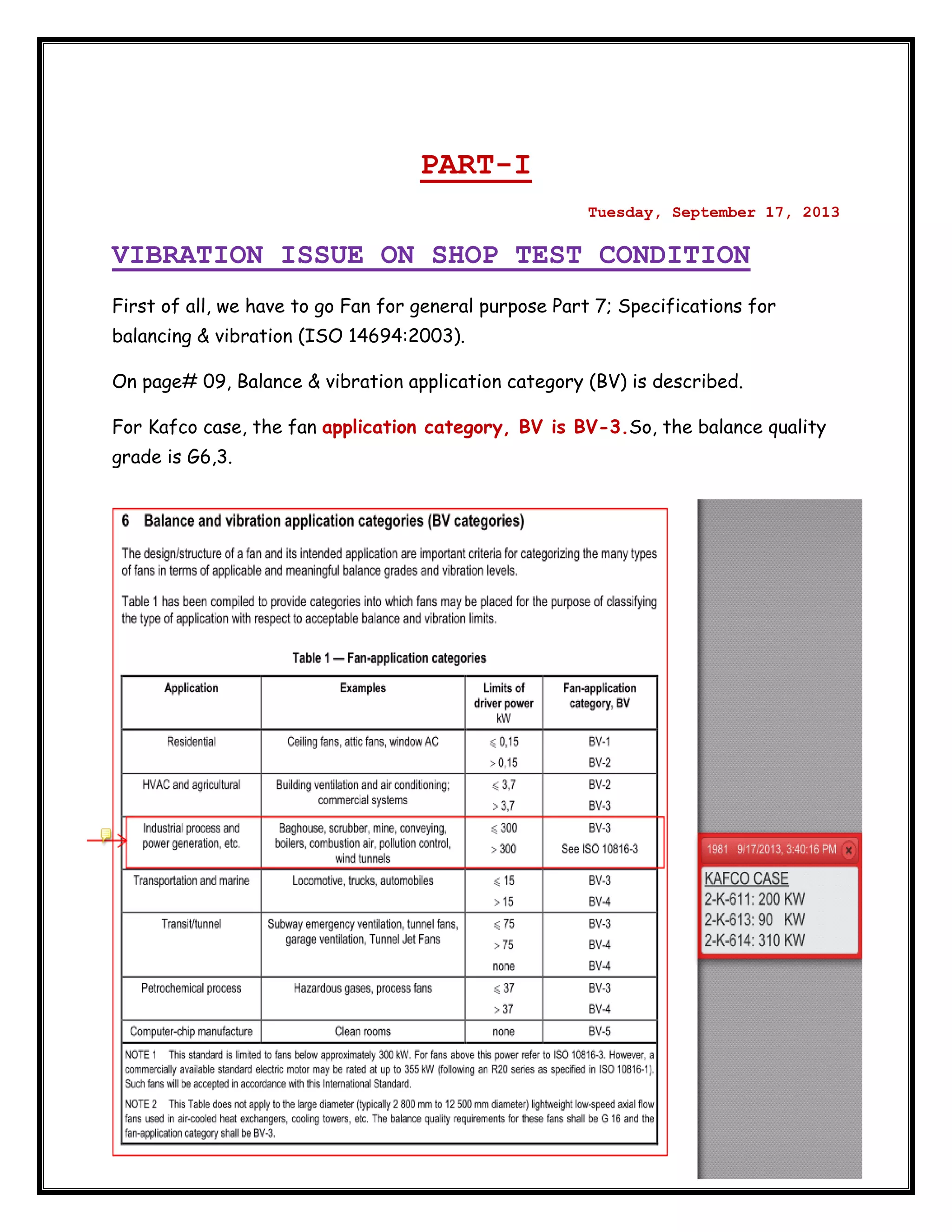

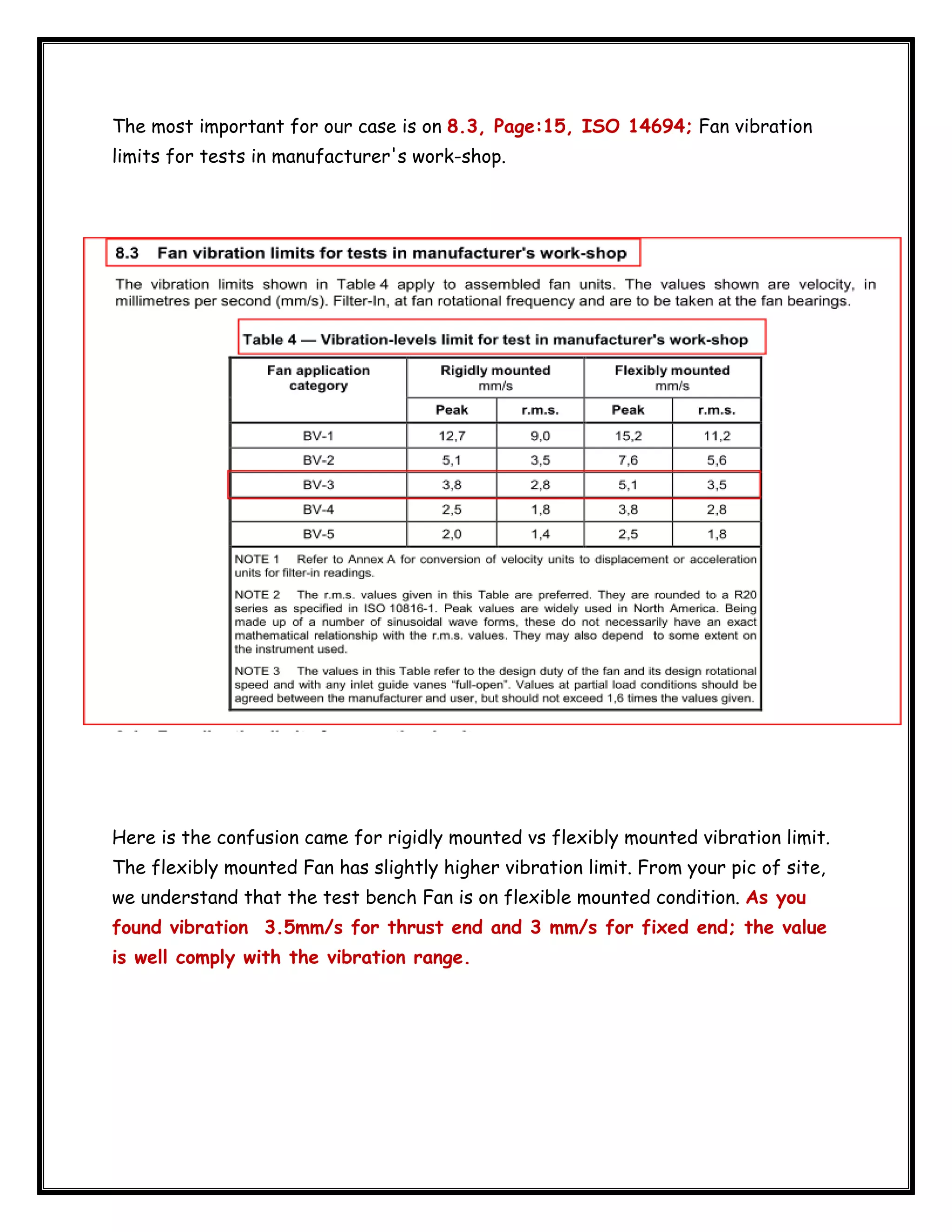

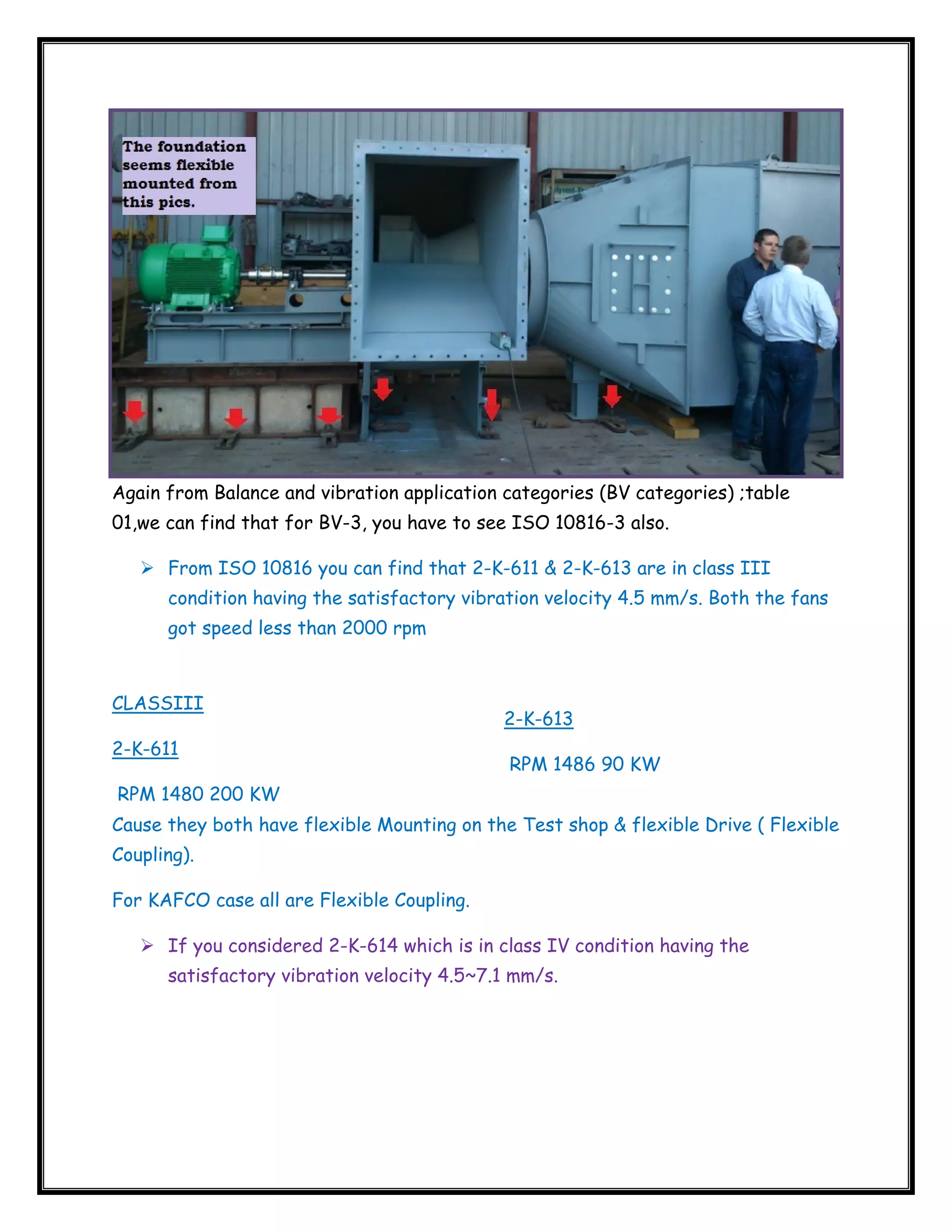

