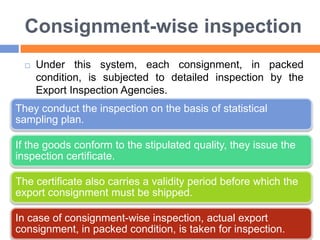

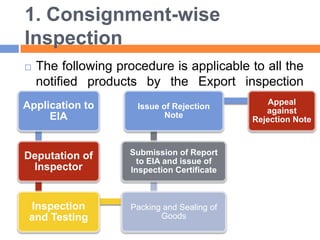

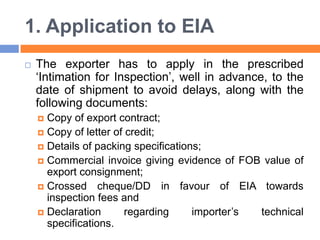

This document discusses three methods of pre-shipment inspection: consignment-wise inspection, in-process quality control, and self-certification. Consignment-wise inspection involves inspecting each export consignment before shipment. In-process quality control allows continuous process industries to conduct their own inspections if they have the required quality control infrastructure. Self-certification allows reputable manufacturers with a proven quality track record to issue their own inspection certificates. The document outlines the procedures for obtaining inspection certificates under each method.