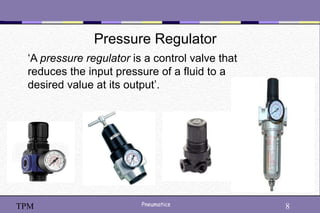

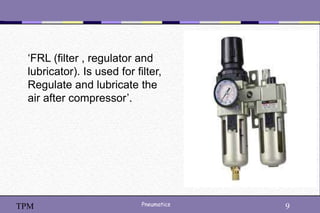

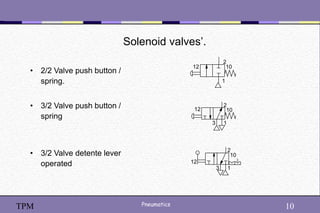

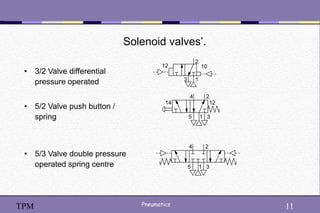

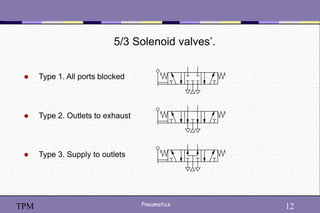

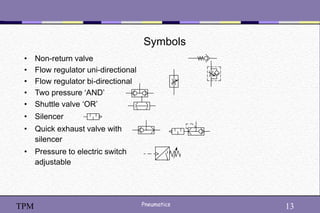

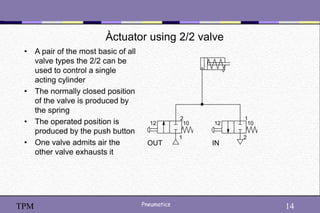

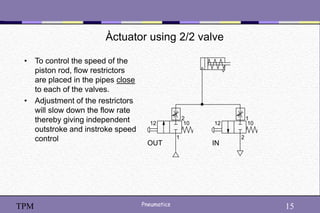

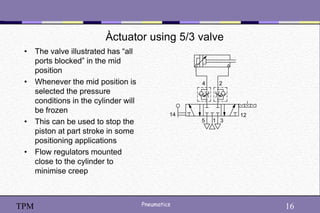

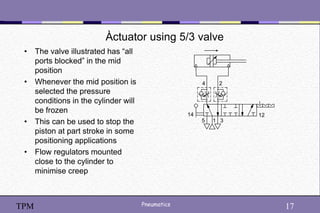

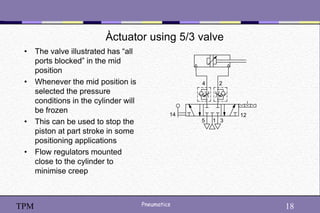

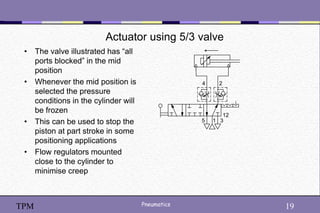

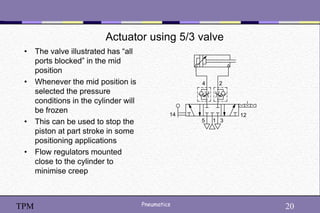

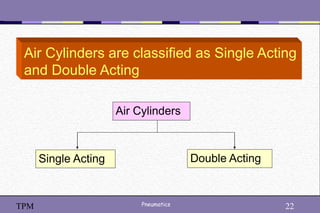

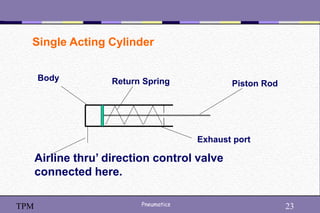

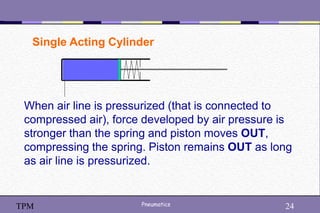

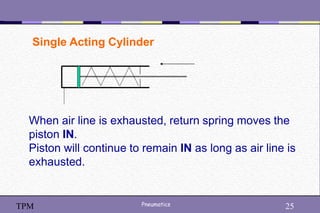

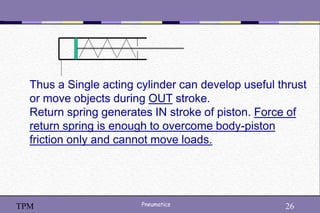

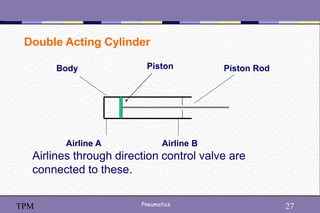

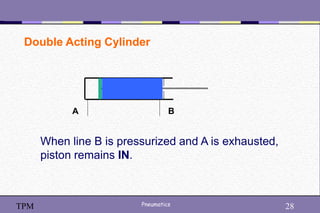

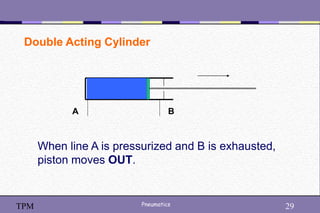

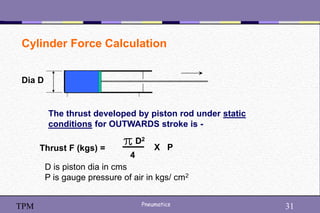

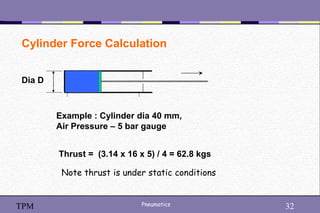

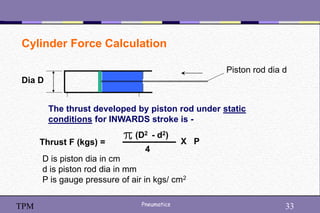

