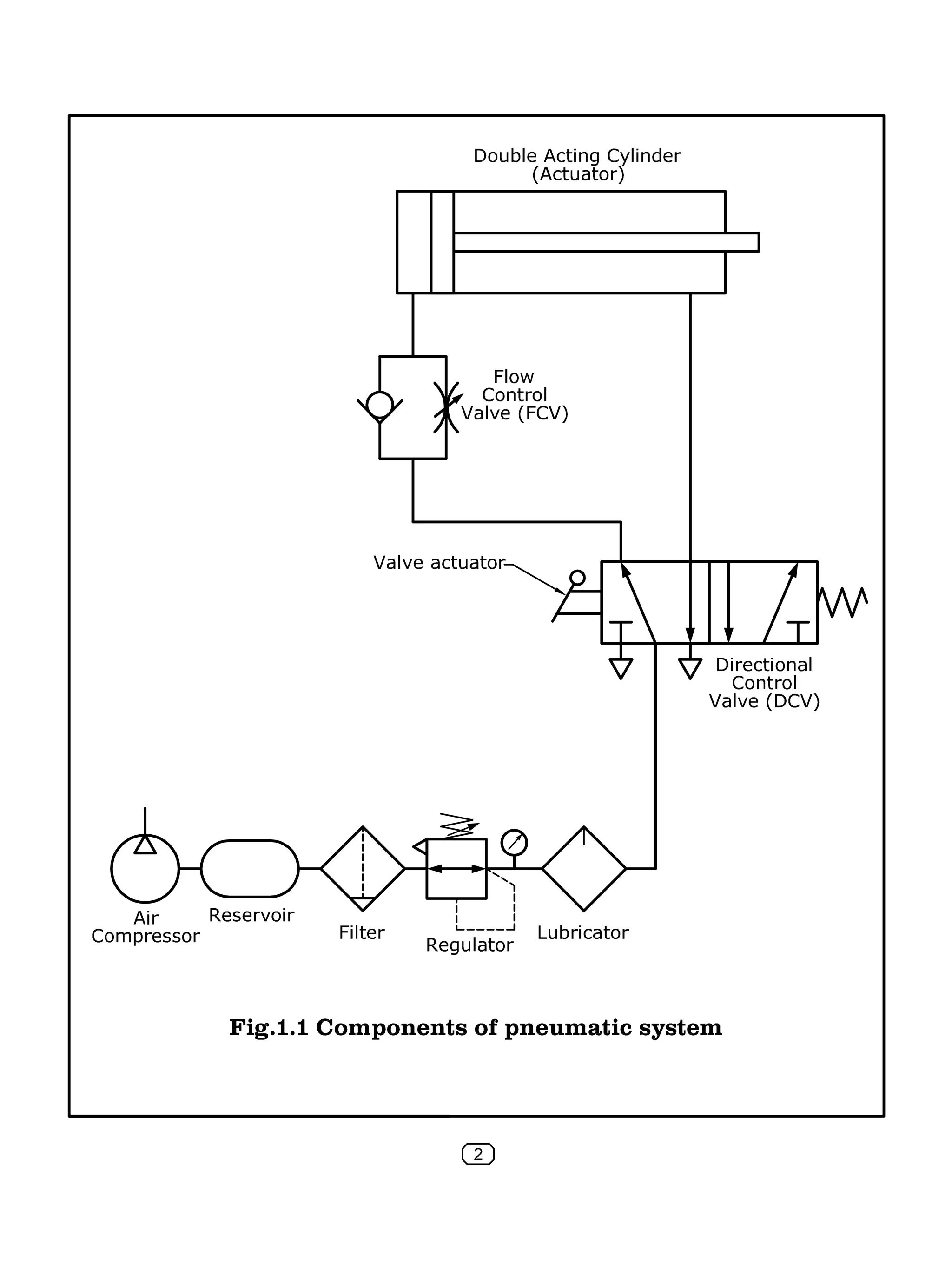

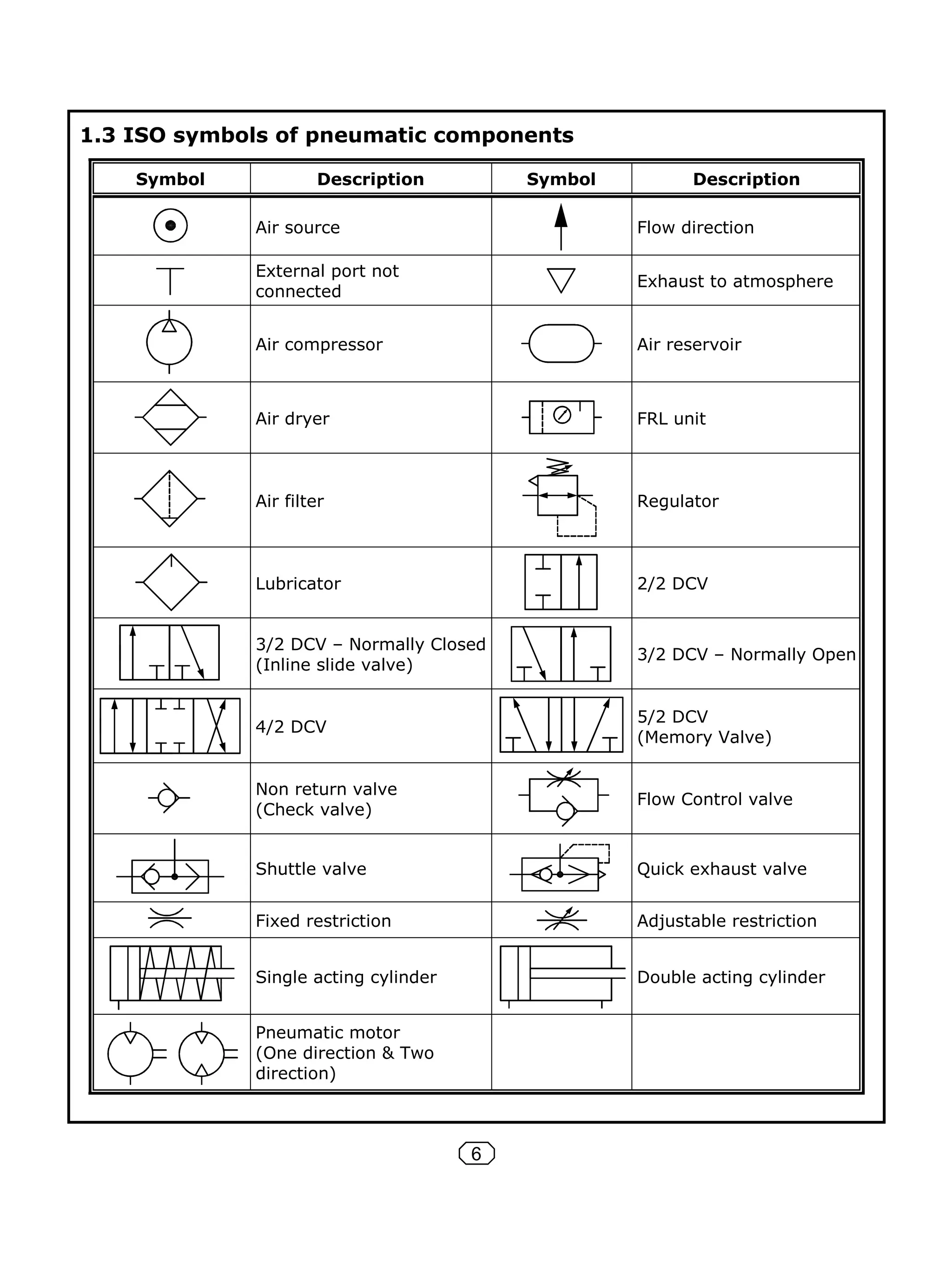

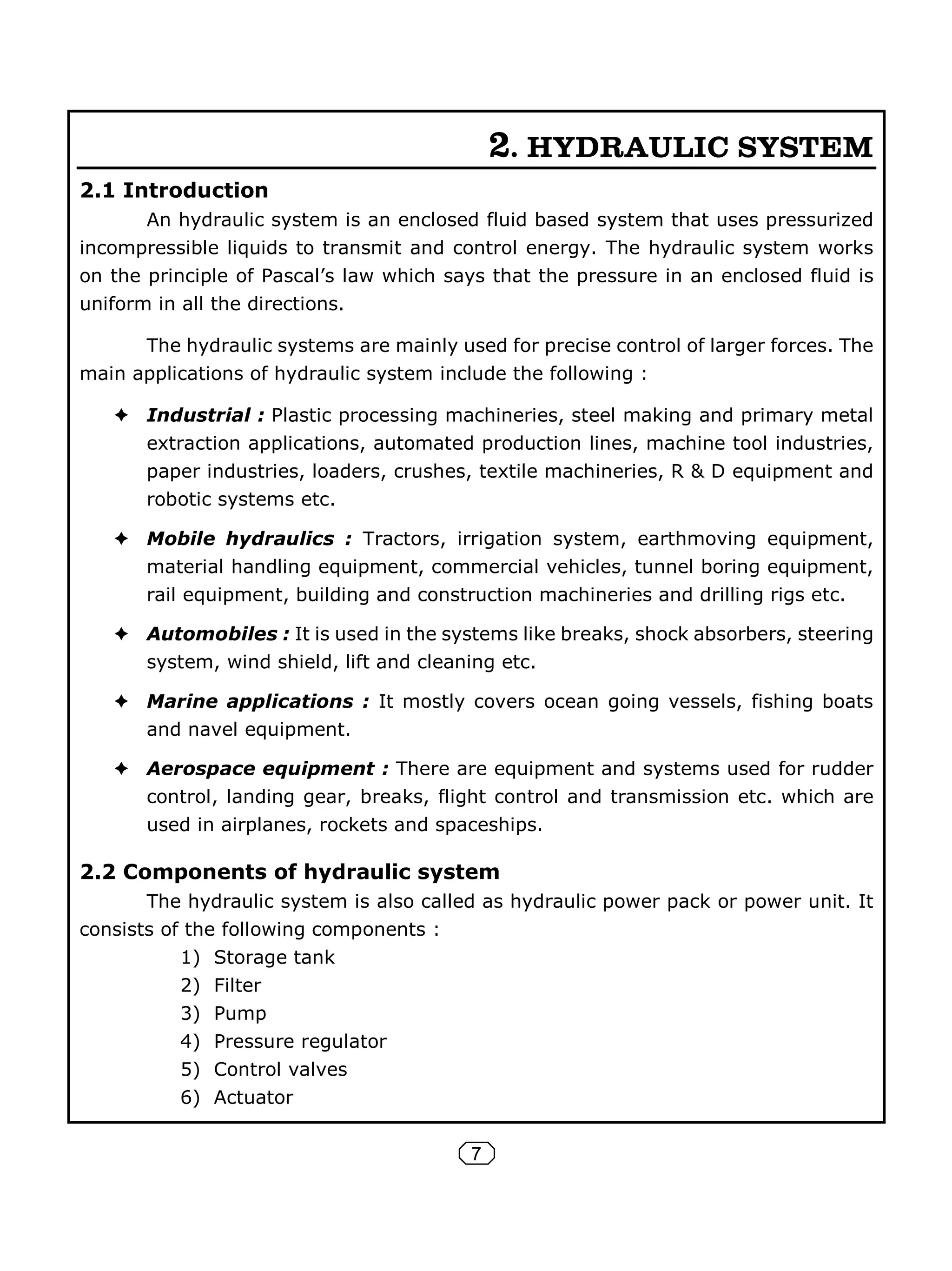

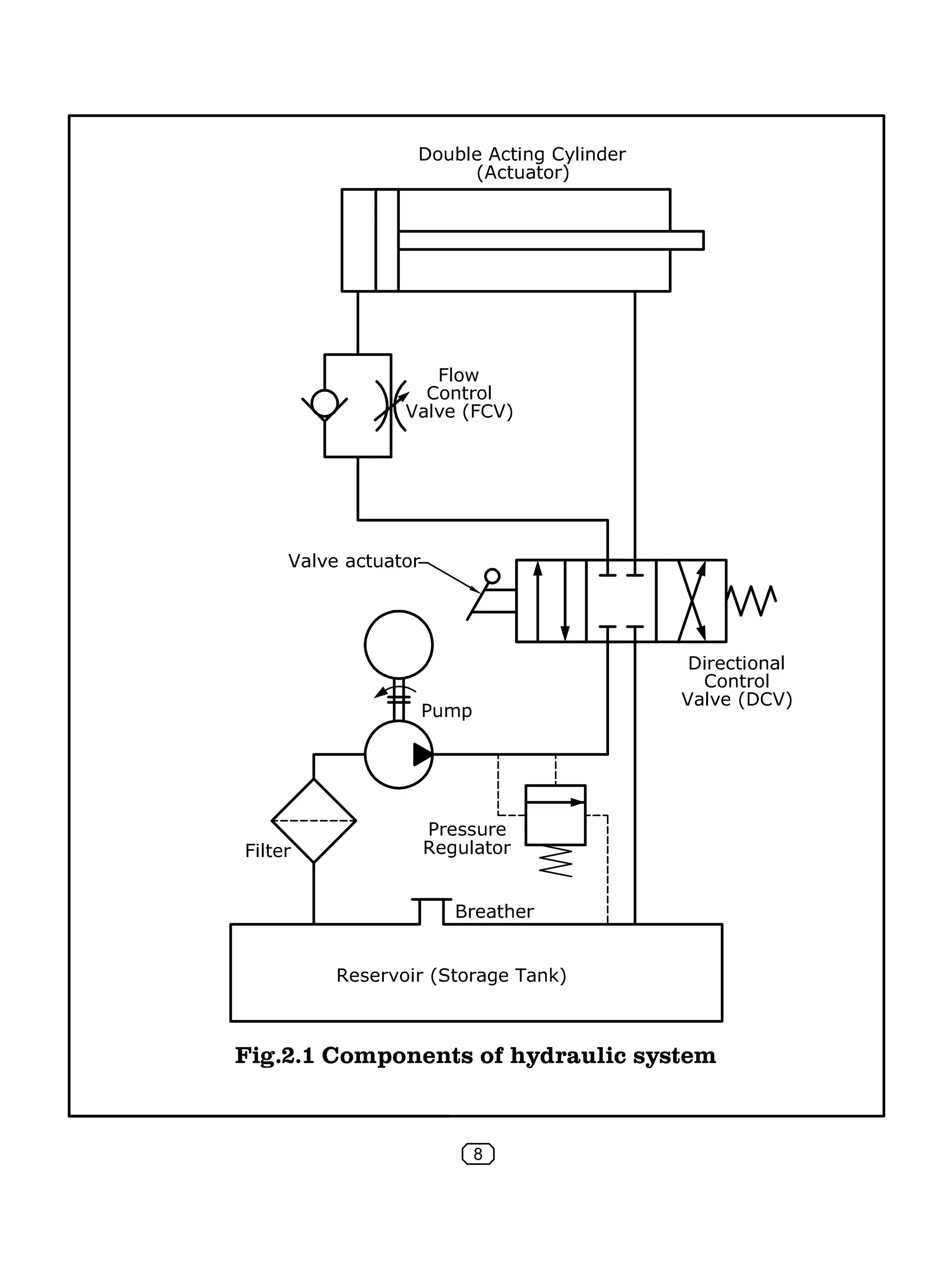

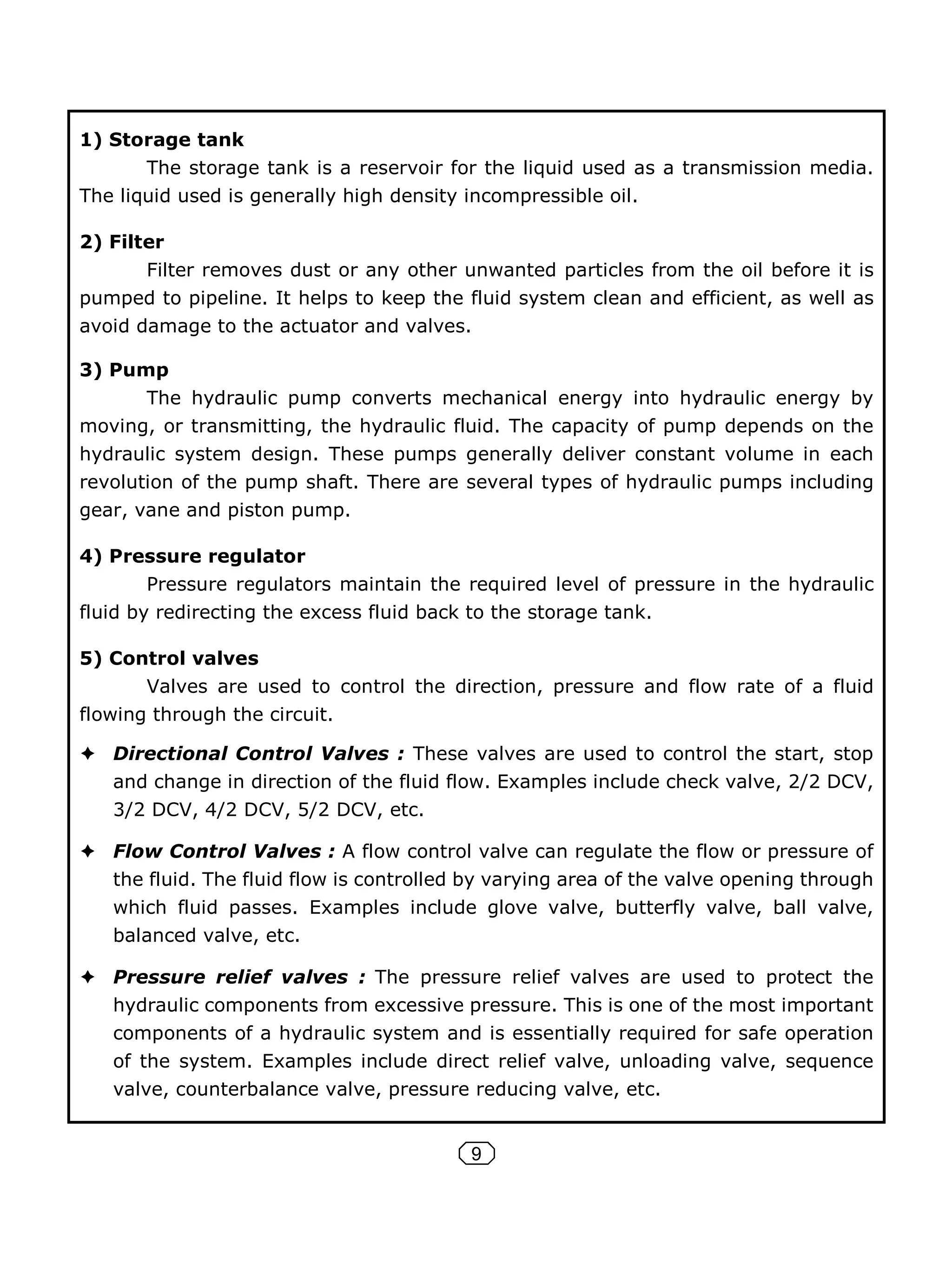

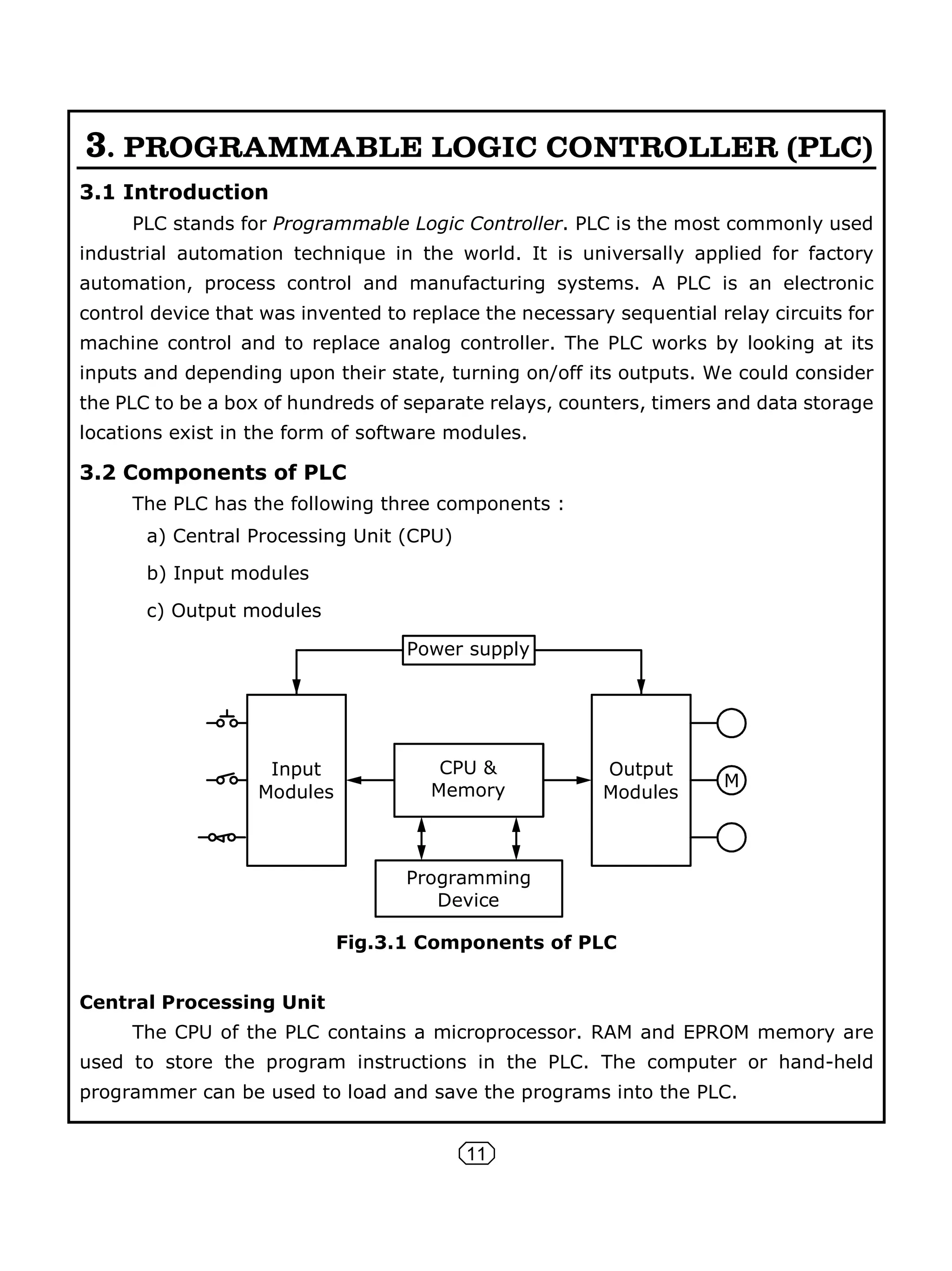

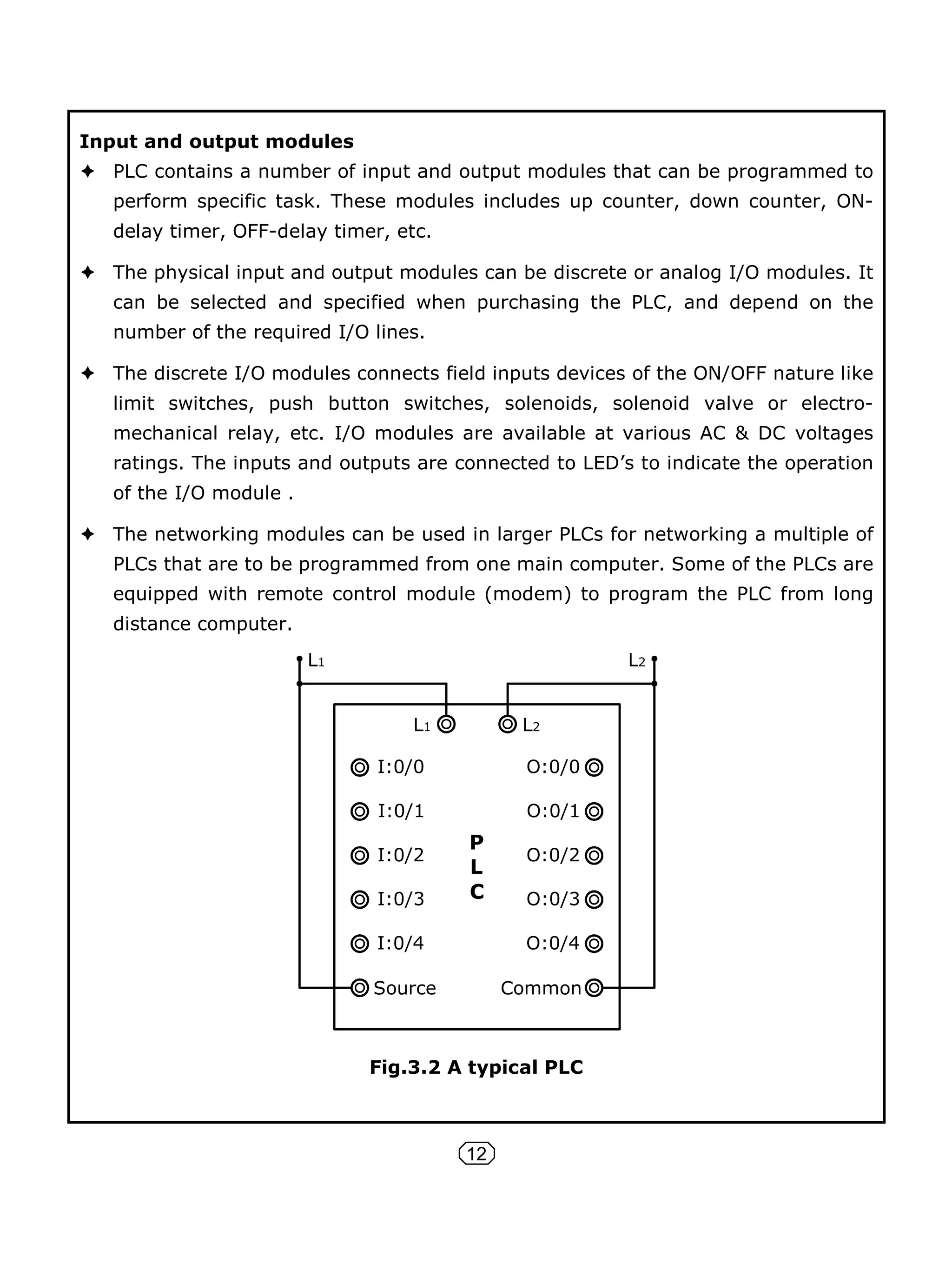

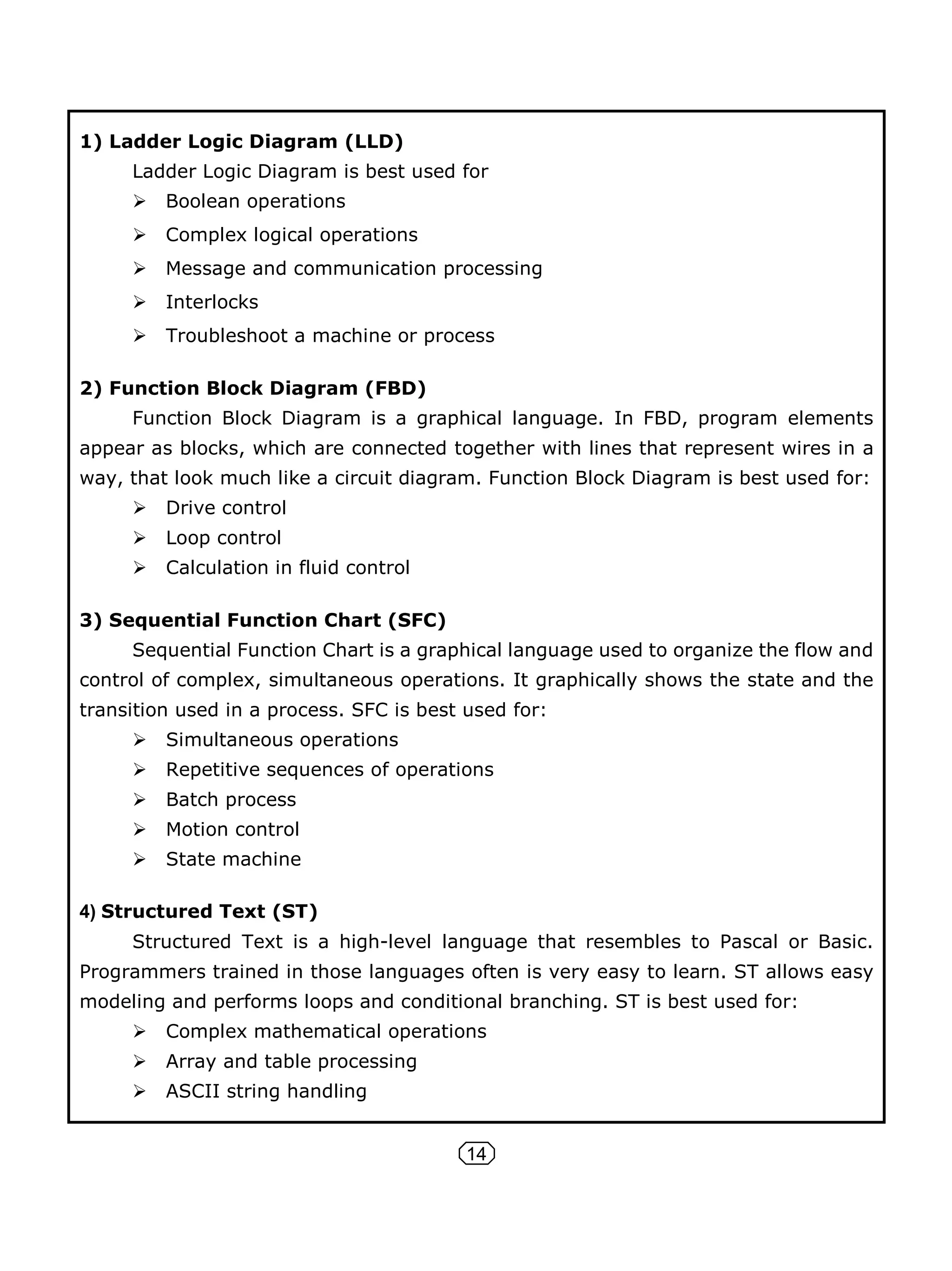

