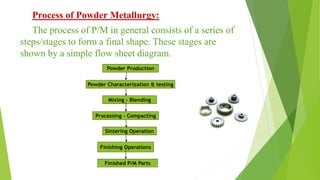

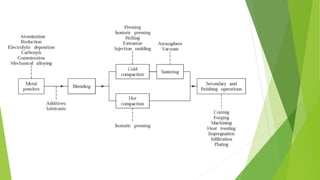

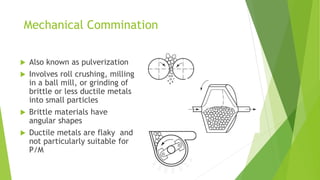

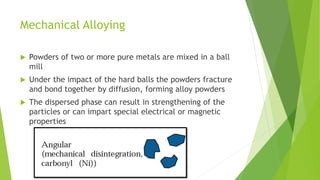

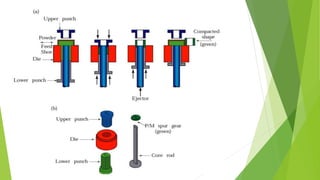

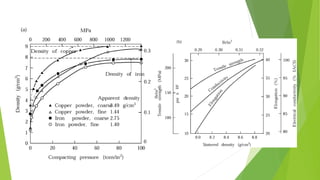

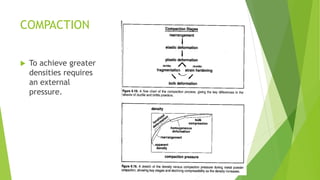

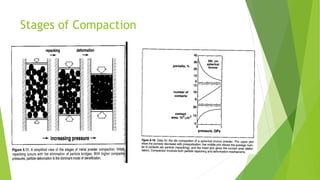

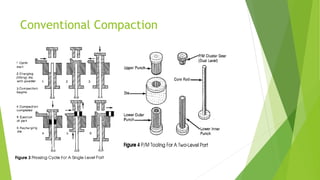

Powder metallurgy is a process that involves compacting and forming metal powders into a solid object through sintering. It consists of 3 main steps - producing metal powders through various methods, compacting the powders into a green compact through pressing, and sintering the compact by heating it to fuse the particles together into a solid object. It allows for net-shape production of complex parts and close dimensional tolerances, and is used for applications where other fabrication methods are not suitable.