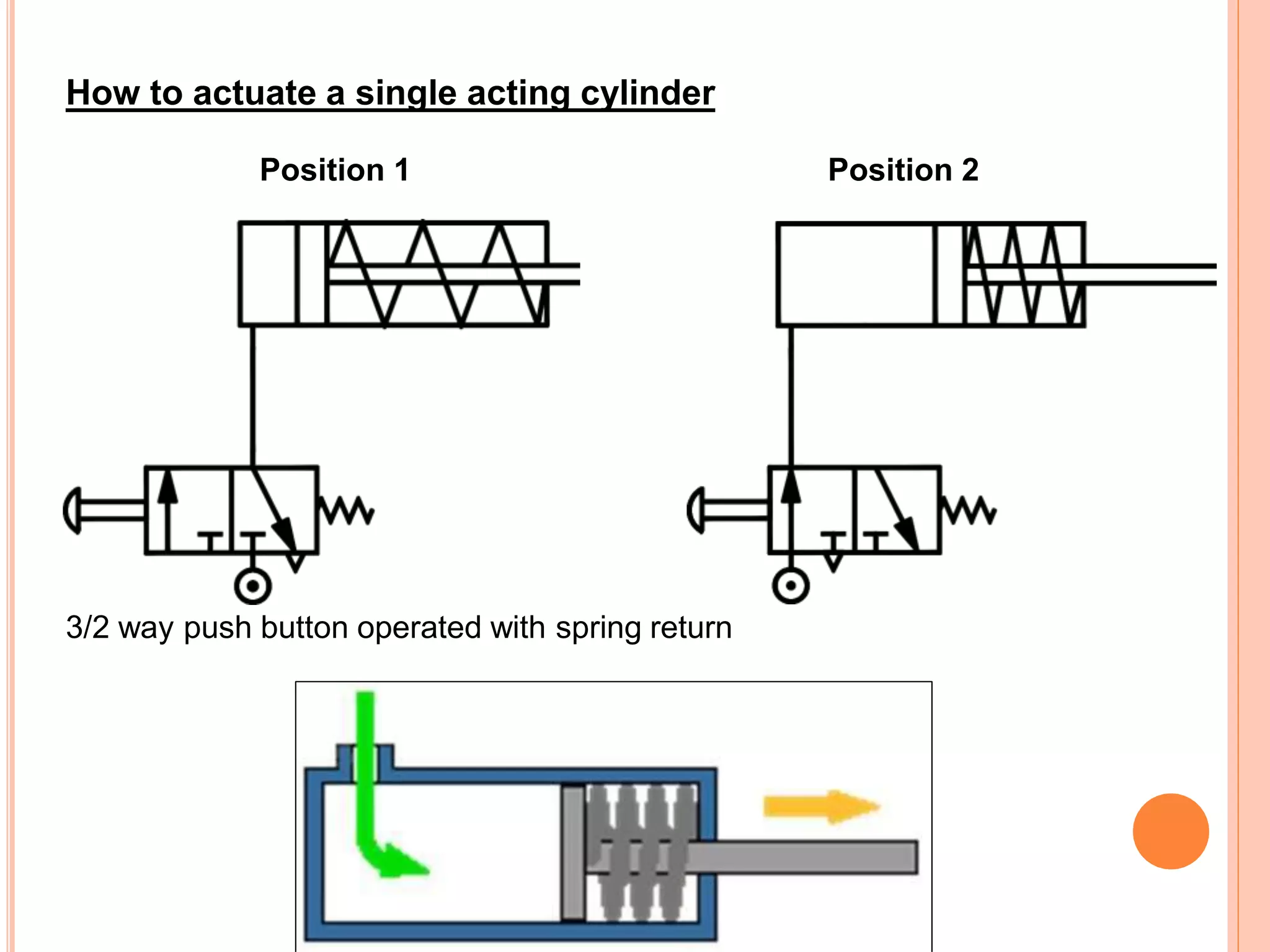

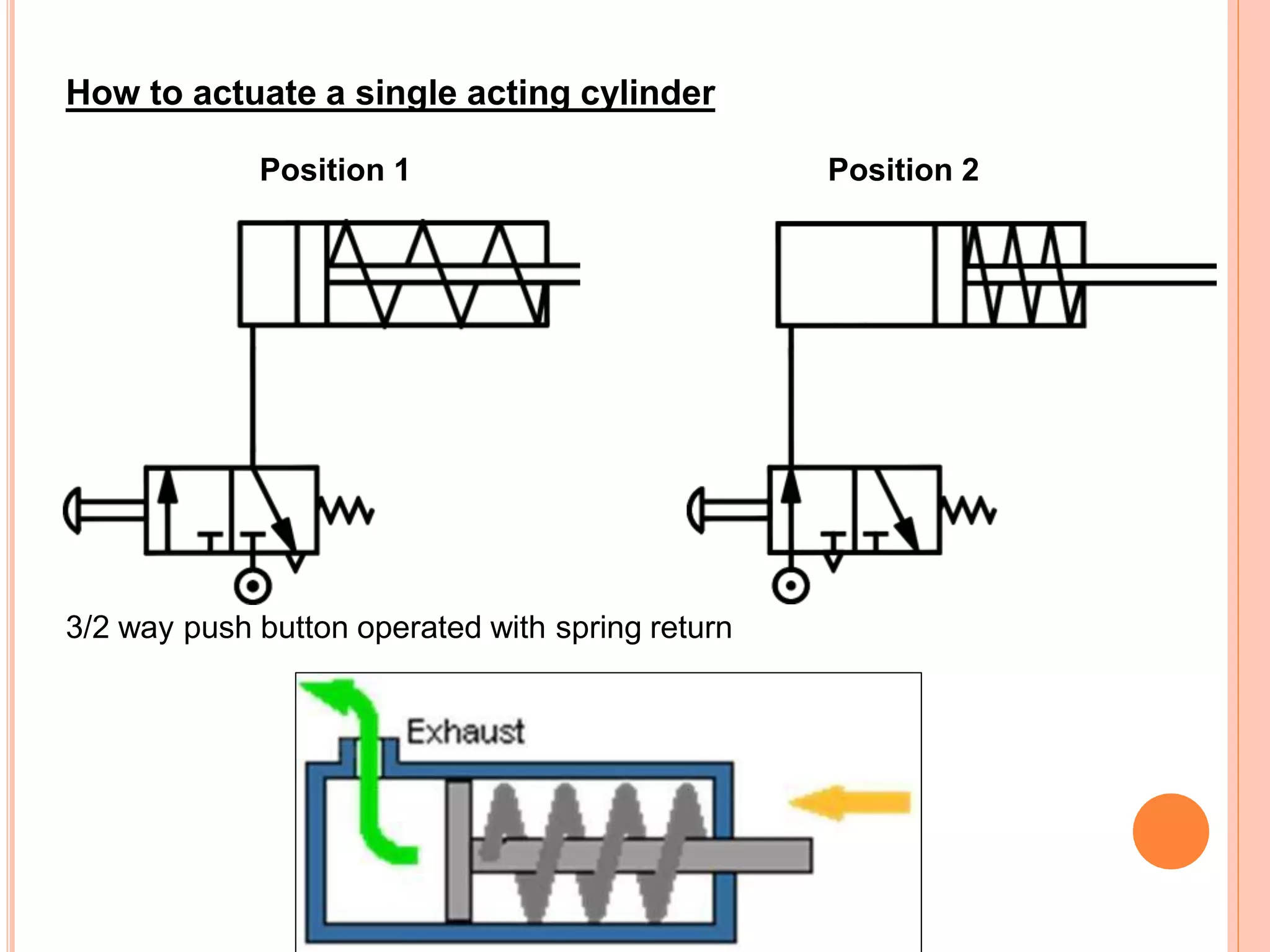

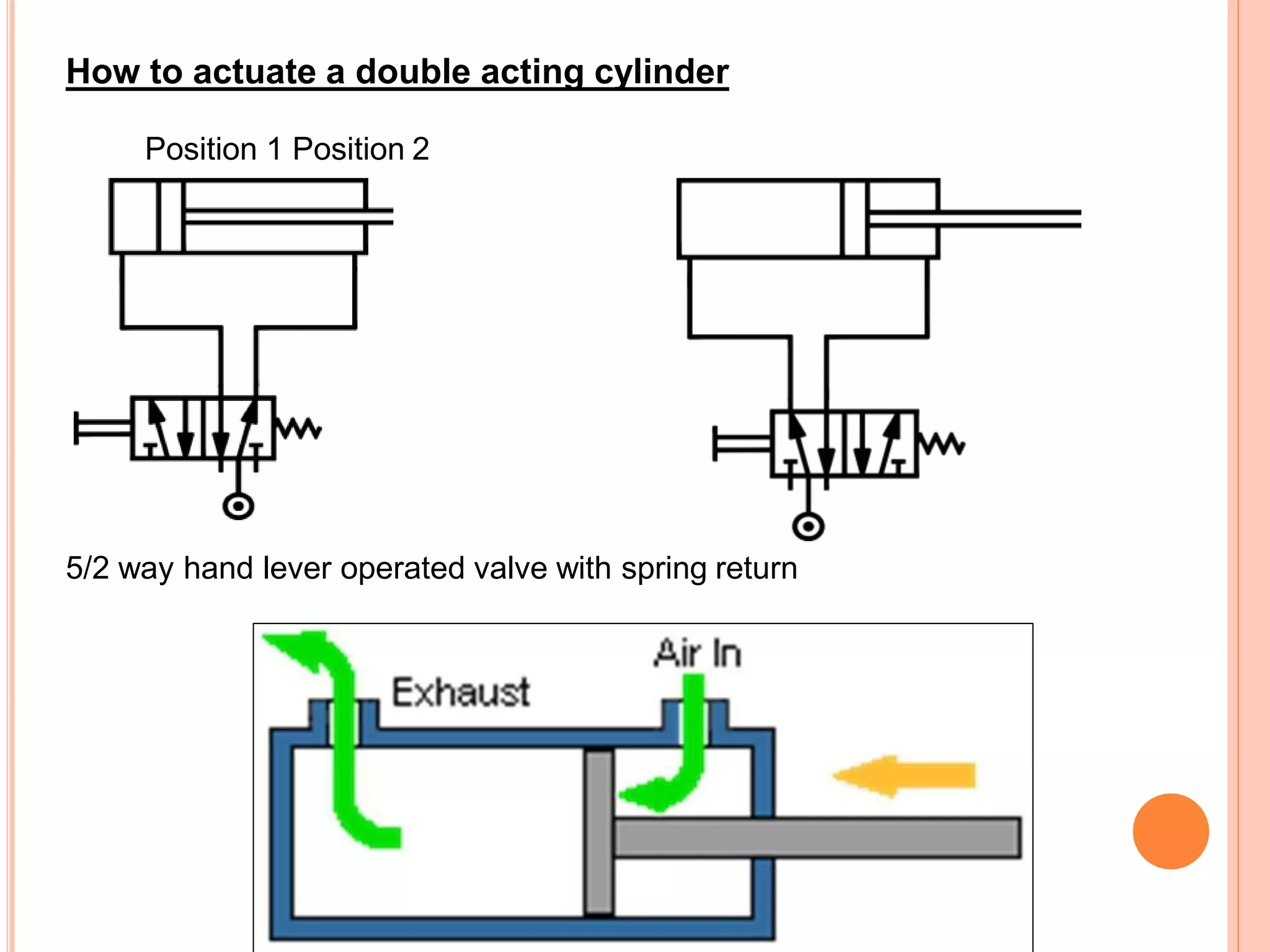

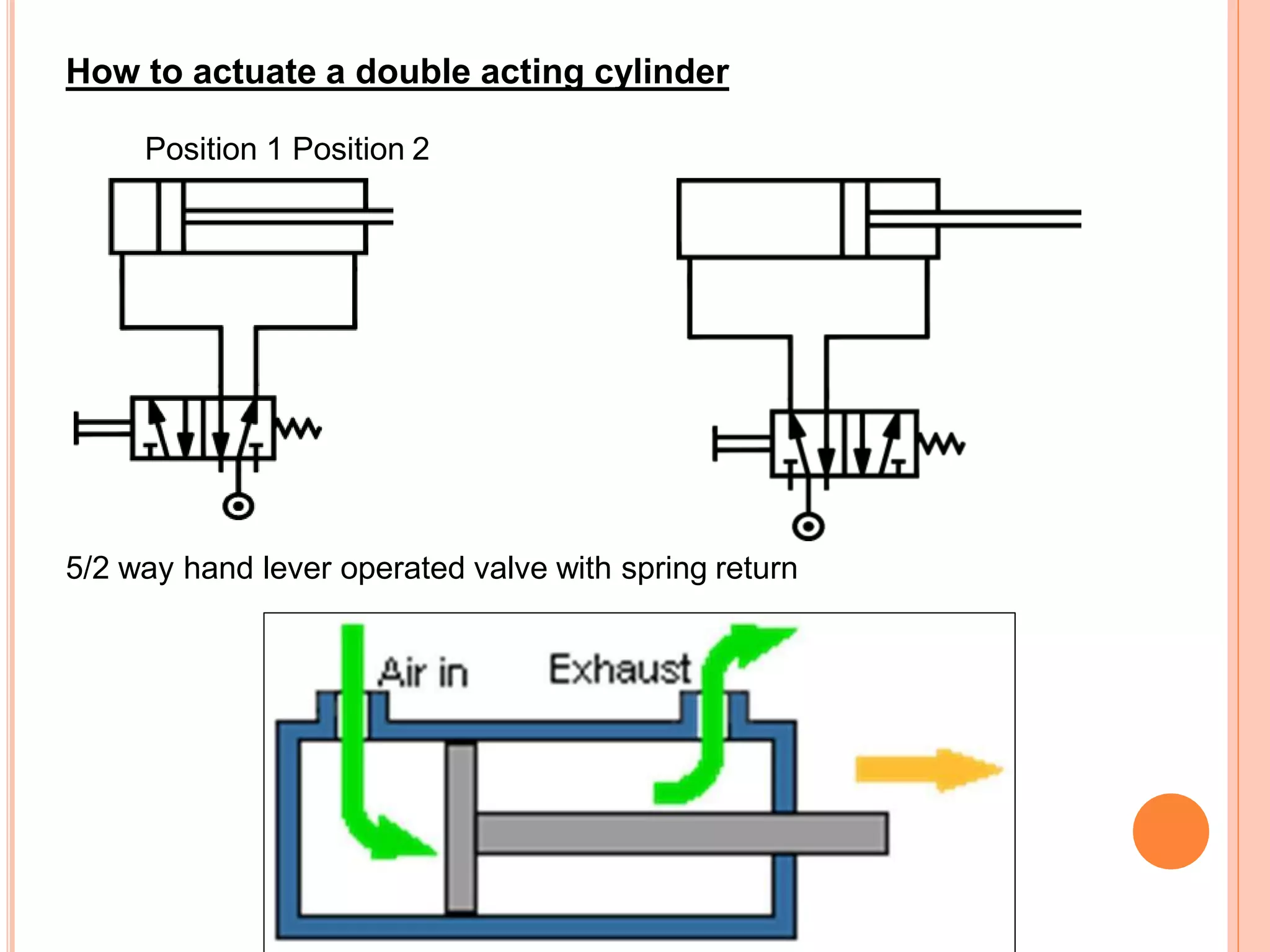