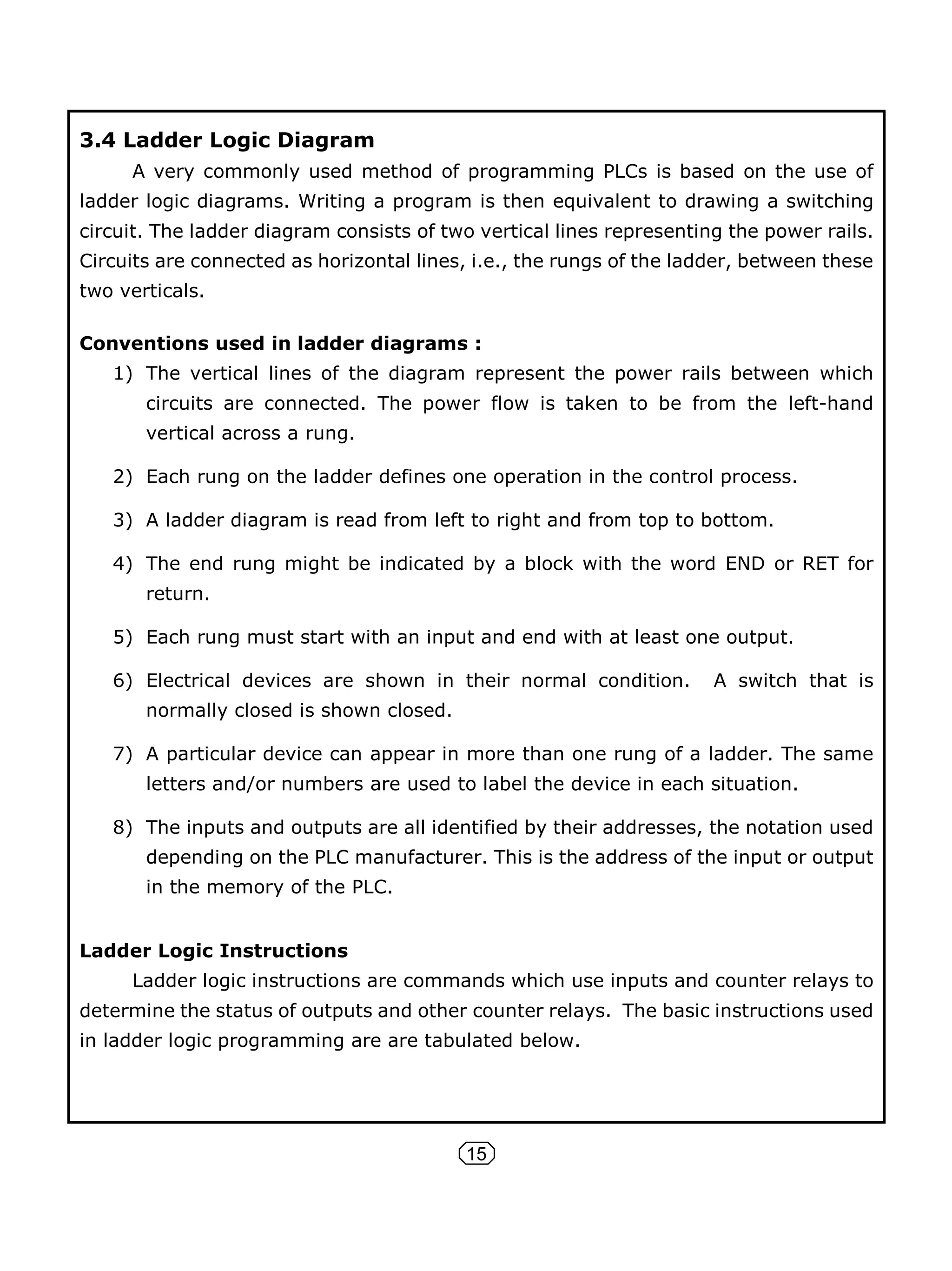

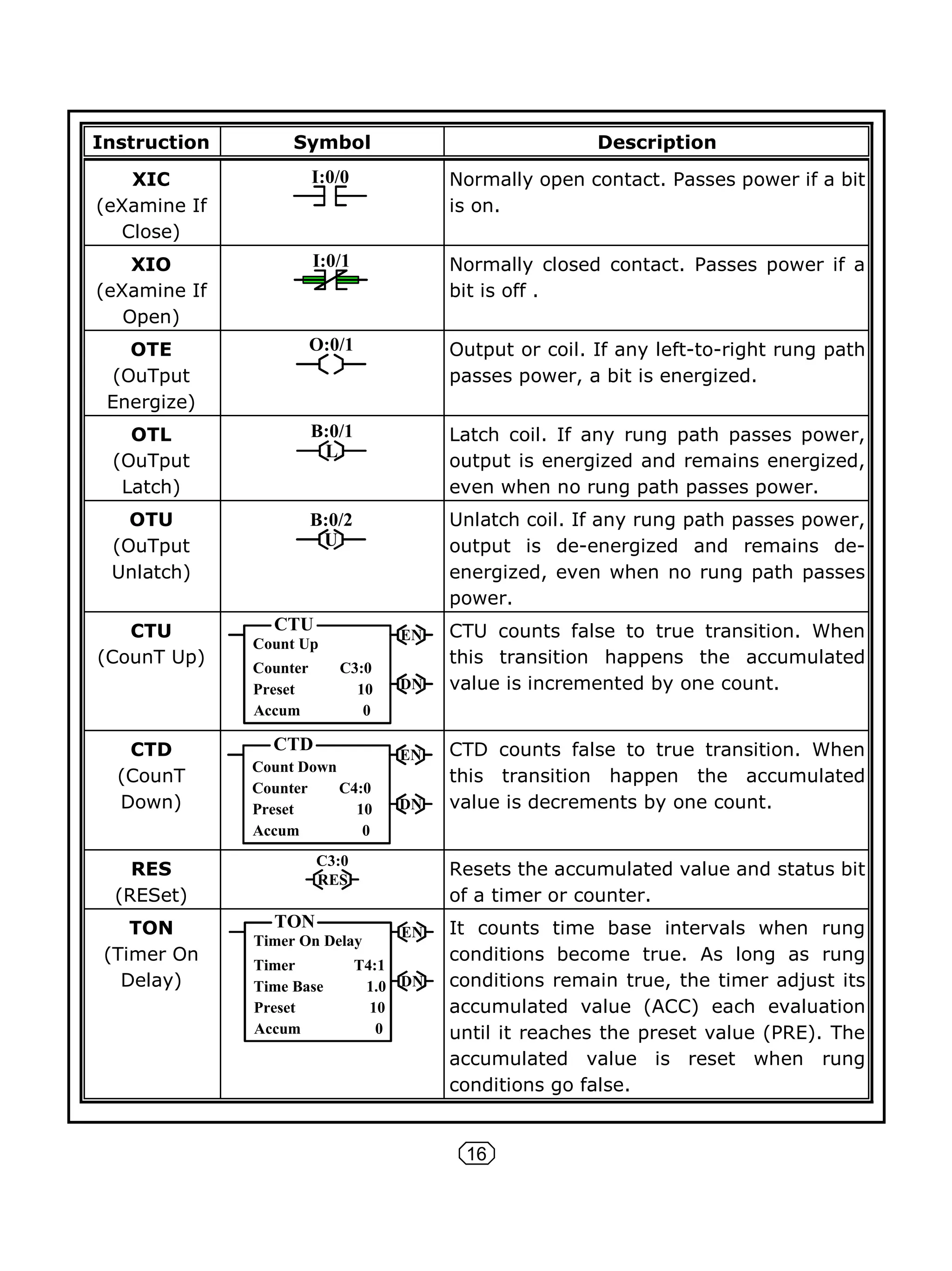

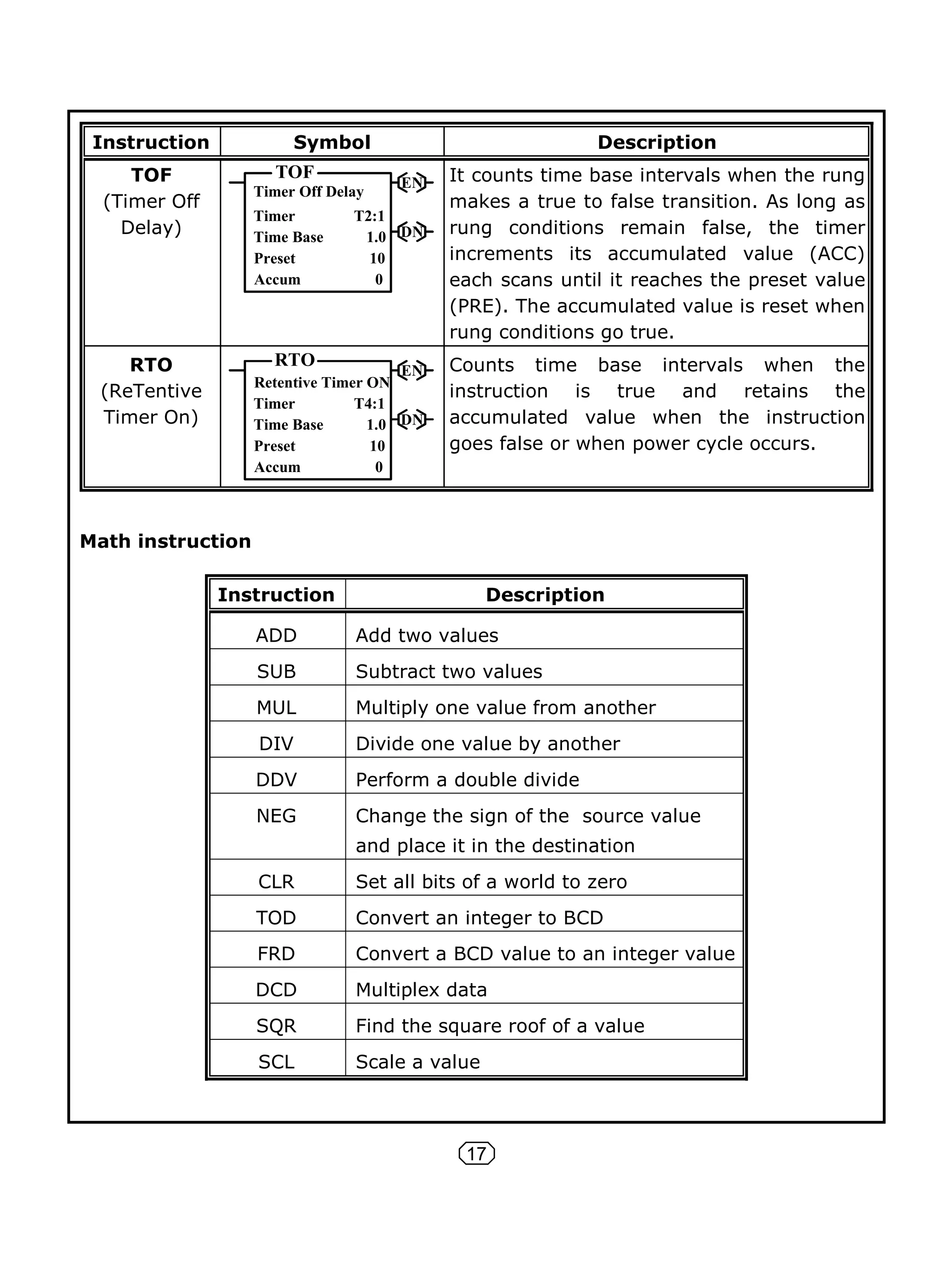

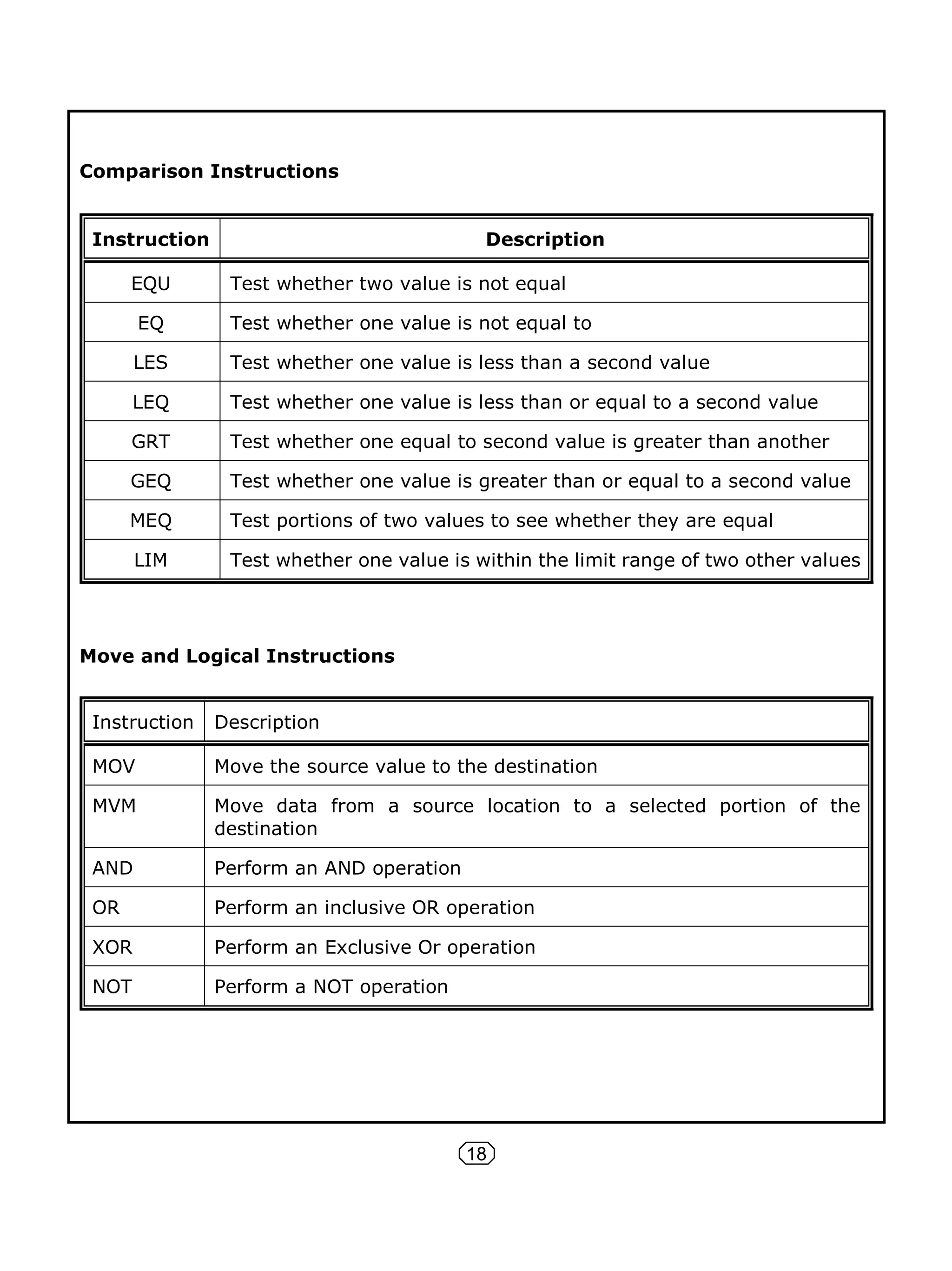

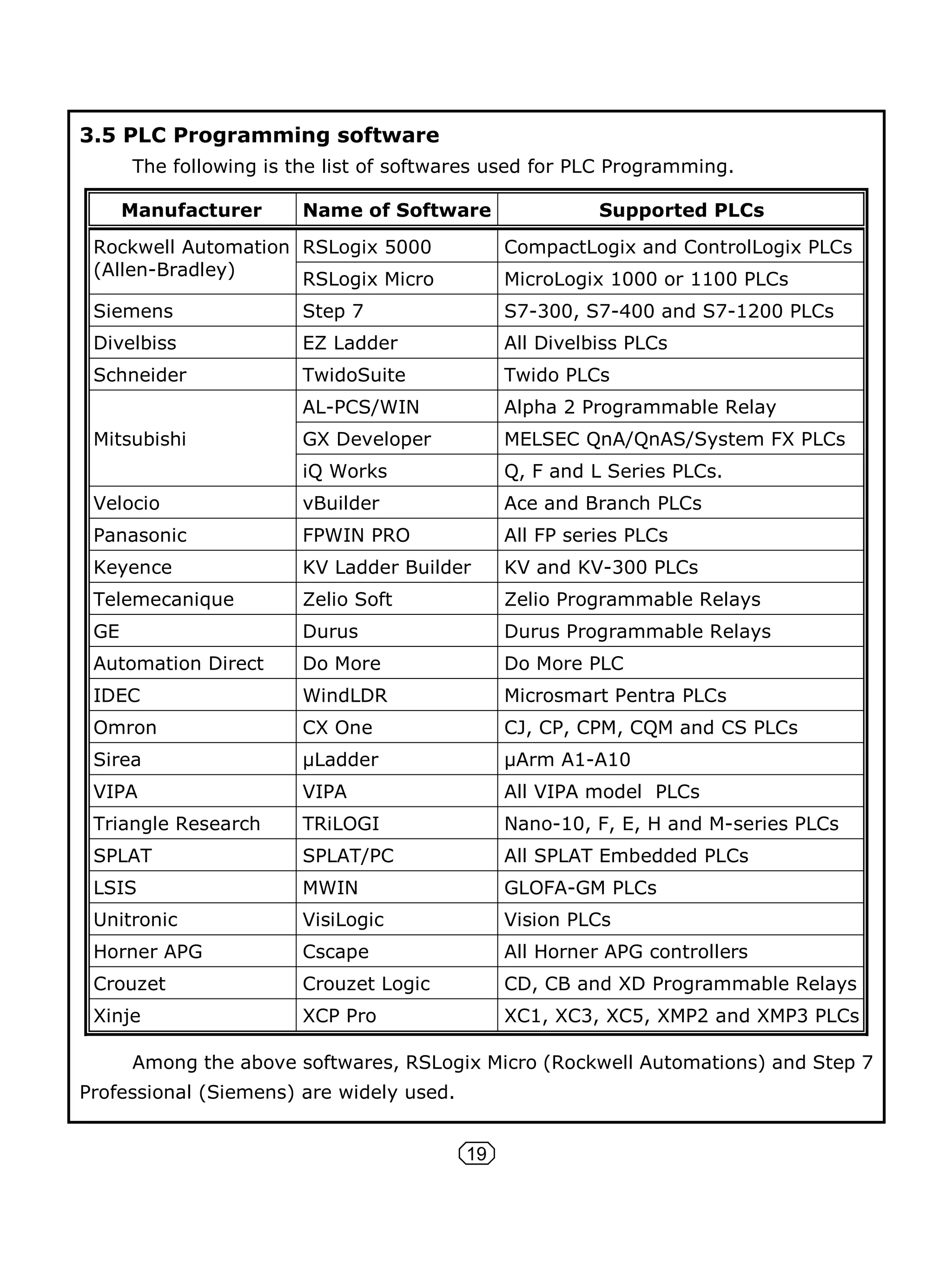

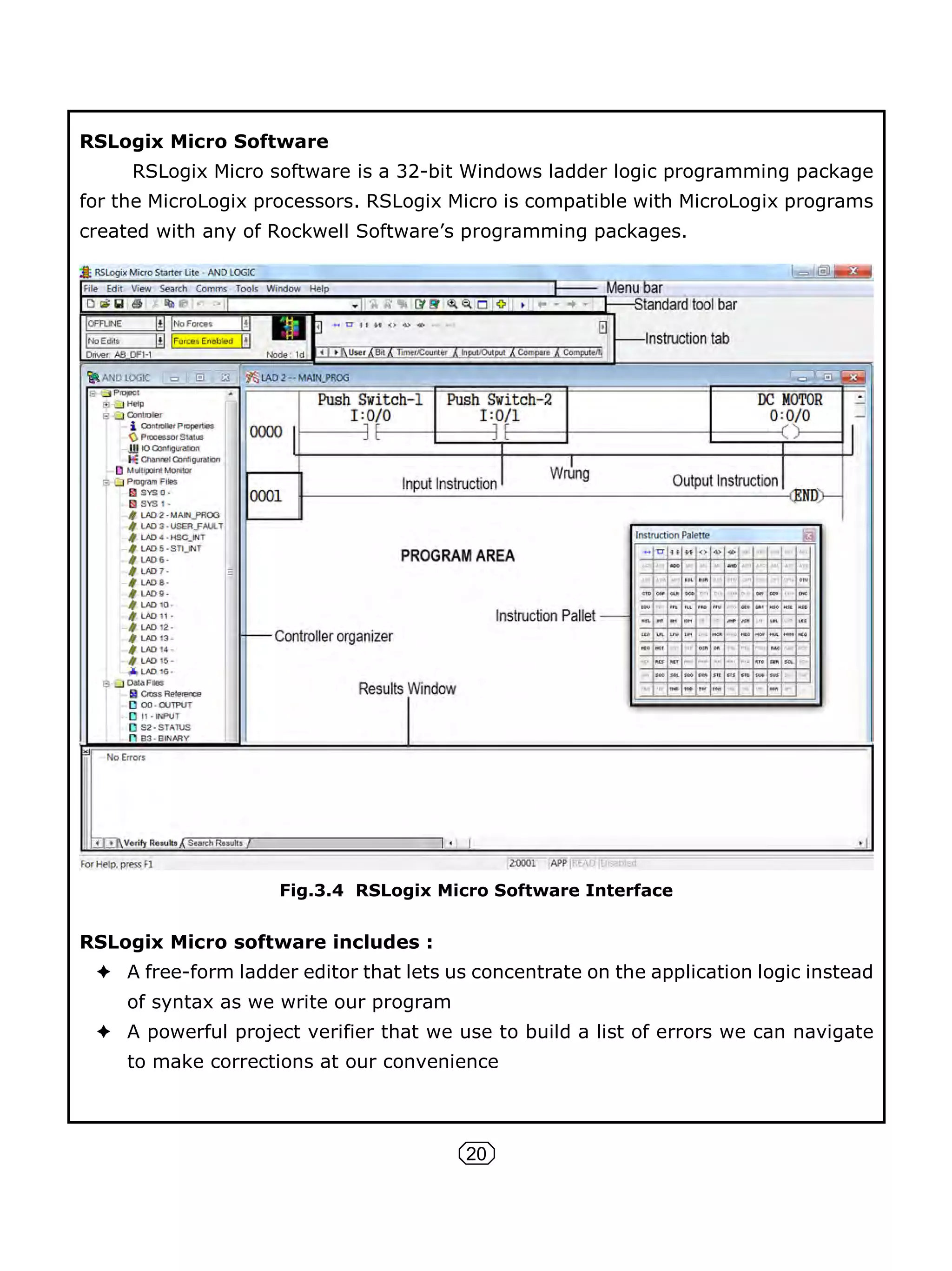

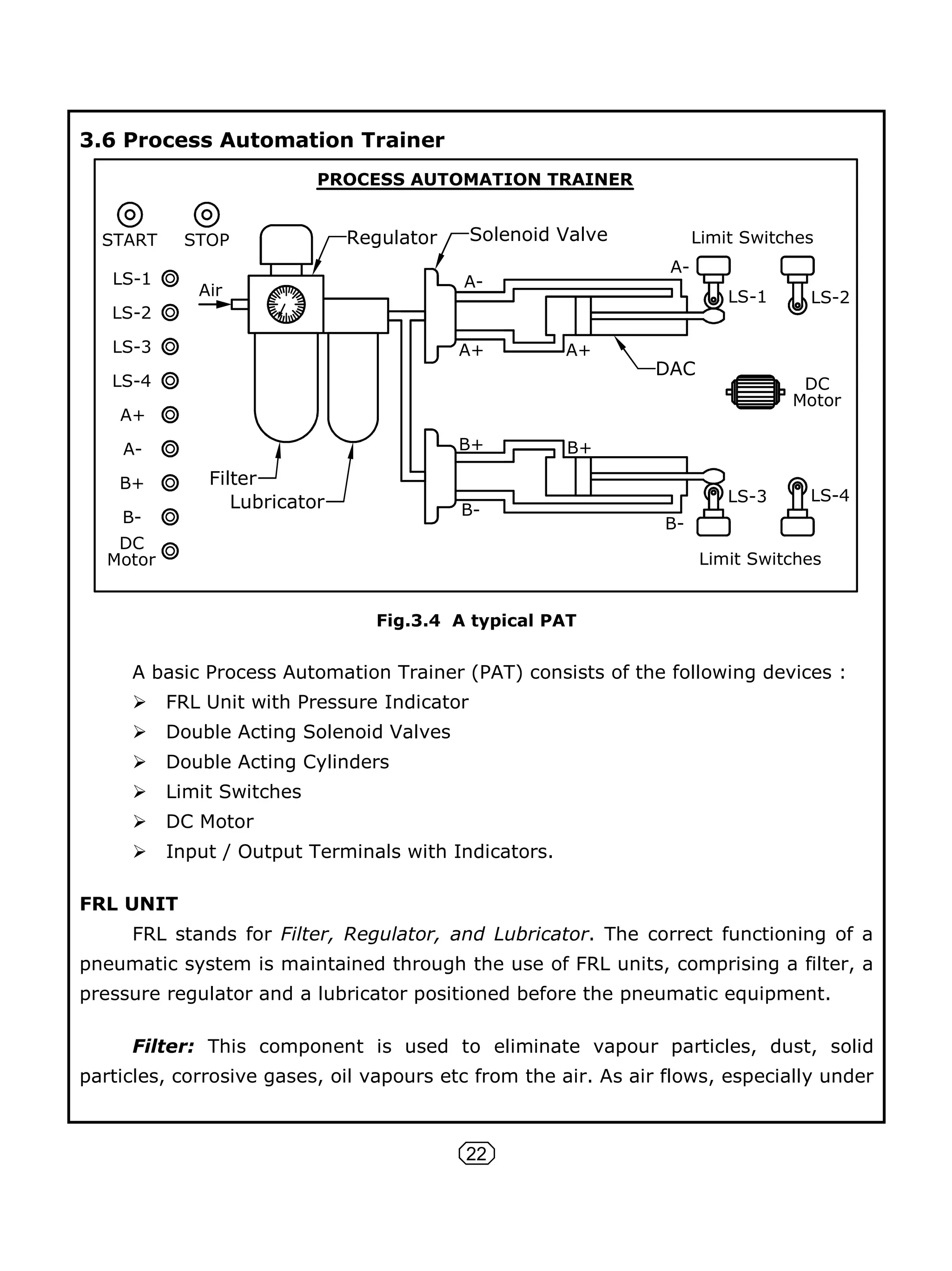

