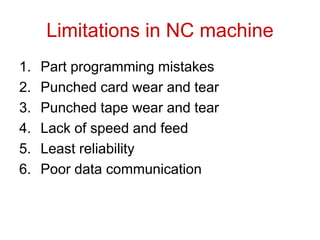

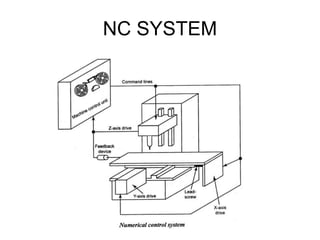

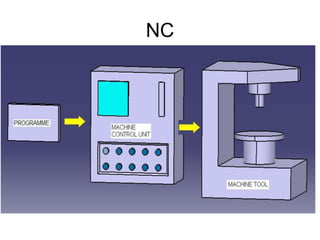

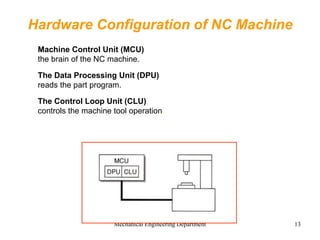

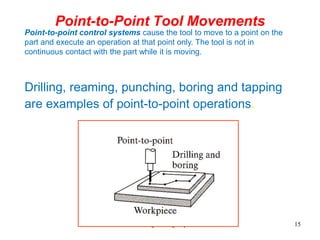

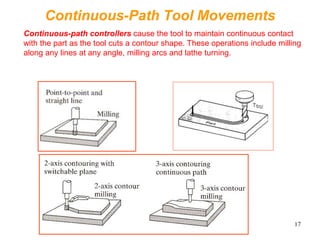

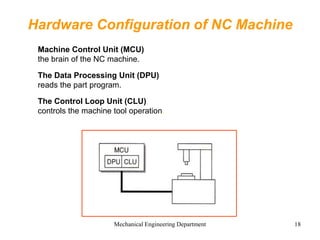

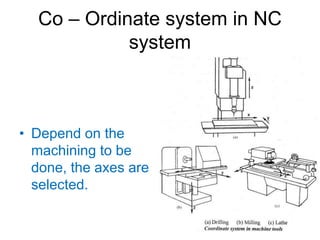

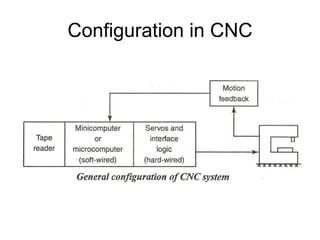

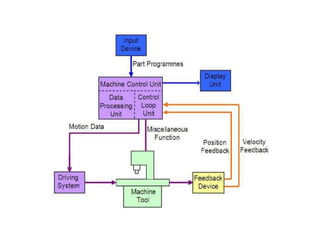

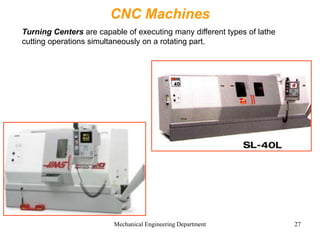

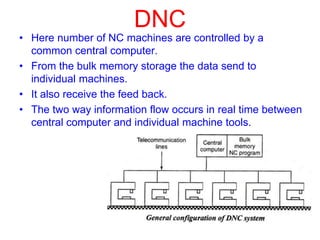

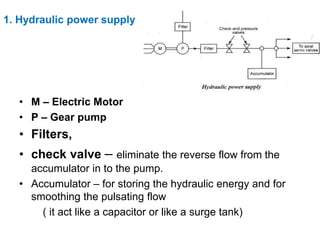

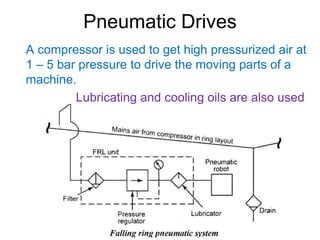

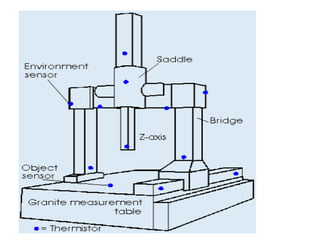

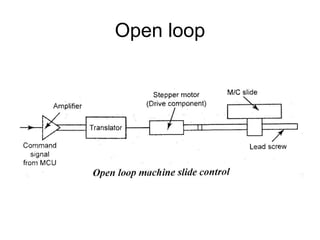

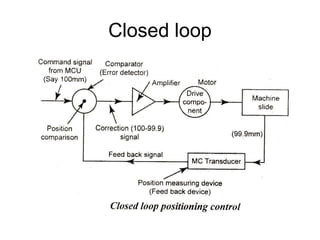

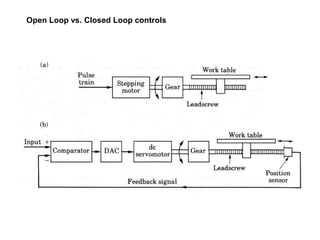

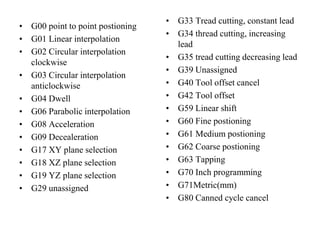

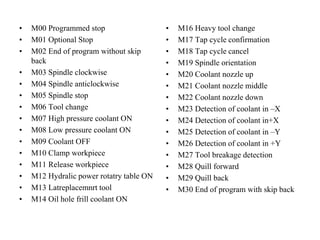

The document details the history and evolution of CNC (Computer Numerical Control) machining, beginning with its inception in the 1940s and the development of numerical control systems. It discusses various types of NC systems, their advantages over traditional machining methods, and advances like DNC (Direct Numerical Control) and different types of CNC machines. Furthermore, it outlines the hardware configurations, drive systems, inspection methods, and programming commands associated with CNC machining.