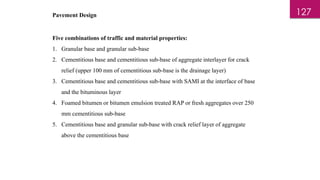

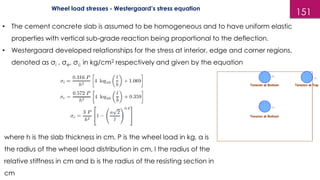

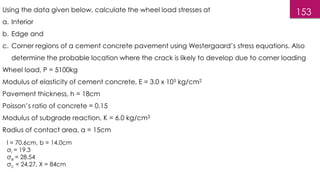

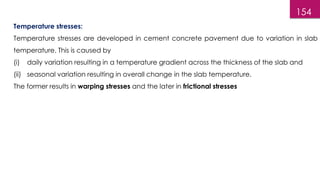

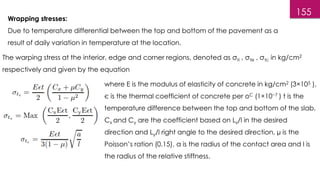

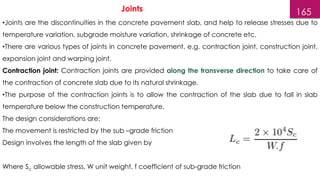

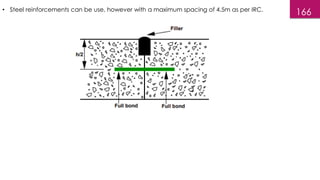

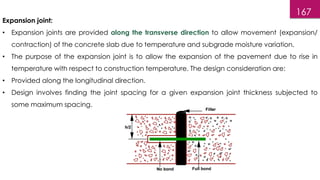

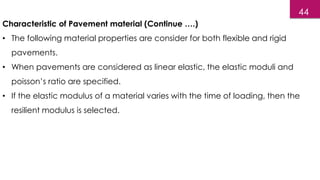

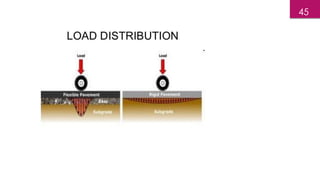

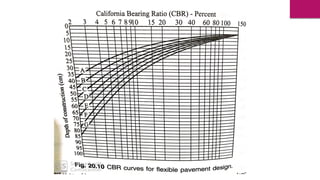

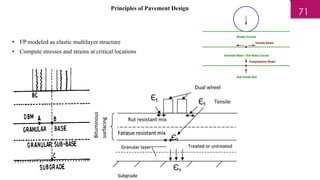

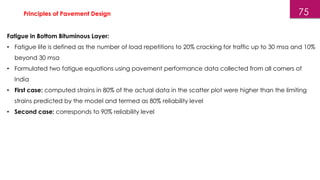

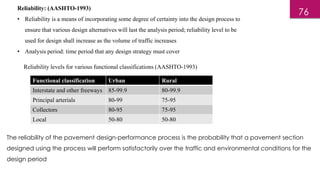

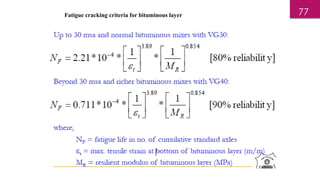

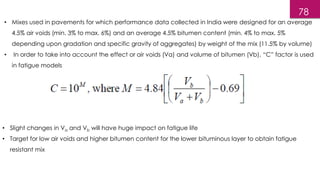

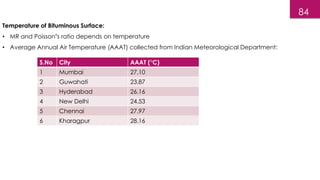

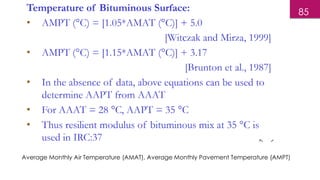

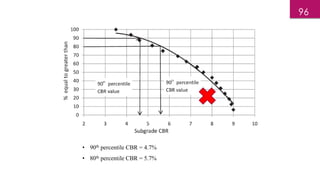

The document provides a comprehensive overview of pavement design, including materials used for flexible and rigid pavements, properties of soil and aggregates, and critical design factors like wheel load and climatic conditions. It discusses various pavement types, their structural differences, and the importance of layer theory in design. Emphasis is placed on characteristics of materials, design methods according to IRC standards, and the performance of highways under different load conditions.

