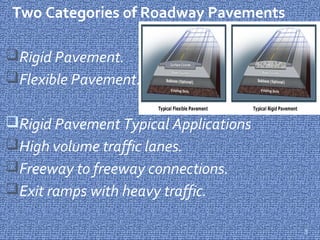

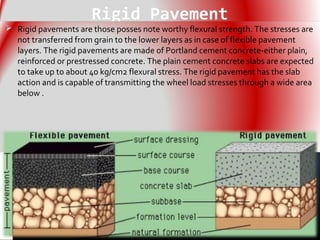

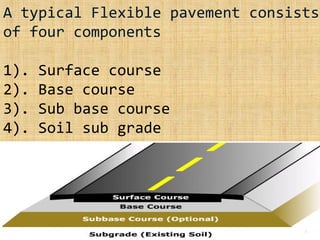

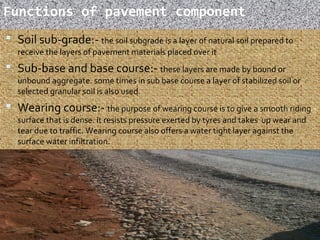

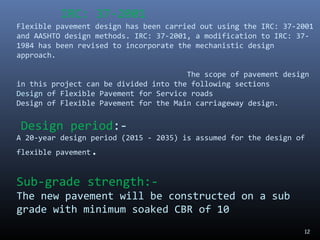

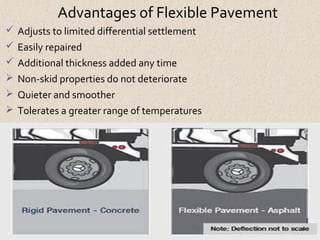

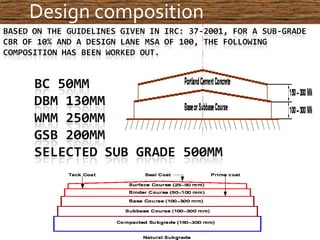

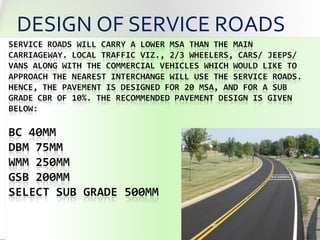

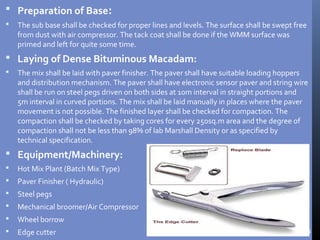

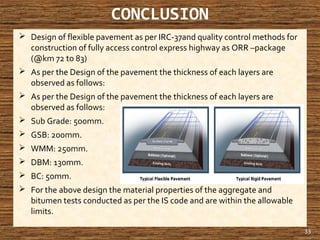

This document discusses the design aspects of flexible pavements and quality control management. It describes the typical components of a flexible pavement including the surface course, base course, sub-base course, and soil subgrade. It then provides details on the design of service roads including subgrade construction, wet mix macadam construction, and dense bituminous macadam and bituminous concrete construction. The document emphasizes quality control measures throughout construction.