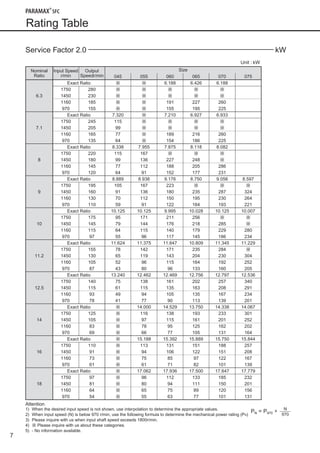

The document provides information about the PARAMAX SFC Series cooling tower gearbox. It includes:

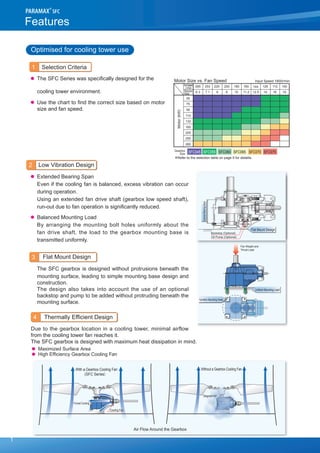

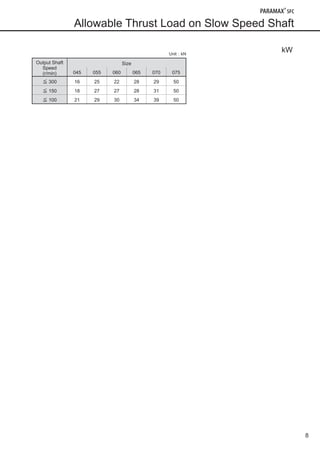

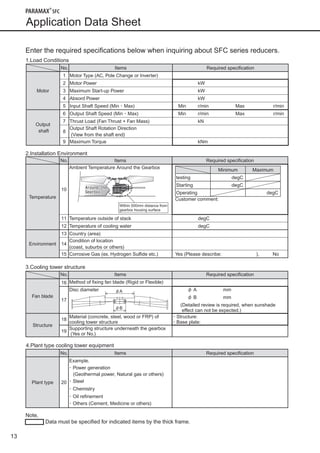

1) Features such as an optimized design for cooling towers with low vibration and a flat mount design. It also has a thermally efficient design with forced cooling and low noise.

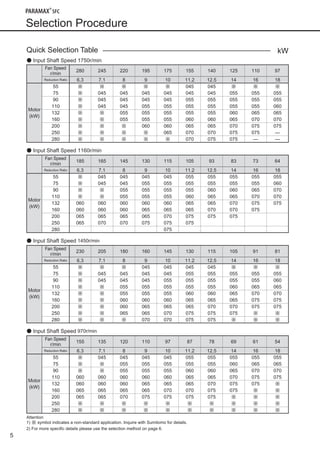

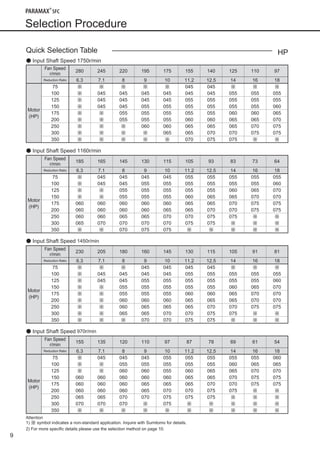

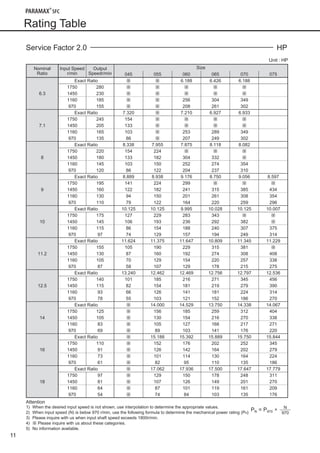

2) Selection criteria including finding the proper size based on motor size and fan speed from the selection chart.

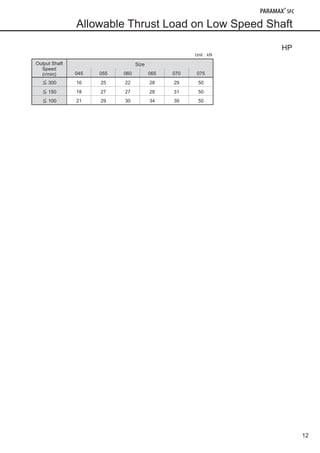

3) Standard specifications including gear and bearing materials, seals, lubrication, and paint.

4) A selection procedure example for a 132kW motor driving a fan at 107rpm in a cooling tower application.