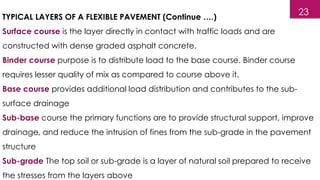

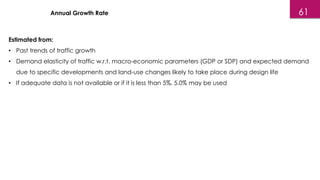

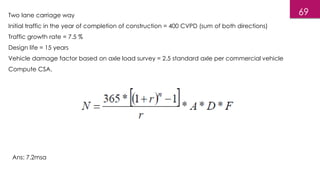

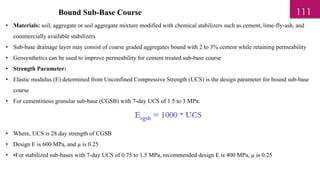

![Design life :

• Number of standard axles – before strengthening of pavement

FP – 10 – 20 yrs, EW – 20, NH and SH – 15, OC – 10-15

RP – 20-30 yrs – HV – 30, LV - 20

Anticipated traffic:

A = P [1+r]n

P = no of commercial vehicles/day

r = traffic growth rate

n = no of years

Example 1: P = 2520 CV/day, r = 7.5%, n = 2 years find A?

Ans: 2912.12 cv/day

25](https://image.slidesharecdn.com/he-unit5-240708040008-8c792745/85/Flexible-and-rigid-pavement-design-using-IRC-and-other-methods-24-320.jpg)

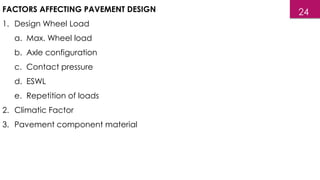

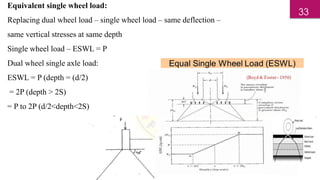

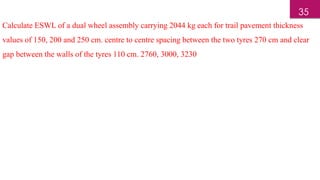

![log 10 ESWL = log10 P + [0.301(log10 (z/(d/2))/(log10 2s/(d/2))]

Assumptions:

Contact area is circle

Influence angle 45 degrees

Soil is homogeneous, elastic, isotropic

Example 2: dual wheel assembly and load on each tyre is 4000 kg. the C/C distance b/w the

tyre is 50 cm, the clear distance b/w tyre is 25 cm. Determine ESWL at a depth of

1) 10 cm,

2) 120 cm,

3) 70 cm , 7185. 55 kg

Ans: Z = 10 cm (d/2 = 25/2 ) =P= 4000

Z = 120 cm = >2S (2x50) =2P = 2x4000 = 8000

ln 10 =

ln 70 =

ln 100 =

ln ESWL = ln 4000 + [(ln 8000-ln 4000)/(ln 100 – ln 10)]*(ln70-ln10)

34](https://image.slidesharecdn.com/he-unit5-240708040008-8c792745/85/Flexible-and-rigid-pavement-design-using-IRC-and-other-methods-33-320.jpg)

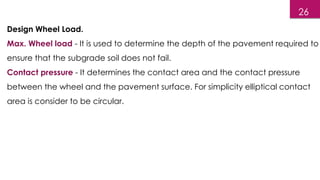

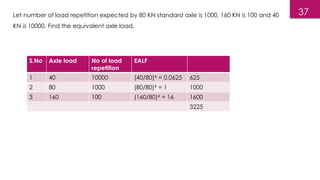

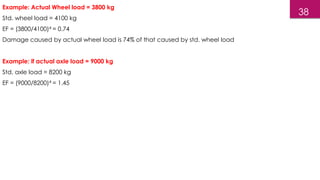

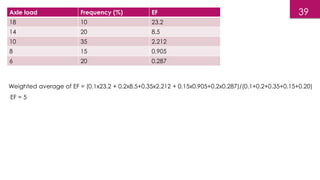

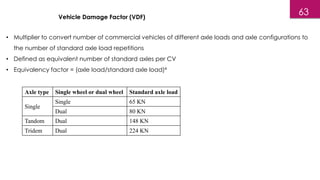

![Equivalency factor (EF) :

EF = (Actual Wheel load / standard wheel load)4

Gives the % of damage

Example: actual wheel load =3800 kg flexible pavement, standard wheel load = ?

