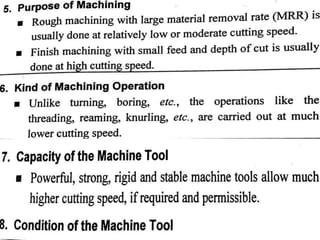

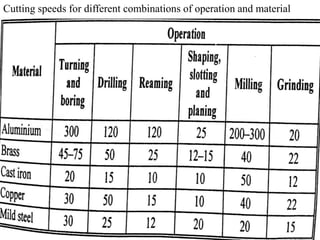

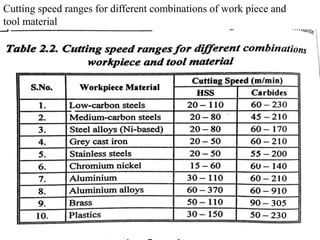

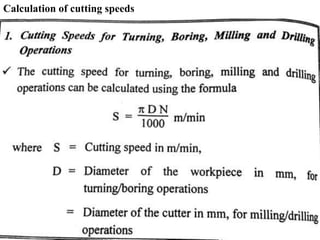

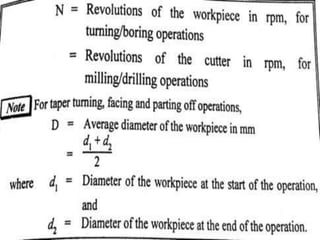

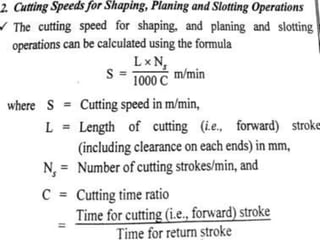

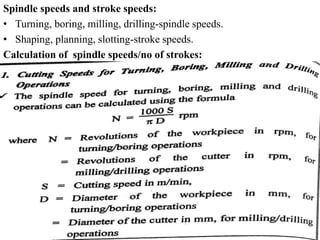

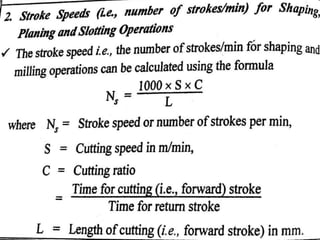

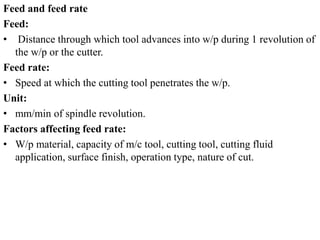

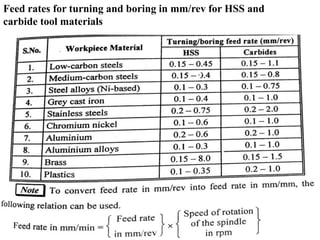

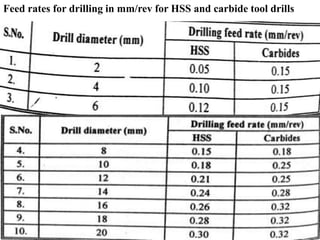

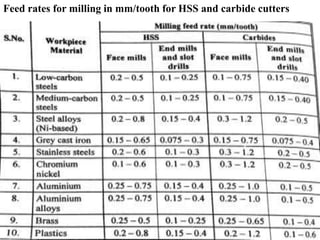

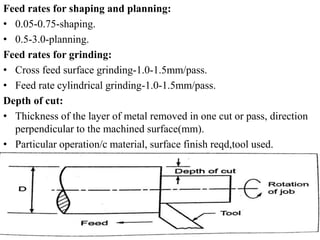

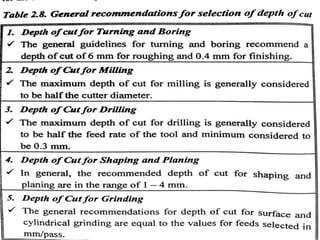

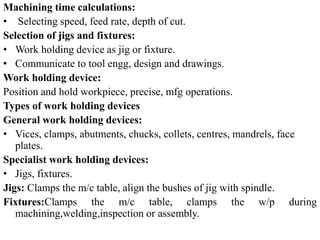

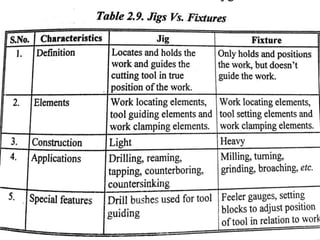

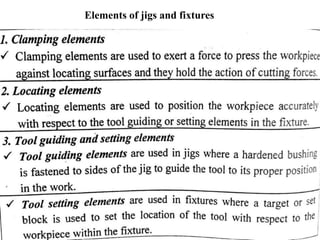

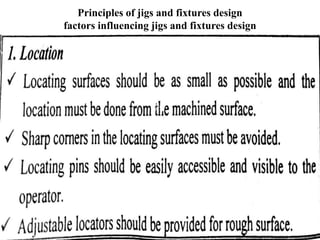

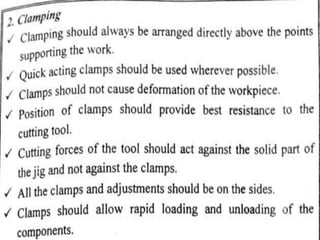