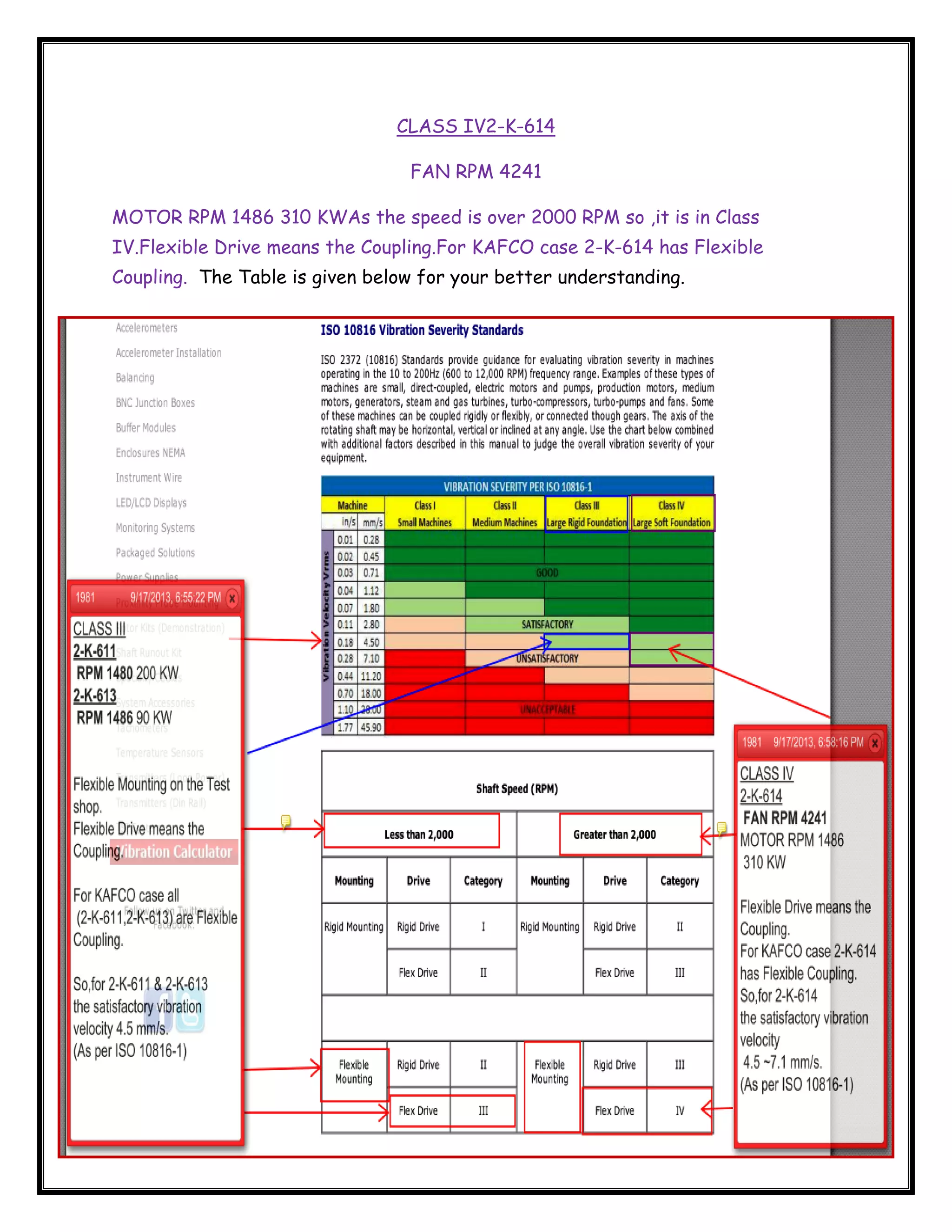

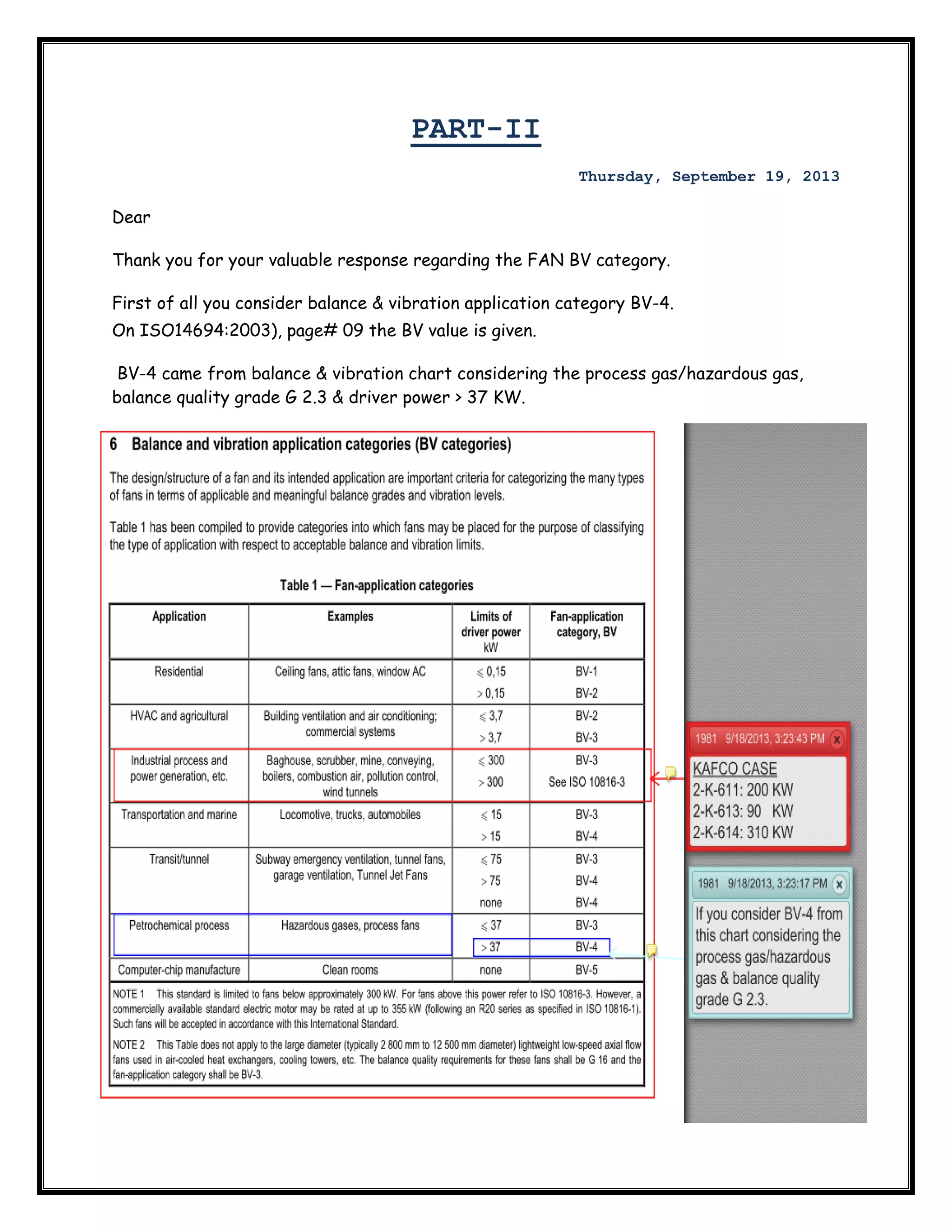

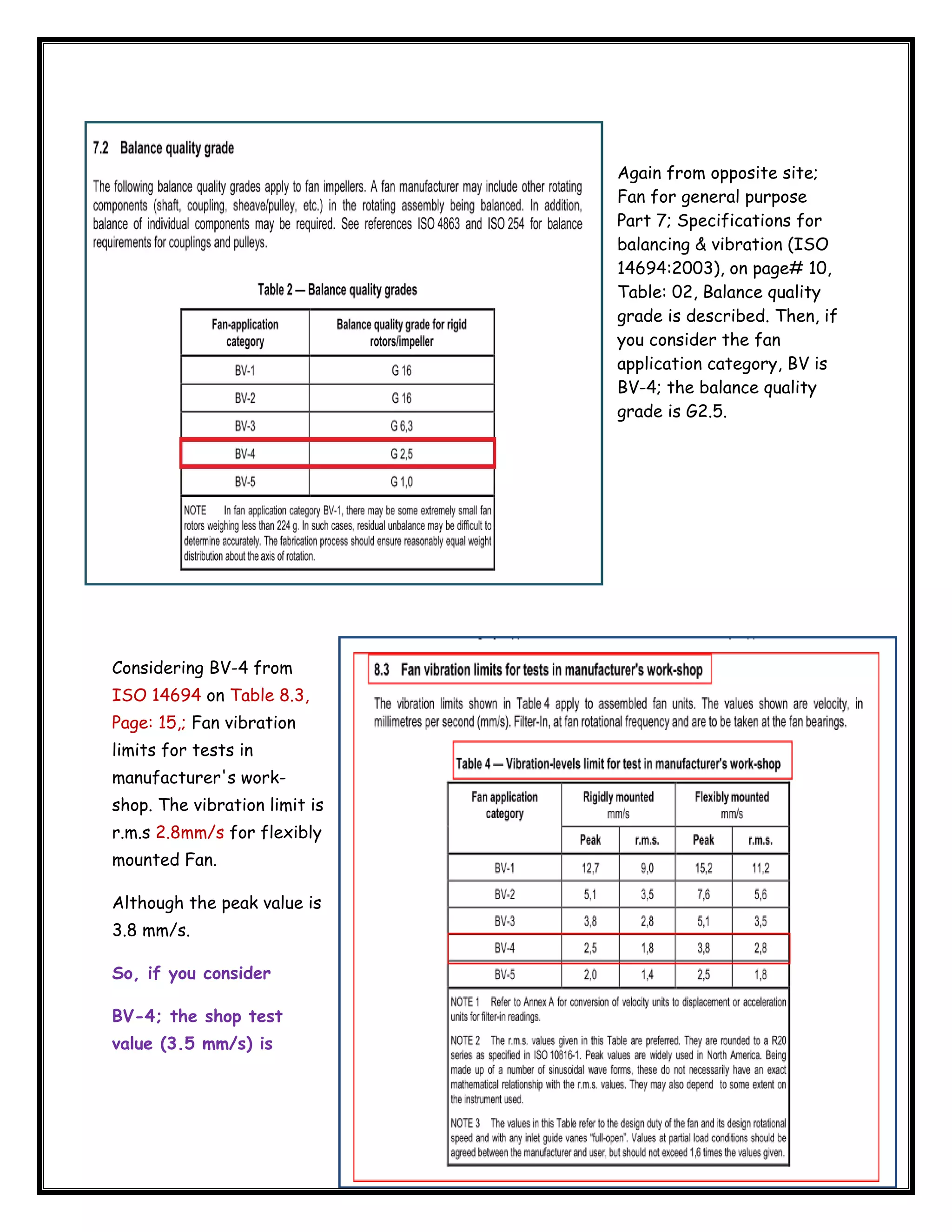

