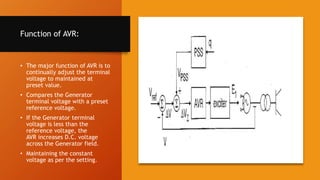

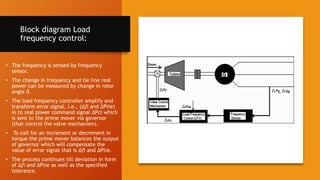

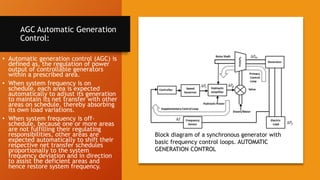

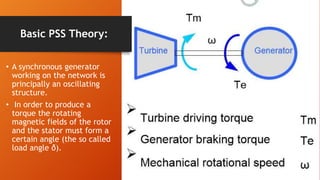

The document discusses various methods for improving power system stability, including automatic voltage regulators (AVR), load frequency control (LFC), and power system stabilizers (PSS). AVR works to maintain generator terminal voltage at a preset value by adjusting excitation current. LFC maintains system frequency and power exchange between areas at scheduled values. PSS adds damping to generator oscillations to stabilize the grid by modulating voltage regulator setpoint based on speed.