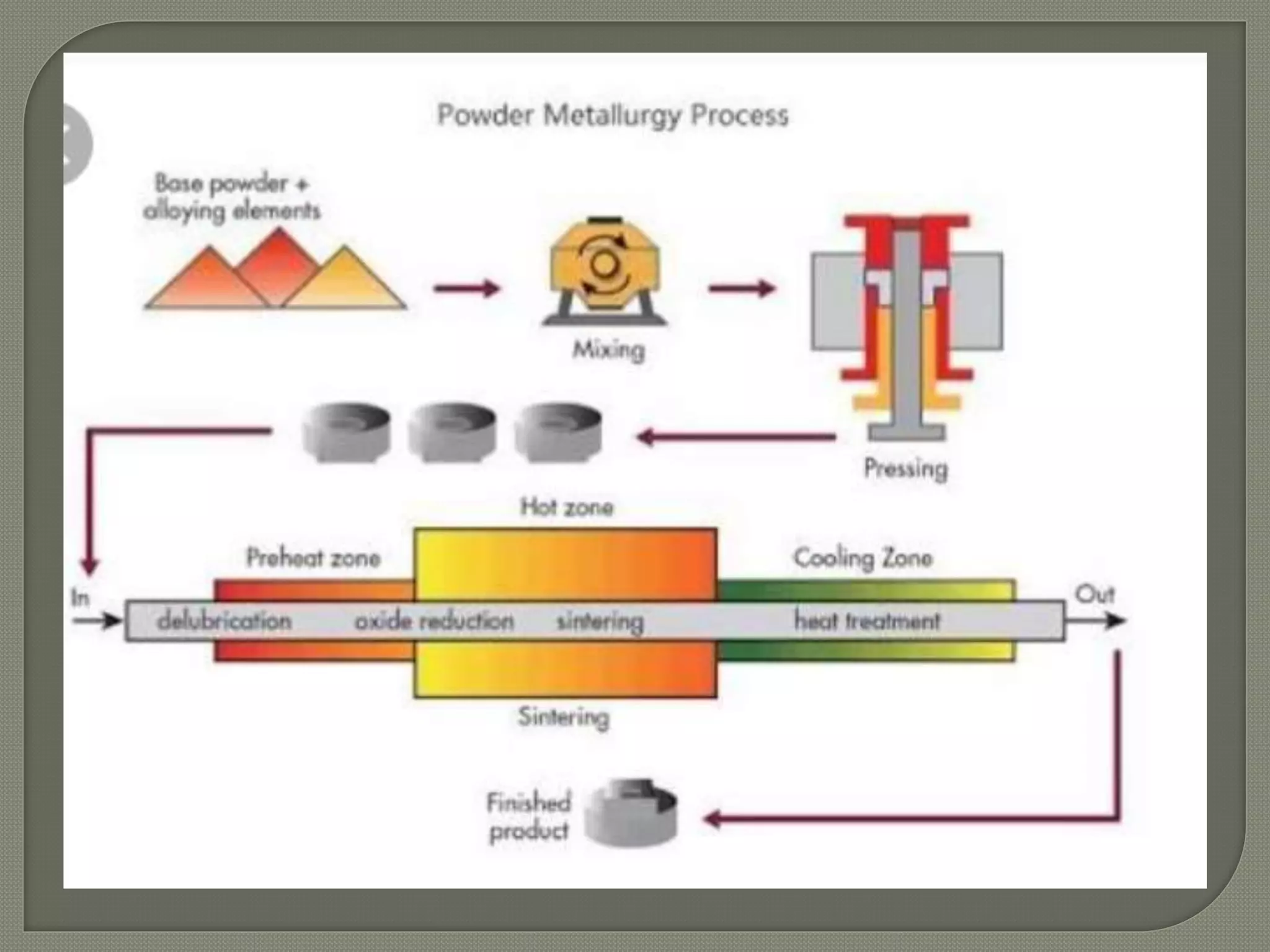

Powder metallurgy is a process that makes materials or components from metal powders rather than melting metals. It involves blending metal powders, compacting them into shapes, and sintering them by heating below the melting point to fuse the particles together. This allows for mass production of parts with complex shapes that would be difficult to make through other methods. An example of a material commonly made through powder metallurgy is tungsten carbide, which is used to cut other metals.