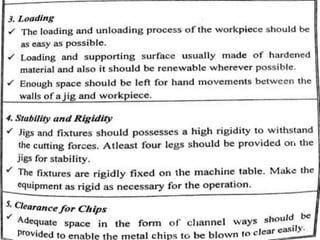

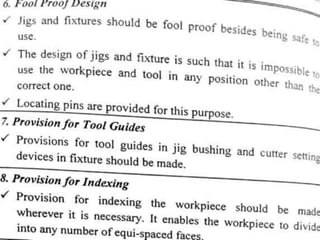

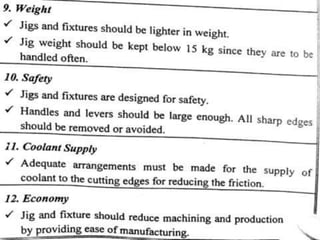

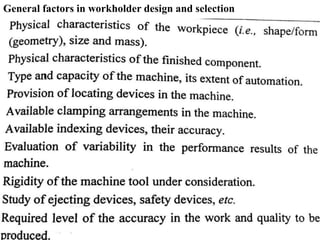

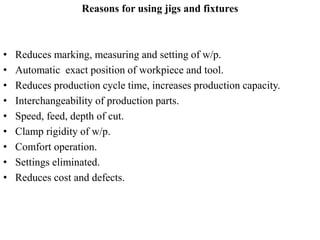

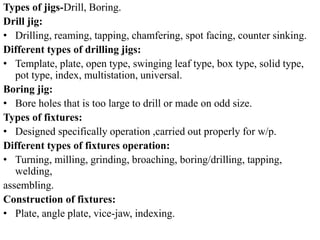

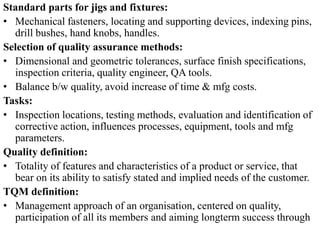

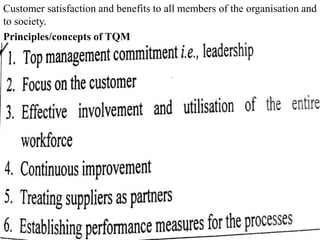

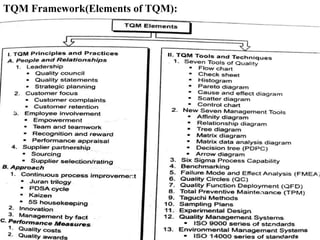

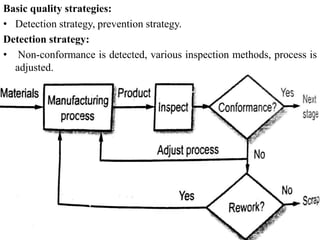

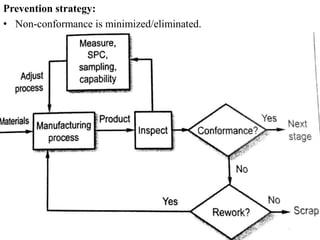

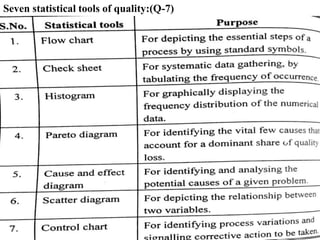

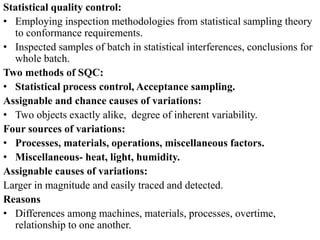

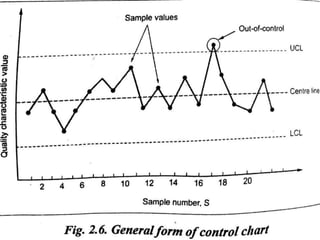

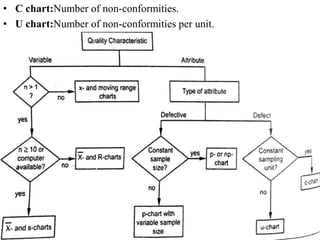

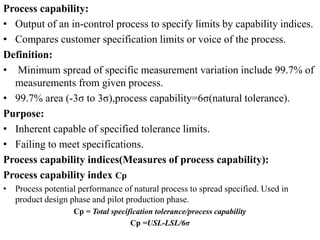

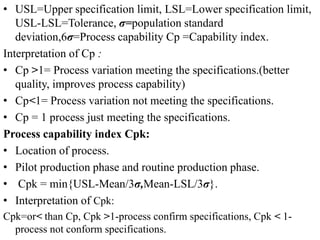

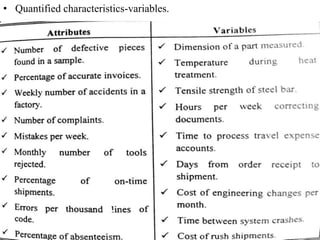

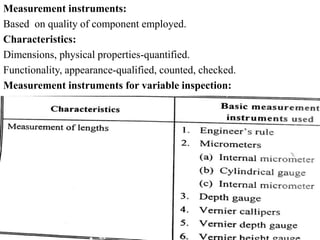

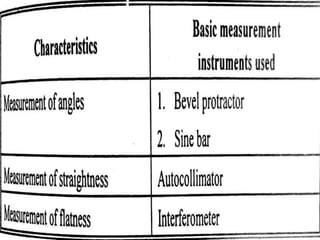

