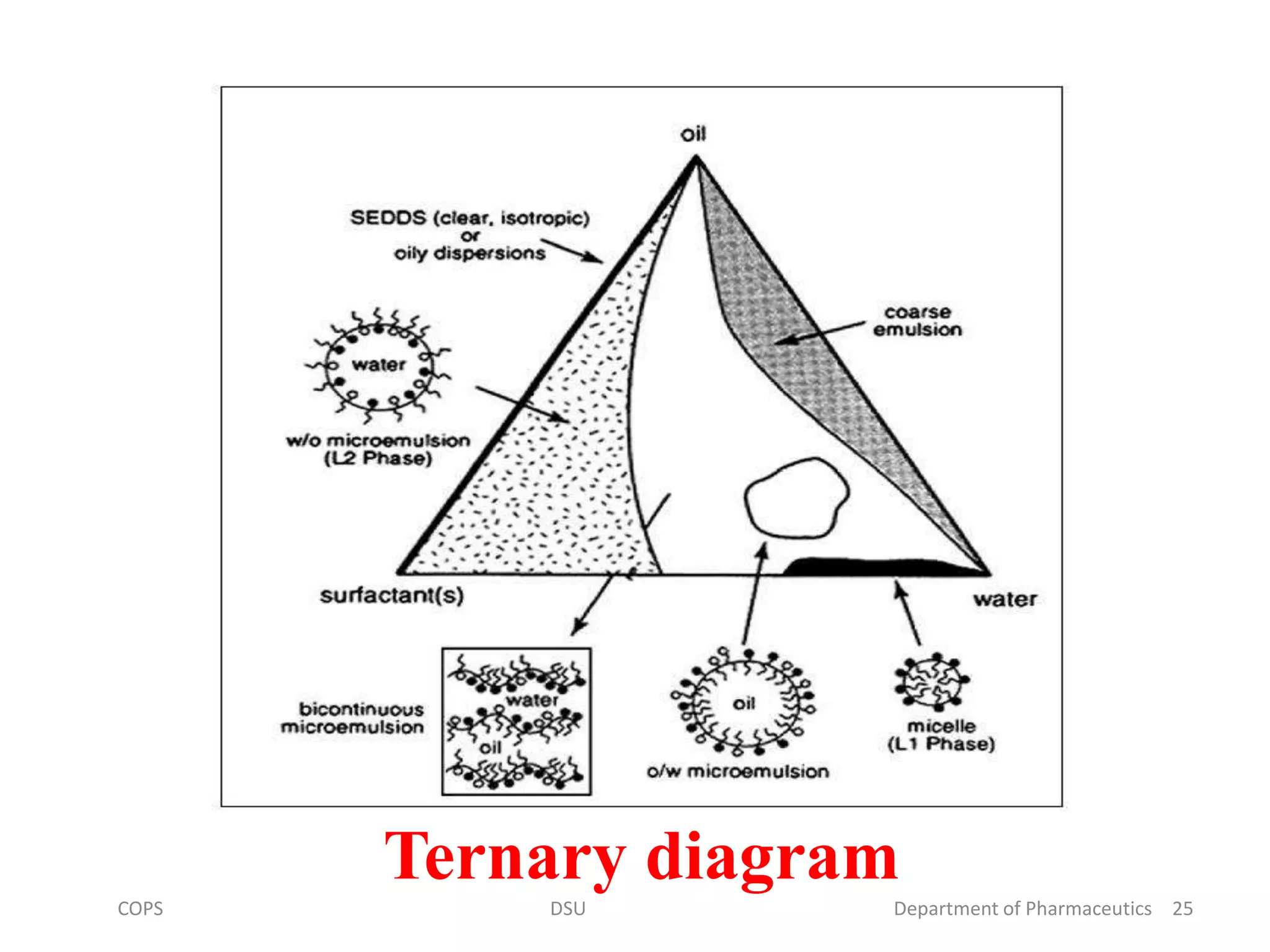

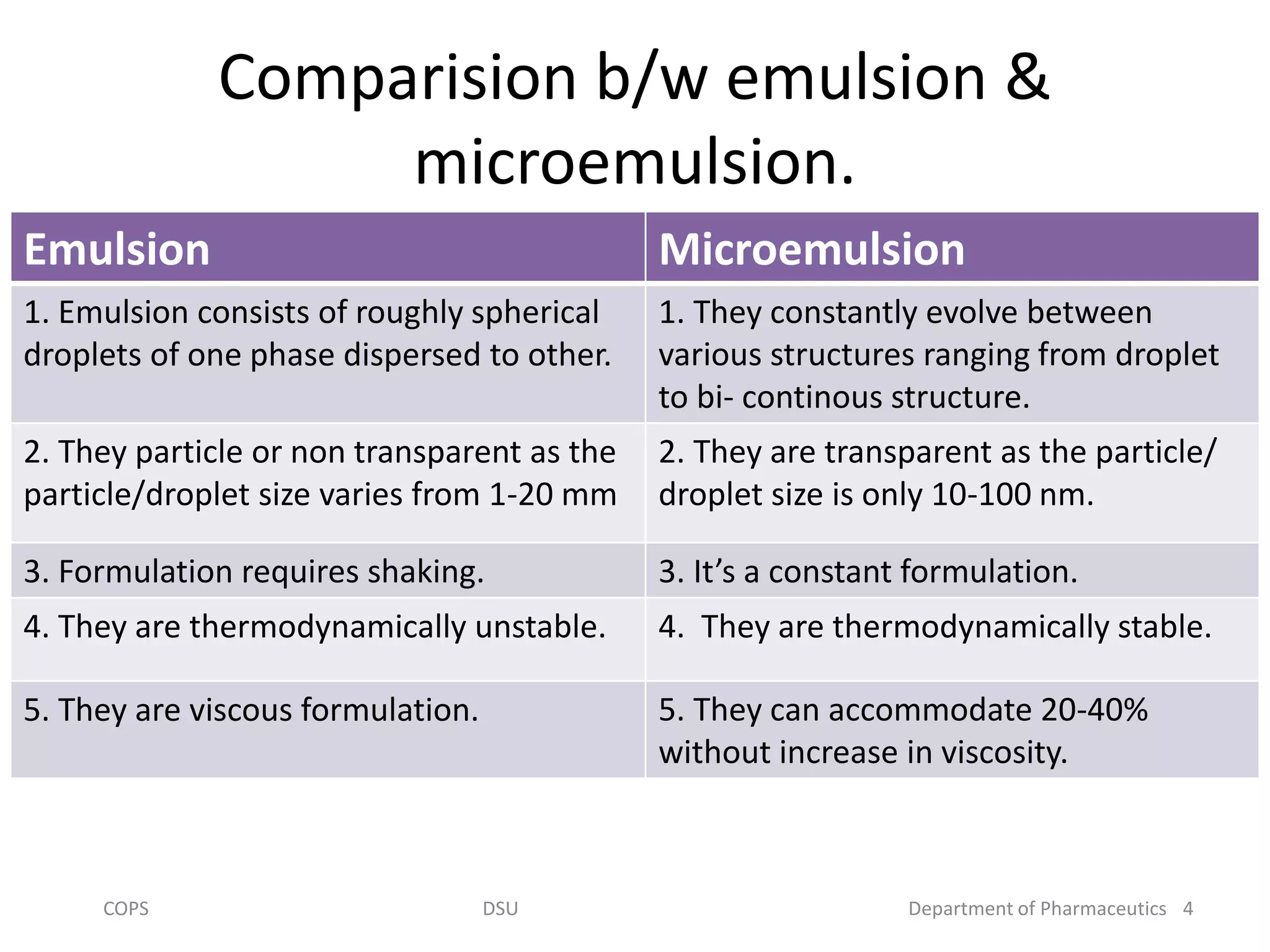

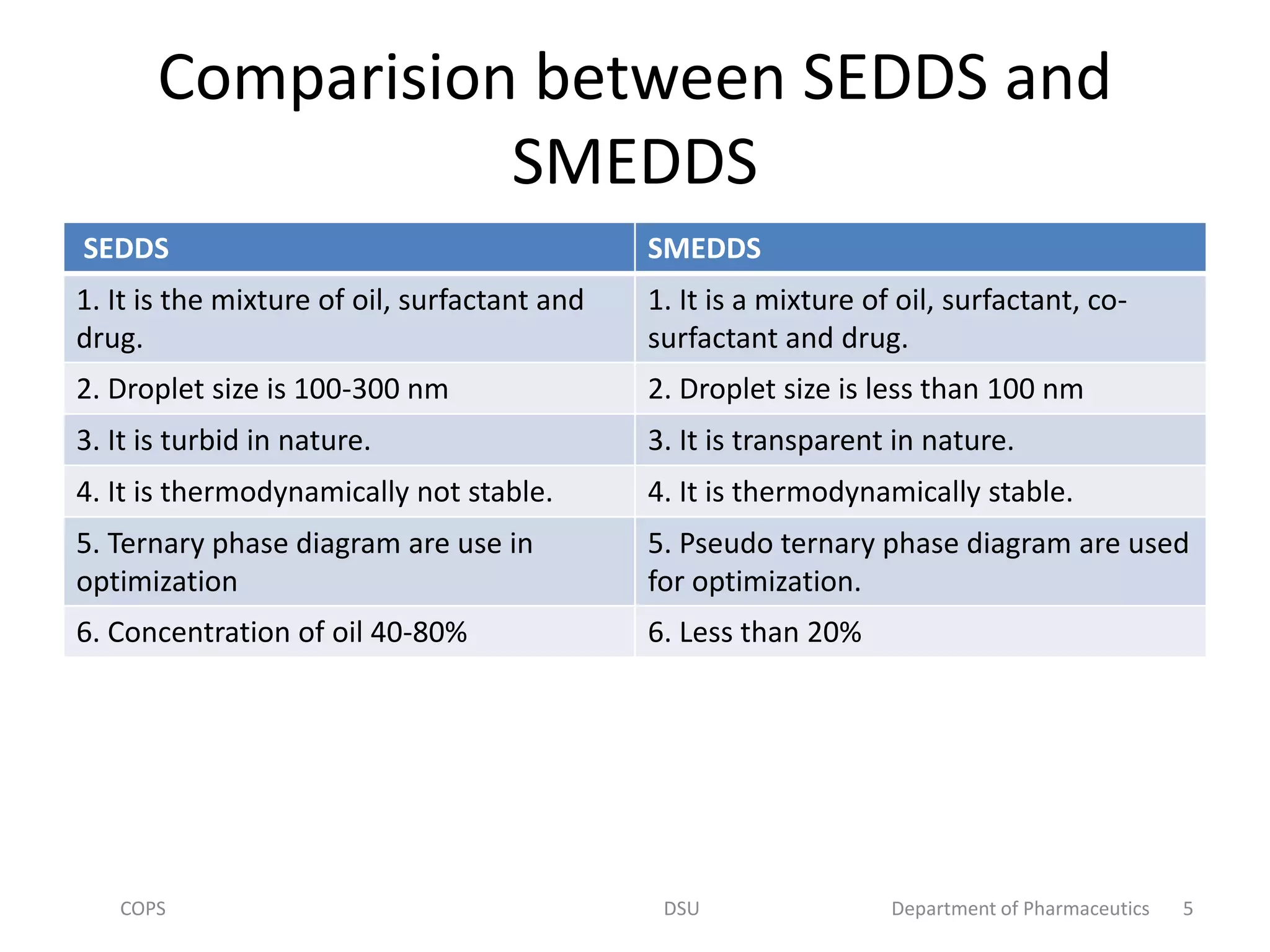

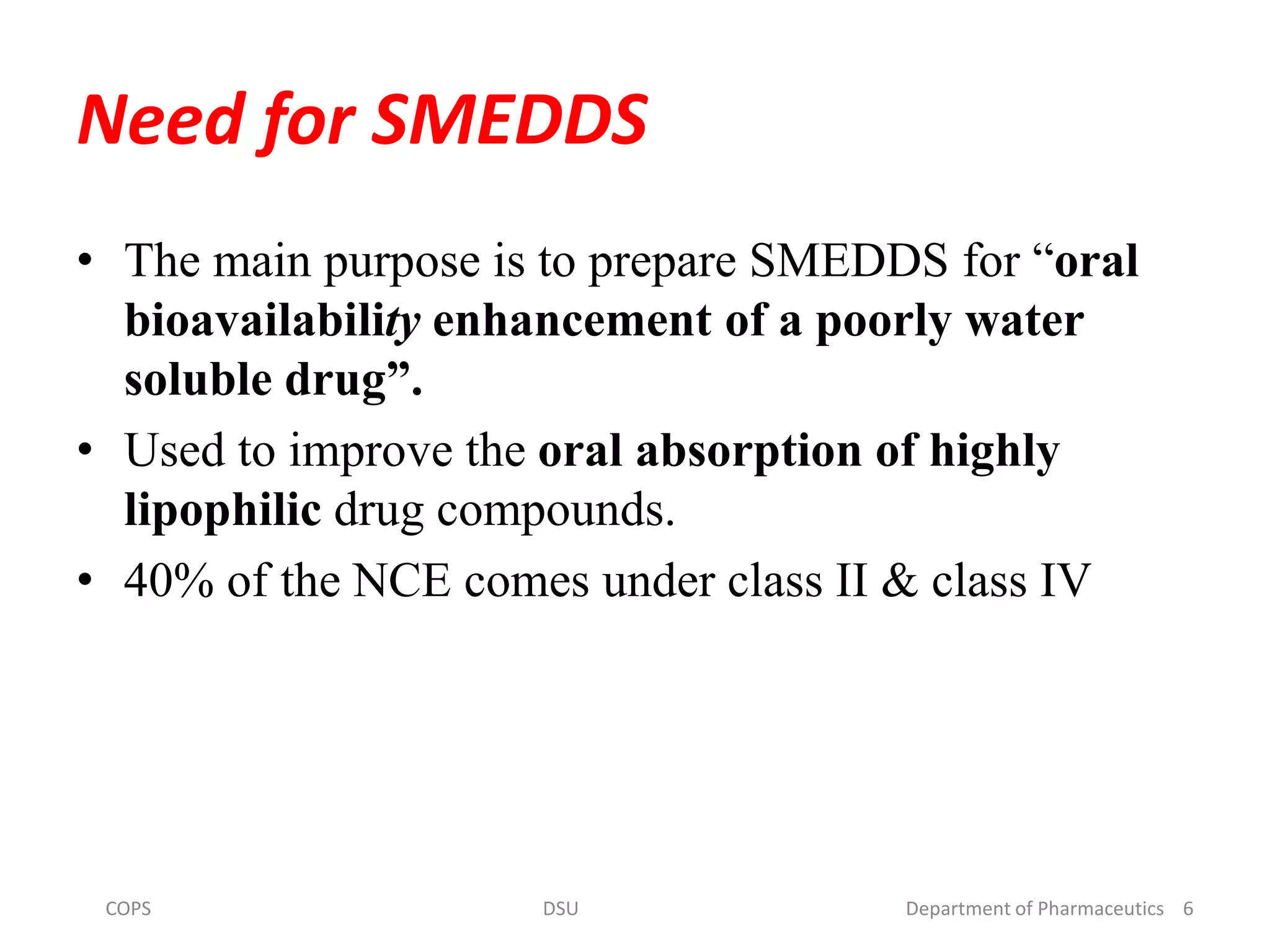

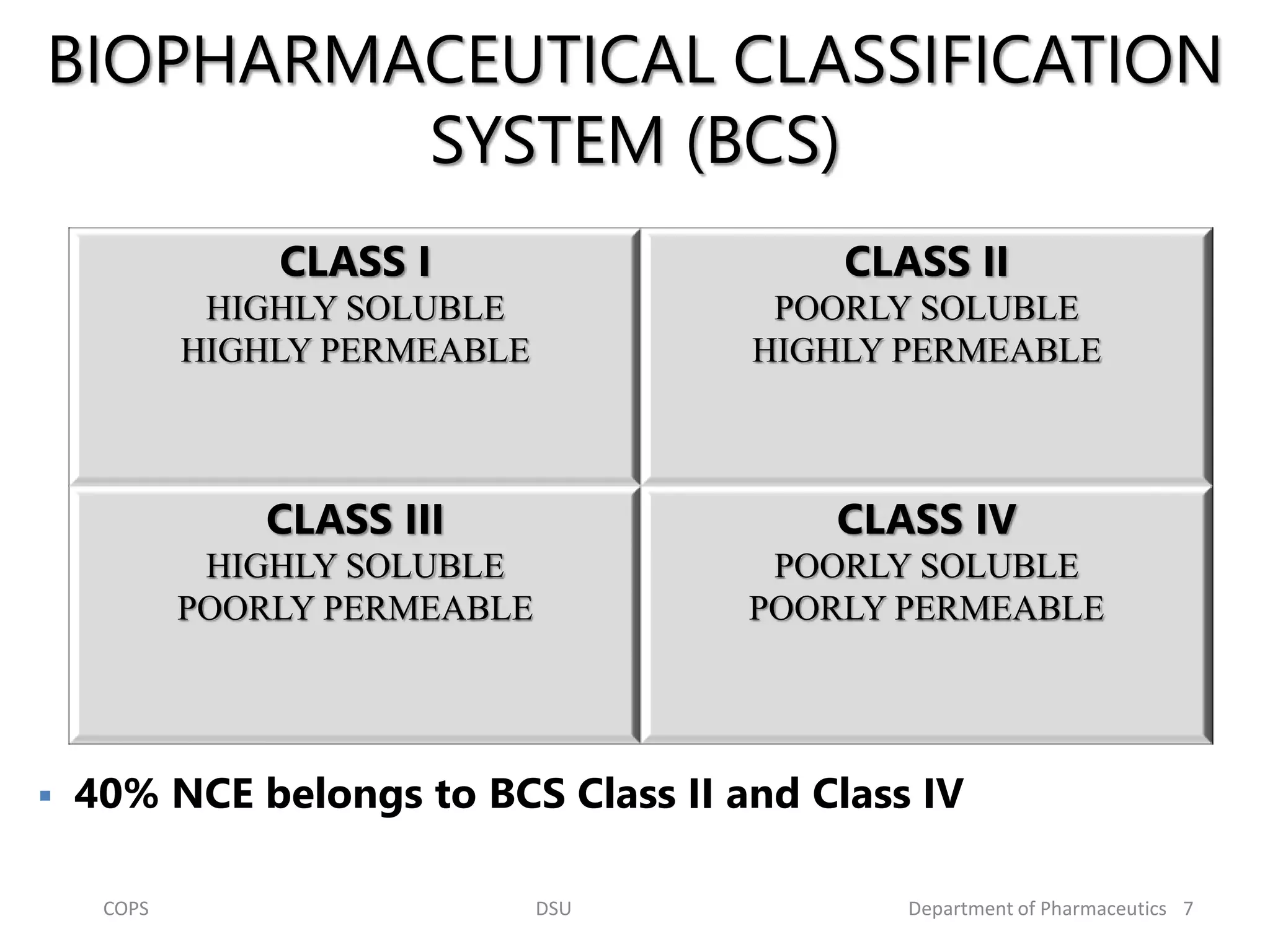

