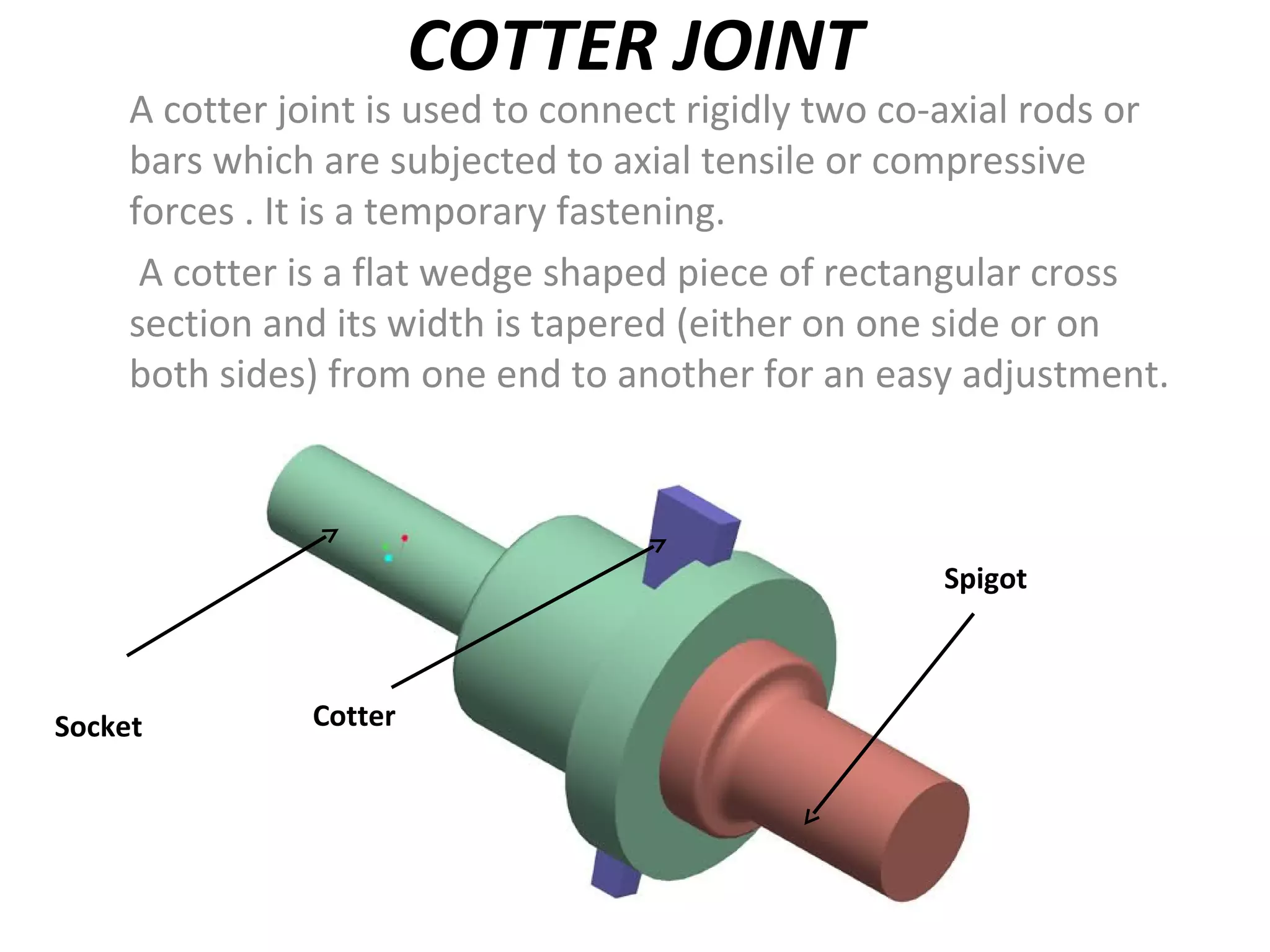

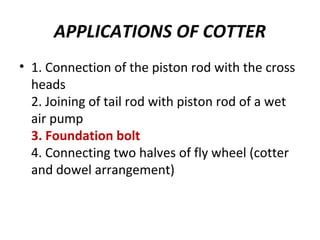

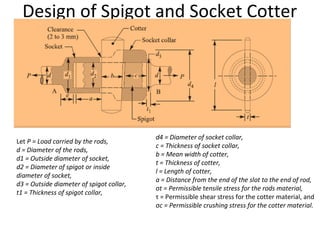

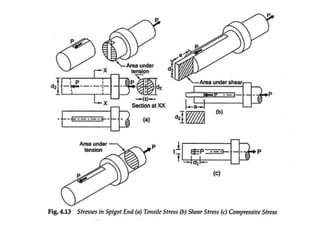

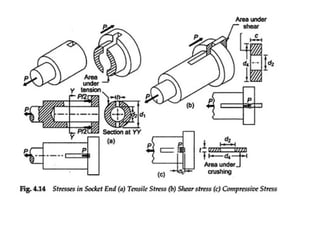

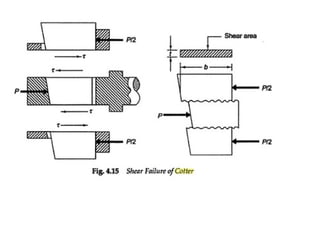

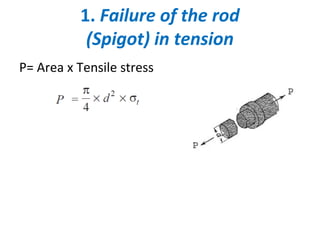

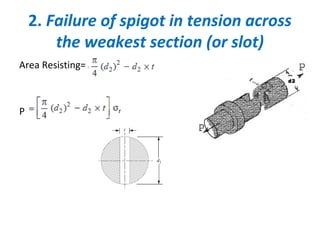

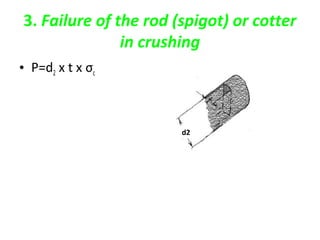

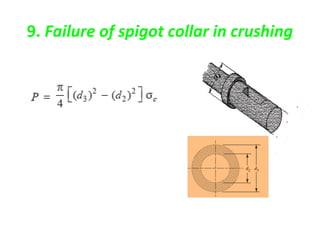

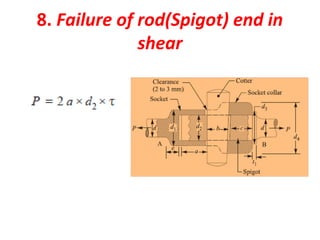

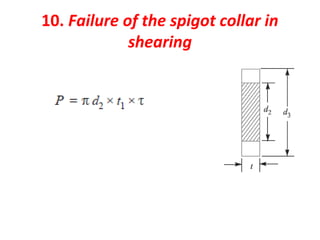

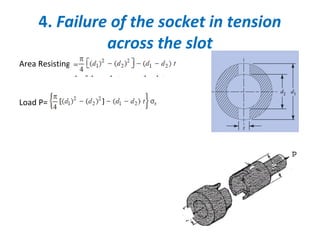

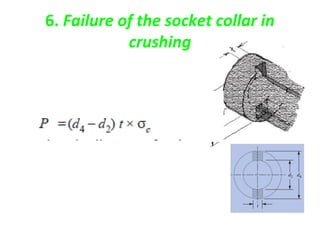

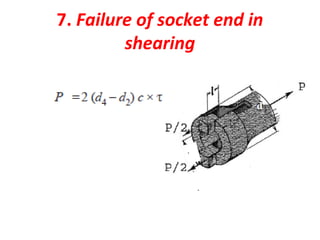

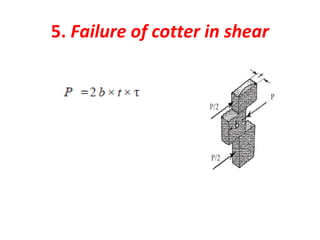

A cotter joint connects two coaxial rods subjected to axial forces. It uses a tapered wedge-shaped cotter inserted into slots in the overlapping ends of the rods. The cotter prevents longitudinal movement but allows for disassembly. Cotter joints are commonly used to connect piston rods, pump parts, flywheels, and foundation bolts. The document provides design considerations and equations for sizing the rods, slots, and cotter to withstand various failure modes from the tensile, compressive, and shear stresses based on the applied load and material properties. It also presents three example problems of designing cotter joints for specified loads.