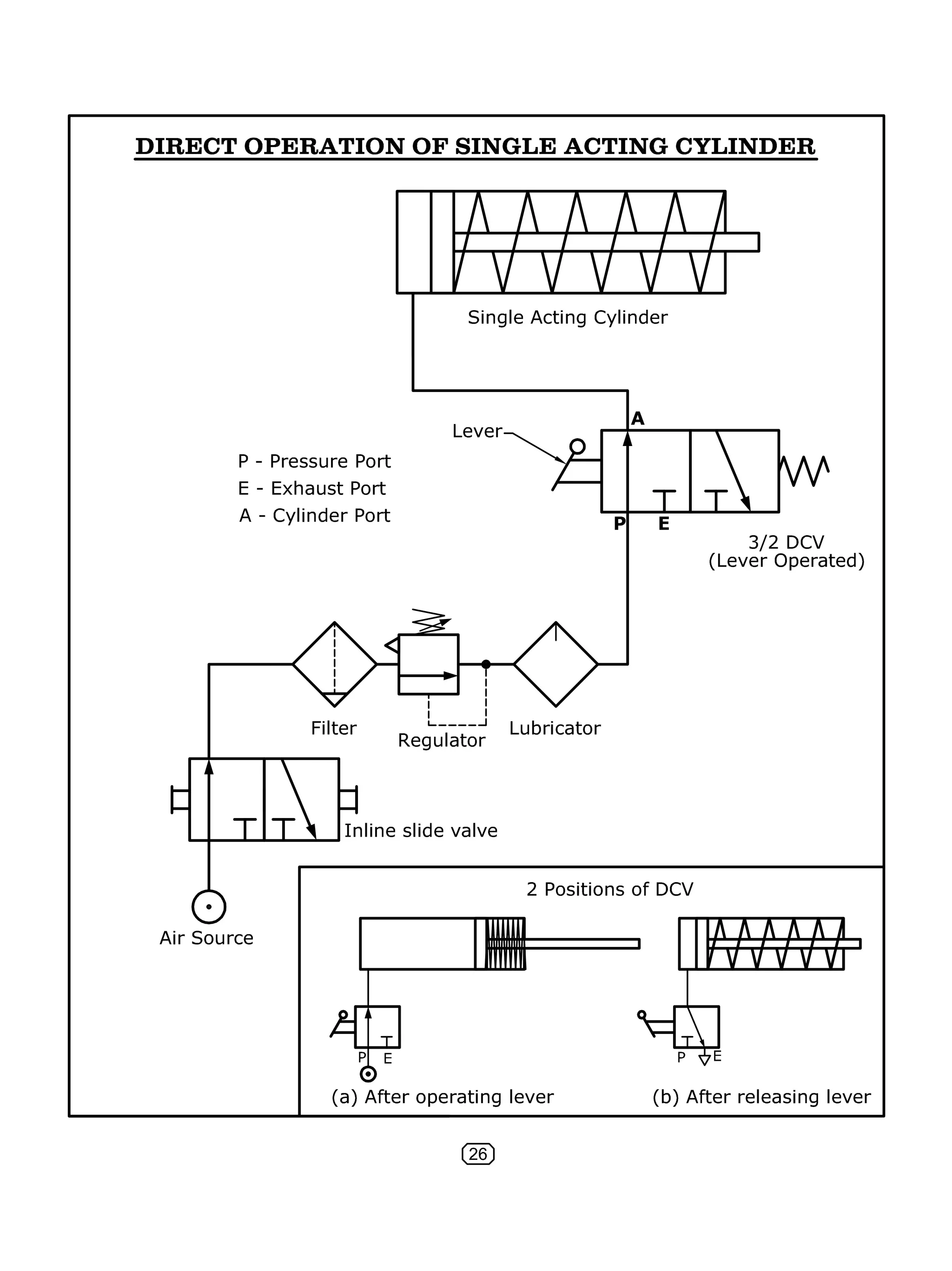

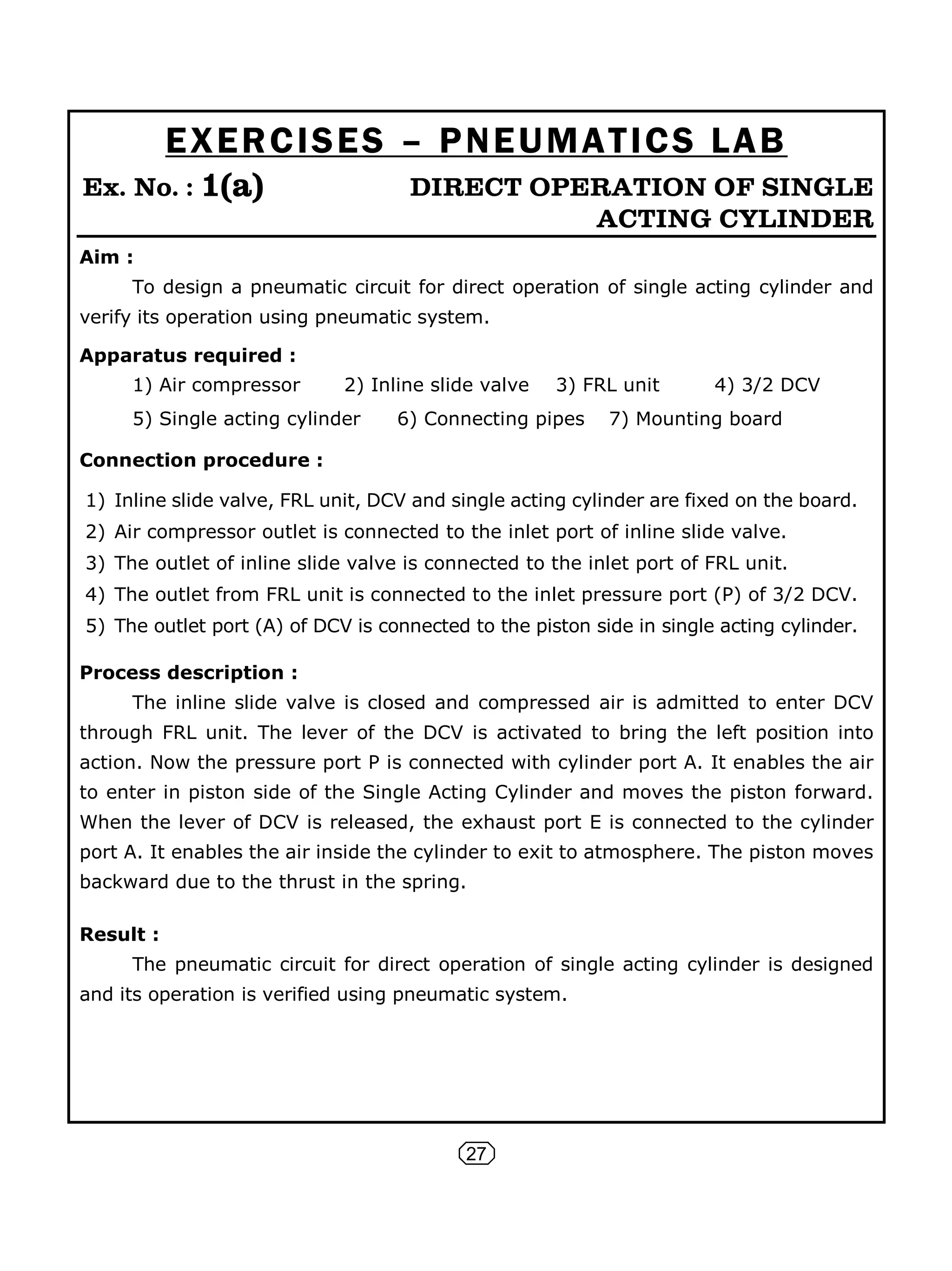

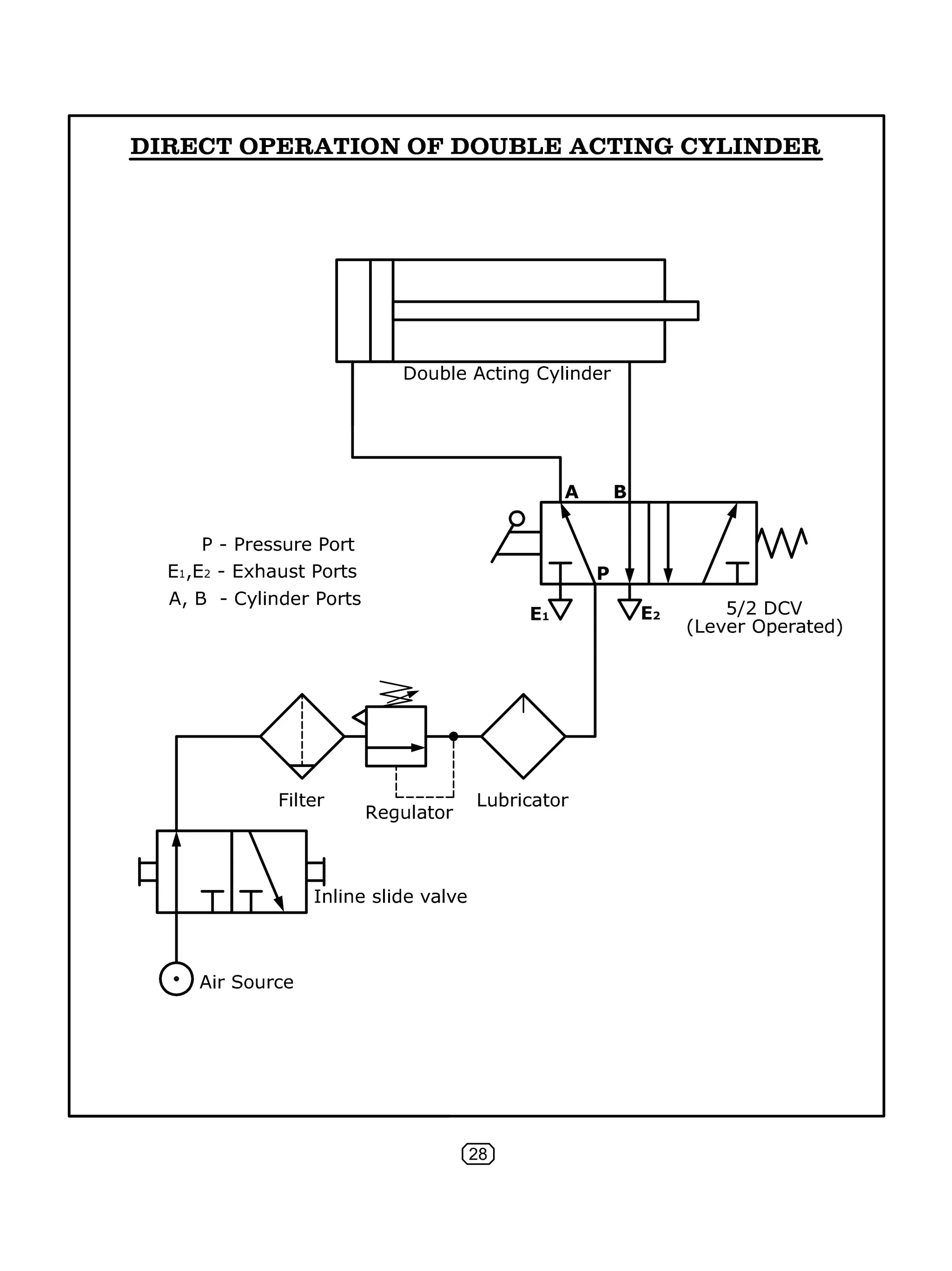

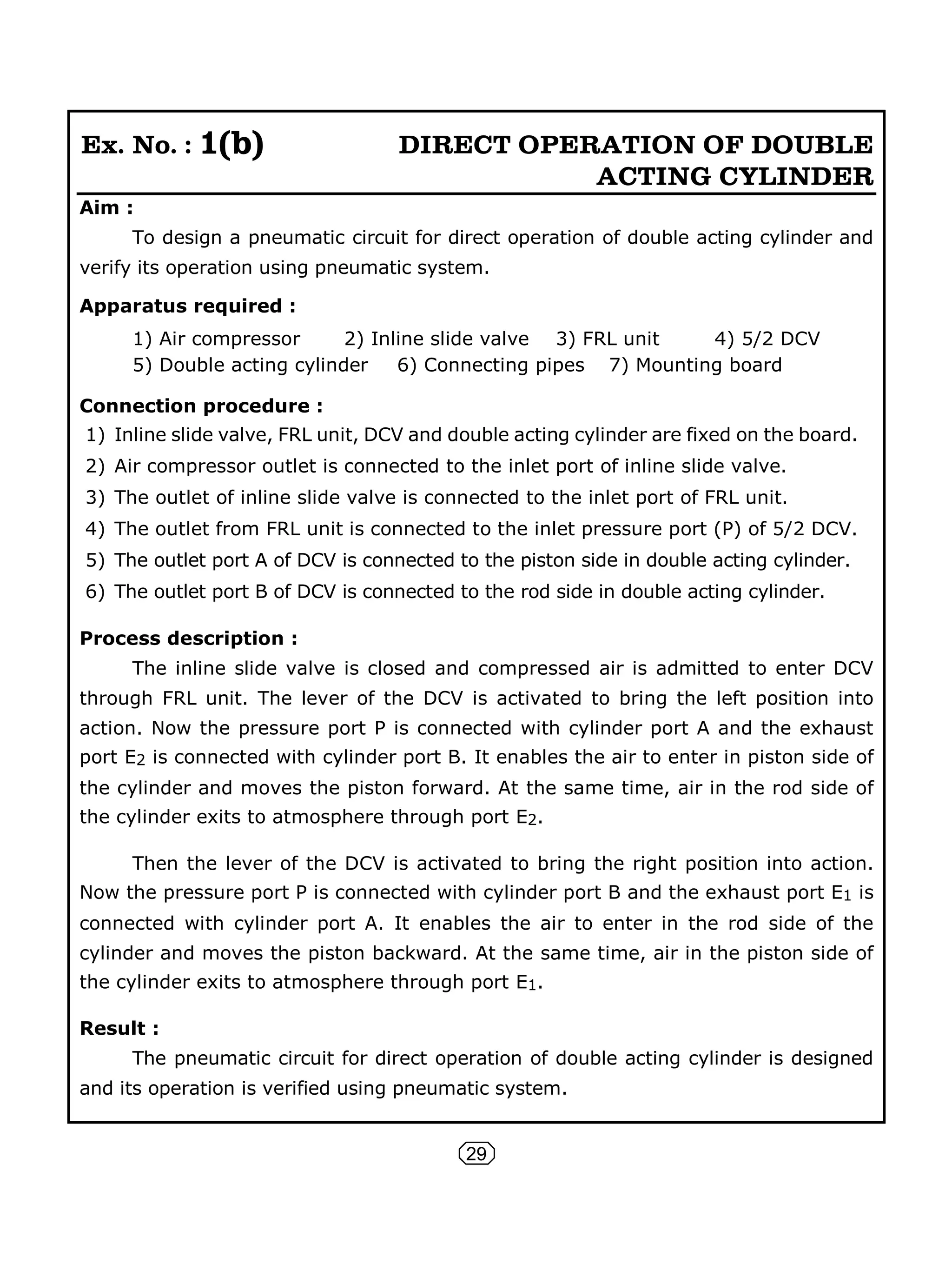

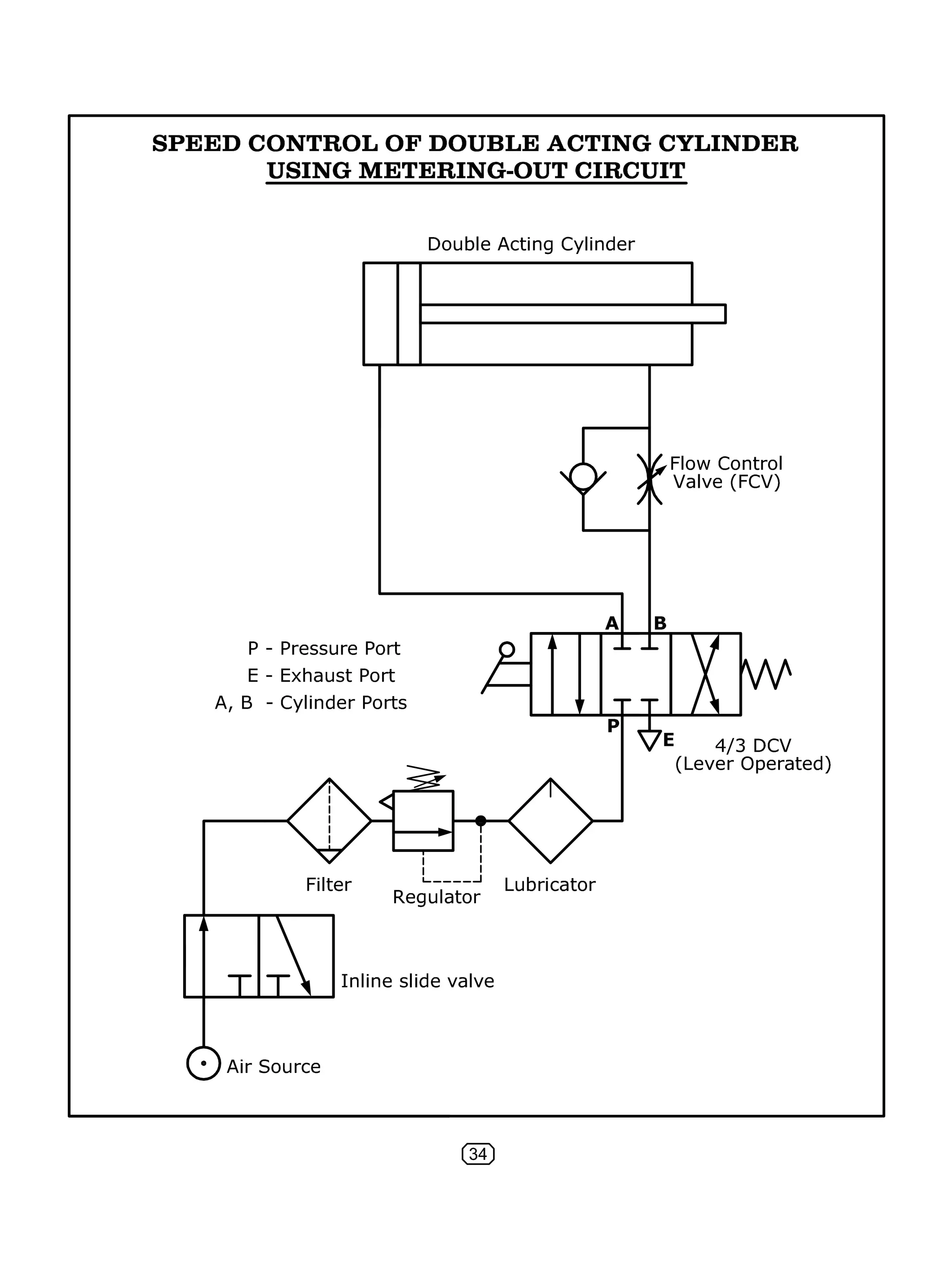

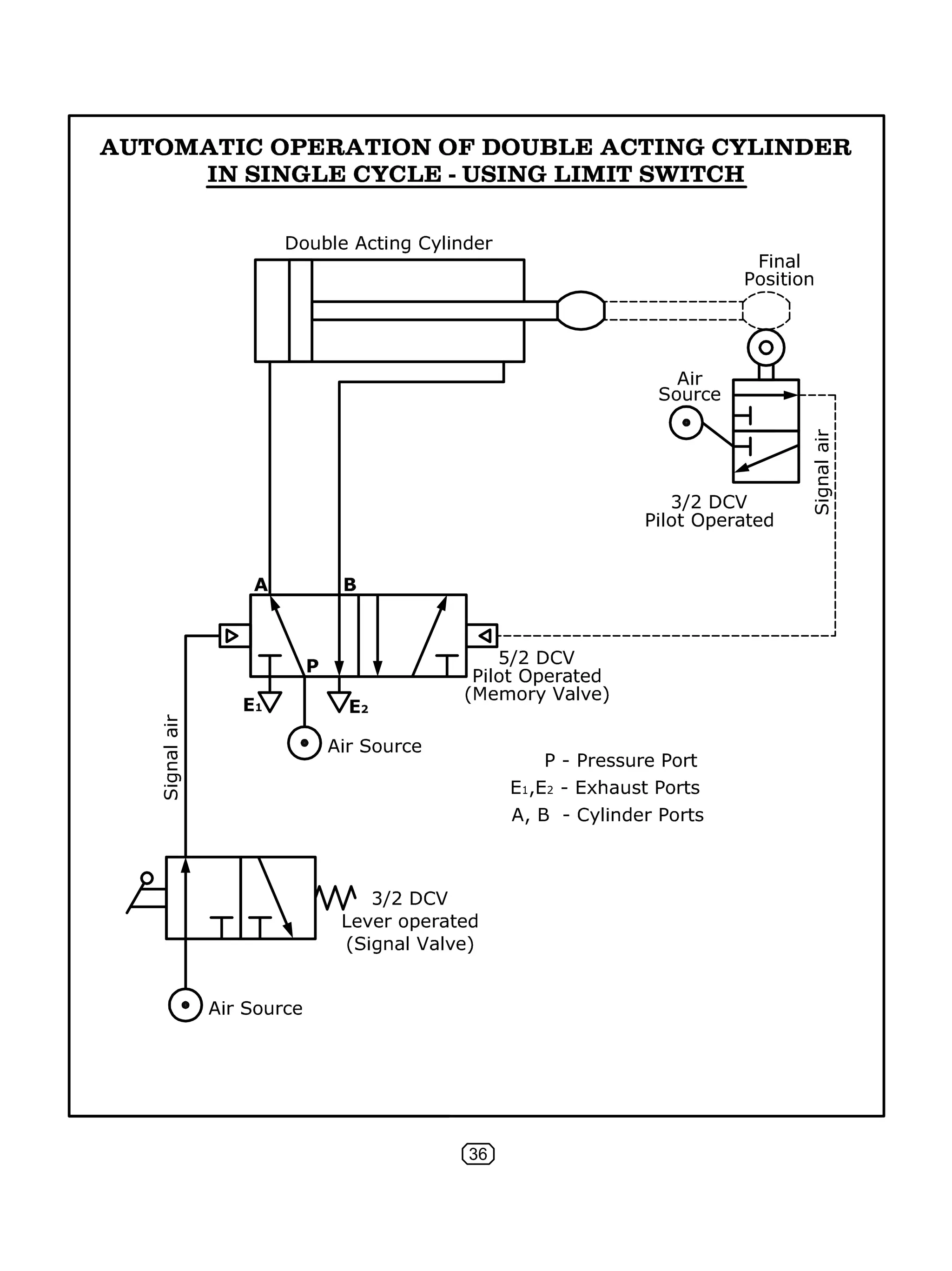

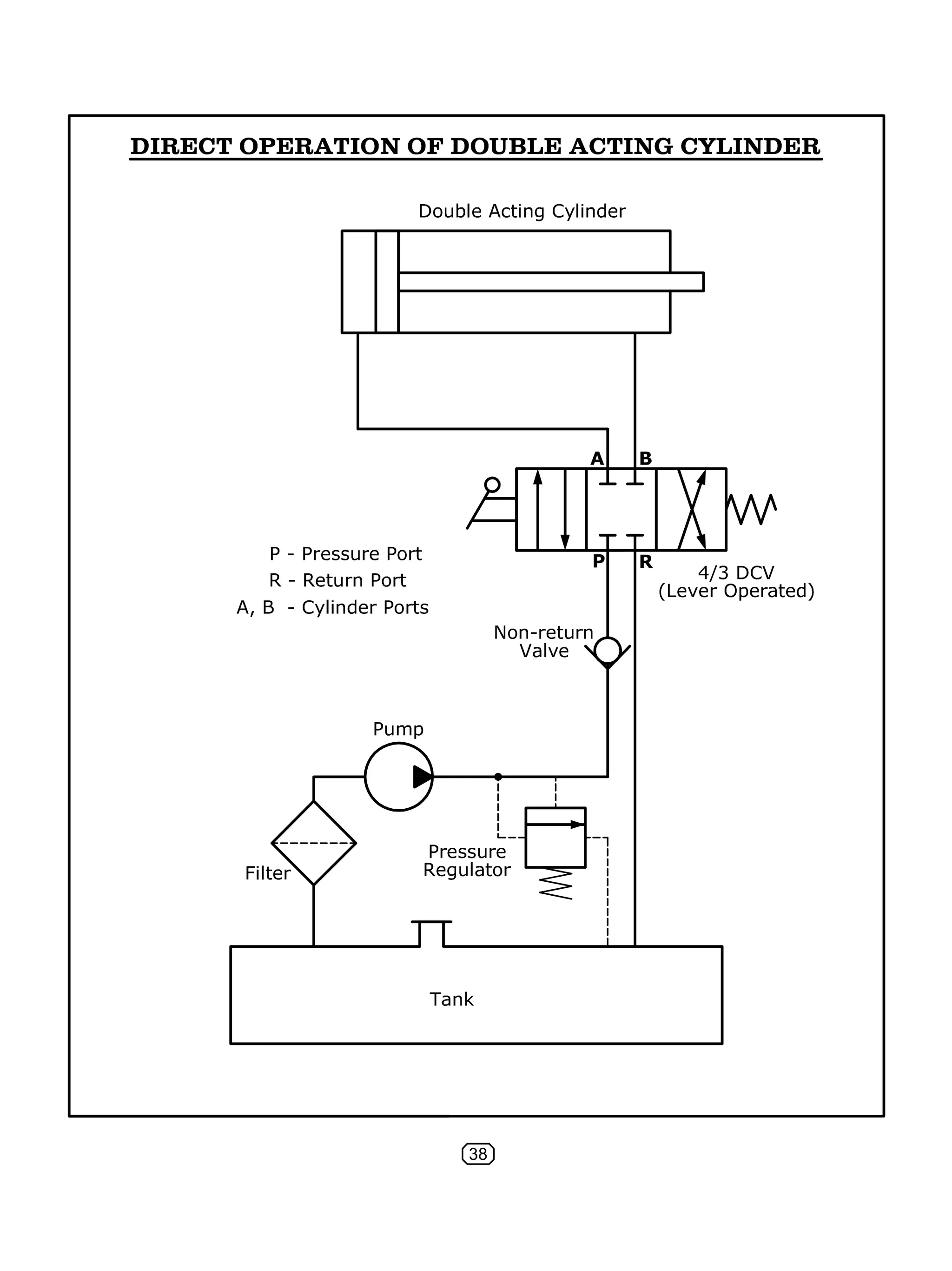

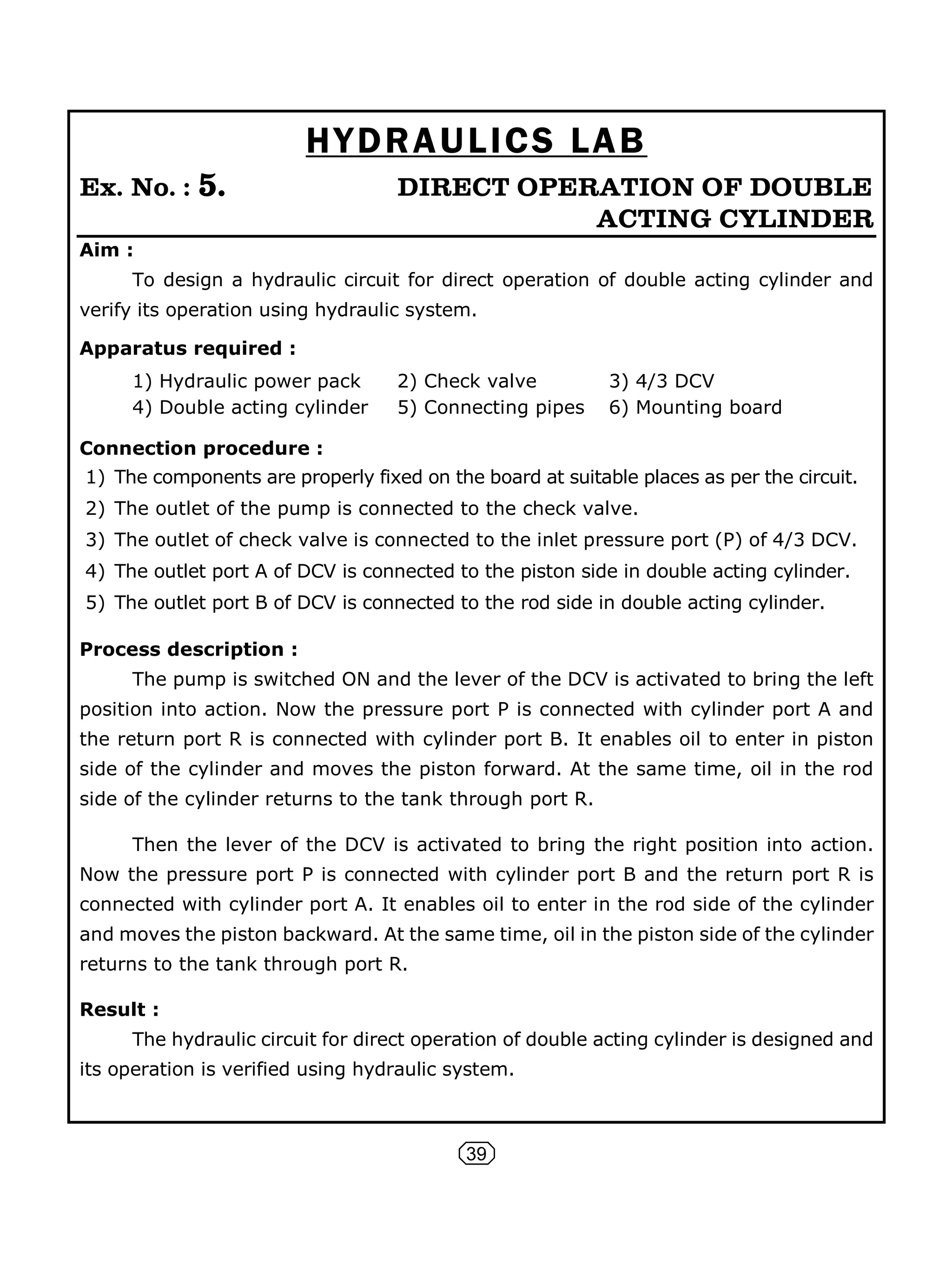