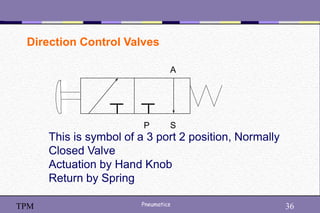

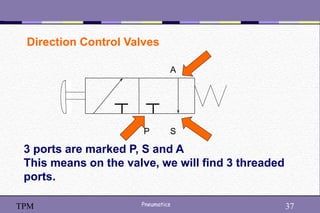

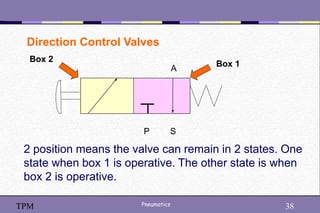

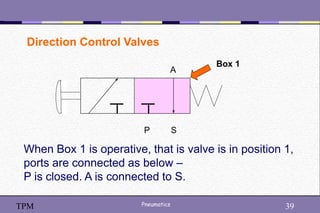

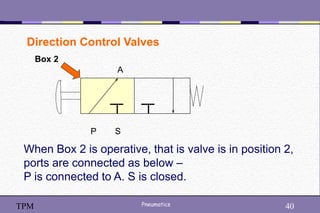

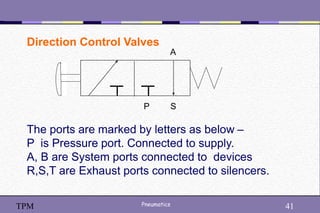

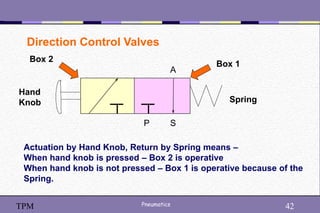

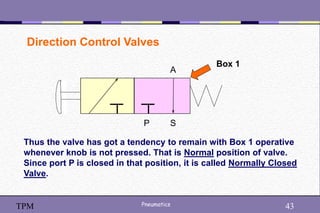

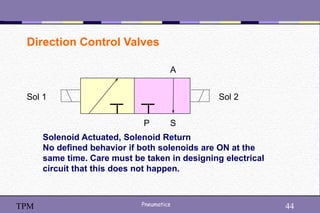

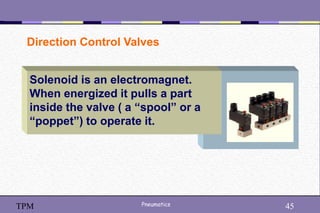

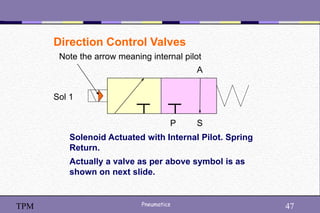

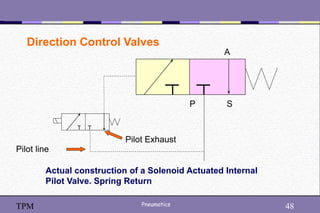

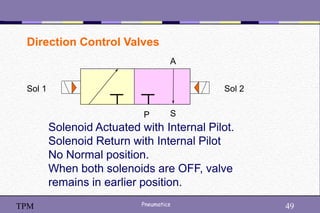

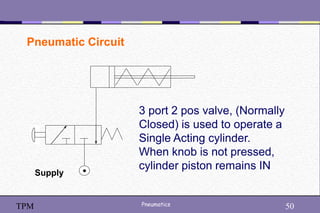

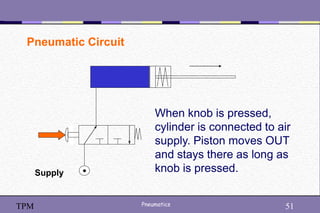

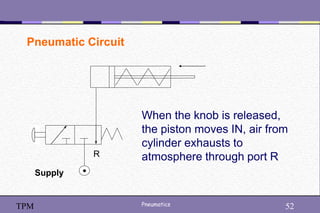

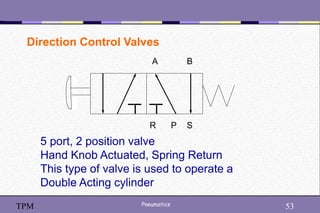

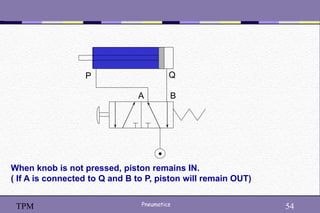

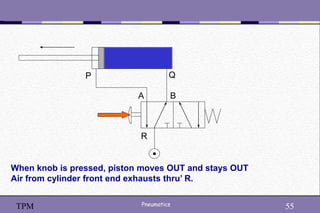

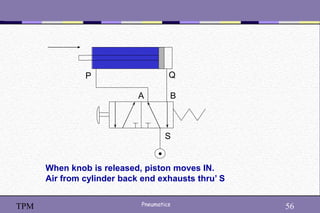

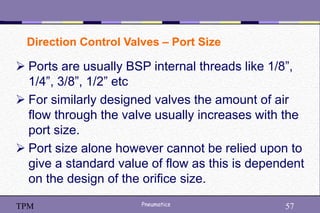

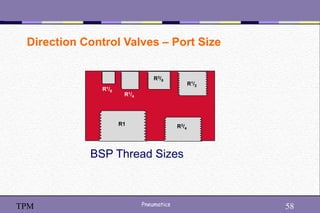

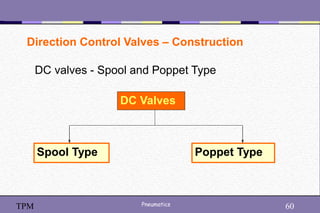

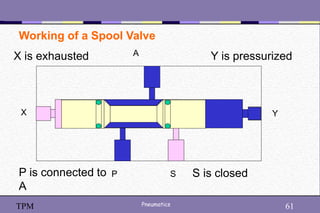

