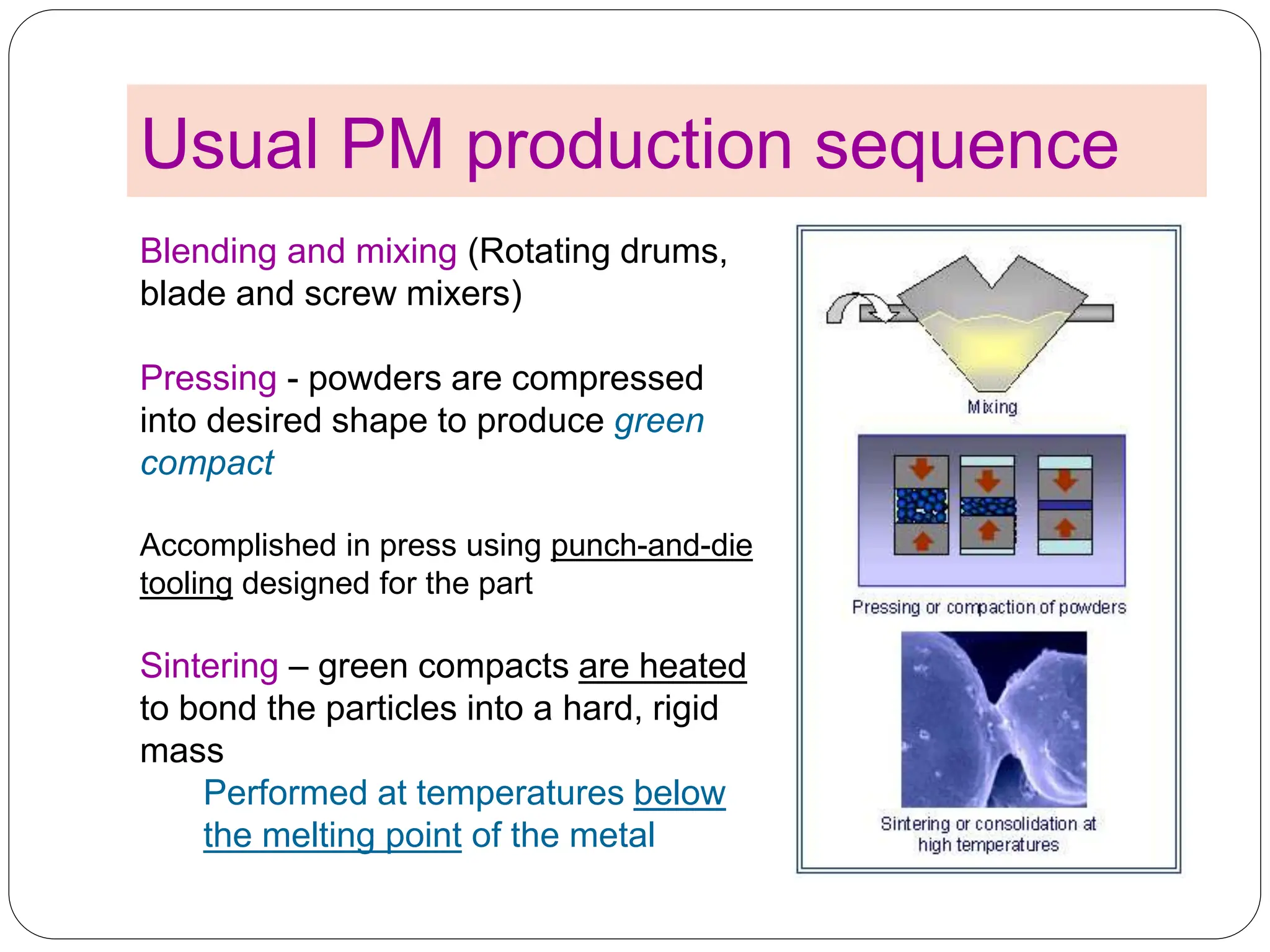

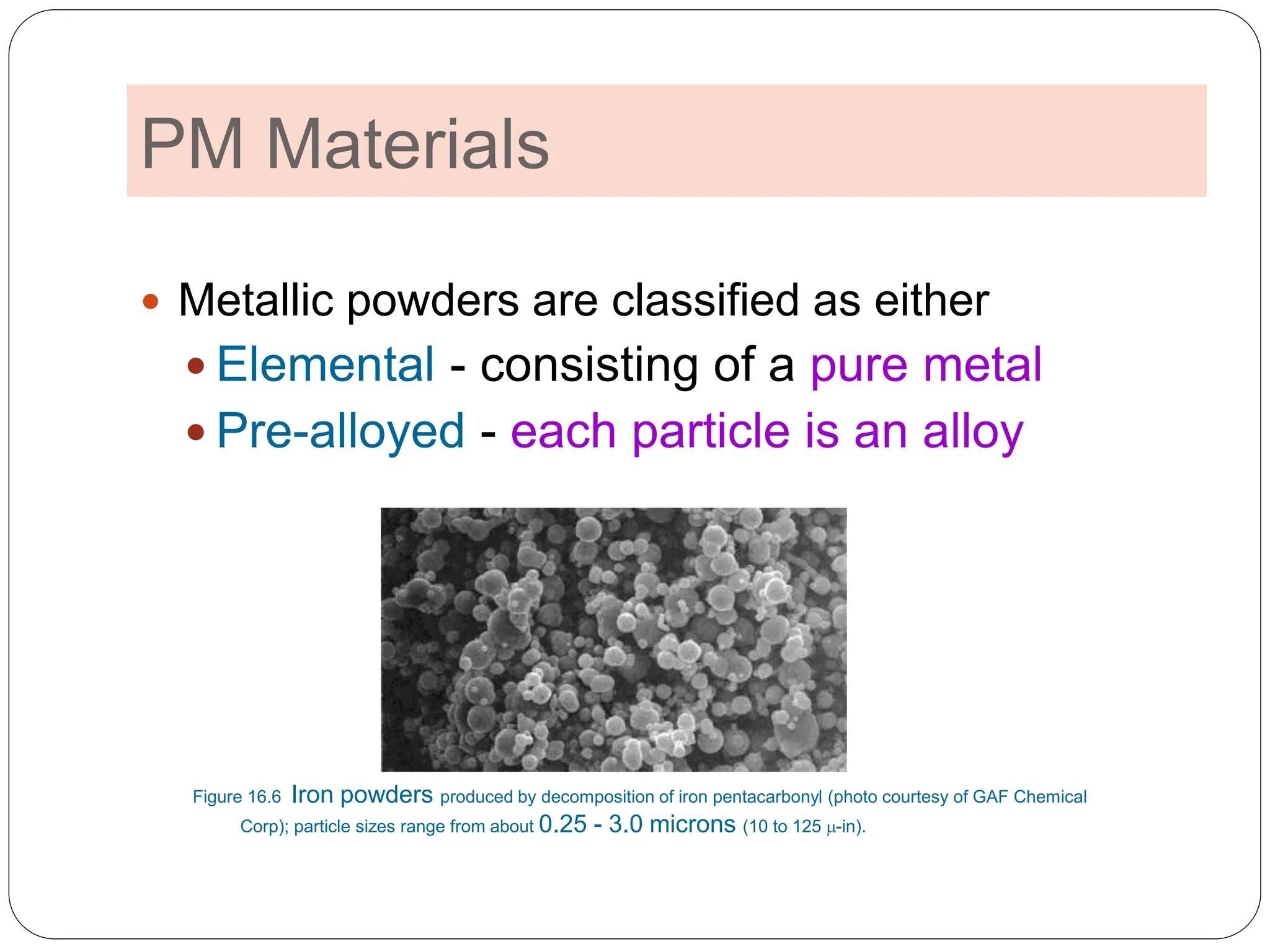

Powder metallurgy is a metal processing technique where parts are produced from metallic powders. Metallic powders are characterized by their particle size, shape, density, and flow properties, which impact the powder metallurgy process. The conventional powder metallurgy process involves blending and mixing powders, compacting the powders into a green part using pressing, and sintering the green part to increase strength. Additional secondary processes like impregnation or infiltration can be used to further improve properties or add functions to the sintered part. Powder metallurgy is used to produce net-shape or near-net-shape parts from a variety of metal powders.