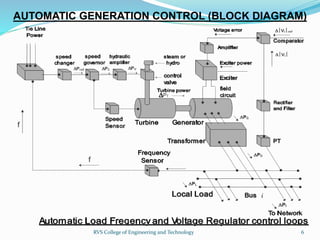

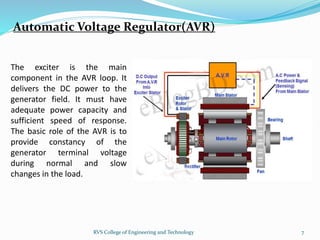

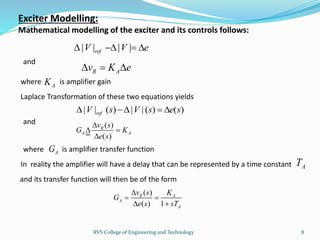

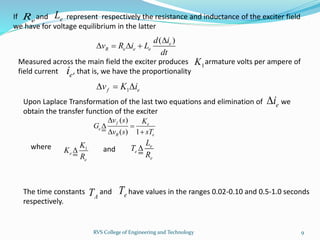

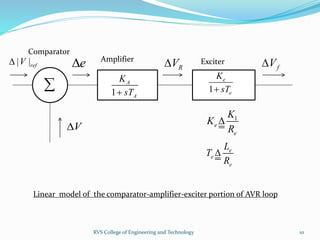

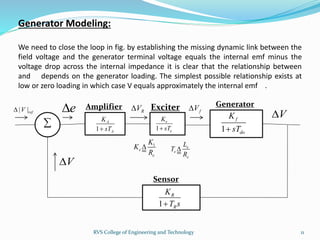

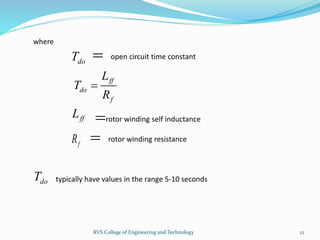

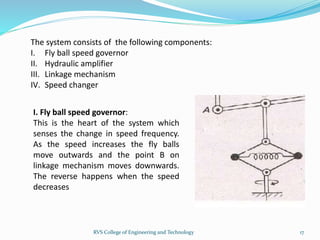

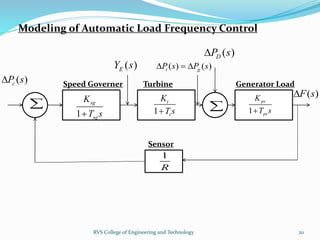

The document discusses Automatic Generation Control (AGC) systems which adjust the power output of generators to balance load in electrical power systems, emphasizing the importance of maintaining constant frequency. It covers components like Automatic Voltage Regulators (AVR) and Automatic Load Frequency Control (ALFC) systems that regulate voltage and power output to prevent frequency fluctuations. Additionally, the document details system components including speed governors and their role in responding to varying loads.