1. Dowel bars and tie bars are used in concrete pavement design. Dowel bars are placed across transverse joints and transfer loads between slabs while allowing for joint openings. Tie bars are placed longitudinally and prevent transverse cracking and lane separation.

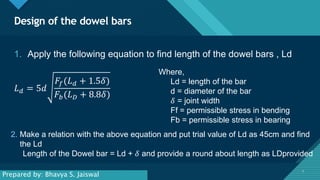

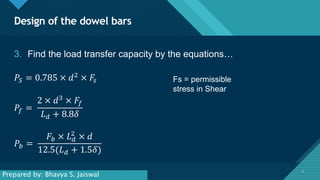

2. The design of dowel bars involves determining the length using an equation considering bar diameter and joint width, and checking that the load transfer capacity meets requirements. Tie bar design involves determining the length based on bar diameter and bond strength, and the spacing is calculated based on the required bar area.

![Click to edit Master title style

6

Design of the dowel bars

6

Actual

capacity = [1 +

1.8𝑙 − 35

1.8𝑙

+

1.8𝑙 − 70

1.8𝑙

+

1.8𝑙 − 105

1.8𝑙

+

1.8𝑙 − 140

1.8𝑙

]

Assume 35cm spacing and find the actual capacity…

Check if Actual capacity > Required capacity

if it is not greater than reduce the spacing and check it again

Prepared by: Bhavya S. Jaiswal](https://image.slidesharecdn.com/dowelbarstiebarsandtheirdesign-210409092640/85/Dowel-bars-tie-bars-and-their-design-6-320.jpg)