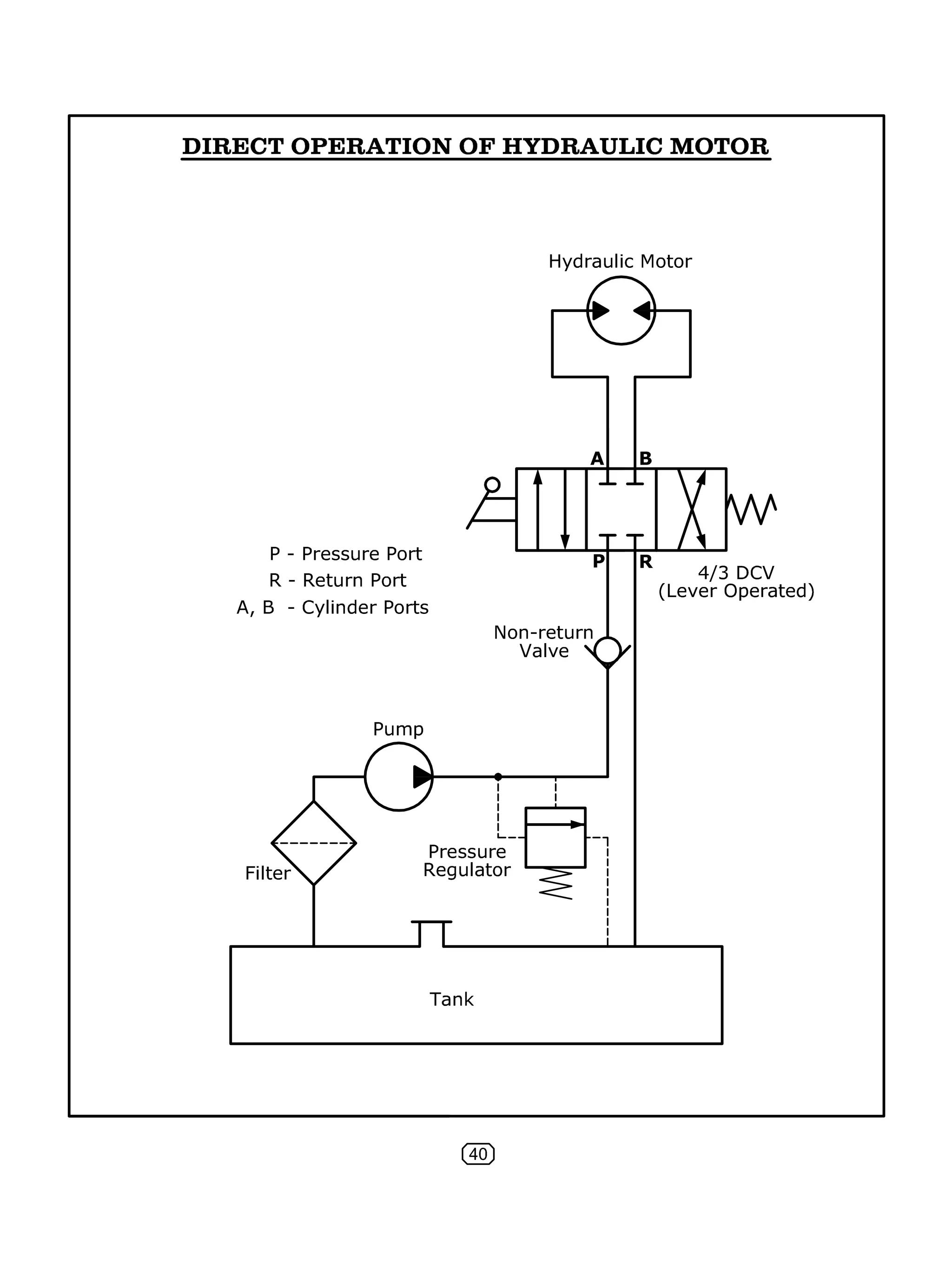

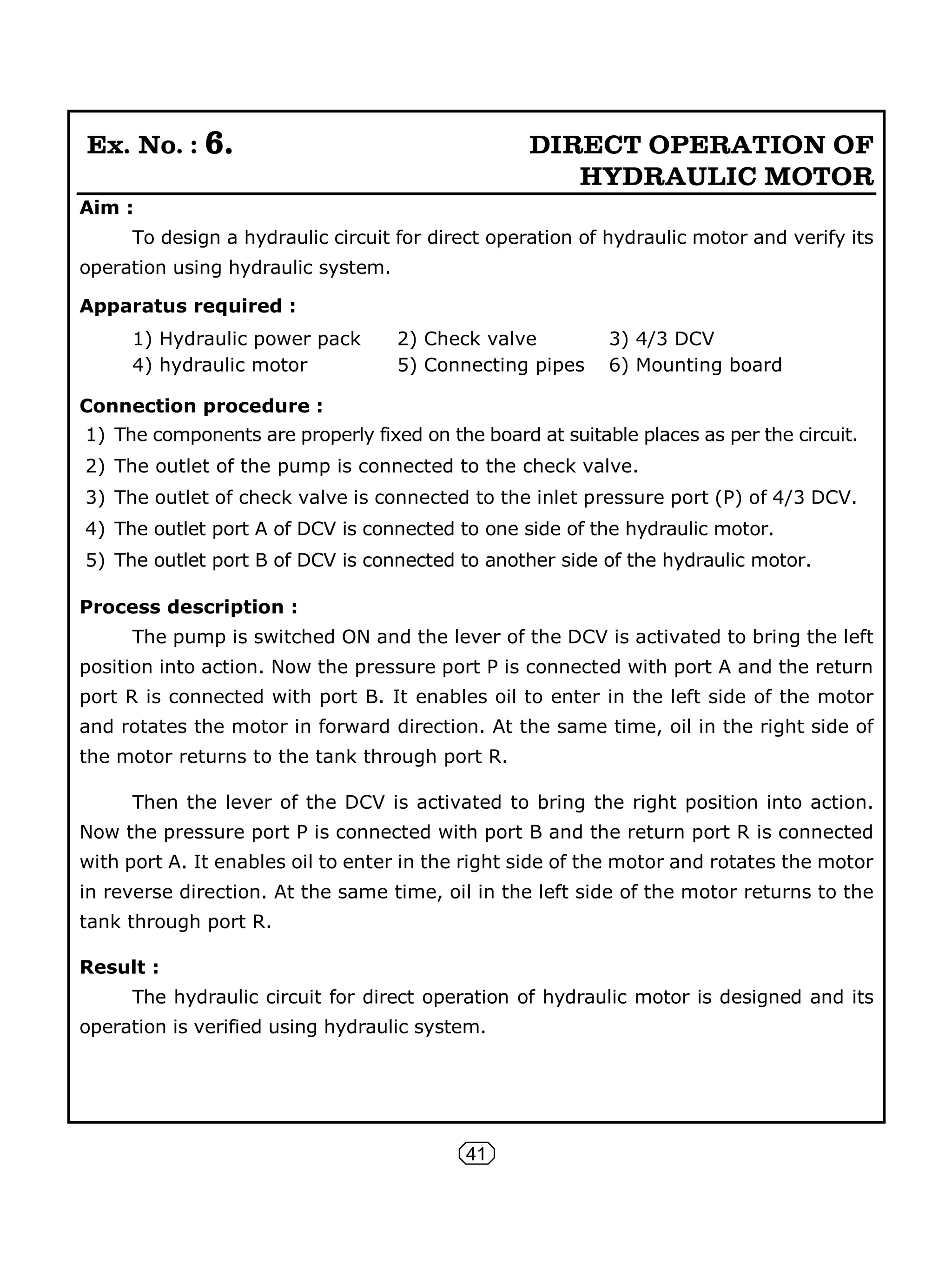

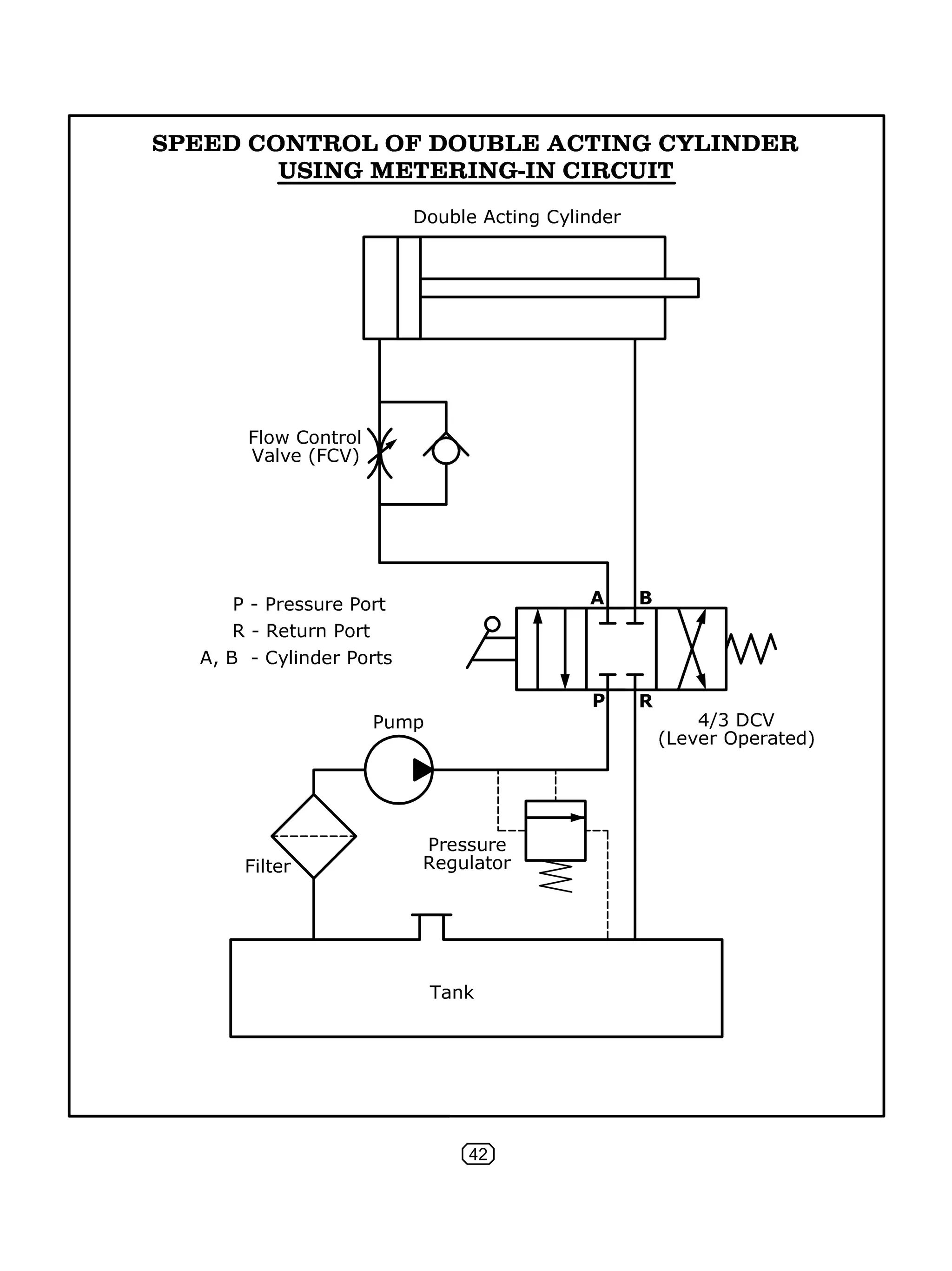

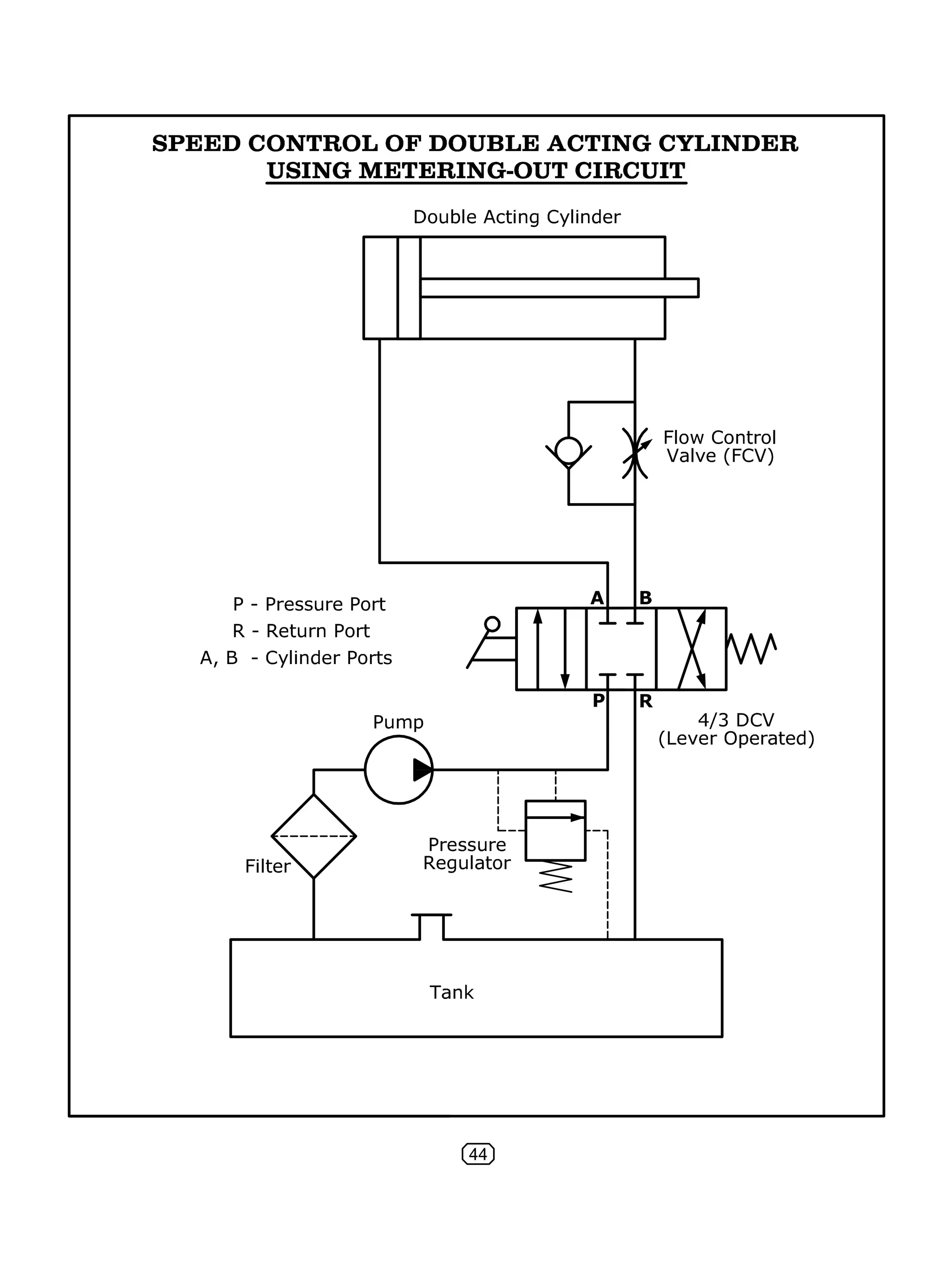

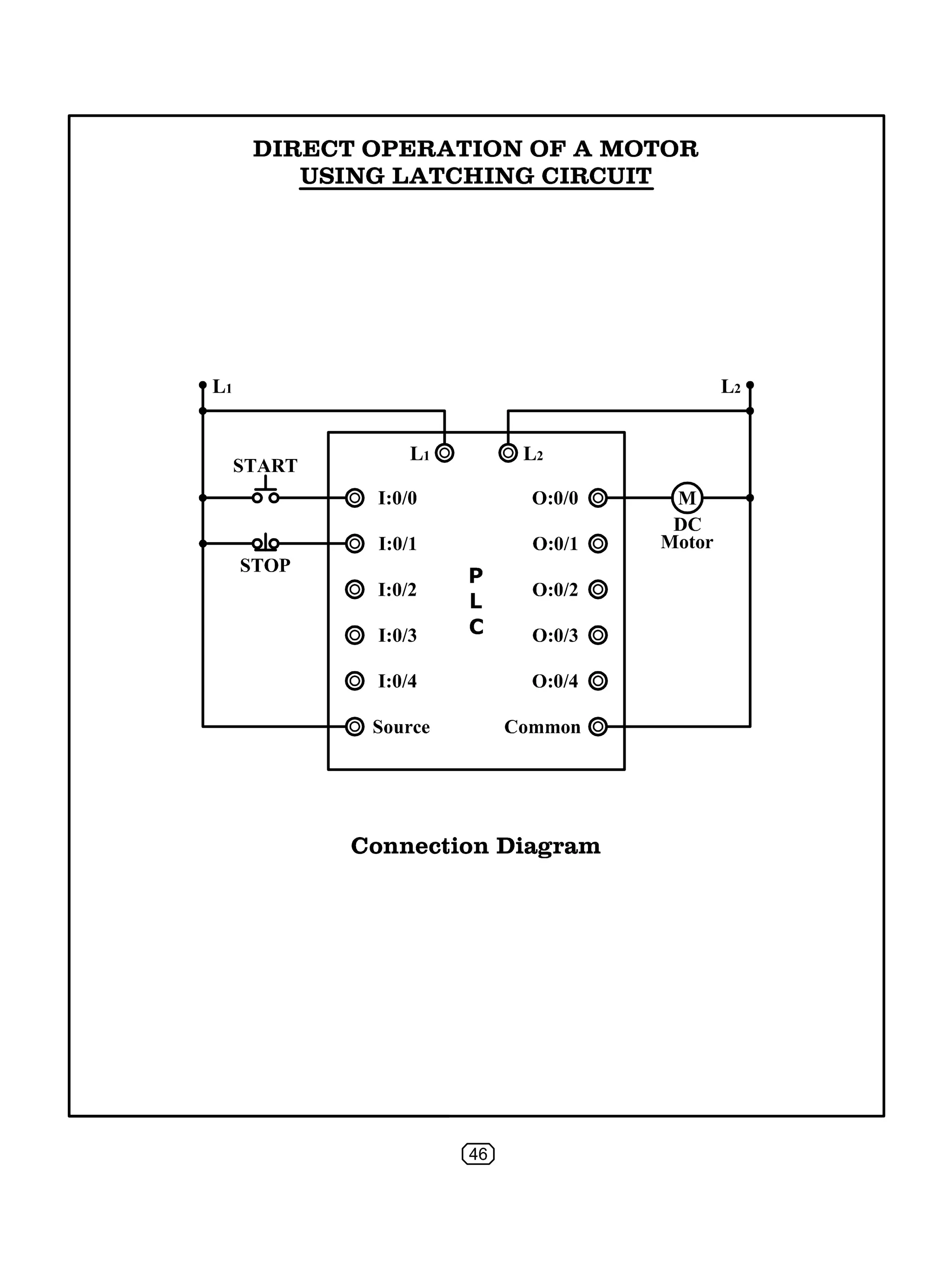

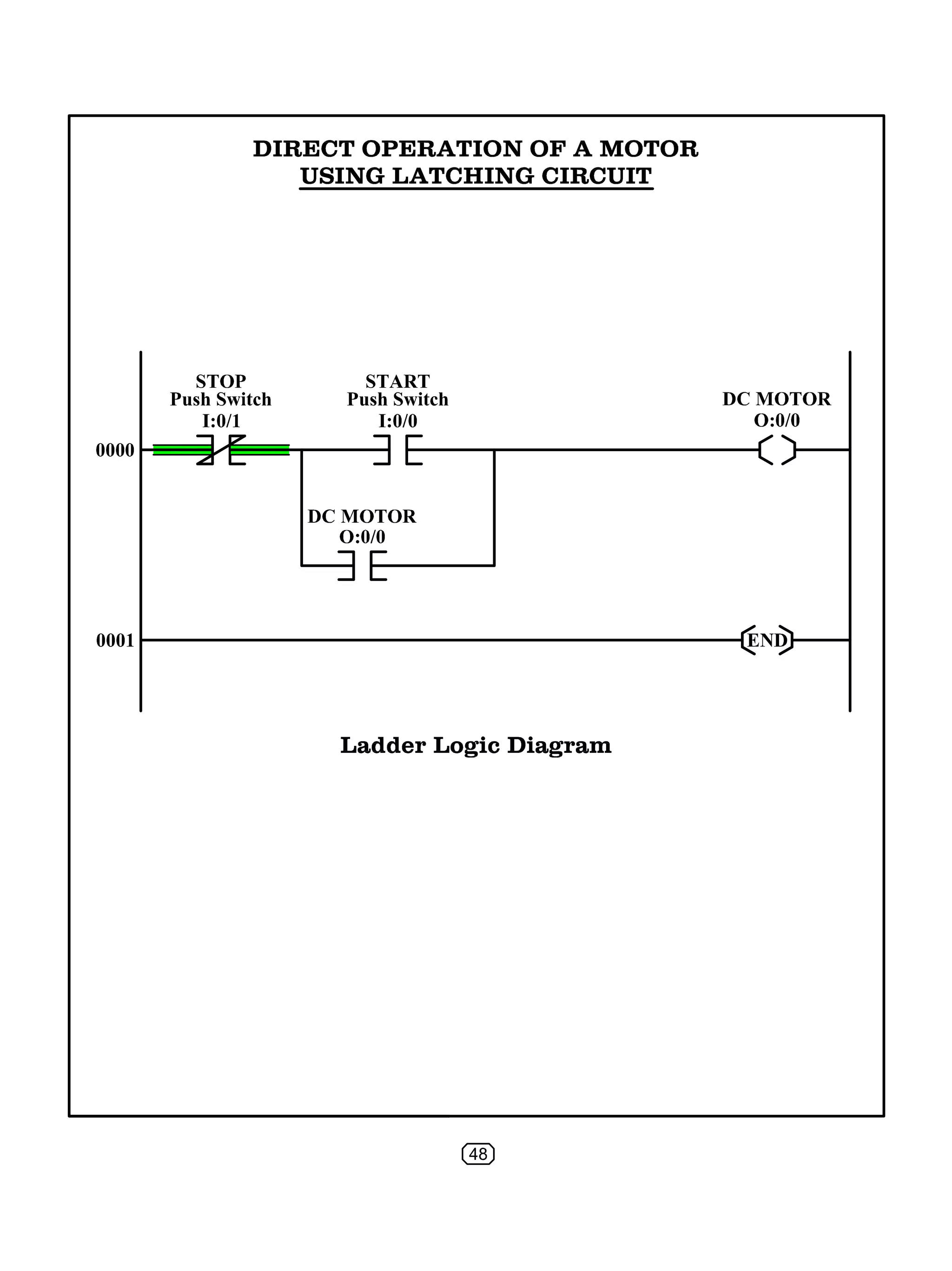

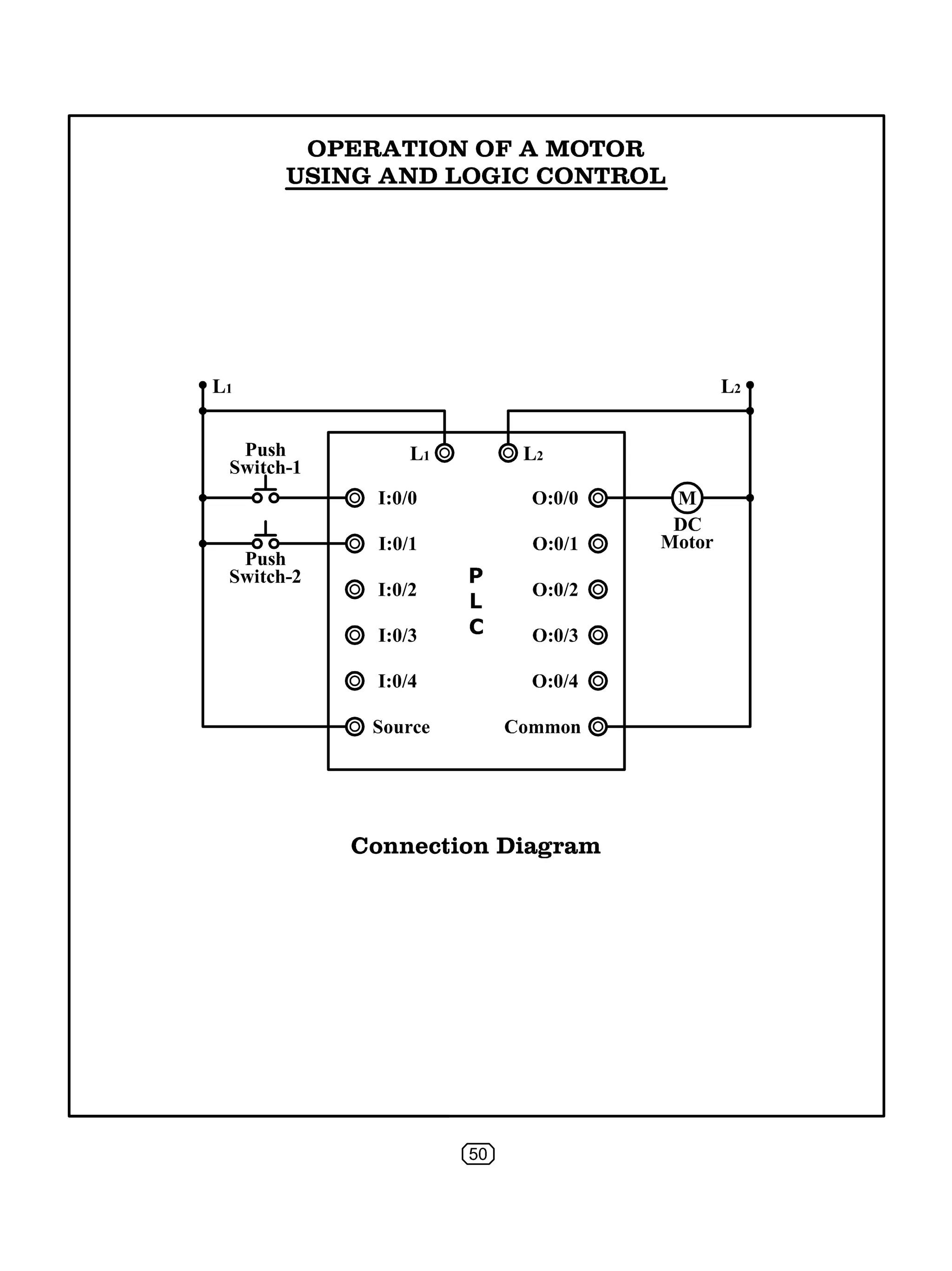