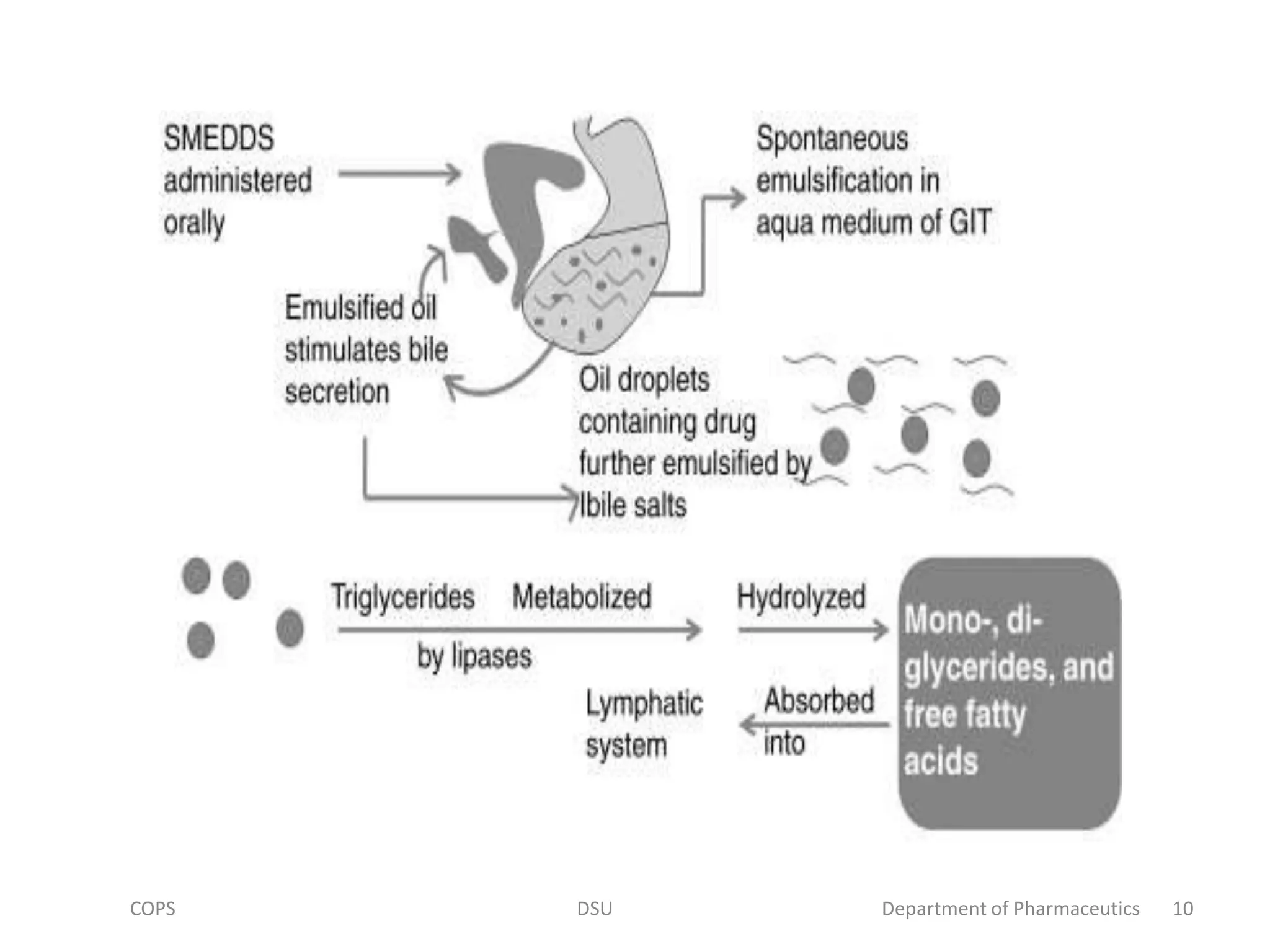

The document discusses self micro-emulsifying drug delivery systems (SMEDDS), highlighting their composition, advantages, and disadvantages in enhancing the oral bioavailability of poorly soluble drugs. It compares SMEDDS with other formulations like self-emulsifying drug delivery systems (SEDDS) and conventional emulsions, emphasizing their thermodynamic stability and smaller droplet size. Various formulation techniques, screening of excipients, and applications in drug delivery are also addressed.

![Other components

• pH adjusters

• Flavours

• Antioxidant agents

– Lipophilic antioxidants(E.g. alpha tocopherol,

Propyl Gallate,Ascorbyl palmitate )

– [ stabilize the oily content of SMEDDS

formulation].

• Consistency builder

21COPS DSU Department of Pharmaceutics](https://image.slidesharecdn.com/smedds-191119134402/75/self-micro-emulsifying-drug-delivery-system-21-2048.jpg)