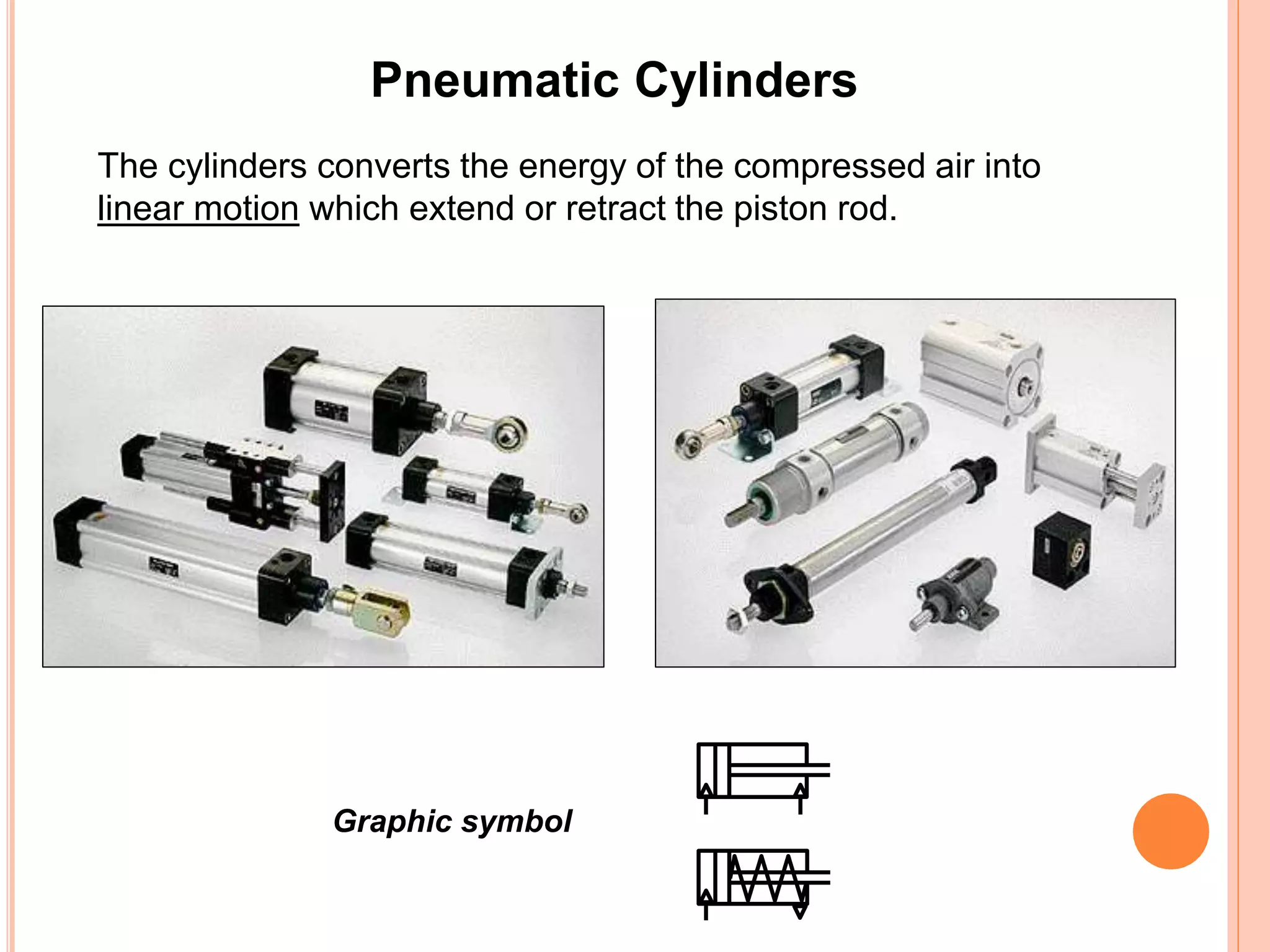

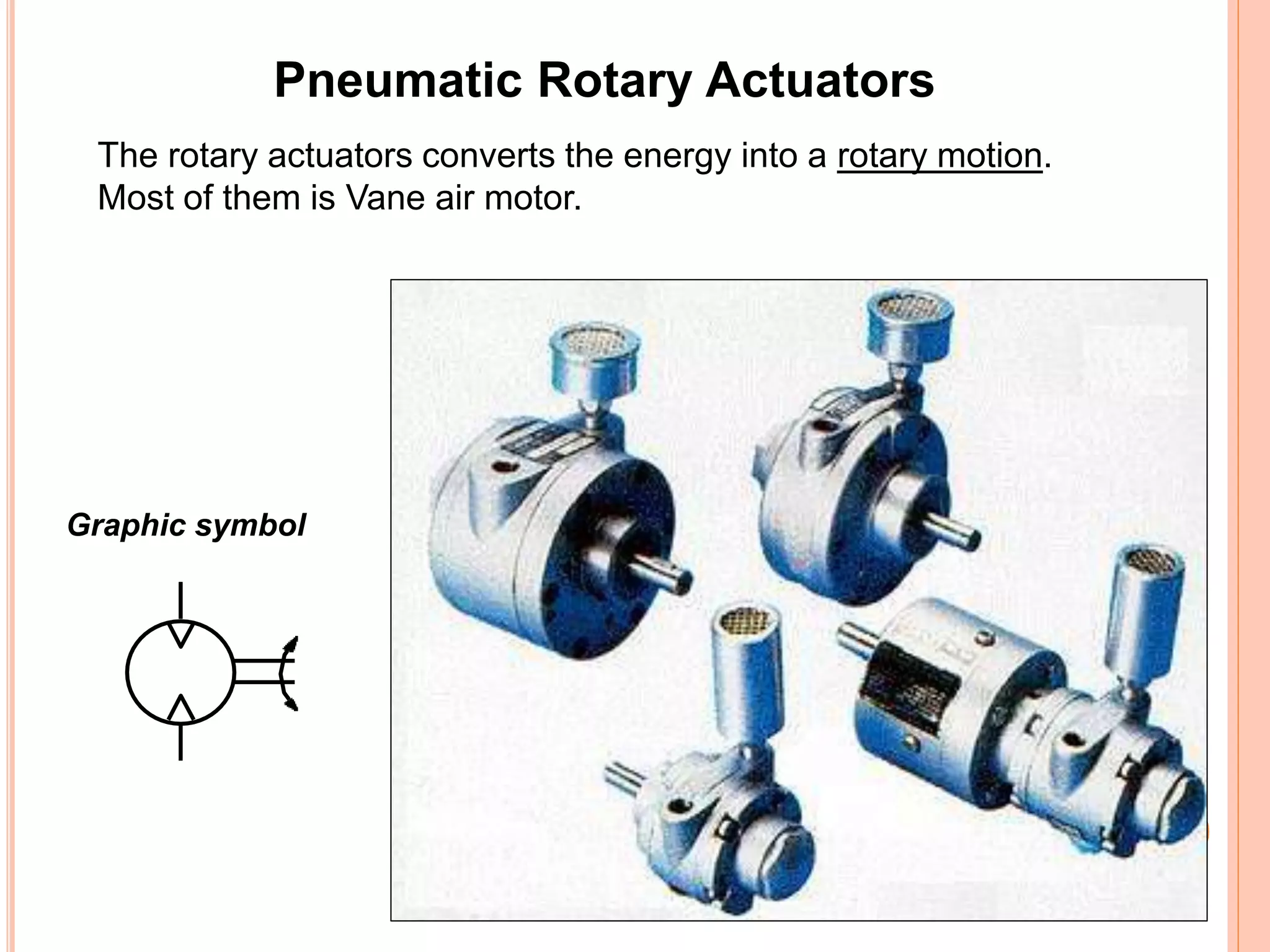

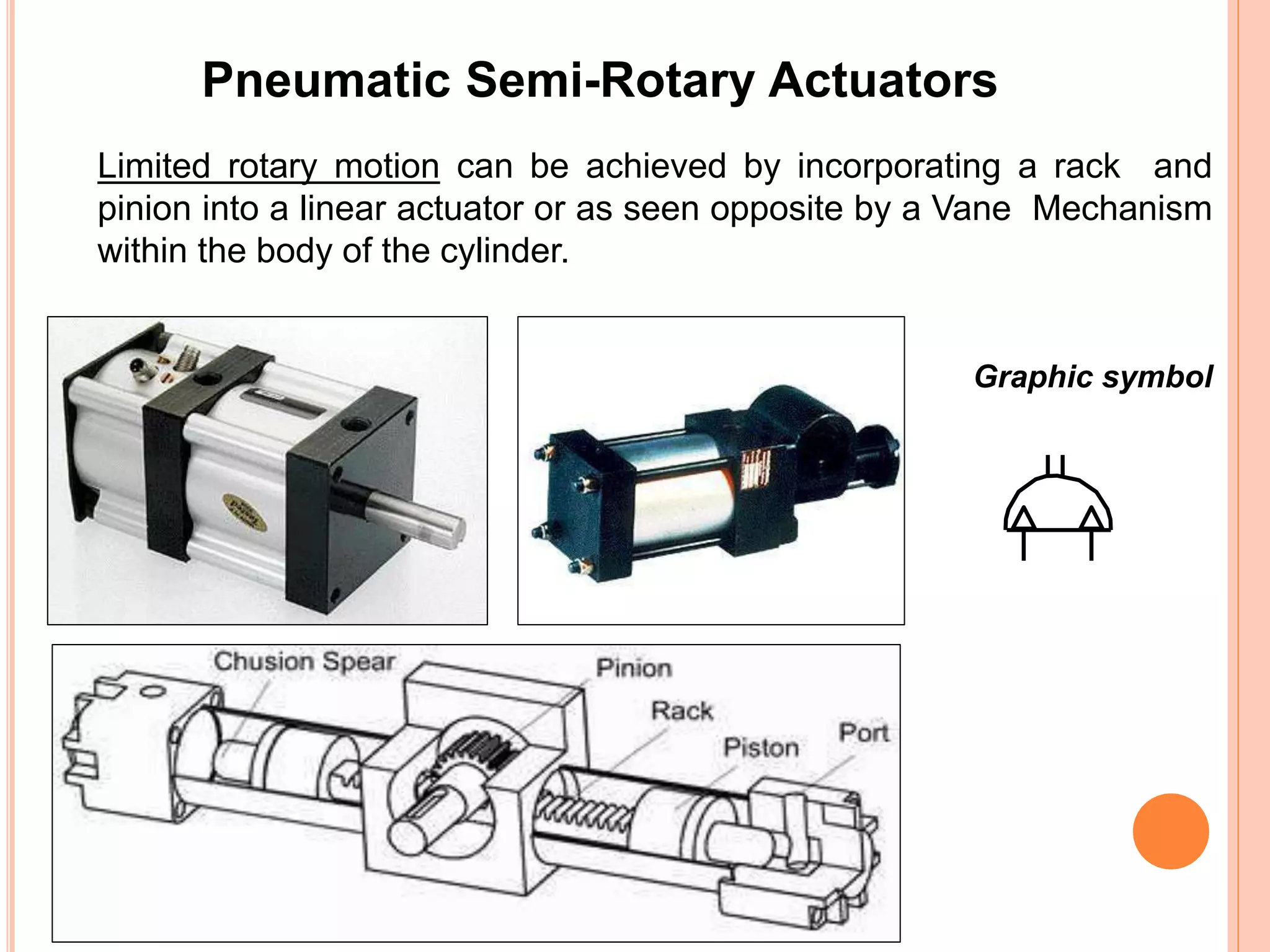