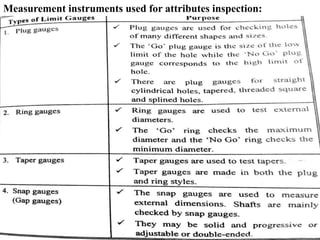

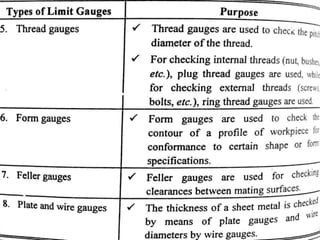

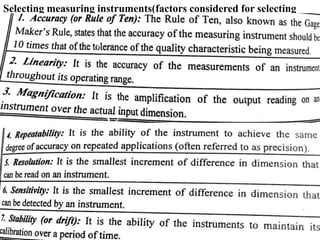

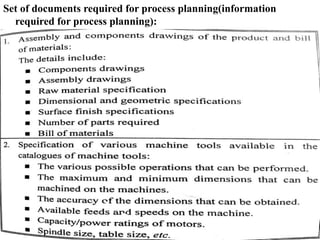

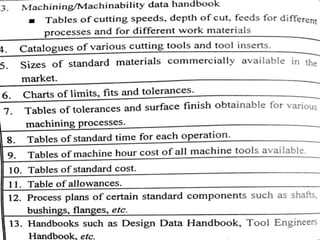

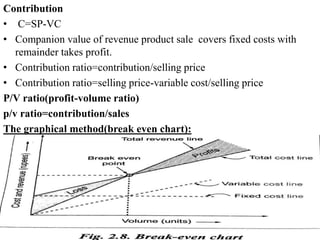

This document discusses process planning activities including setting process parameters, work holding devices, inspection methods, and the economics of process planning. It covers calculating cutting speeds, feed rates, and depth of cut. It also discusses selecting quality assurance methods and different types of work holding devices like jigs and fixtures. The key factors in their design and selection are explained. The document provides details on various inspection and measurement techniques as well as statistical process control.