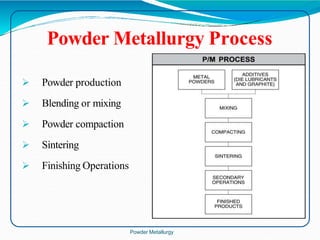

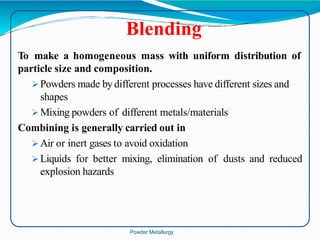

Powder metallurgy involves producing metal powders and using them to make finished or semi-finished products. It begins with powder production, followed by blending, compaction into a green compact, sintering to bond particles, and optional finishing. It allows for intricate shapes from refractory materials and close tolerances at lower costs than alternative methods.

![Powder Metallurgy

An important point that comes out :

The entire material need not be melted to fuse it.

The working temperature is well below the melting point of the

major constituent, making it a very suitable method to work

with refractory materials, such as: W

, Mo, Ta, Nb, oxides,

carbides, etc.

It began with Platinum technology about 4 centuries ago… in

those days, Platinum, [MP = 1774°C], was "refractory", and

could not be melted.

Powder Metallurgy](https://image.slidesharecdn.com/powdermetallurgy-230124095645-597952f5/85/powder-metallurgy-pptx-3-320.jpg)