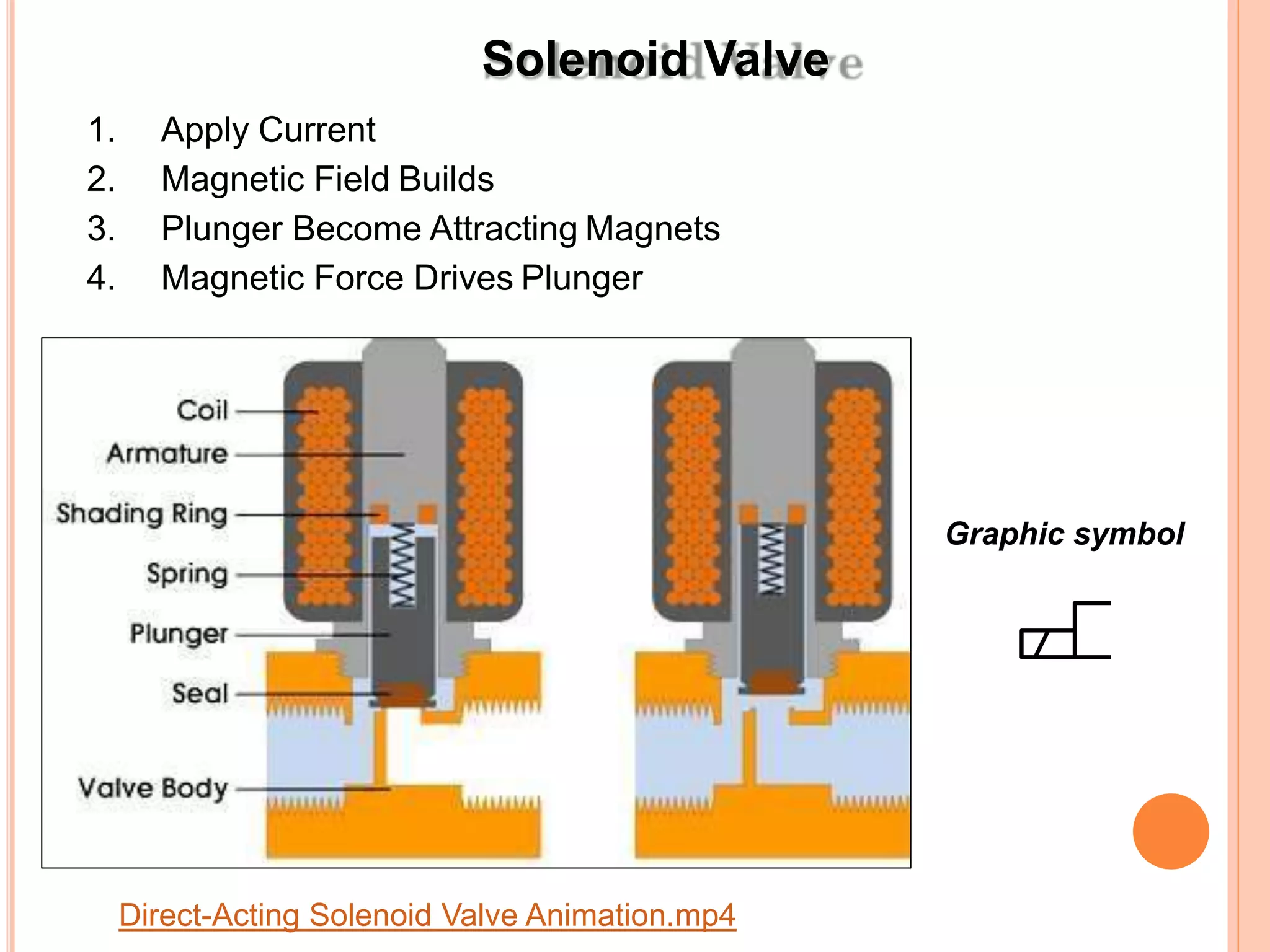

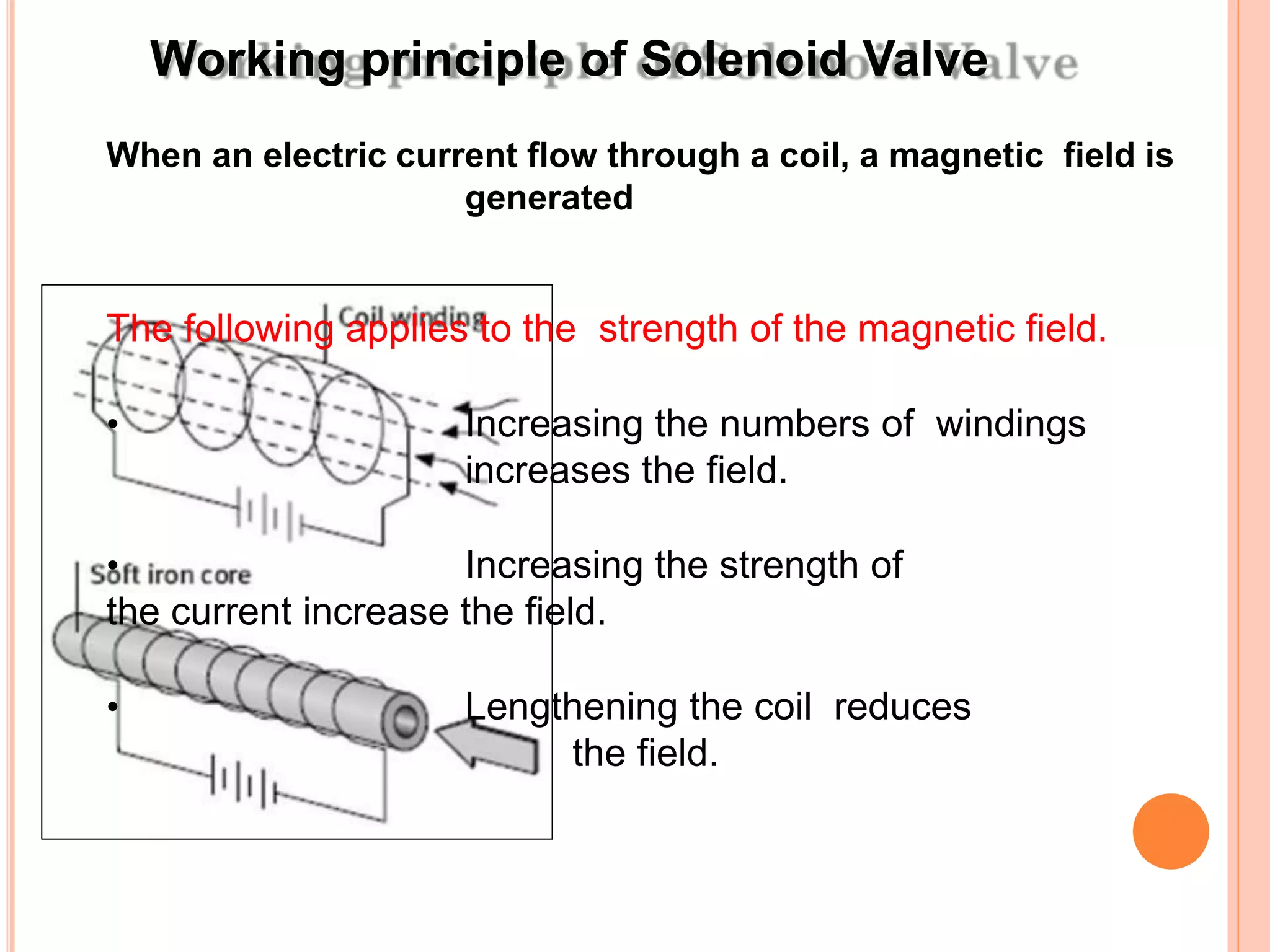

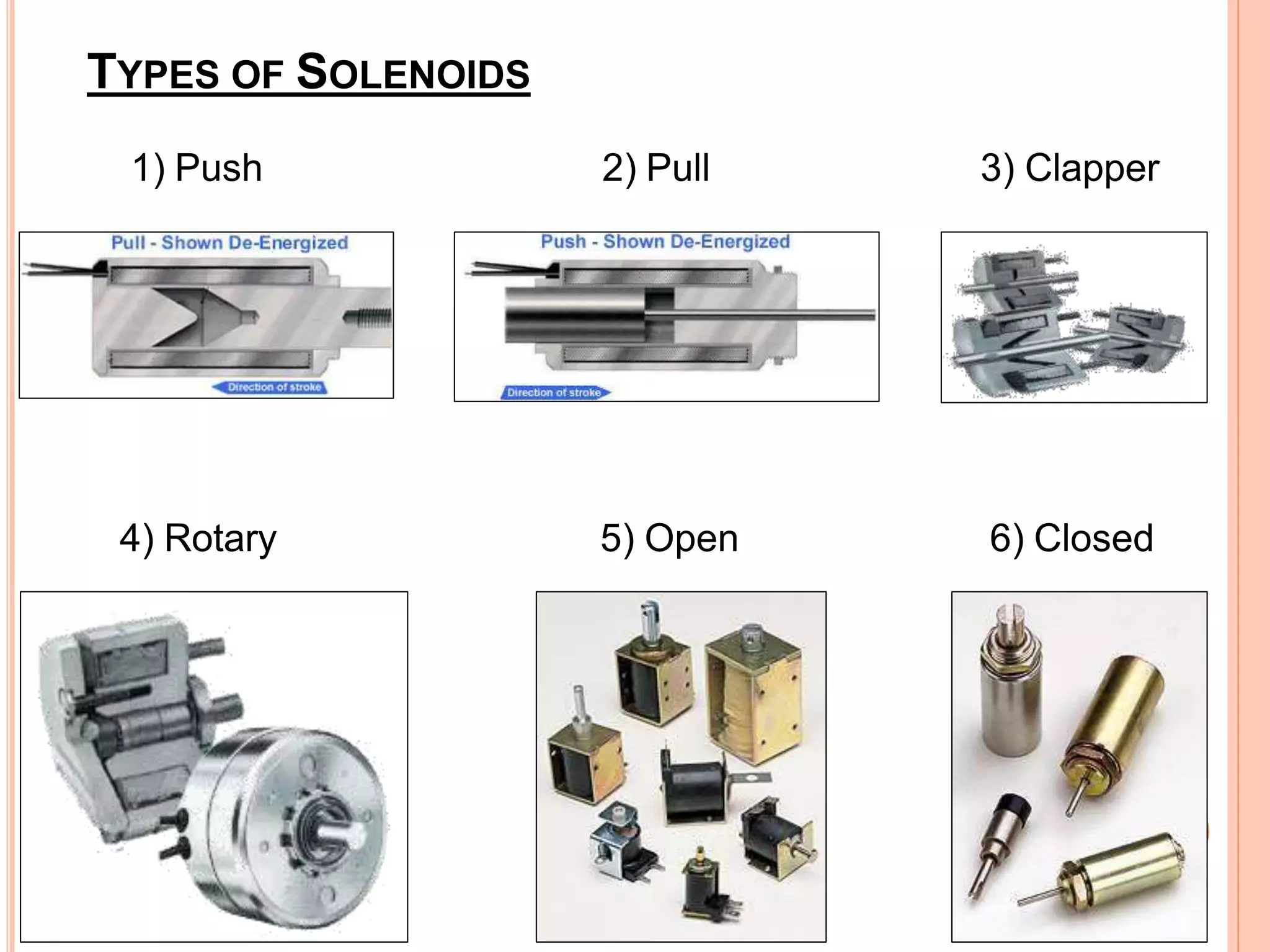

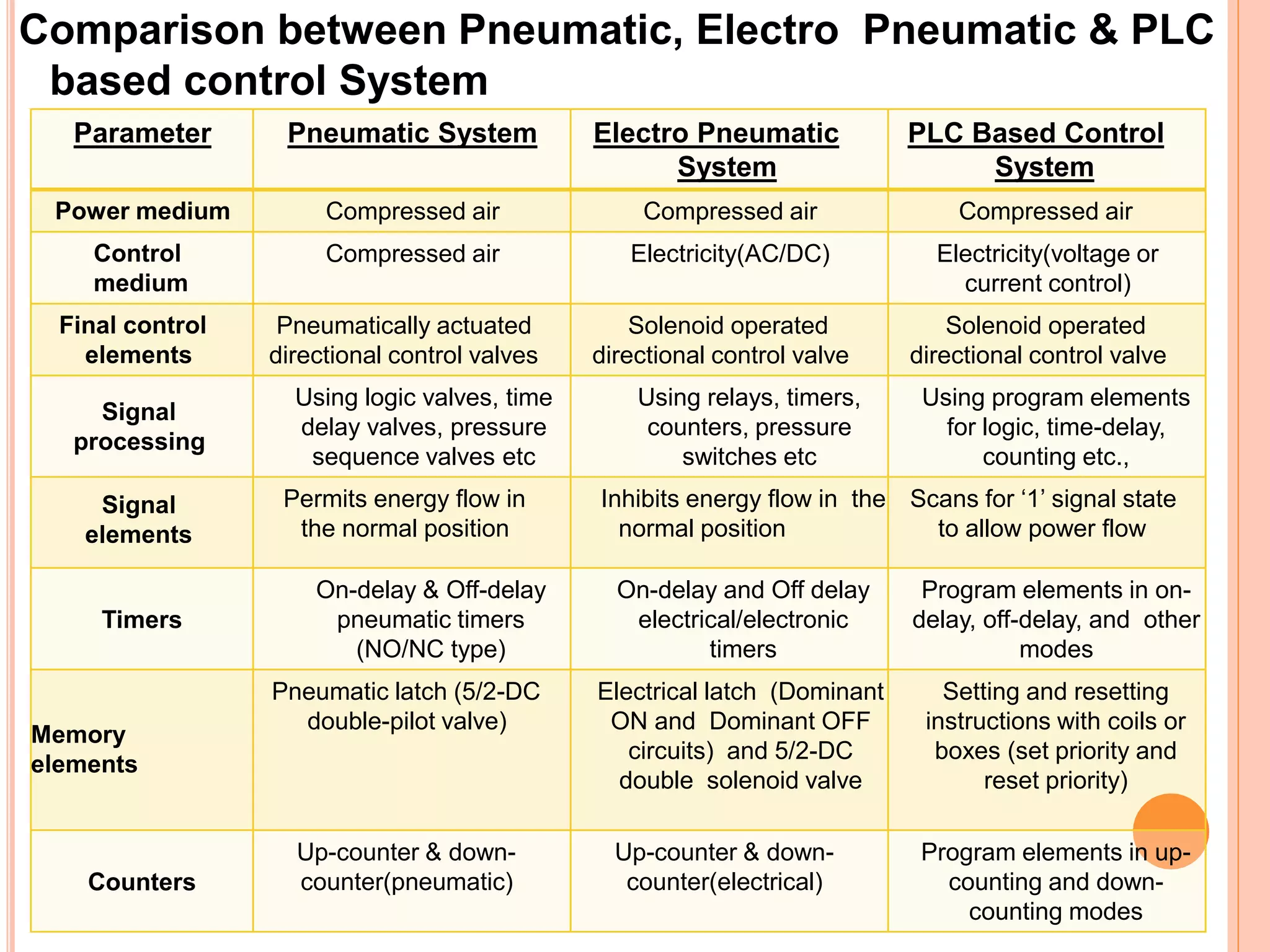

