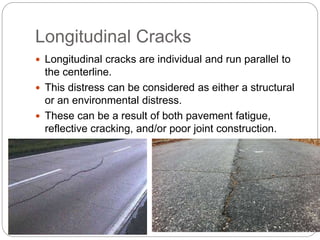

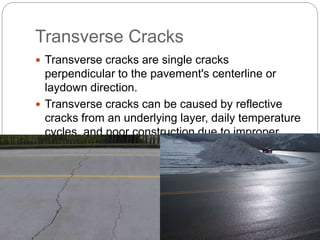

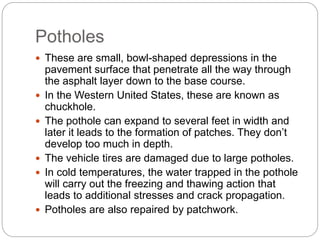

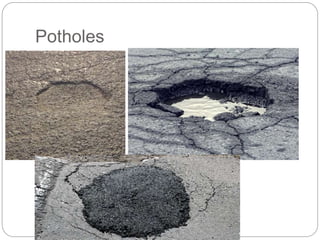

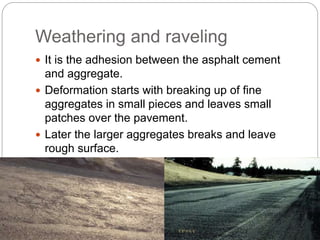

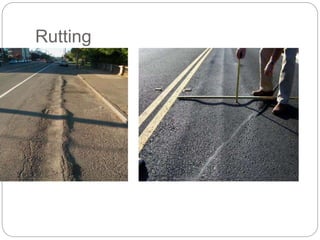

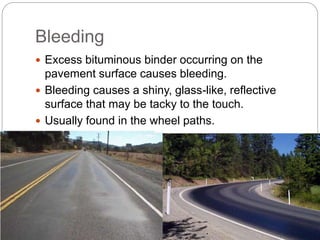

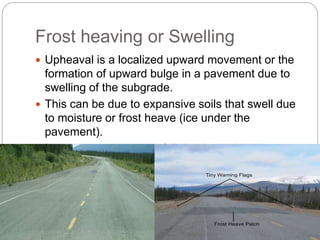

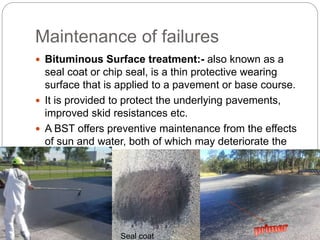

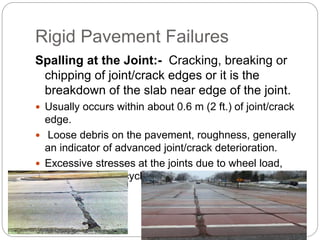

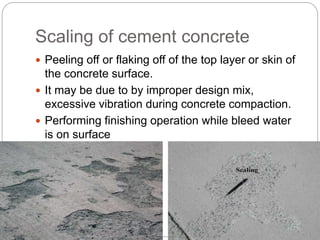

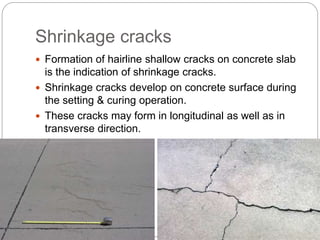

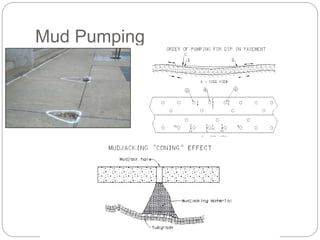

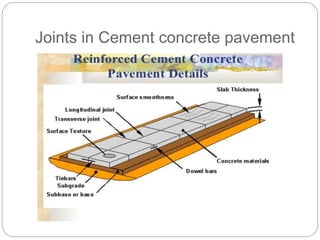

The document discusses various types of pavement failures including flexible and rigid pavement failures. For flexible pavements, failures include surface deformation (rutting, corrugation, shoving), cracking (fatigue, transverse, longitudinal), disintegration (potholes, patches), and surface defects (raveling, bleeding). Common causes are poor soil, inferior materials, improper geometry, overloading, and environmental factors. Maintenance techniques to address failures include bituminous surface treatments, asphalt overlays, slurry seals, and crack sealing. For rigid pavements, failures discussed are spalling at joints, scaling of cement concrete, and shrinkage cracks.