EF = ? 0.74

Example 2: actual axle load = 9000 kg, standard axle load = ? EF = ? 1.45

Example 3: total number of vehicles in terms of standard wheel load? (595 veh/day)

Load range No of veh/day EF

4100 300 1

5200 100 2.59

3800 50 0.74

Standard axle load = [ axle load/8200]4

Tandom axle load = [axle load/14500]4

Total = 300x1+100x2.59+50x0.74

= 595

36](https://image.slidesharecdn.com/he-unit5-240708040008-8c792745/85/Flexible-and-rigid-pavement-design-using-IRC-and-other-methods-35-320.jpg)

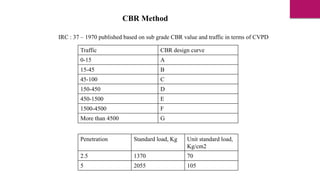

![Developments in IRC :37-2012

• First published : 1970

• Based on subgrade CBR and traffic in terms of CVPD

• [A: 0-15; B: 15-45; C: 45-150; D: 150-450; E: 450-1500]

• First revision : 1984

• Equivalent Axle Load concept introduced

• Pavement thickness related to cumulative number of standard axle loads

• Up to 30 msa

• Second Revision: 2001

• Up to 150 msa

• Third Revision: 2012

• Usage of new materials and mixtures

46](https://image.slidesharecdn.com/he-unit5-240708040008-8c792745/85/Flexible-and-rigid-pavement-design-using-IRC-and-other-methods-45-320.jpg)

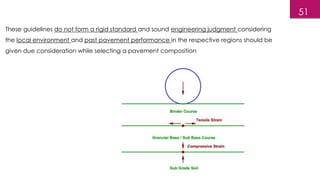

![• Used to design Flexible Pavements for Expressways, NHs, SHs, MDRs, and other

category of roads with predominant motorized traffic

• Not applicable to low volume roads (ODRs, and VRs) [designed based on

IRC:SP:72-2015]

• Applicable to new pavements.

• IRC:81-1997 {BBD}/IRC:115-2014 {FWD} are used for strengthening existing

pavements

• Design traffic up to 150 msa

IRC (37-2012) Method of FP Design

Note: BBD – benkelman beam deflection, FWD – falling weight deflectometer

50](https://image.slidesharecdn.com/he-unit5-240708040008-8c792745/85/Flexible-and-rigid-pavement-design-using-IRC-and-other-methods-49-320.jpg)

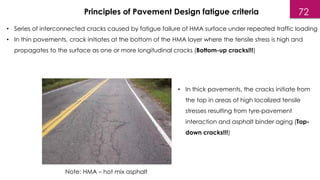

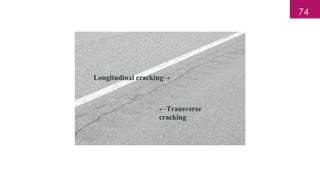

![• Tensile strain near surface close to edge of a wheel results in longitudinal cracking followed by

transverse cracking before flexural cracking if mix tensile strength is not adequate at high

temperatures [tensile strain in wearing course near edge of tyre can be higher than that at bottom of

bituminous layer at higher temperatures]

• High tensile strength at higher temperatures can delay top down cracking (using VG40/PMB/CRMB

binders)

• Wearing course must also be fatigue resistant in addition to being rut resistant (high modulus mix)

Principles of Pavement Design

Note: PMB – polymer modified bitumen, CRMB – crumb rubber modified bitumen

73](https://image.slidesharecdn.com/he-unit5-240708040008-8c792745/85/Flexible-and-rigid-pavement-design-using-IRC-and-other-methods-72-320.jpg)

![117

Crack Relief Layer (SAMI) •

• Interlayers designed to dissipate energy by deforming horizontally and vertically, allowing the movement

(vertical/horizontal) of underlying layers without causing large tensile stresses in bituminous overlay

• Barksdale, 1991: SAMI is a soft layer [flexible!] (usually thin) used to reduce tensile stress in the overlay in

the vicinity of the crack in the underlying old layer and absorb stress

• Lytton, 1989:

• Crack starts to propagate (due to thermal and traffic loading) from its original position upward until it

reaches the stress-relieving layer. Due to its low stiffness, the interlayer will exhibit large deformations

resulting in dissipation of energy. The crack propagation will stop for a while due to lack of energy, and

then propagate from the top of the interlayer upward to the surface (bottom-up cracking)

• In the second failure mode, crack starts to propagate from its original position upward until it reaches the

stress-relieving layer. The crack then begins from the top of the overlay to the interlayer (top-down

cracking)](https://image.slidesharecdn.com/he-unit5-240708040008-8c792745/85/Flexible-and-rigid-pavement-design-using-IRC-and-other-methods-116-320.jpg)