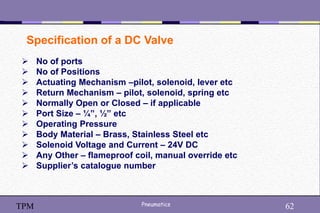

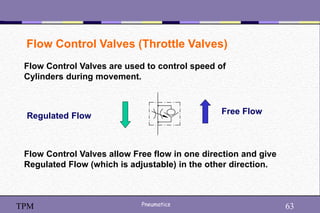

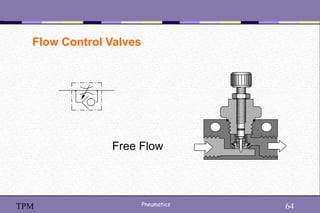

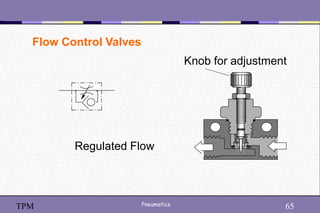

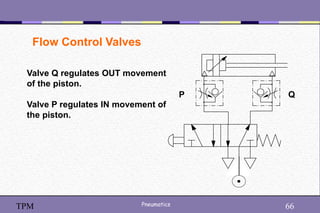

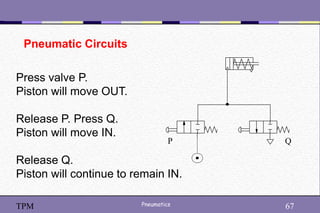

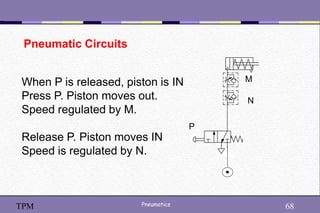

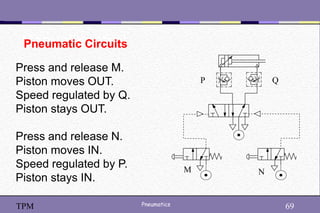

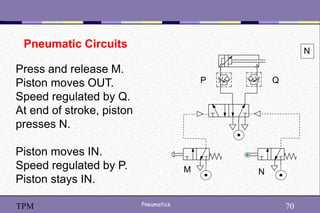

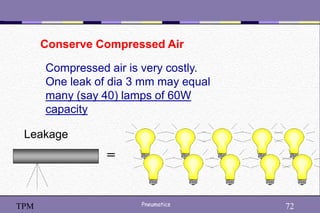

The document provides information about pneumatic systems. It describes the main components of pneumatics including compressors, dryers, sensors, regulators, reservoirs, solenoid valves, and actuators. It explains the functions of key components like compressors, dryers, sensors and regulators. It also discusses pneumatic circuits and different types of valves and actuators like single-acting cylinders, double-acting cylinders, and 5/3 solenoid valves that can be used in circuits. The document aims to introduce the basic components and applications of pneumatic systems.