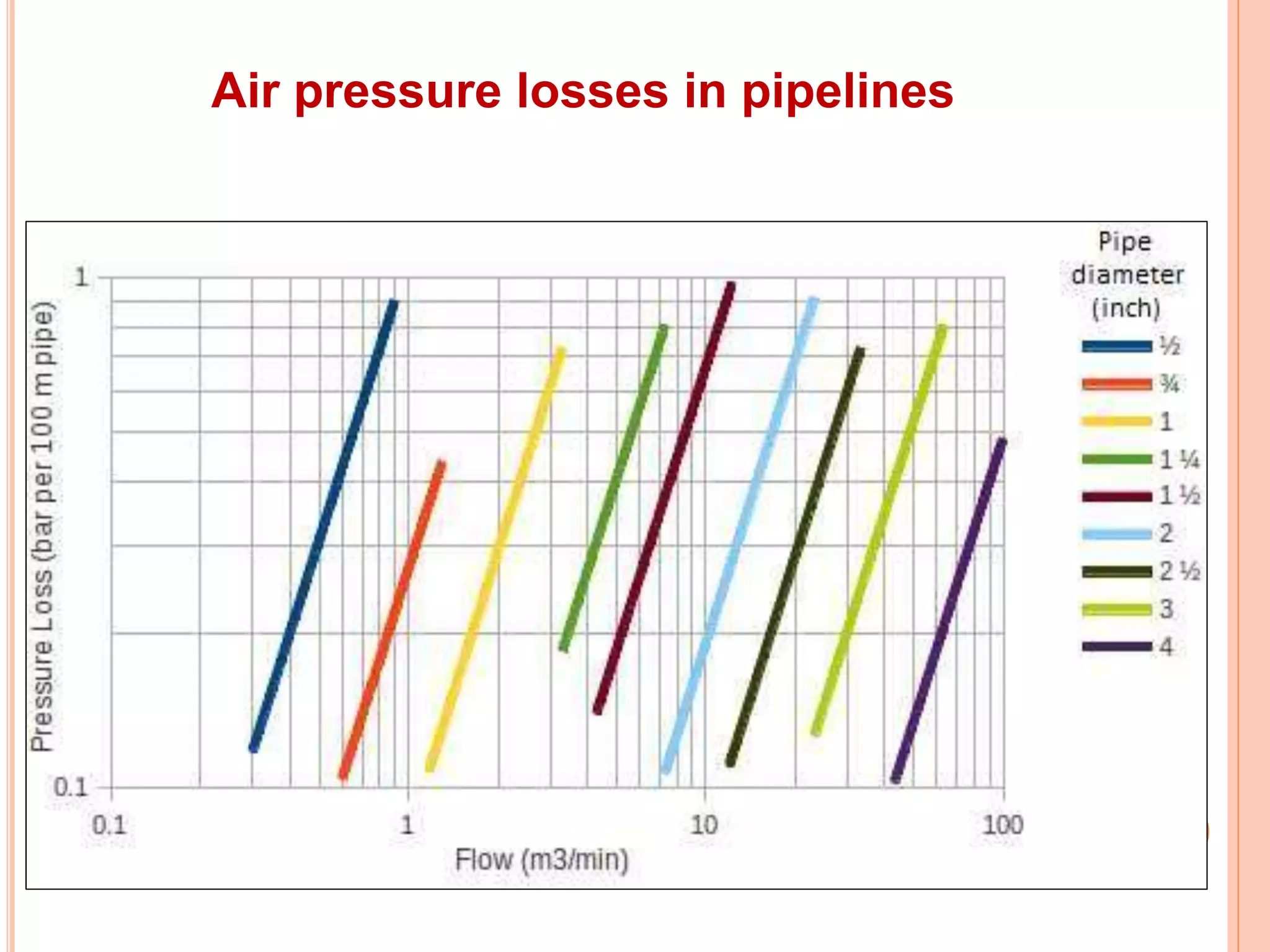

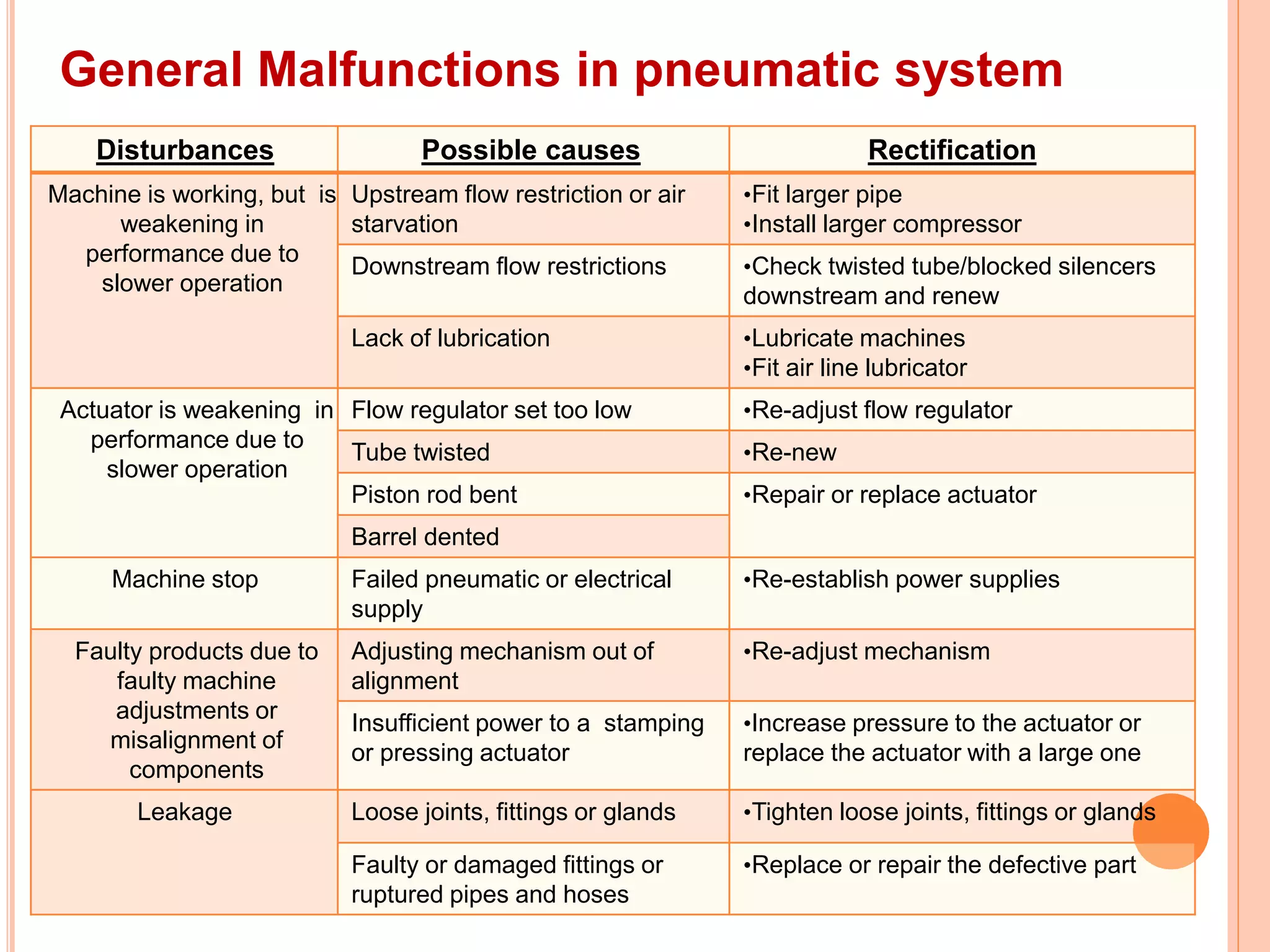

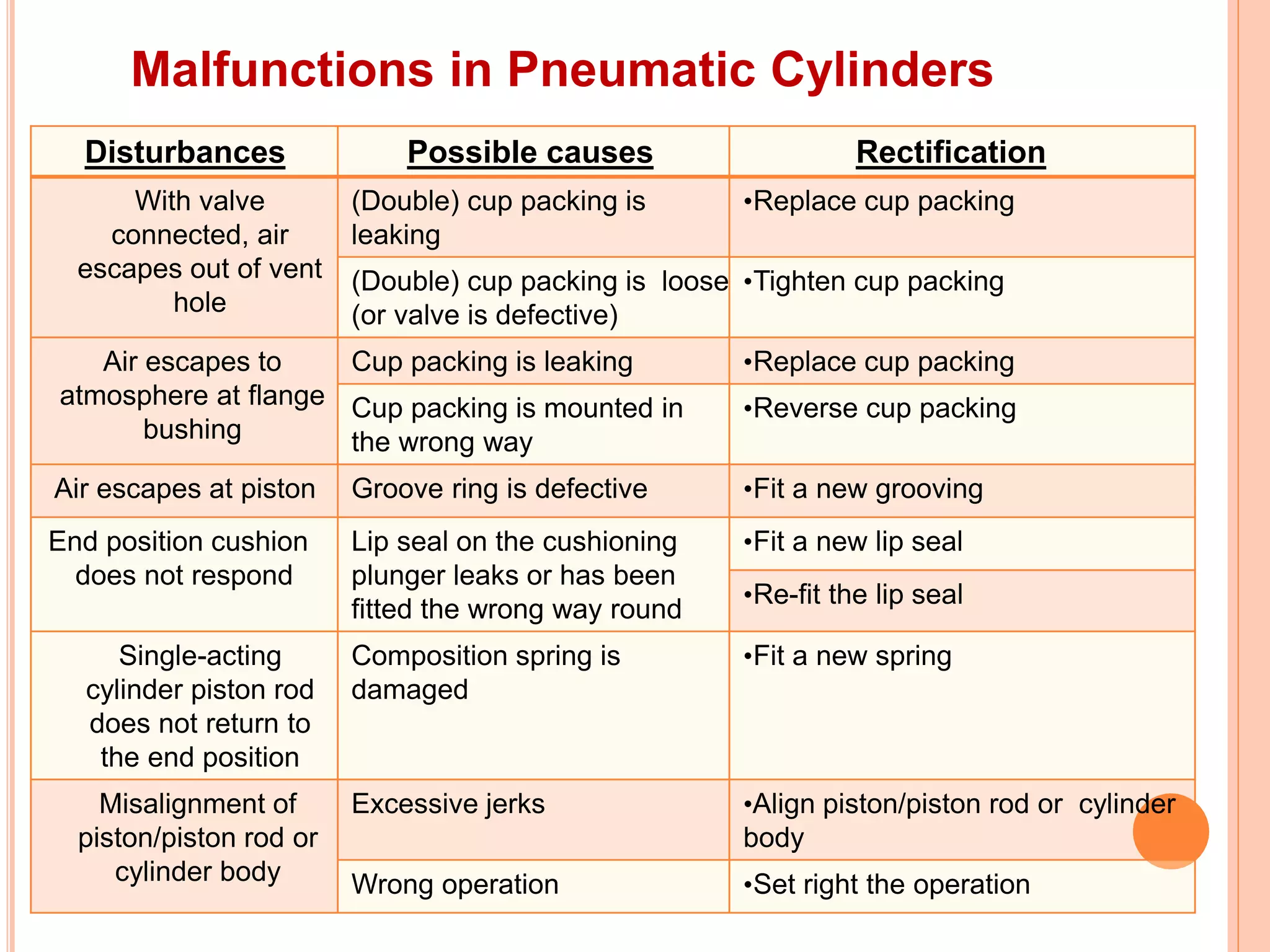

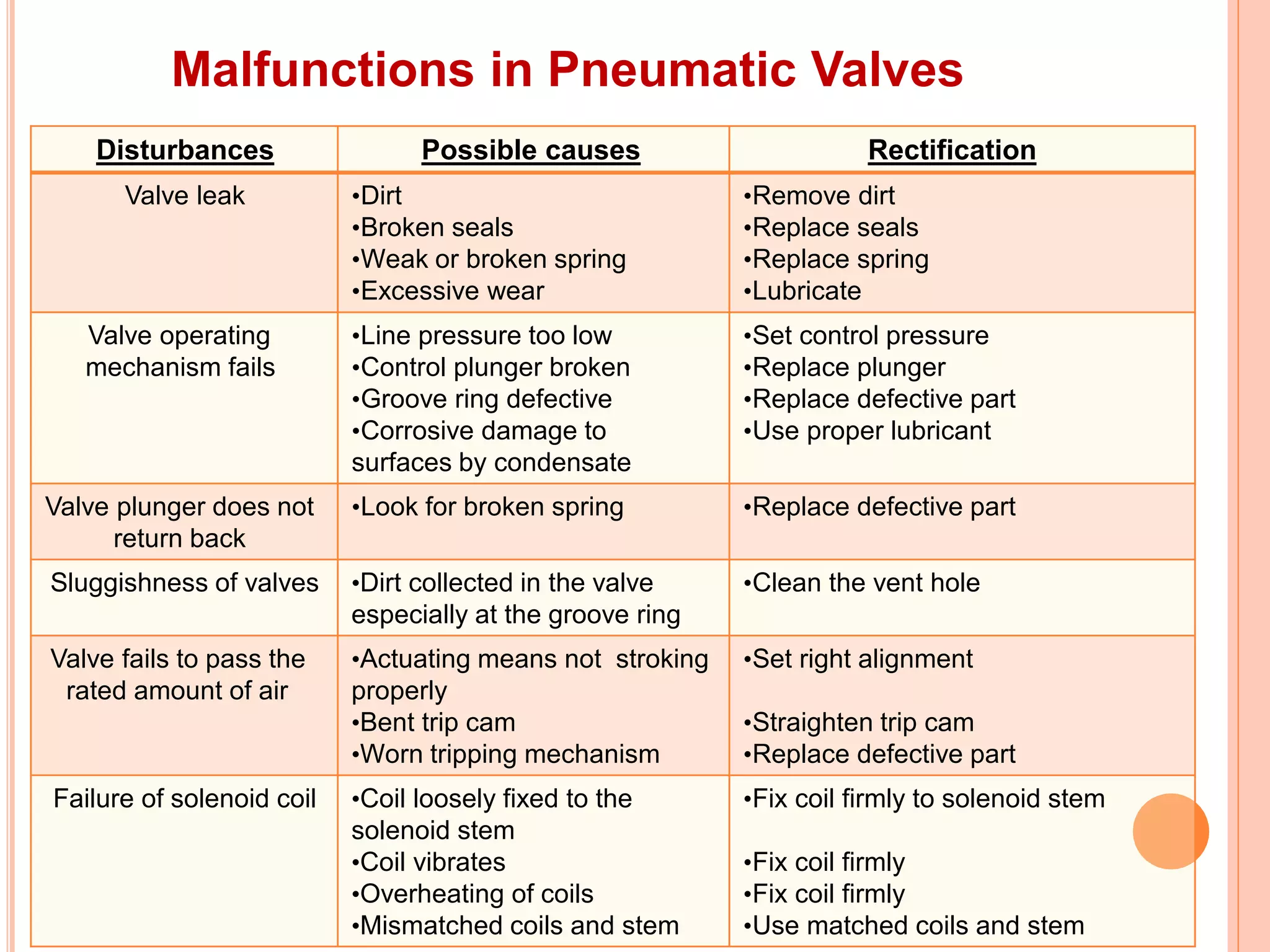

