This document provides information about axial flow compressors including:

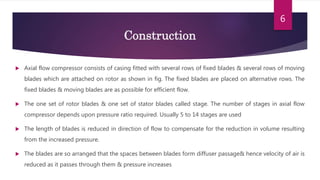

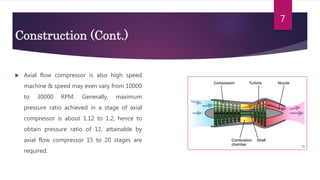

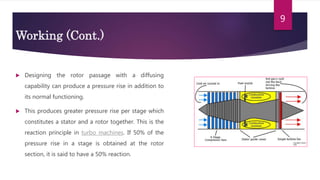

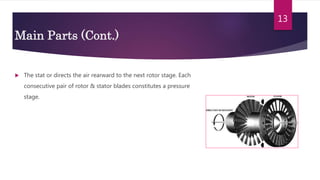

- They consist of multiple rows of fixed and moving blades that continuously pressurize gas flowing parallel to the axis of rotation, achieving high efficiency and mass flow.

- Each pair of rotor and stator blades constitutes a pressure stage, with typical single stage pressure increases of 15-60% and multiple stages used to achieve higher overall pressure ratios.

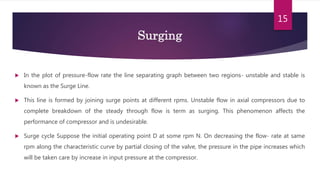

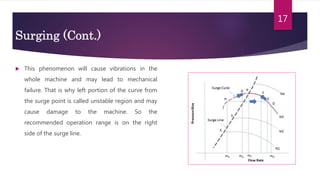

- Stalling and surging refer to unstable flow conditions that reduce compressor performance and must be avoided through proper design and operation.

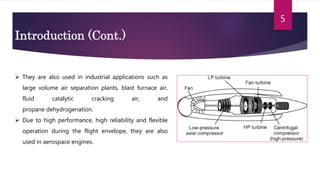

- They find applications in industries like oil refining and power generation as well as aircraft engines due to their high performance capabilities.