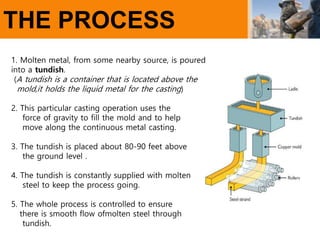

Continuous casting is a process used to cast metal into a continuous length. Molten metal is poured into a mold and solidifies into a casting as it travels downward. New molten metal is continuously supplied to the mold to keep the process going and produce a casting of indefinite length. The process requires precise control of parameters like molten metal flow to ensure smooth, continuous casting.