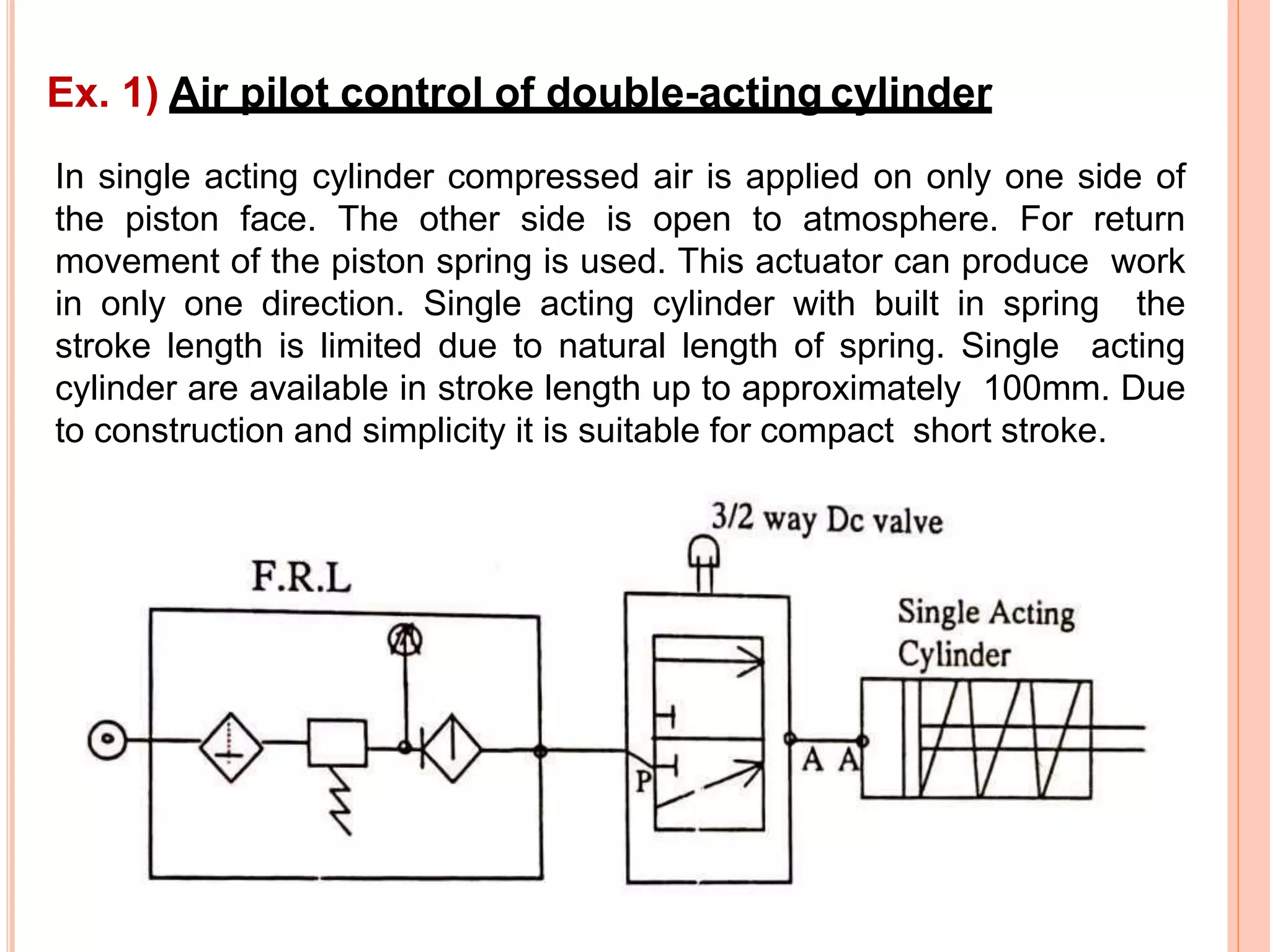

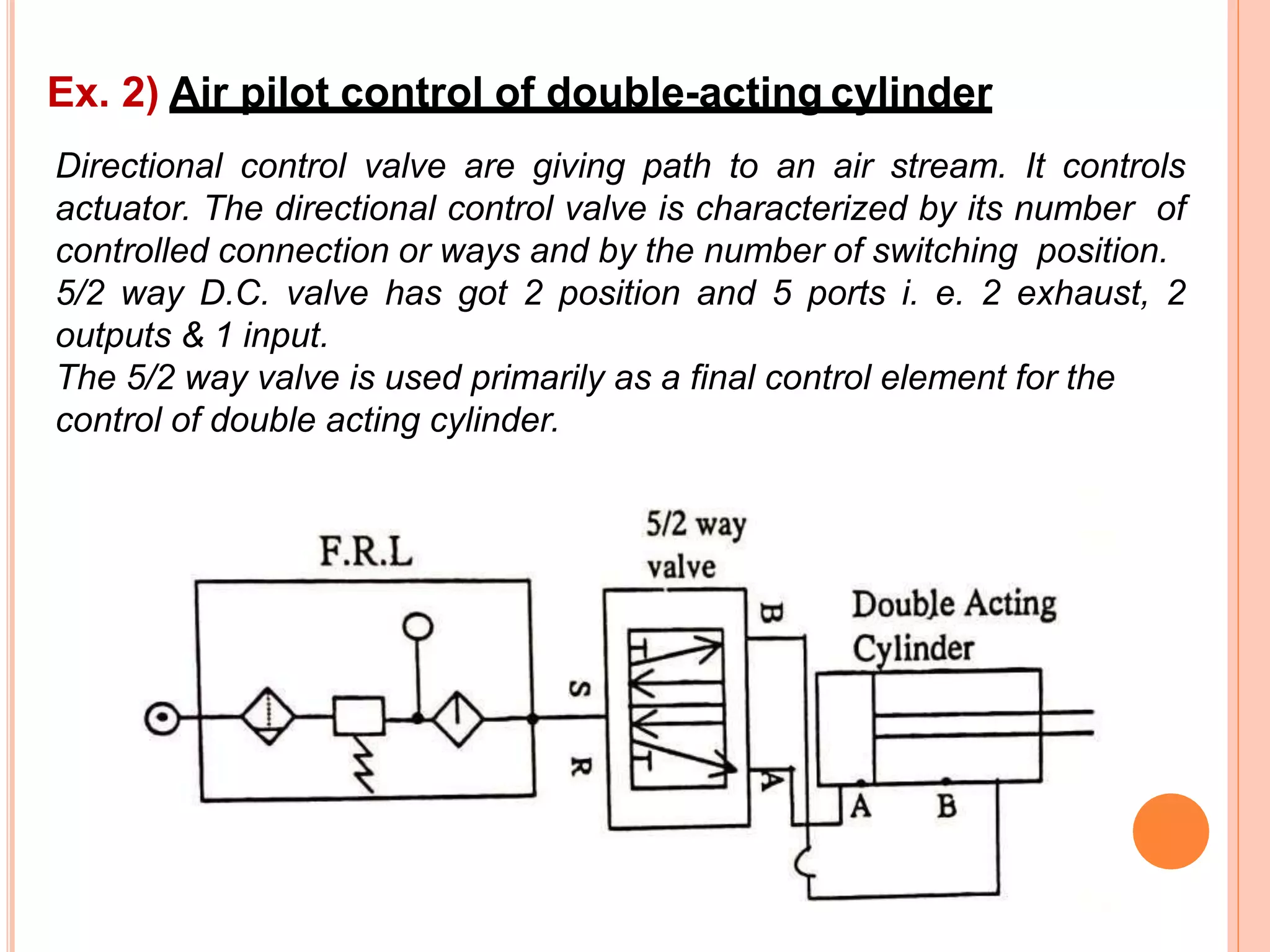

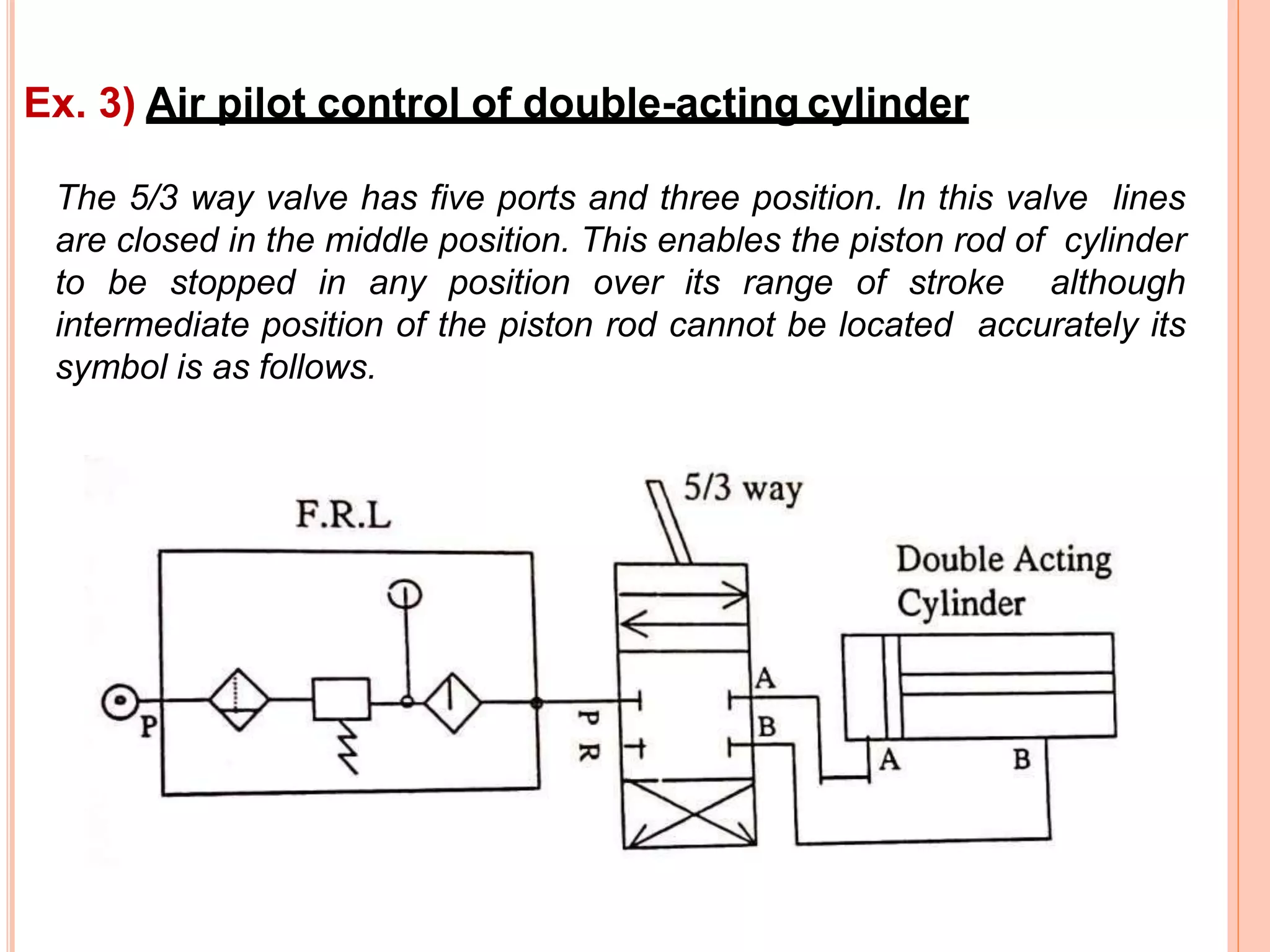

The document explains the operation and components of pneumatic actuators, highlighting the differences between single-acting and double-acting cylinders along with their control mechanisms. It details the principles of solenoid valves, various types of solenoids, as well as pneumatic and electro-pneumatic systems and their comparisons. Additionally, it addresses common malfunctions in pneumatic systems, including troubleshooting steps and emphasizes safety measures during operation.