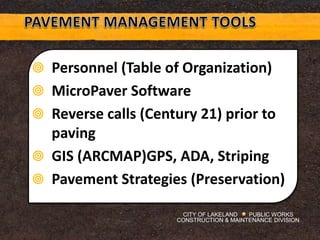

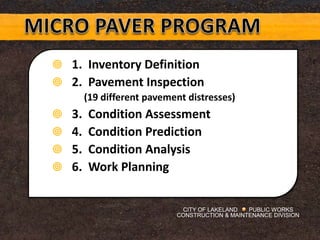

The document discusses the pavement management strategies used by the City of Lakeland's Public Works Construction & Maintenance Division. It provides details on the division's budget, staffing, equipment, and software used. It also summarizes the various pavement preservation techniques utilized over the past 30 years, including surface treatments, slurry seal, microsurfacing, cape seal, and full depth reclamation. Case studies are presented on projects where microsurfacing was used as a "band aid" and on resurfacing runways at Joker Marchant Stadium. Ongoing efforts to improve practices and adopt new preservation methods are also outlined.