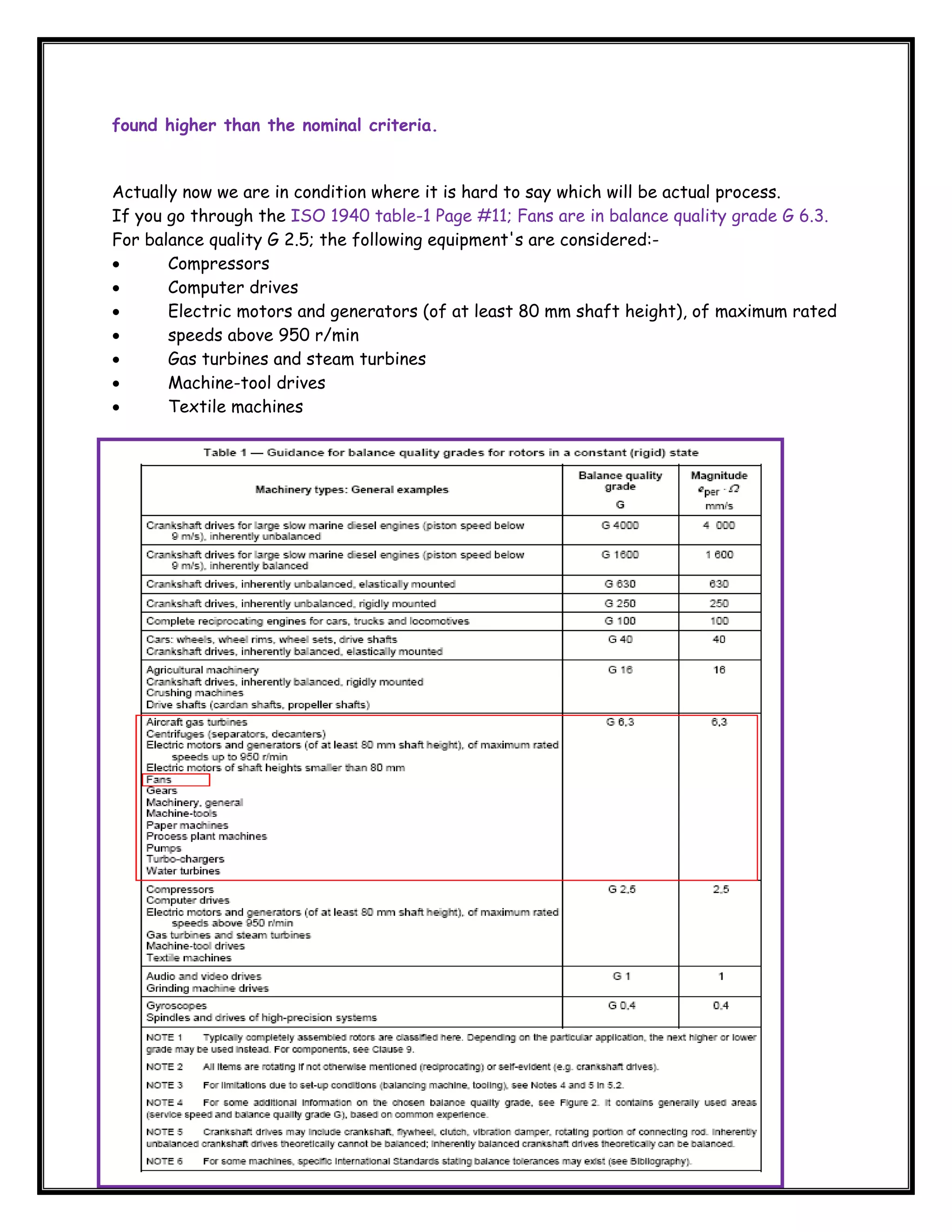

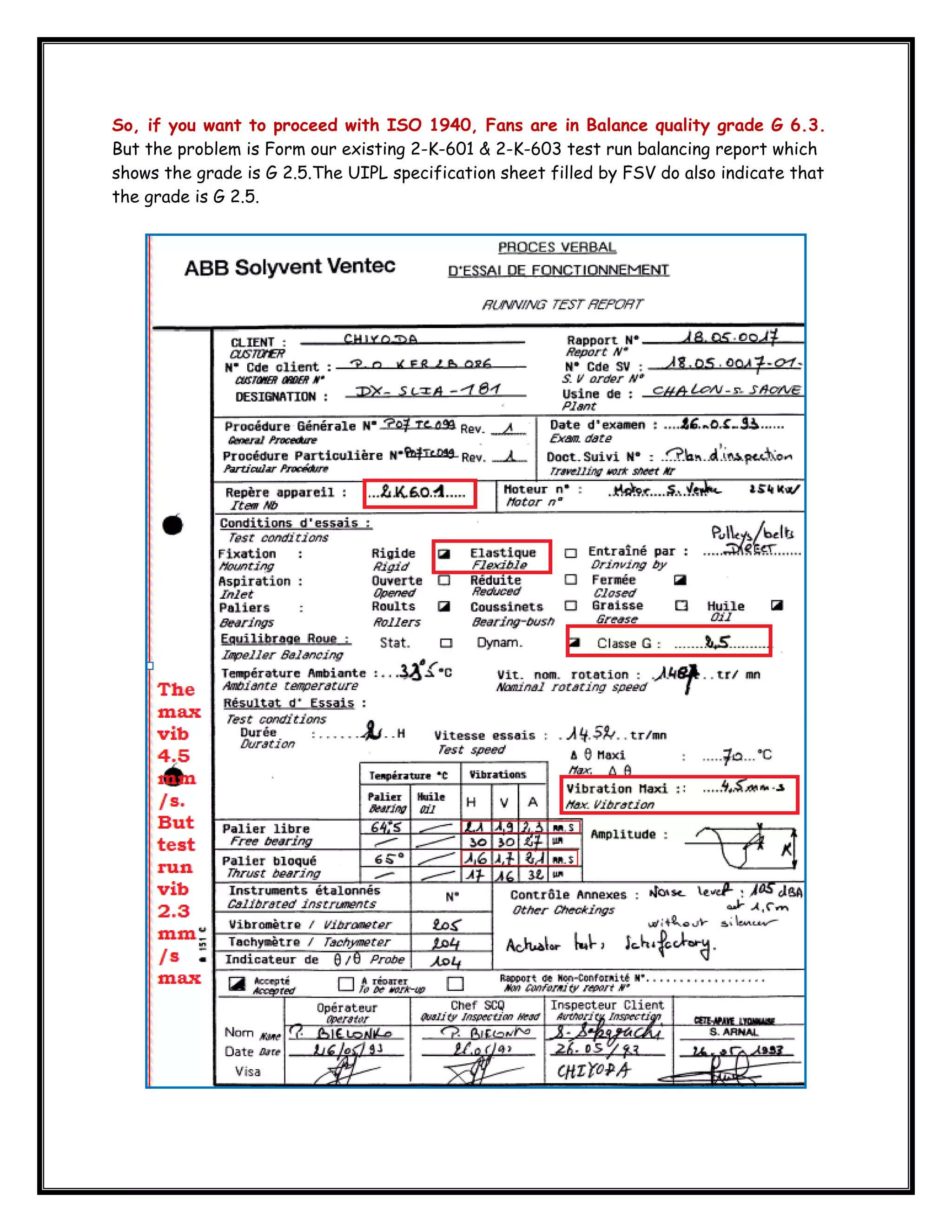