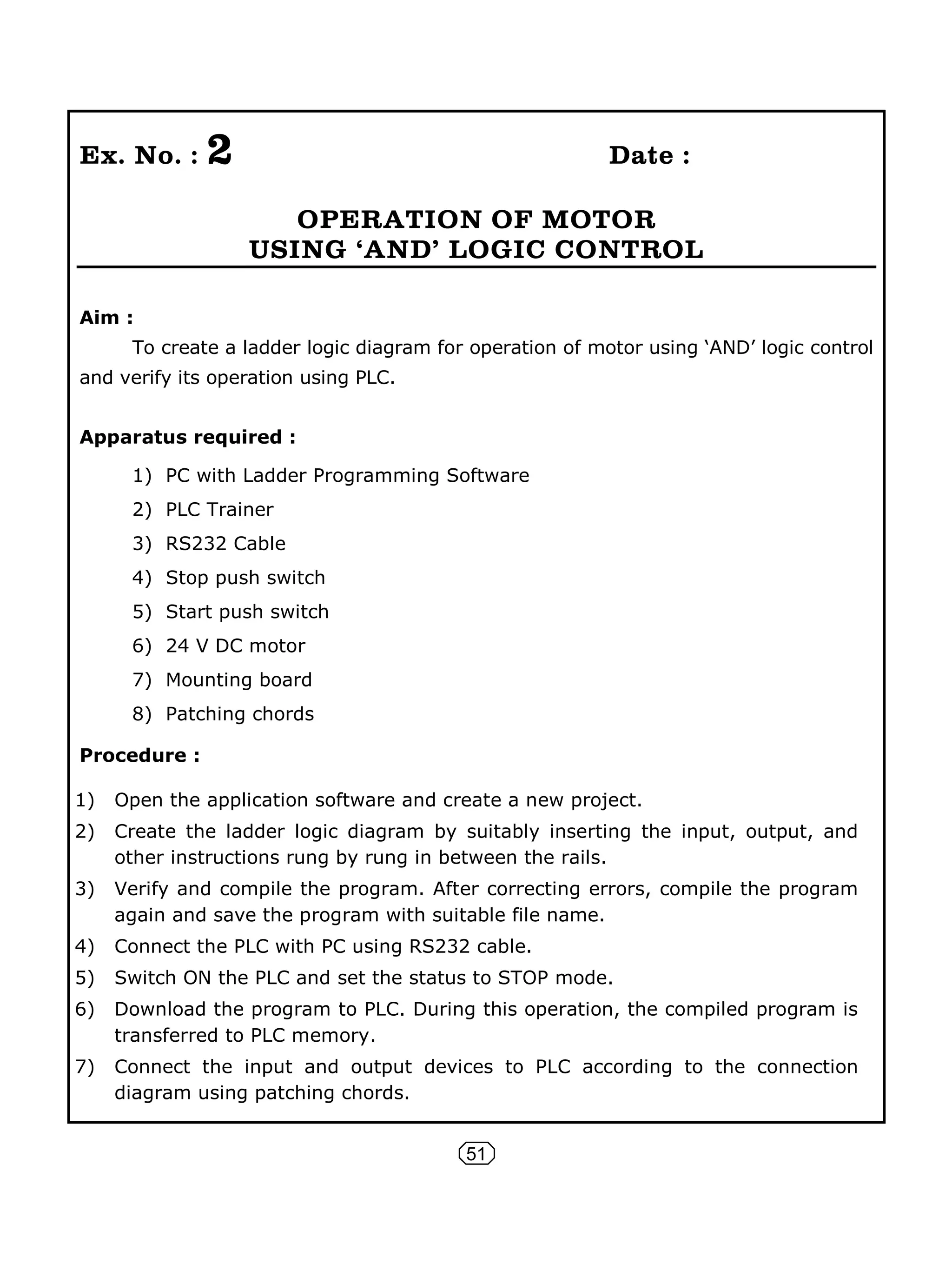

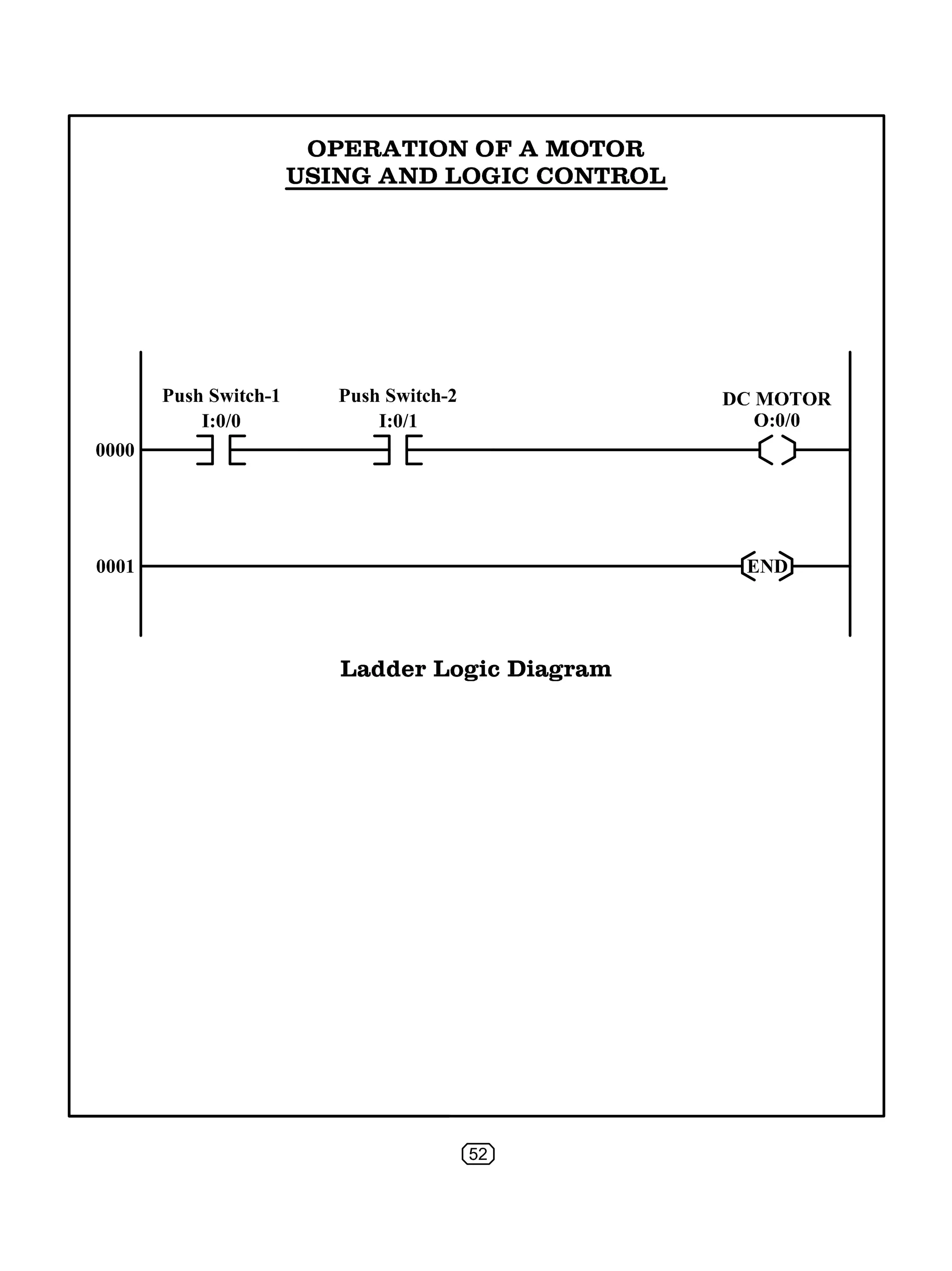

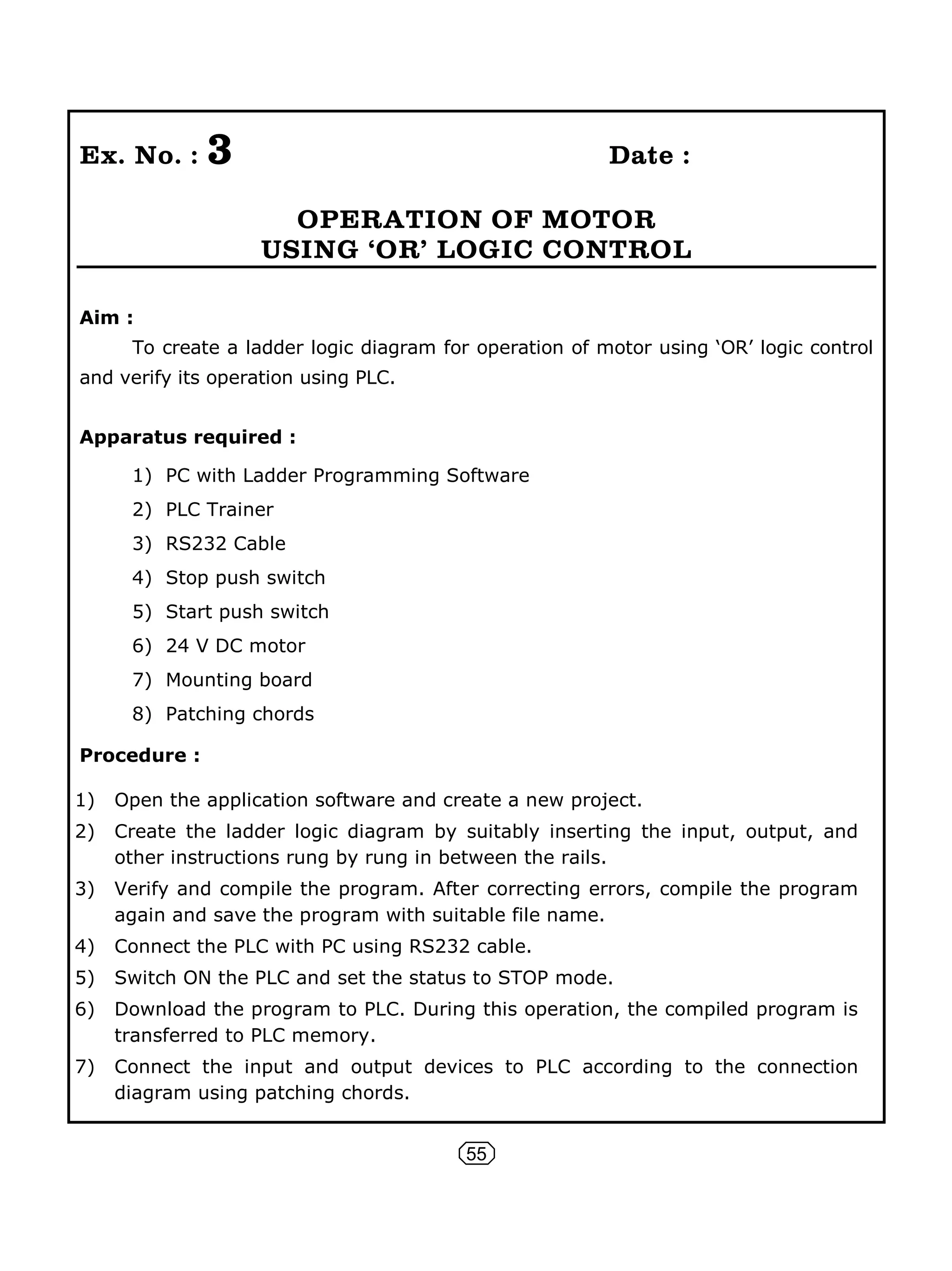

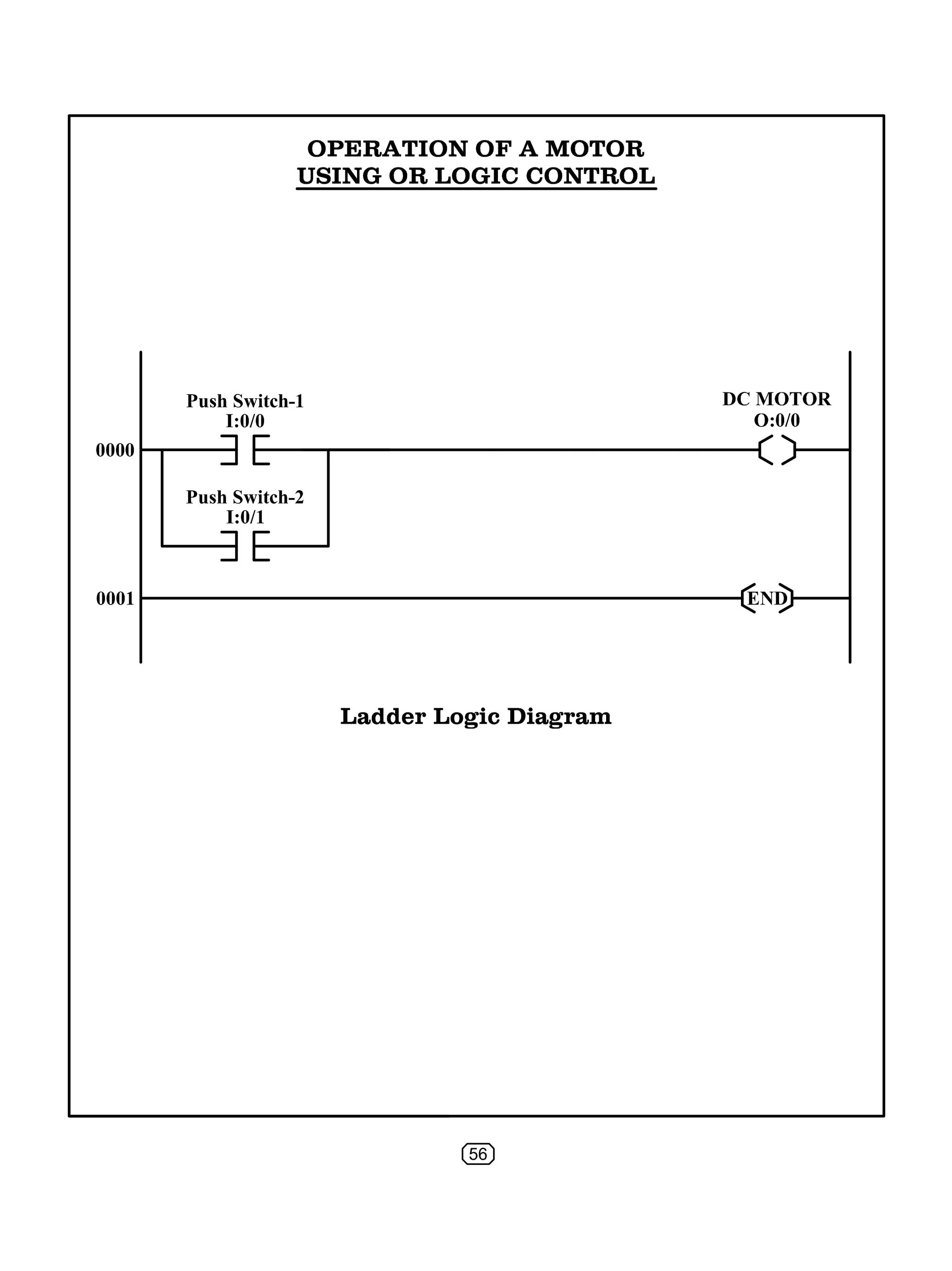

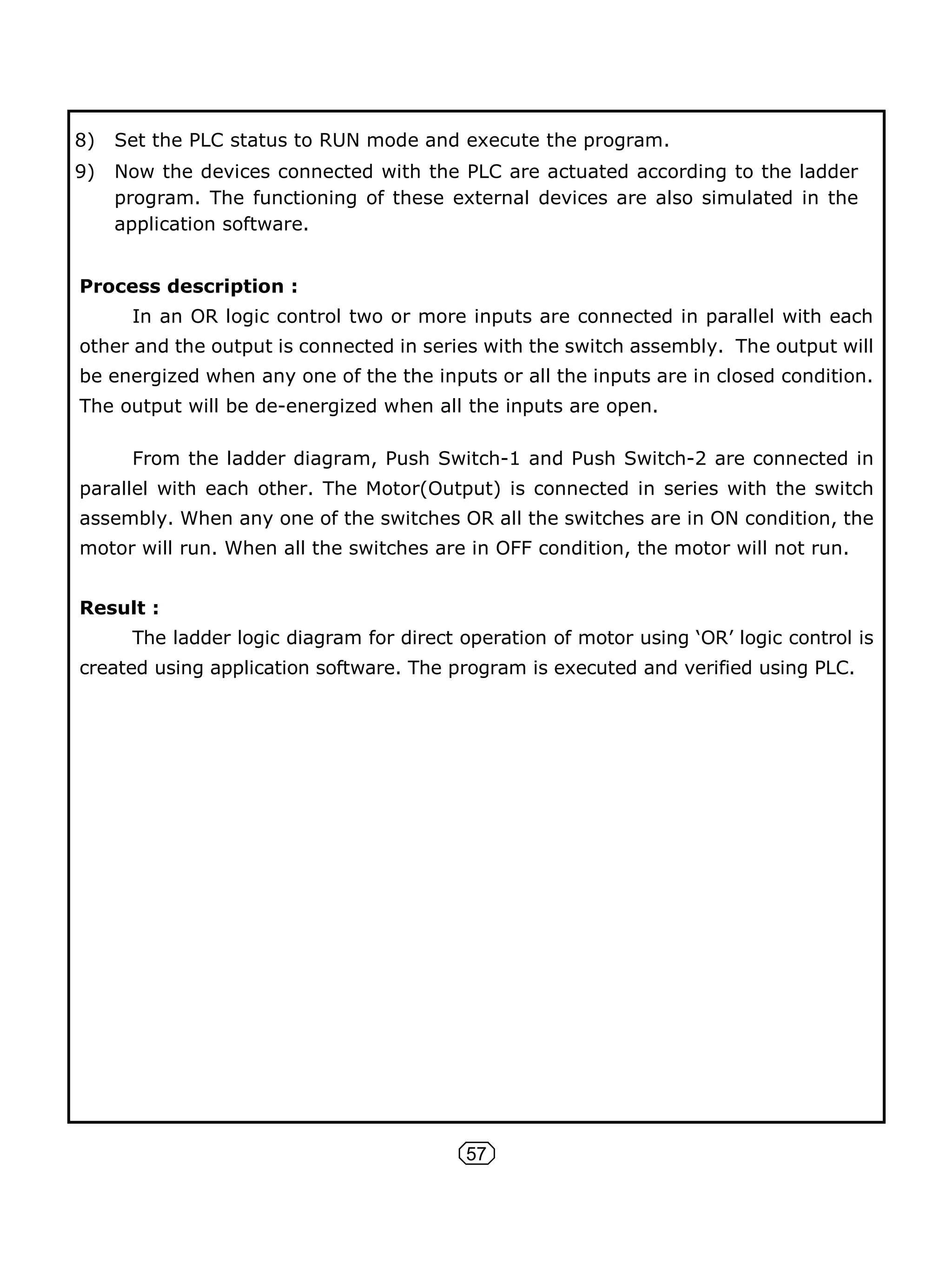

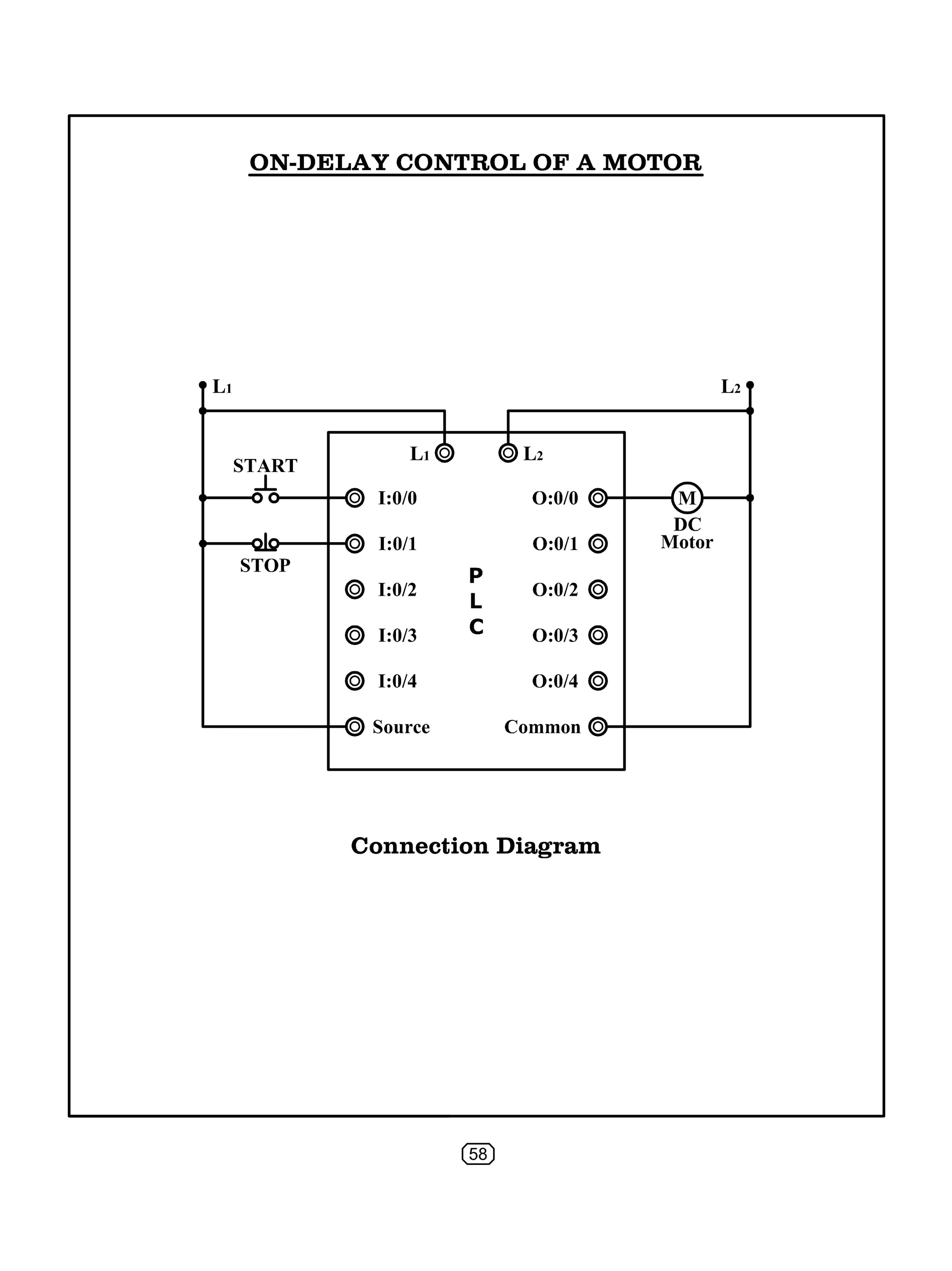

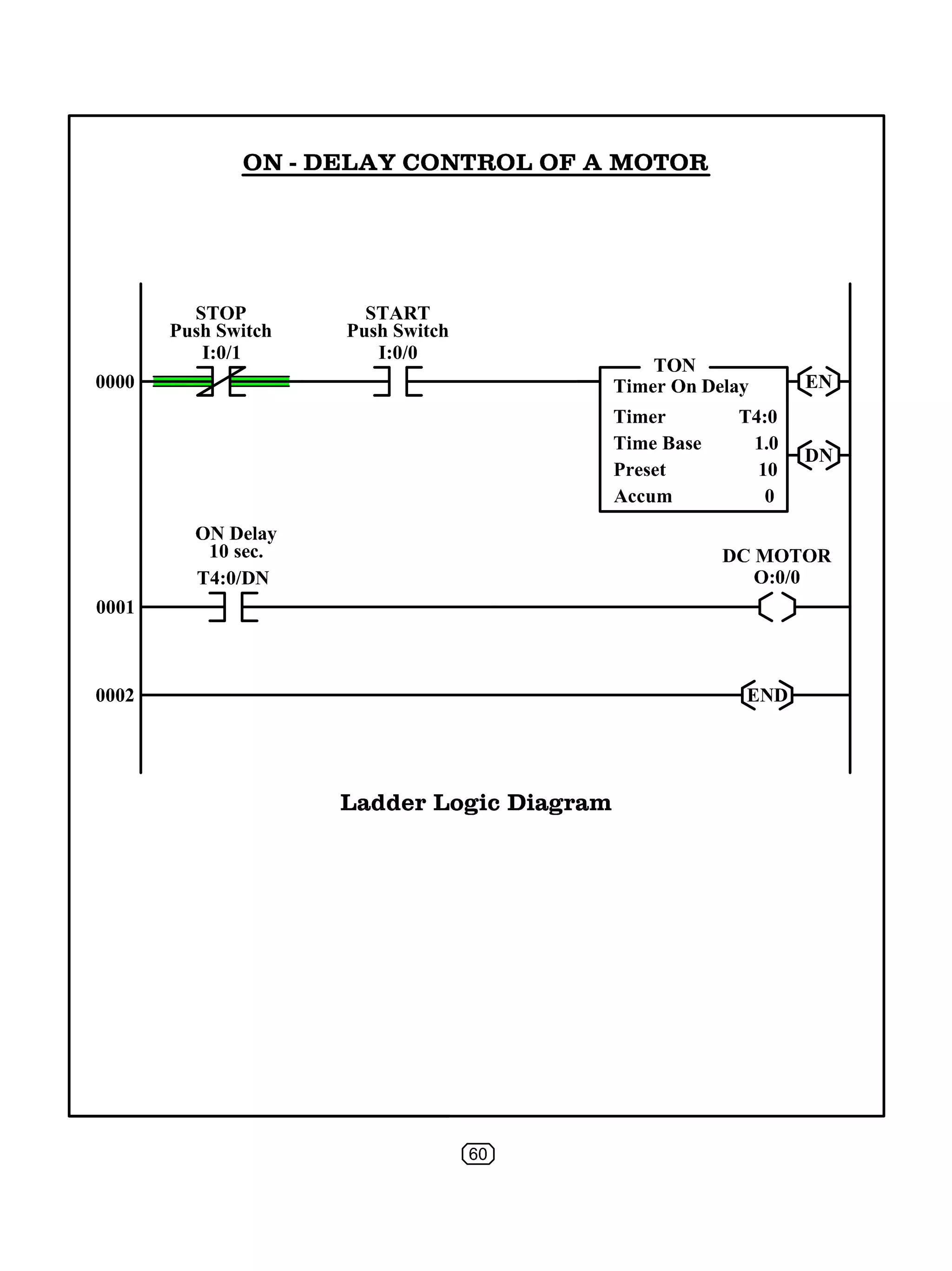

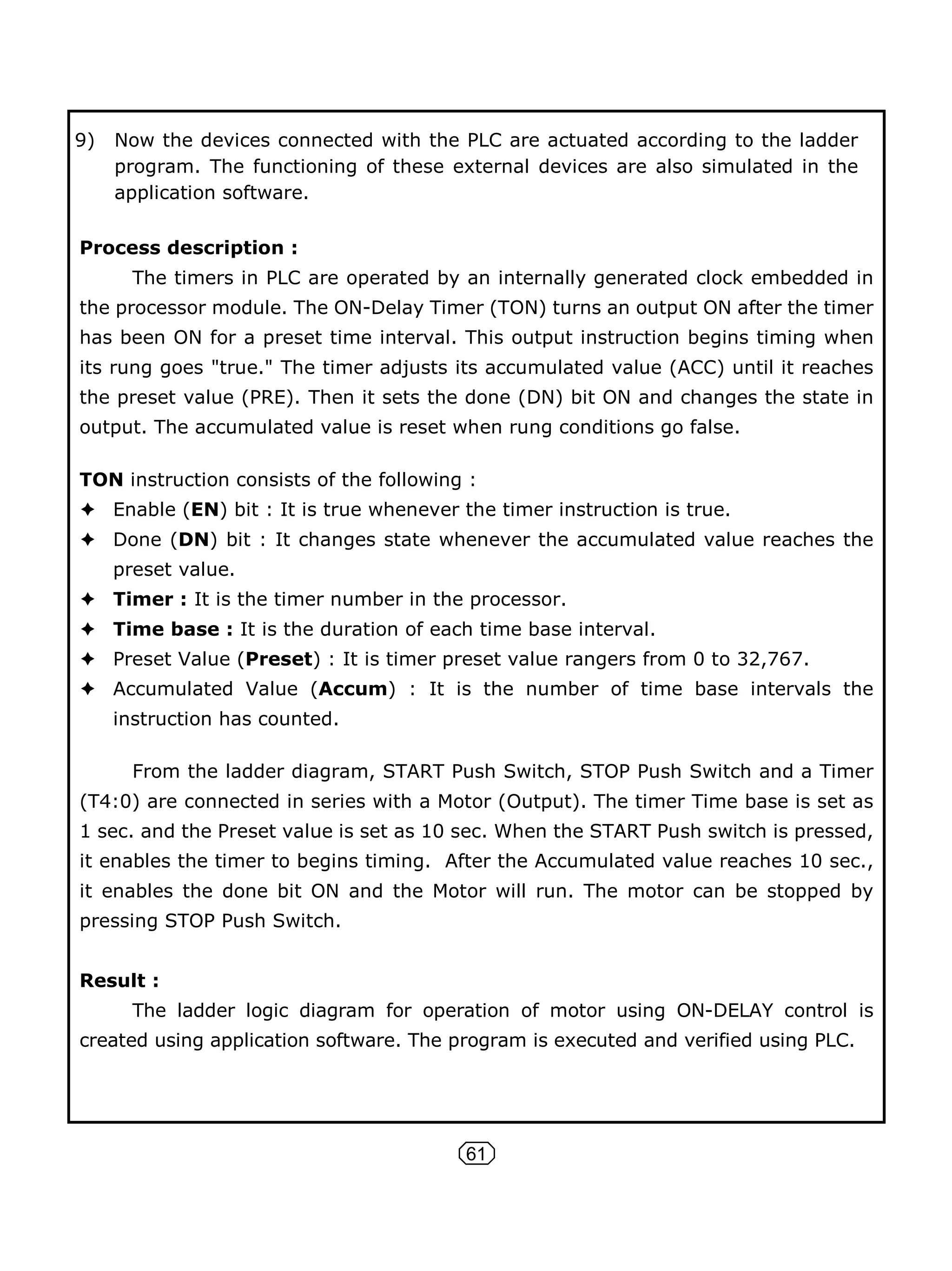

