This document discusses various aspects of product planning and control including product planning, need for product planning, product planning process, value analysis, concept of value and function, value analysis vs value engineering, process planning, machine capacity, and balancing machine processes. The key points are:

1) Product planning involves evaluating existing products, pricing, and specifying new product design and development. It aims to satisfy market and company objectives.

2) The product planning process includes initial market analysis, performance/feasibility studies, and advanced product planning to select and justify new product specifications.

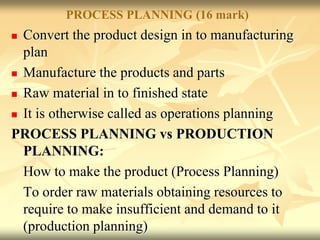

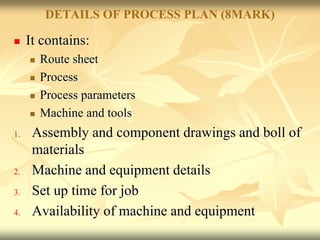

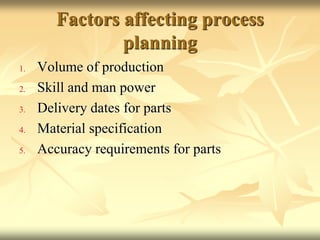

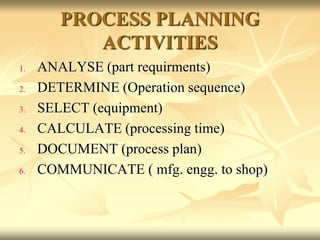

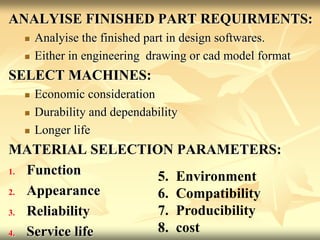

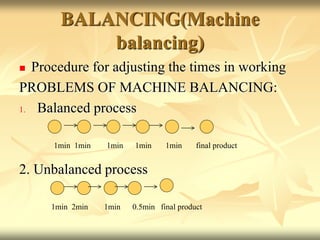

3) Process planning converts product designs into manufacturing plans by determining operations, equipment, and processing times to produce product parts from raw materials to the finished state