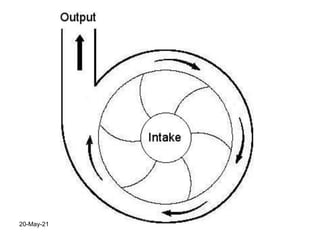

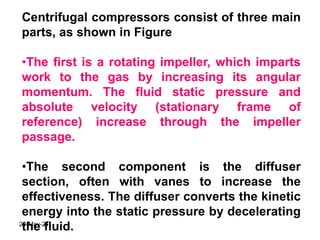

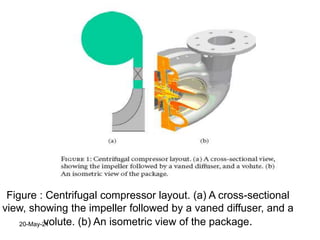

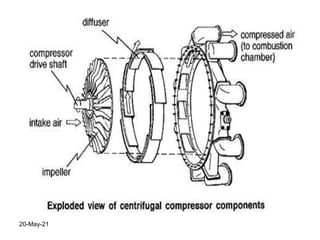

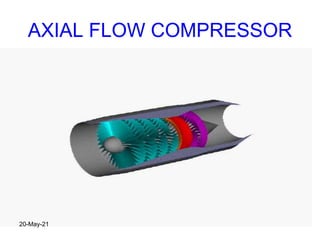

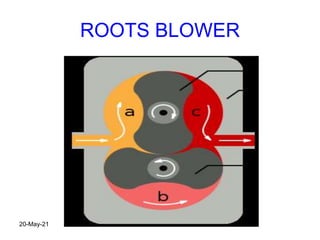

This document discusses different types of compressors used in mechanical engineering. It covers positive displacement compressors like roots blowers, vane compressors, and screw compressors. It also discusses steady flow compressors such as centrifugal and axial flow compressors. For each type of compressor, the document provides details on their working principles, applications, pressure ratios, flow rates and comparative advantages.

![ROOTS BLOWER ANALYSIS

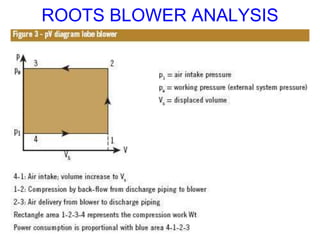

• Work required to drive the root blower with two lobes per

revolution

• W = V (P2-P1)

Note: V= 4V for 2 lobe rotor and 6V for 3 lobe rotor

• Volume of air compressed per minute (Va) = 4V*N [ for 2 lobe]

Where N = speed of blower in RPM

- ACTAUL POWER REQUIRED TO COMPRESS Va AIR in

m3/min = Pa = Va (P2-P1)

- IDEAL POWER REQUIRED TO COMPRESS Va AIR in

m3/min = Pi = (γ/ γ-1) P1 Va [(p2/P1)(γ-1/ γ) - 1]

(The same relation we’ve derived for reciprocating compressor in class )

- Root Efficiency = Ideal Power/Actual Power

20-May-21](https://image.slidesharecdn.com/rotarycompressorsppt-210520170404/85/Rotary-compressors-ppt-8-320.jpg)

![Root Blower Efficiency

- Root Efficiency = Ideal Power/Actual Power

= (γ/ γ-1) P1 Va [(p2/P1)(γ-1/ γ) - 1]

Va(P2-P1)

OR

ROOT EFFICIENCY = (γ/ γ-1) [(rp) )(γ-1/ γ) - 1]

[rp-1]

Where rp is the pressure ratio

20-May-21](https://image.slidesharecdn.com/rotarycompressorsppt-210520170404/85/Rotary-compressors-ppt-9-320.jpg)

![VANE BLOWER ANALYSIS

1

2

c

P1

Pc

P2

P

V

Pressure rise due to

back flow of air

Pressure rise due to

internal compression

Total pressure rise = Internal compression pressure rise + Back flow

W = W1-c + Wc-2

W = (γ/ γ-1) P1 V1 [(Pc/P1)(γ-1/ γ) - 1] + Vc (P2-PC)

Also P1V1γ = Pc Vc

γ

So, W = (γ/ γ-1) P1 V1 [(Pc/P1)(γ-1/ γ) - 1] + (P1/Pc)(1/ γ) V1 (P2-Pc)

20-May-21](https://image.slidesharecdn.com/rotarycompressorsppt-210520170404/85/Rotary-compressors-ppt-12-320.jpg)