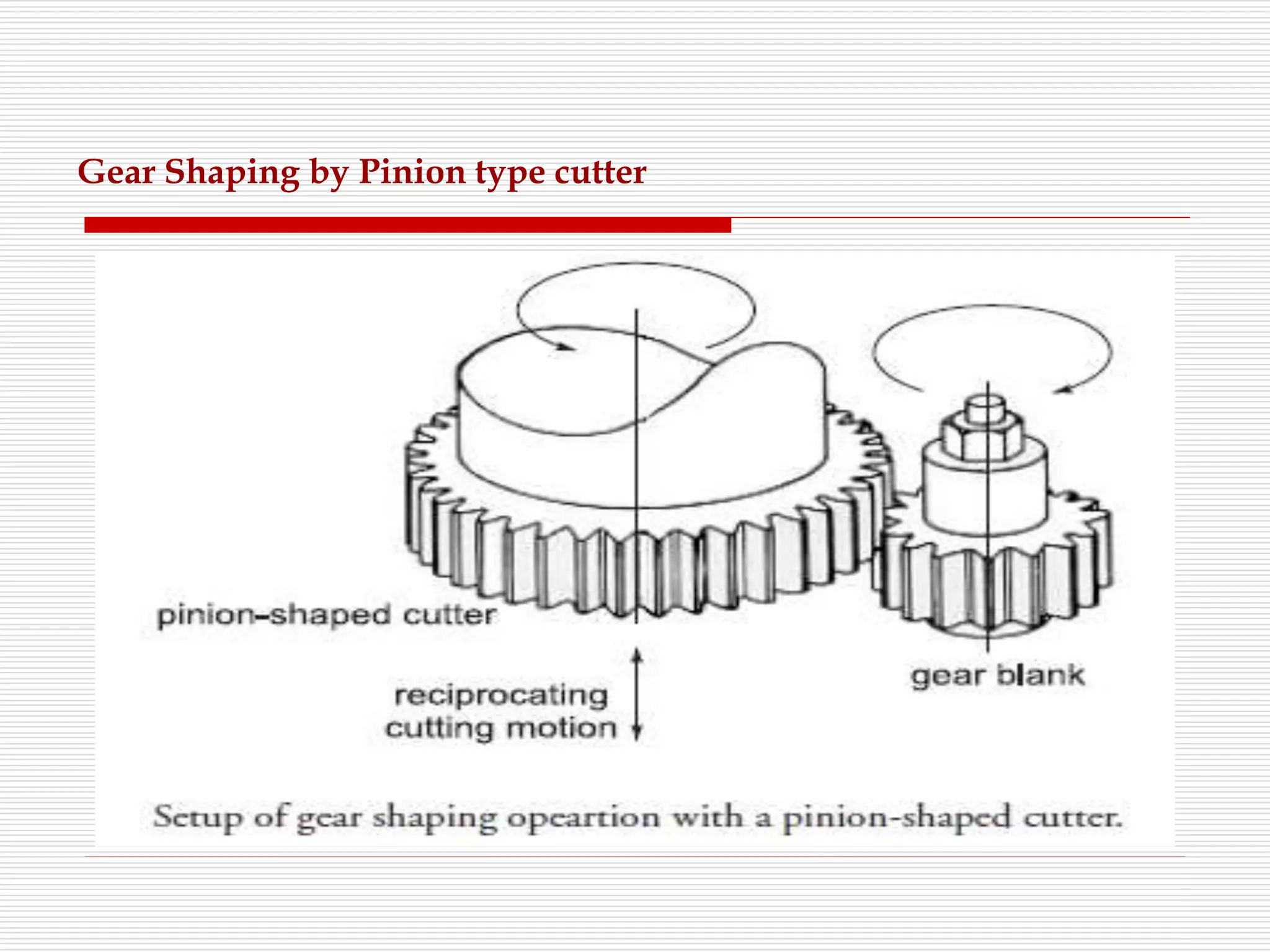

The document summarizes the gear shaping process. Gear shaping uses a cutting tool shaped like a gear that reciprocates axially across a gear blank to cut the teeth while the blank rotates. The gear-shaped tool cuts itself into mesh with the blank. Gear shaping can produce spur, helical, rack, and internal gears using different types of cutters. It provides good accuracy for medium and batch production of gears. However, its production rate is lower than gear hobbing.