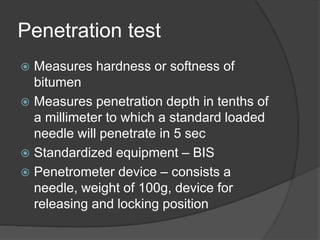

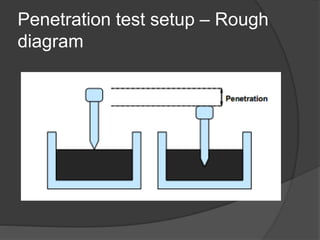

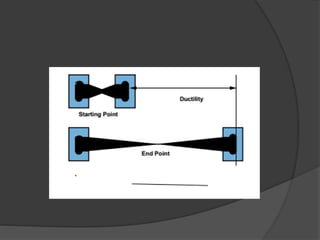

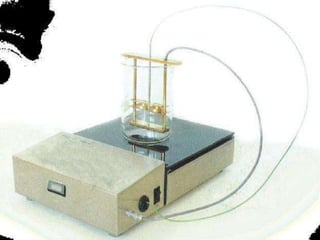

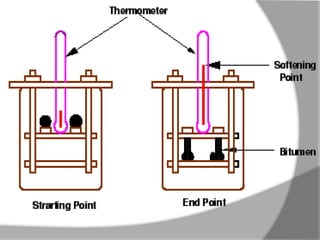

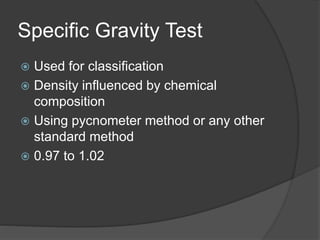

This document provides information on bitumen, which is used as a binding material in pavements. It discusses the types of bitumen including paving grade, modified, cutback and emulsion. Cutback bitumen has solvents added to increase fluidity while bitumen emulsion uses water. Modified bitumen has additives added to improve properties. The document also describes various tests conducted on bitumen like penetration, ductility, softening point and viscosity to determine hardness and grading. Bitumen requirements include adequate viscosity and adhesion properties. The grading of bitumen depends on the results of penetration tests.