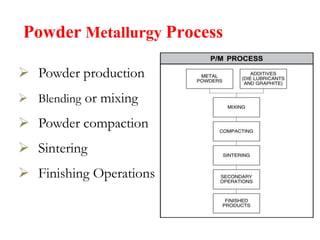

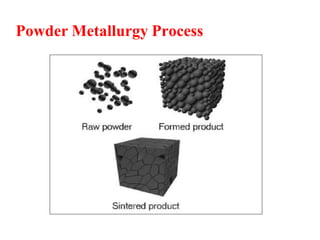

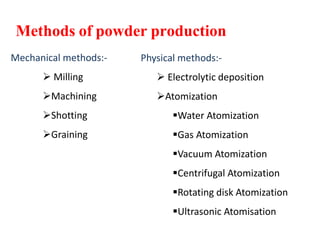

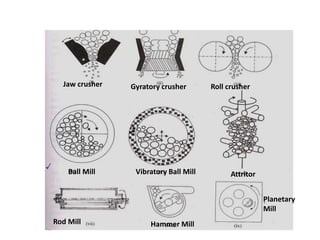

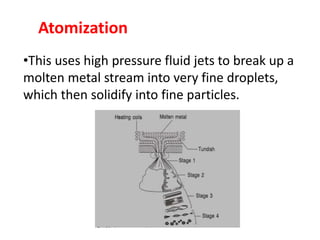

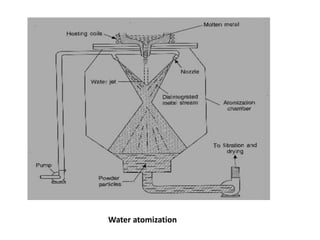

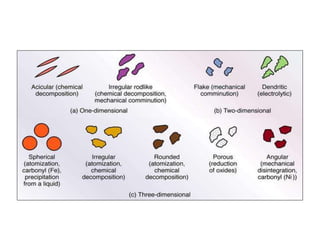

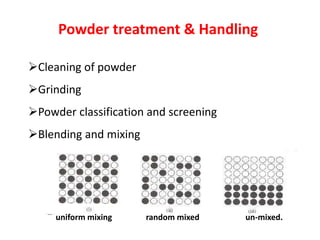

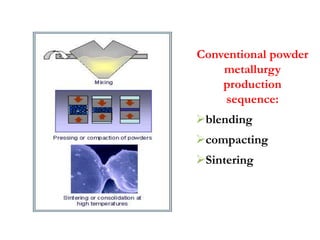

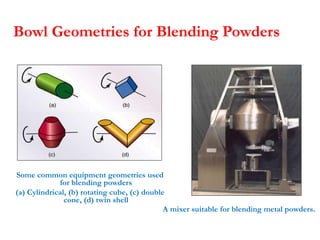

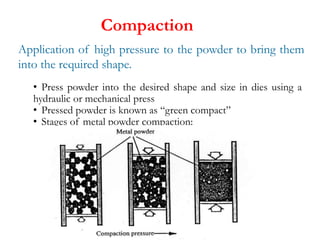

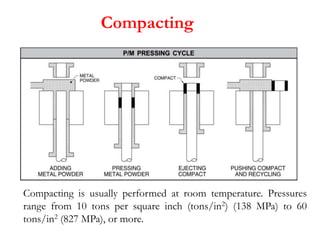

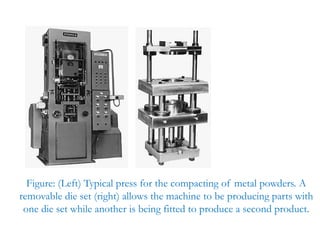

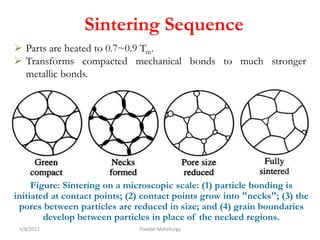

Powder metallurgy is a process that involves producing metal powders and compacting and sintering them to form finished parts. Key steps include powder production through mechanical or physical methods like milling or atomization, blending and mixing powders, compacting the powder in a die under pressure, and sintering the compact at high temperatures to bond the particles together. Powder metallurgy allows for net-shape manufacturing of complex parts, flexibility in alloy compositions, and close control over material properties. Common applications include automotive and aerospace components like gears and bearings.