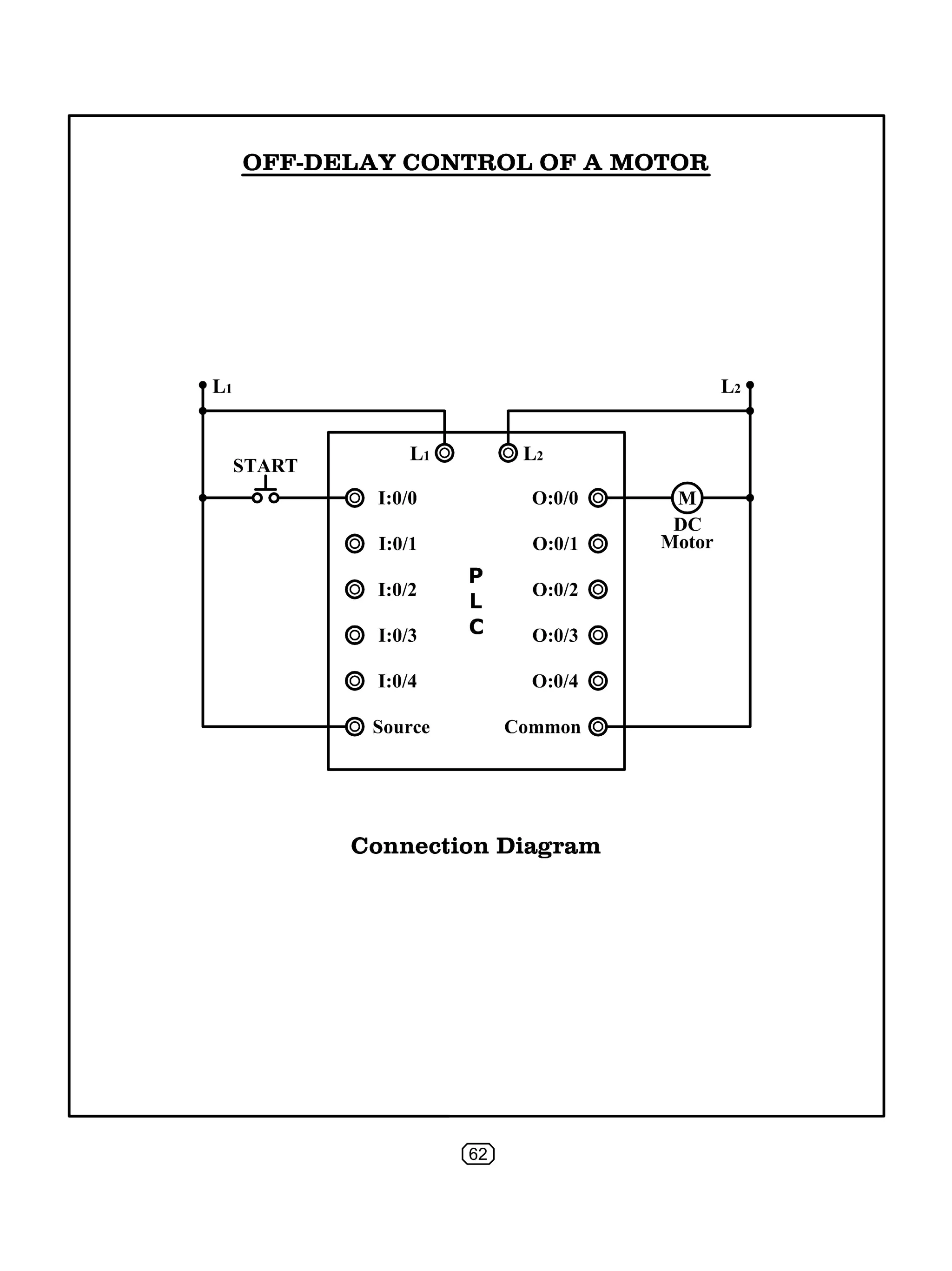

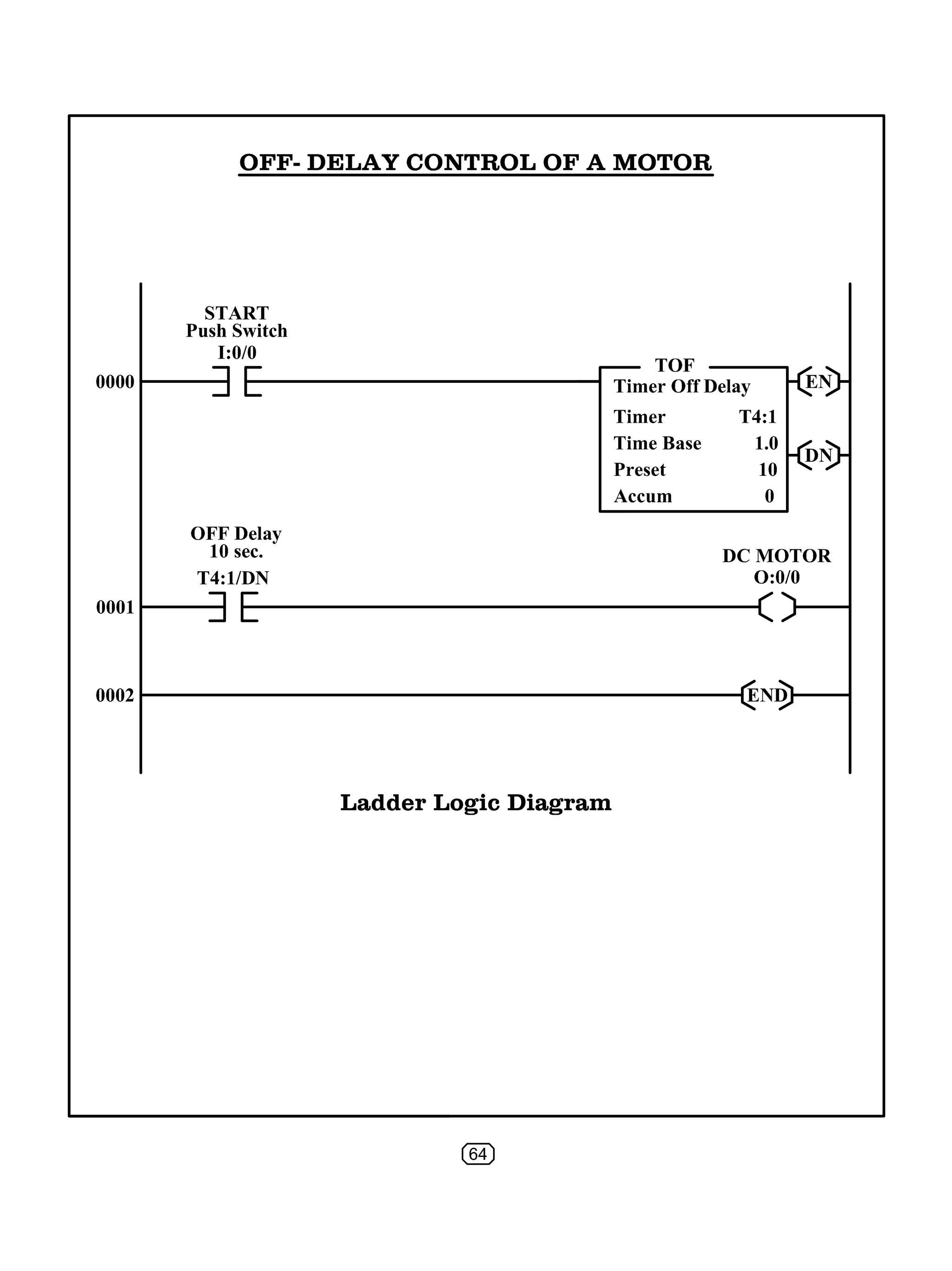

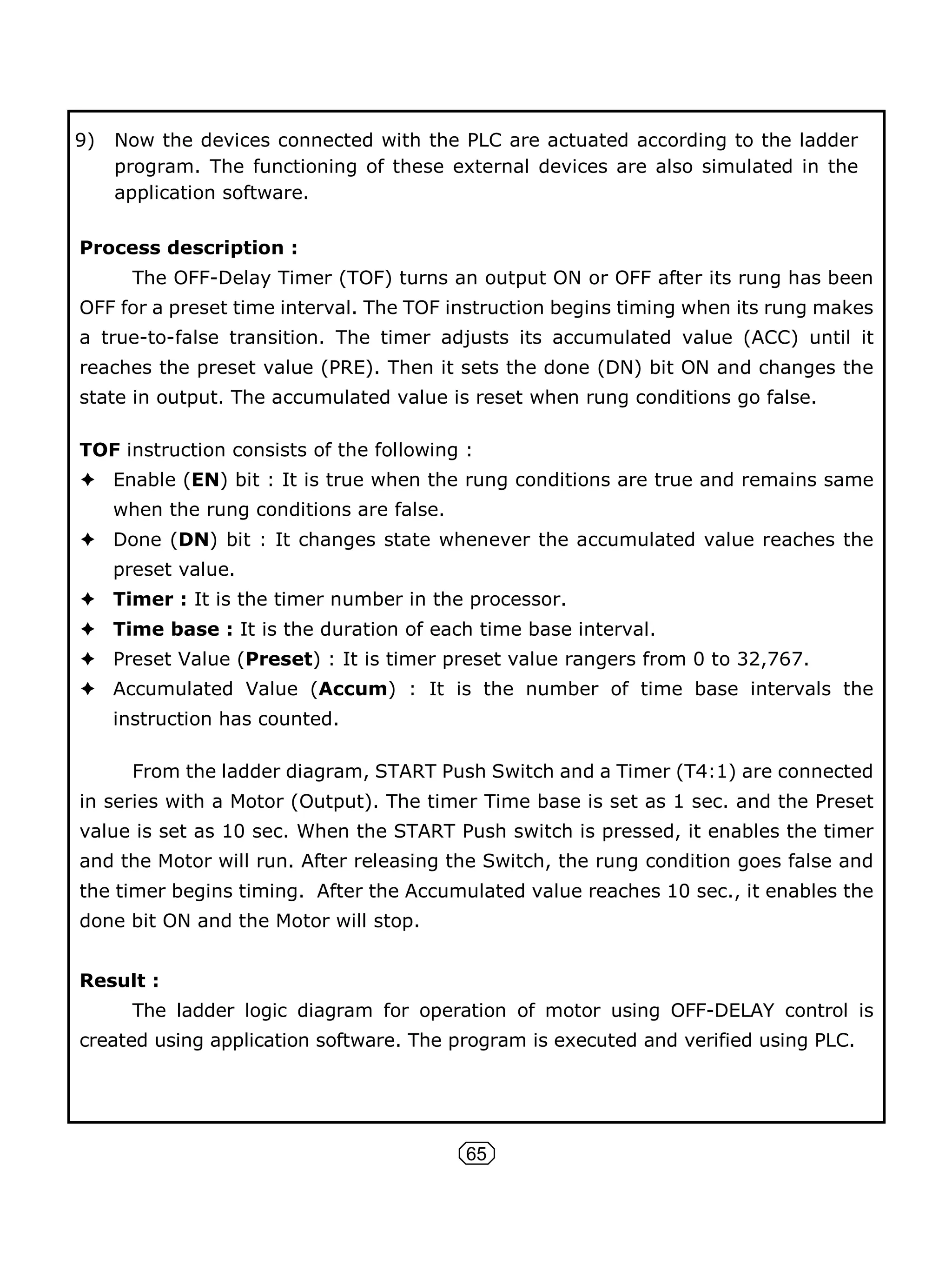

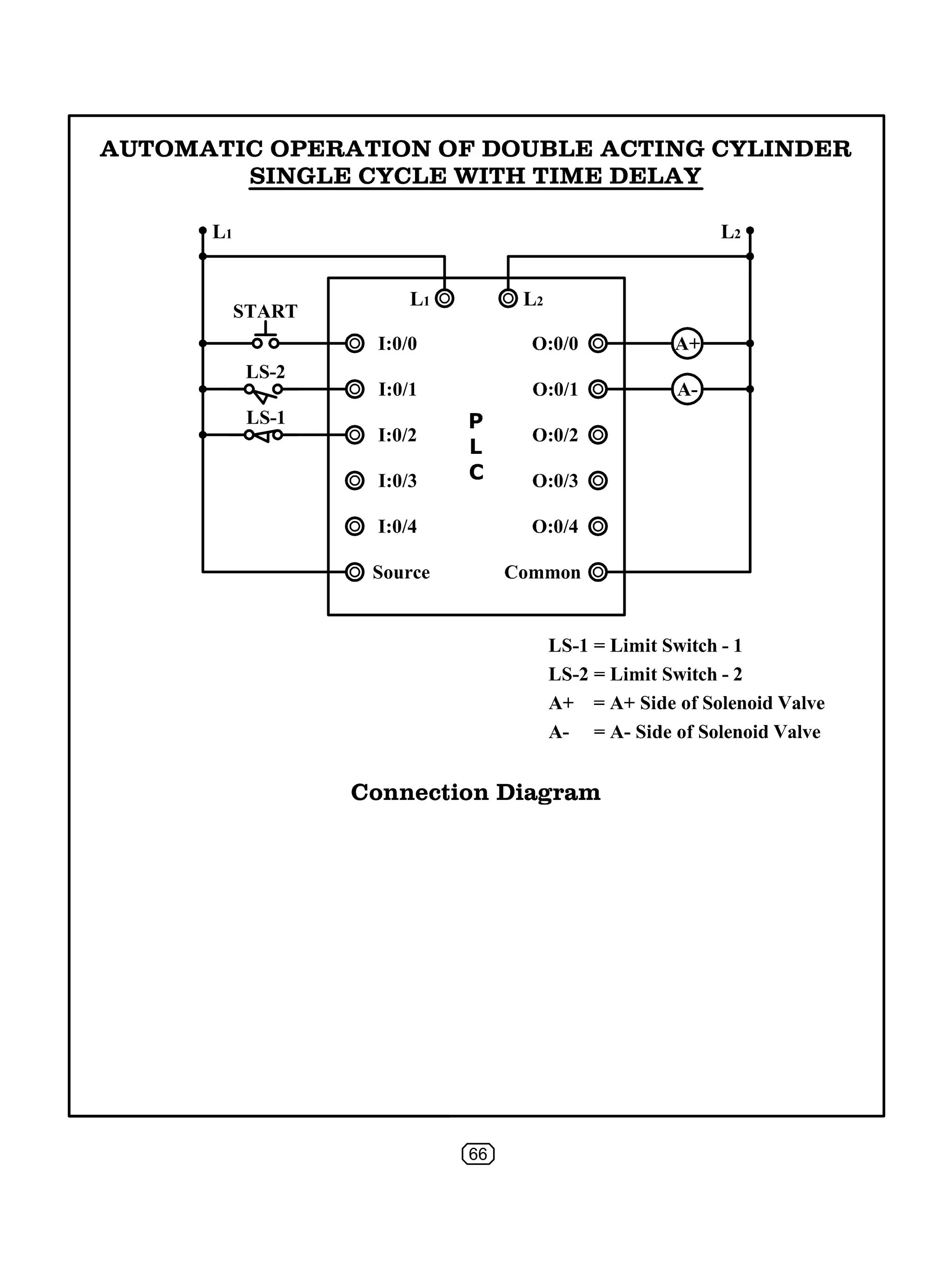

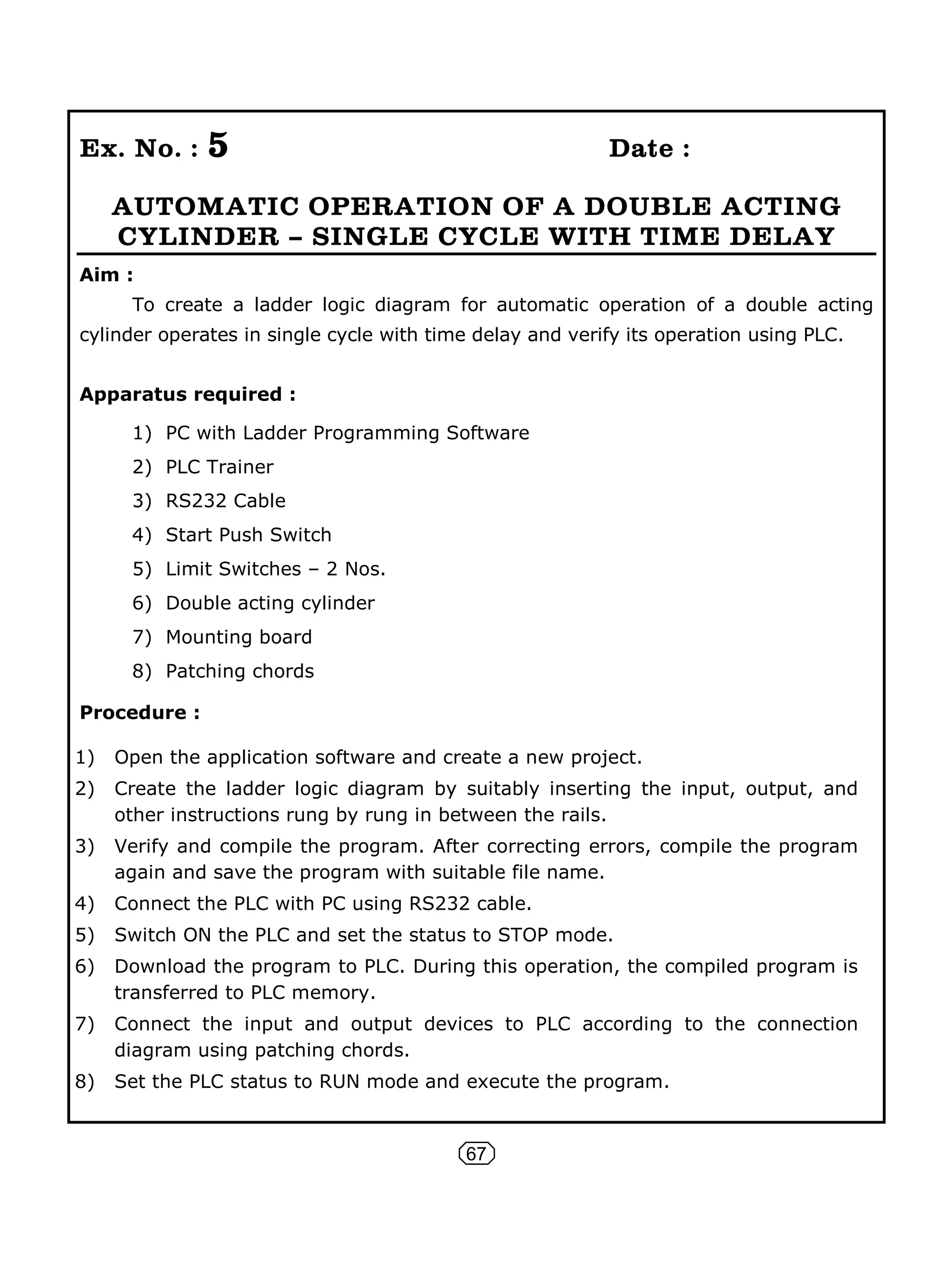

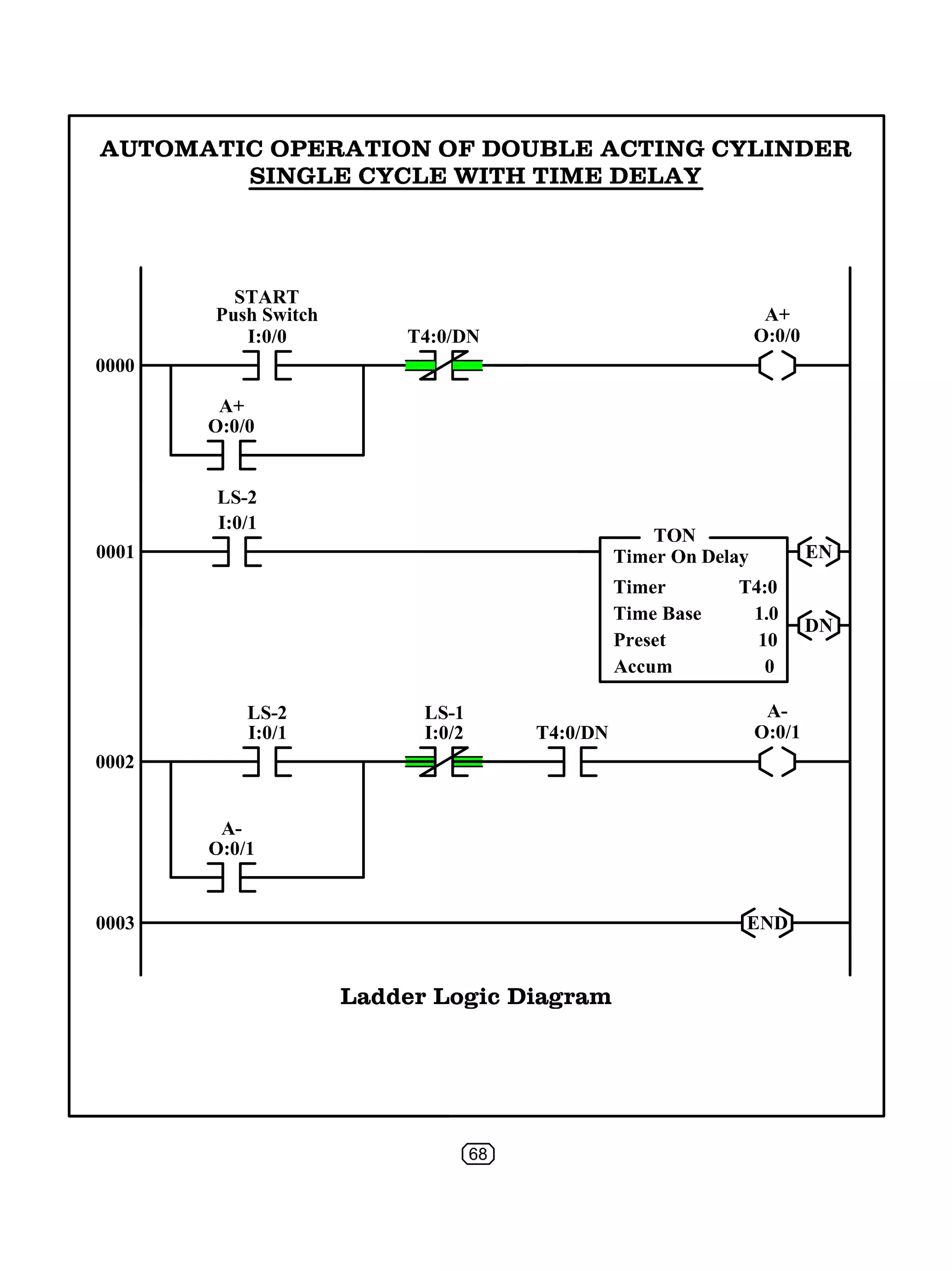

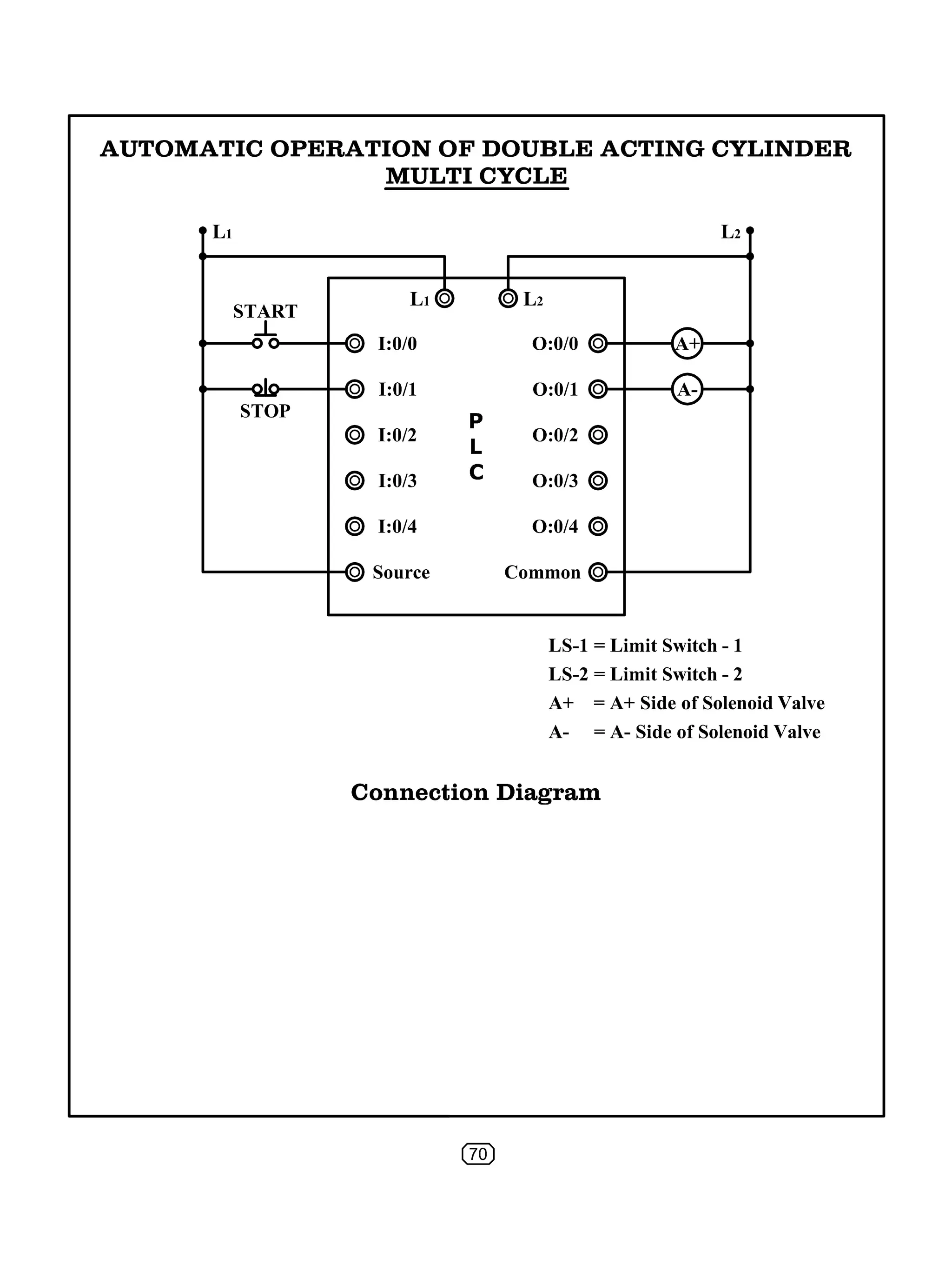