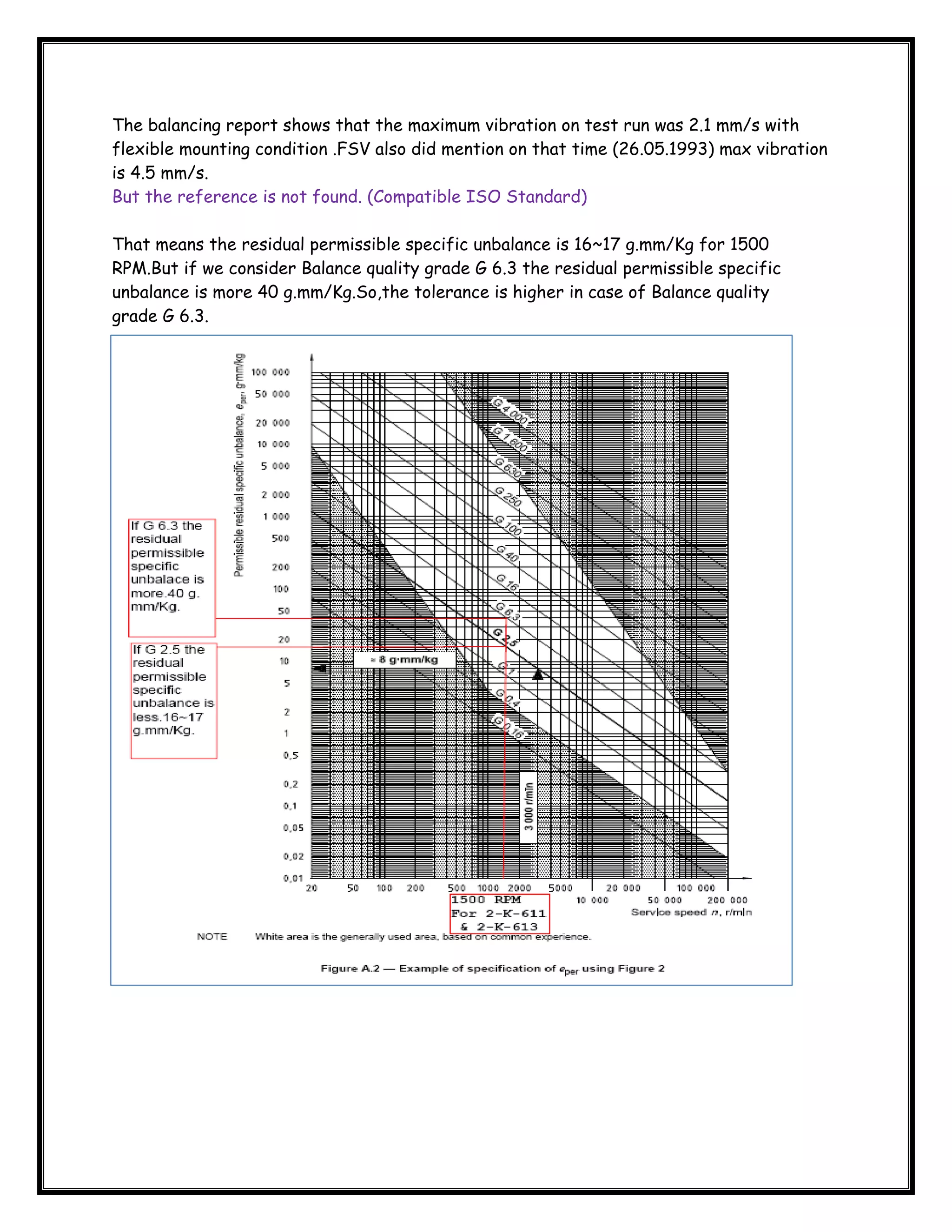

The document discusses vibration acceptance limits for fans, compressors, and blowers during shop tests, outlining the relevant ISO standards for balanced vibrations. It highlights the confusion between rigidly and flexibly mounted vibration limits, emphasizing that for the flexibly mounted fan tested, the vibrations were within acceptable limits of 3.5 mm/s and 3.0 mm/s. Despite this, the desired balance quality grade of g 2.5 based on vendor specifications cannot accept a test value of 3.5 mm/s, leading to a preference for rotor balancing at the vendor's site.