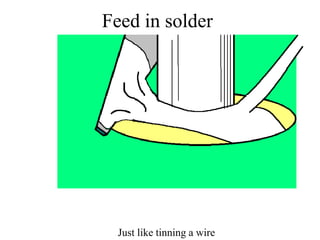

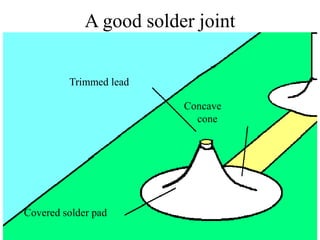

Soldering is both an art and a science. Solder is an alloy of 60% tin and 40% lead. A soldering iron is a simple device that gets hot when electricity flows through a coil of wire inside. Soldering is used for tasks like splicing wires, working on circuit boards, and tinning wires by applying solder to them. Good solder joints on circuit boards are concave in shape and cover both the component lead and solder pad fully, while cold solder joints do not properly bond. Different wire splices like simple twist, side by side, and woven are explained.