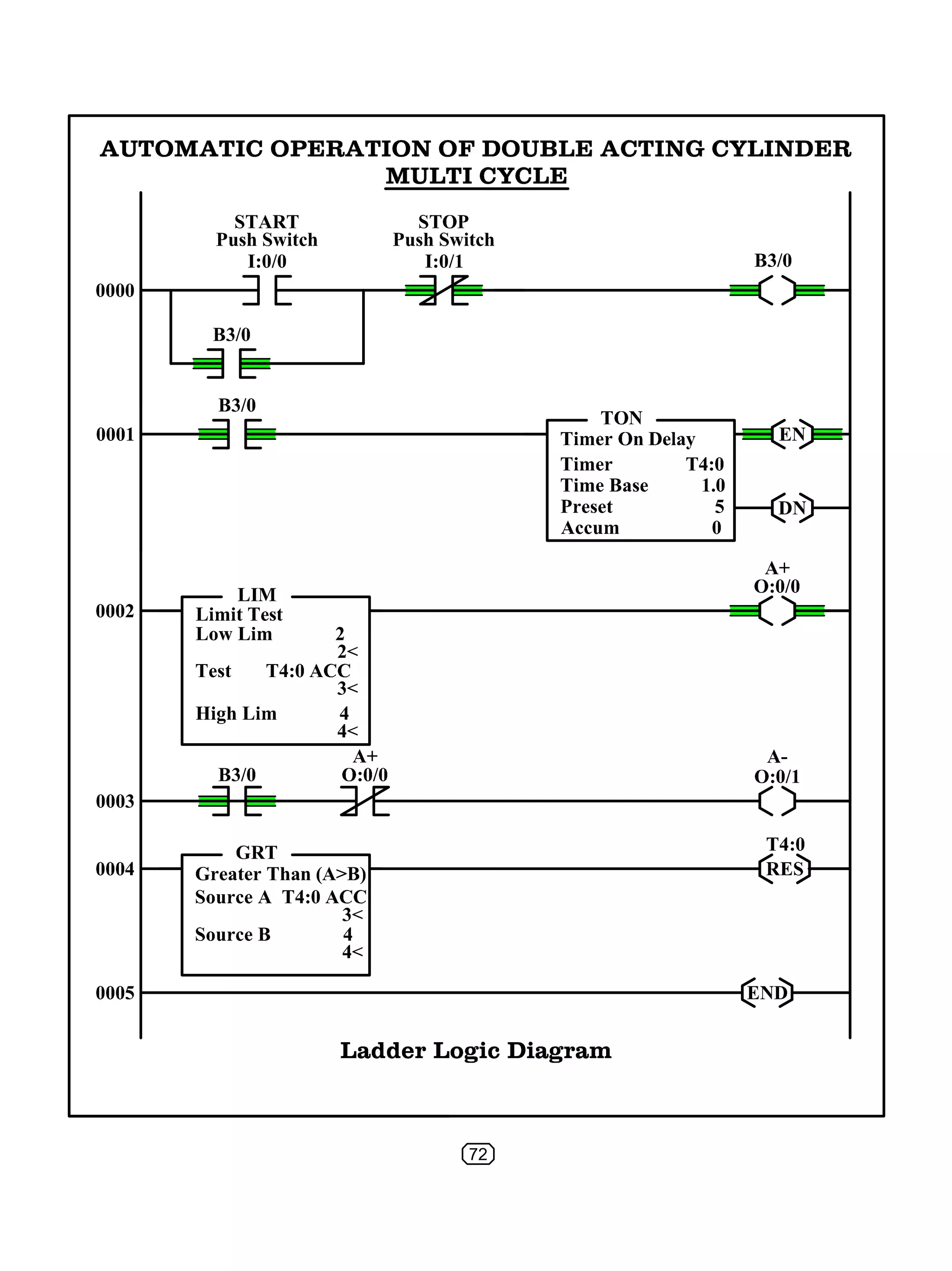

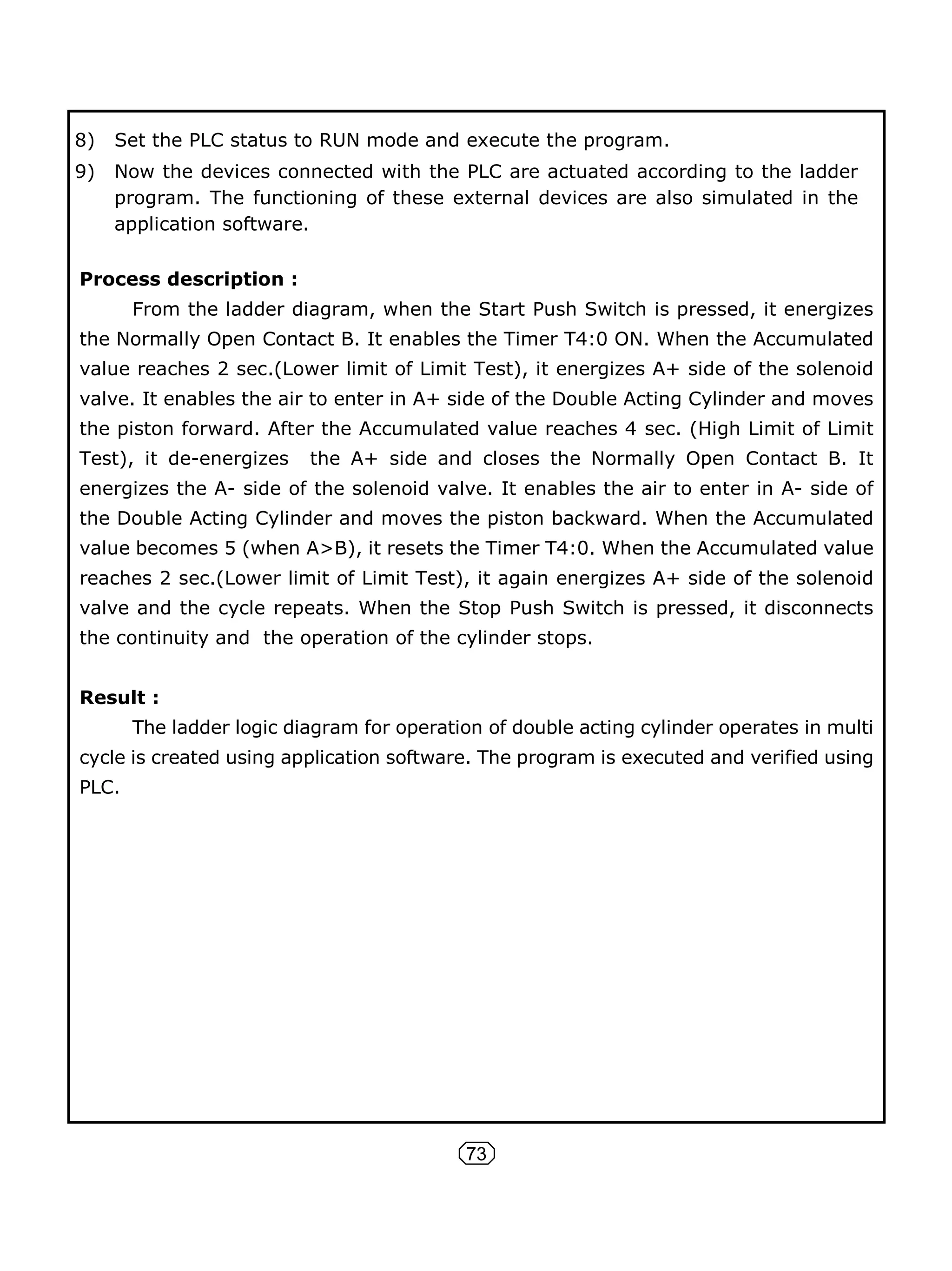

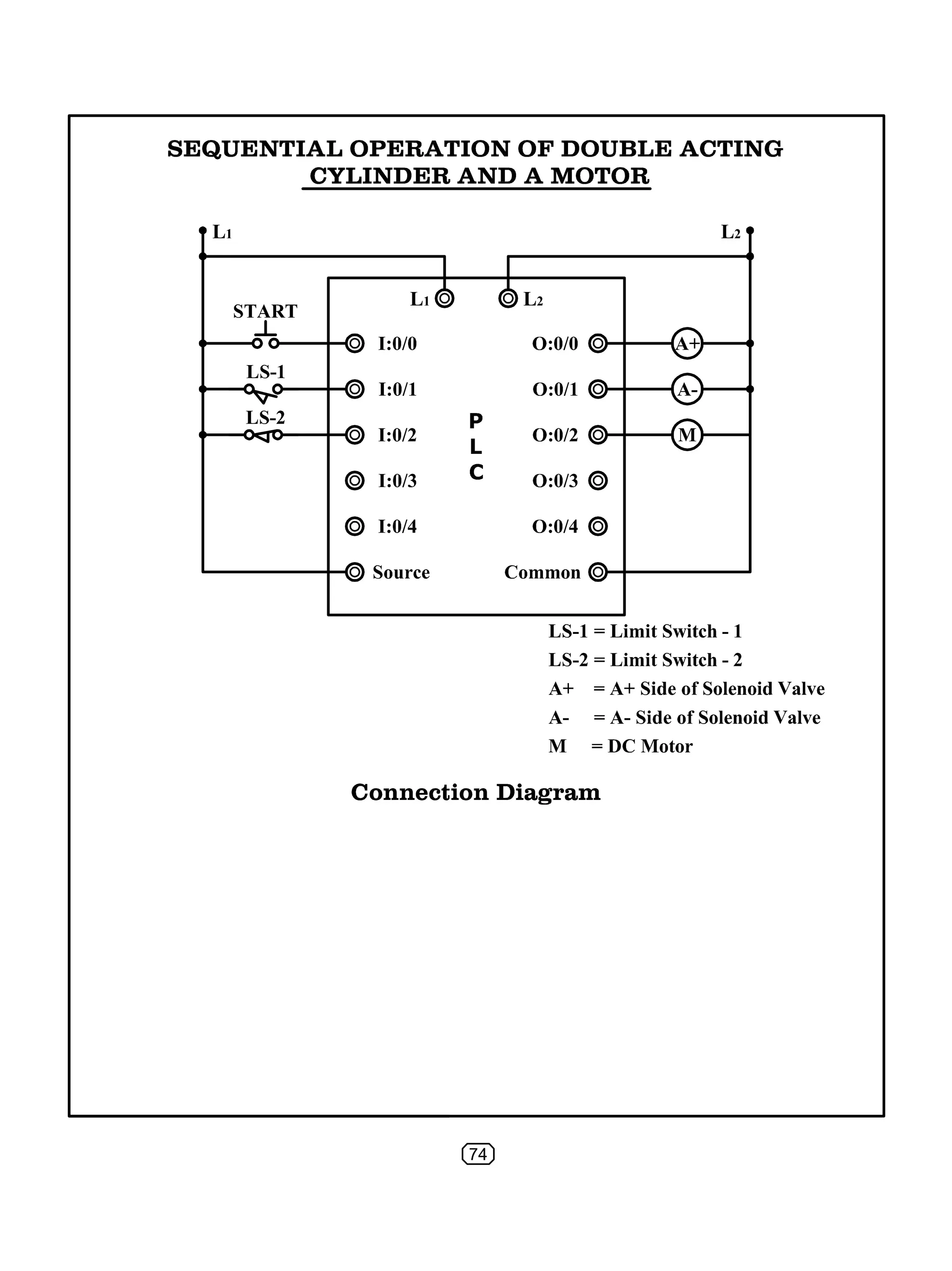

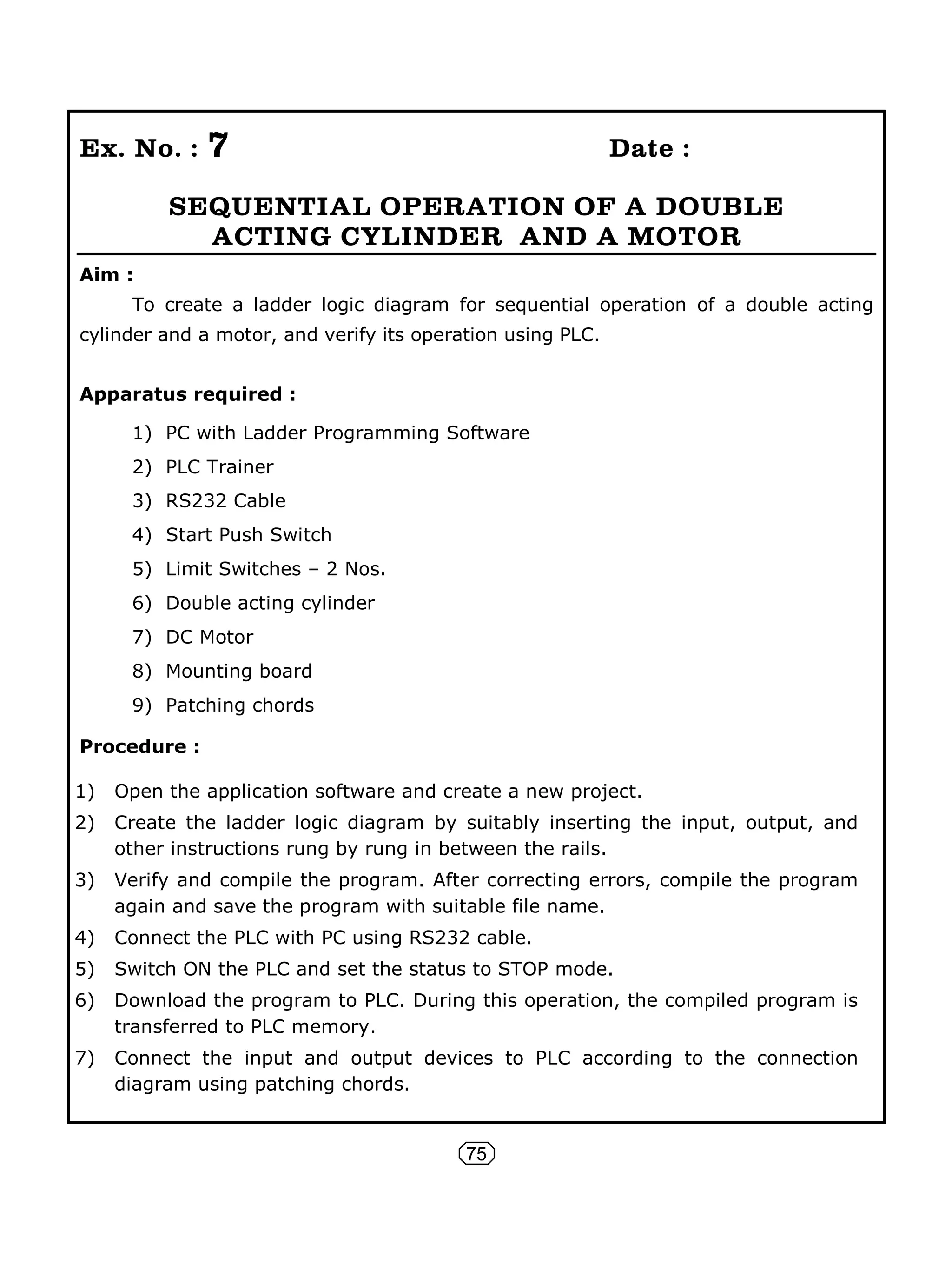

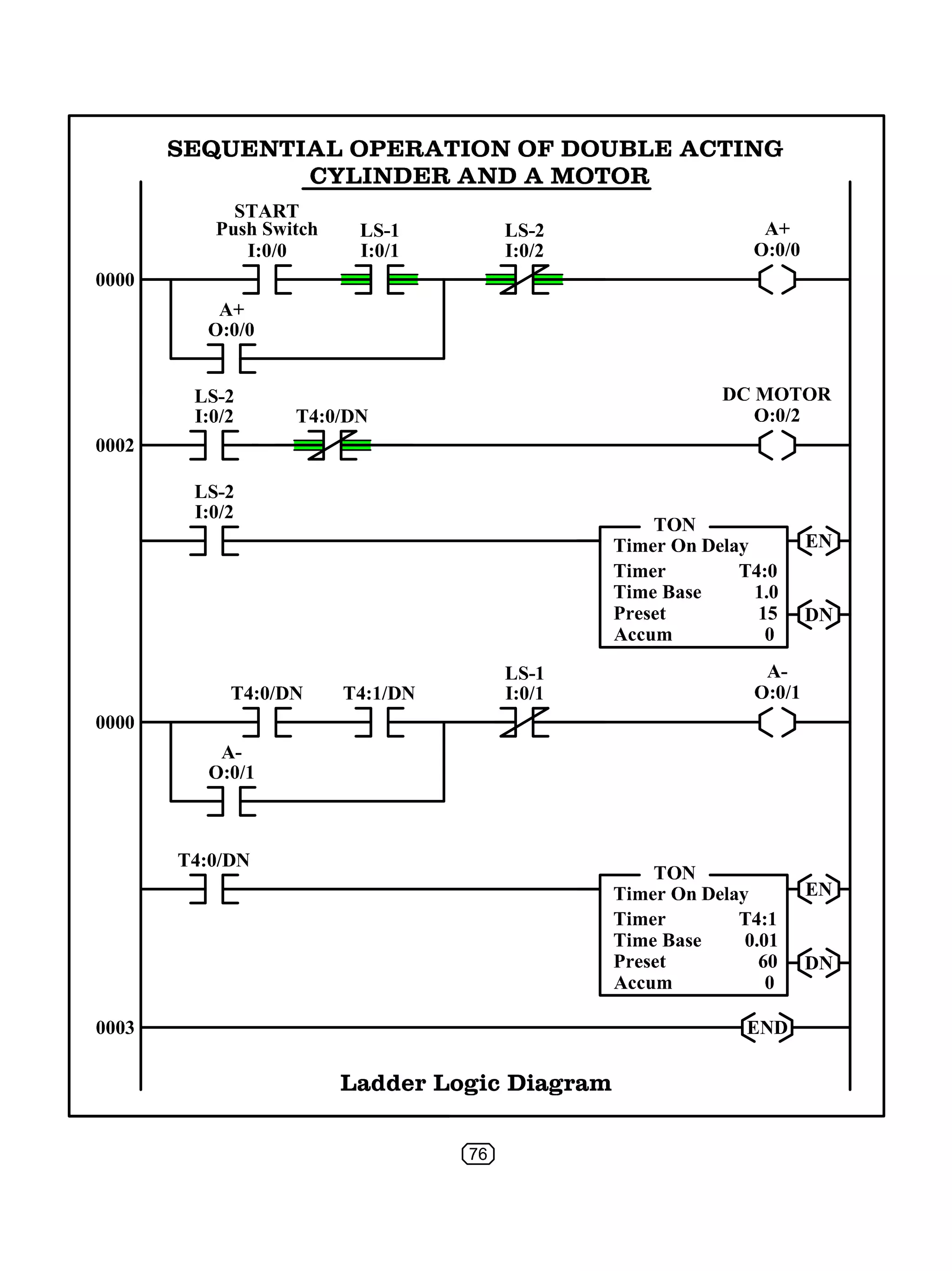

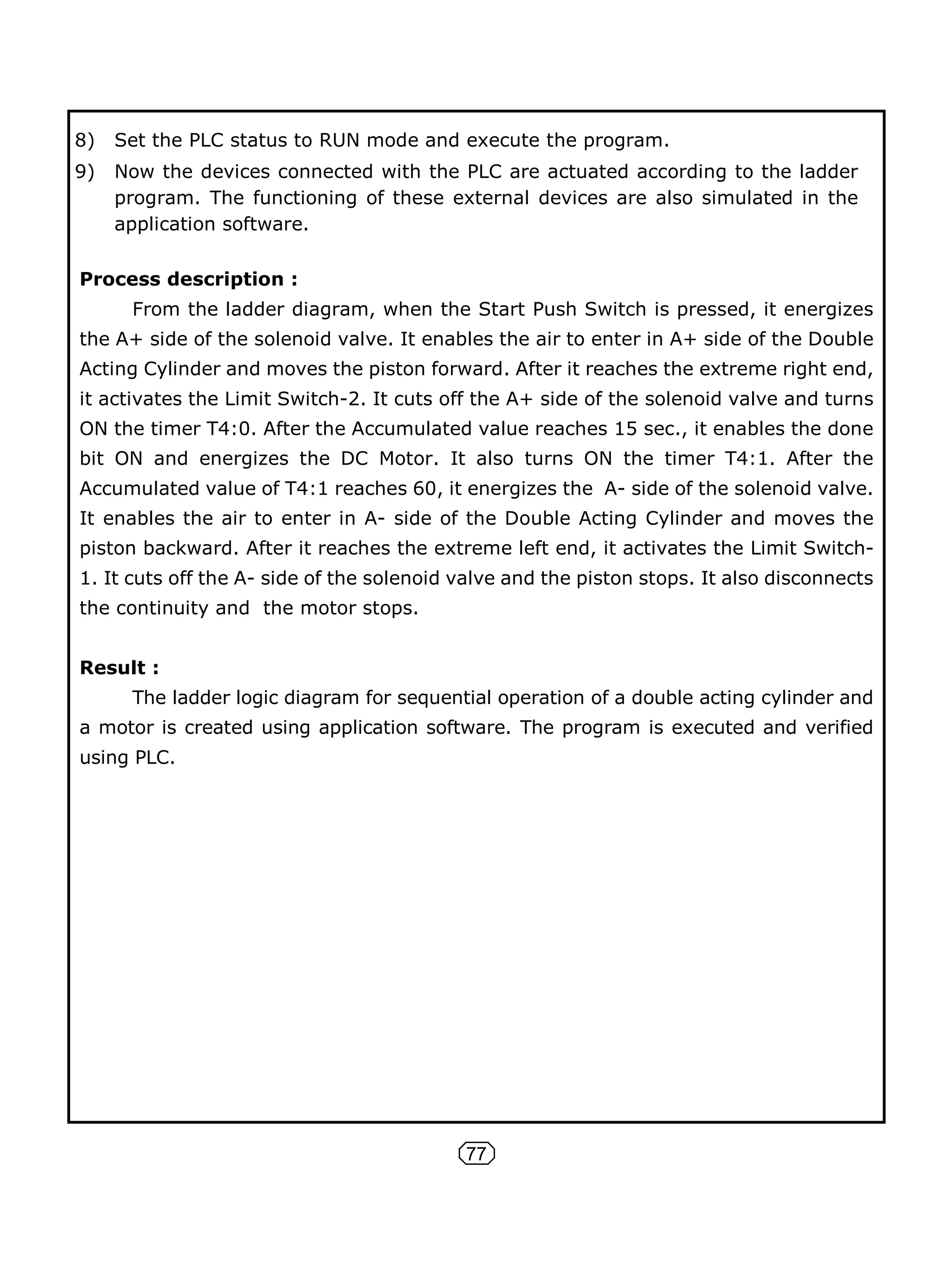

The document is a practical manual on process automation covering pneumatic, hydraulic systems, and programmable logic controllers (PLC). It includes detailed explanations of system components, operation methods, and laboratory exercises designed for hands-on learning. The content is aimed at educating users on designing and operating fluid power circuits and using PLC systems for process control.