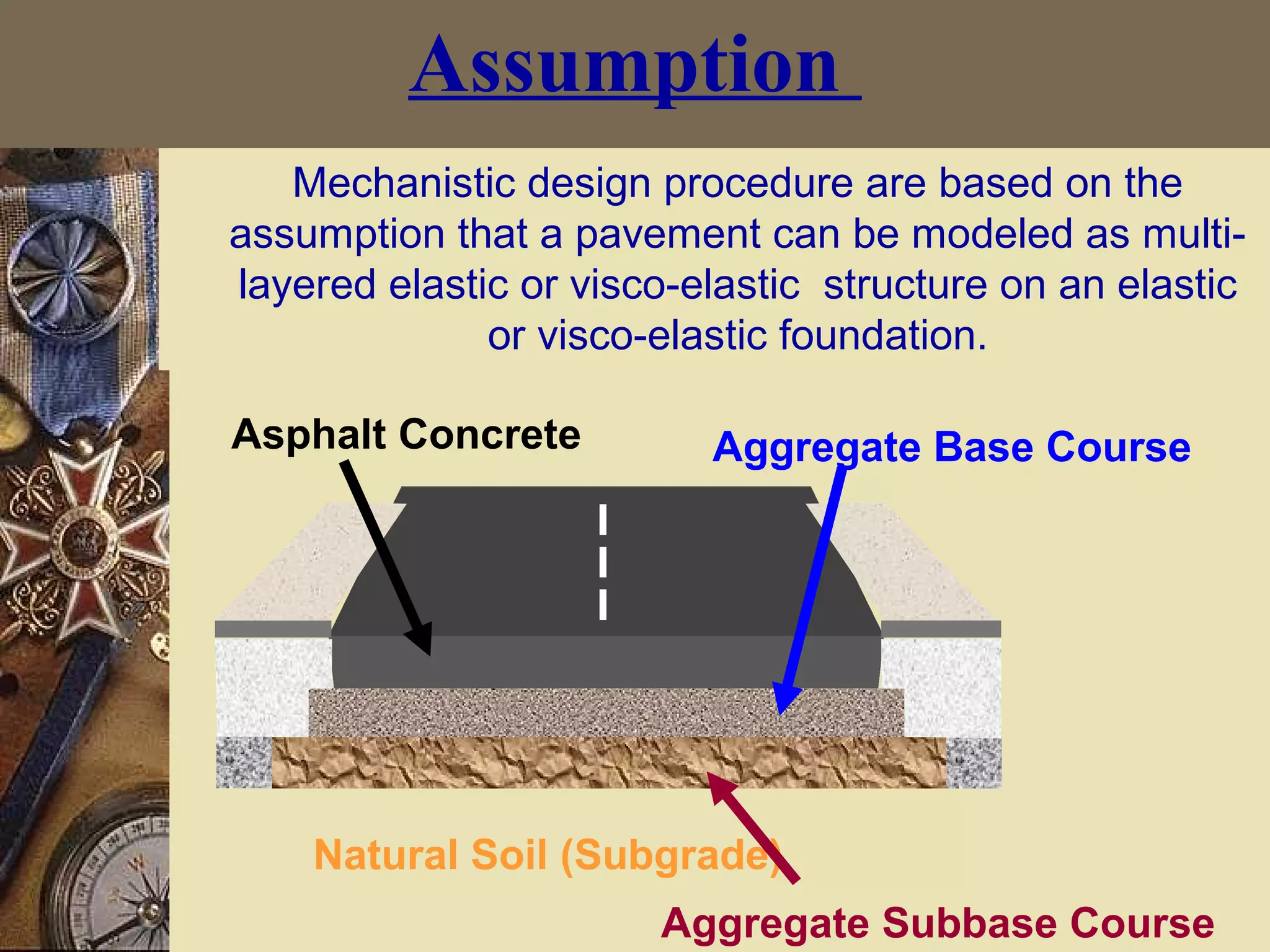

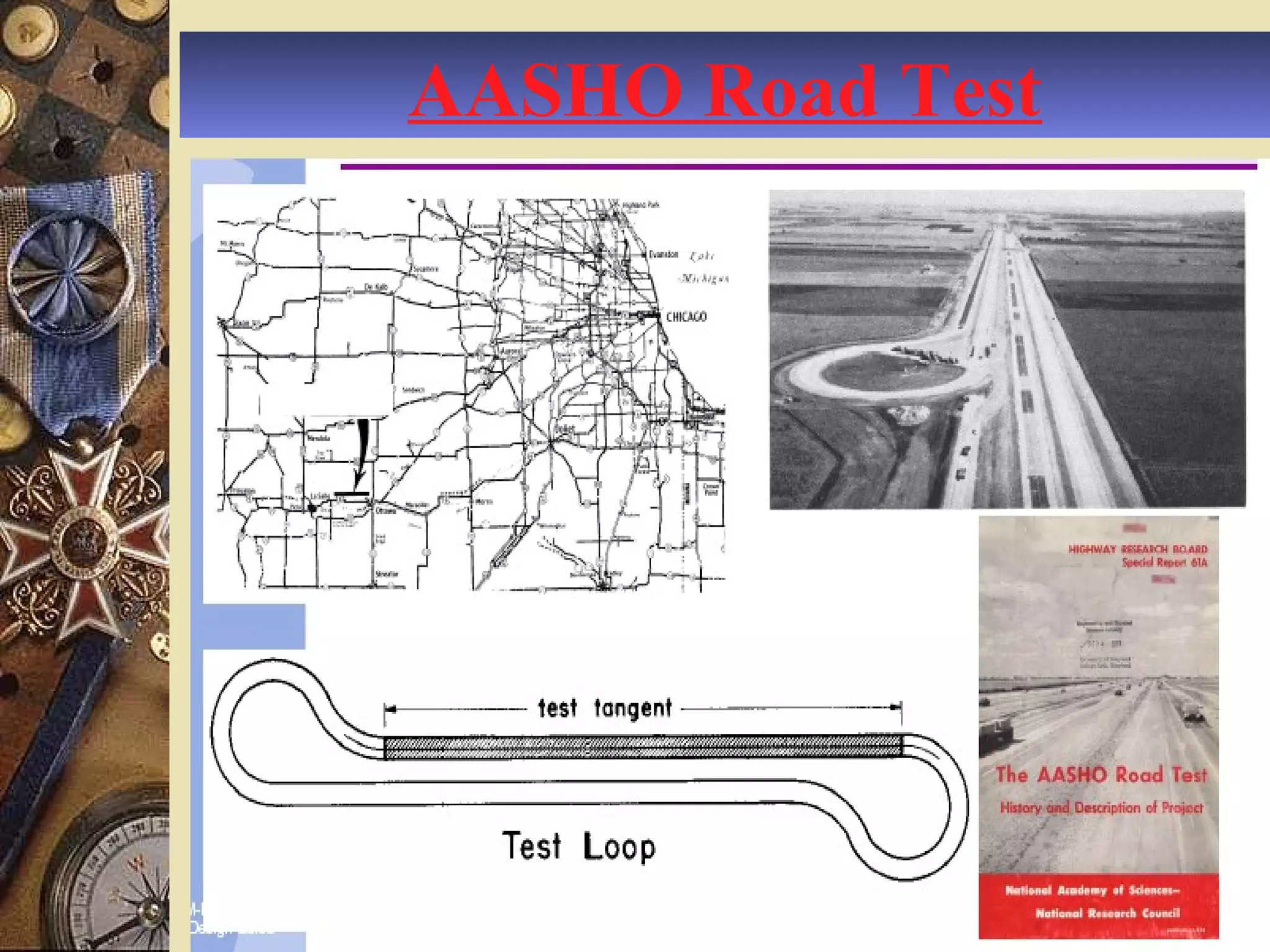

The document discusses different approaches to flexible pavement design, including empirical, mechanistic, and mechanistic-empirical approaches. It provides details on each approach, such as the empirical approach using the 1993 AASHTO Guide equation relating pavement characteristics to performance, and the mechanistic approach modeling the pavement as layers and calculating stress/strain. The mechanistic-empirical approach combines both, using mechanics to calculate stresses/strains and empirical data to define failure criteria. Road tests like the AASHO and Maryland tests helped develop the empirical relationships used in design methods.