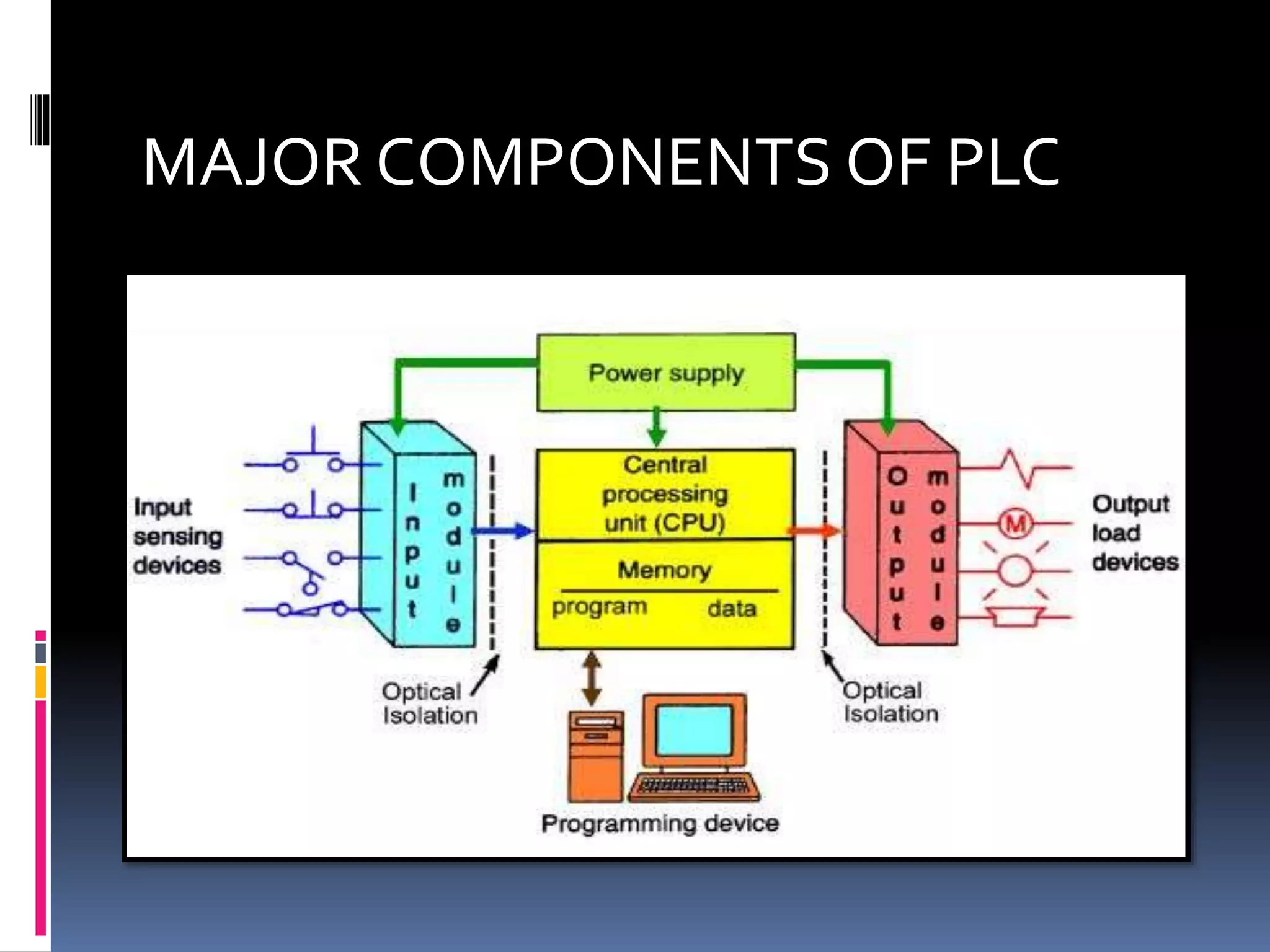

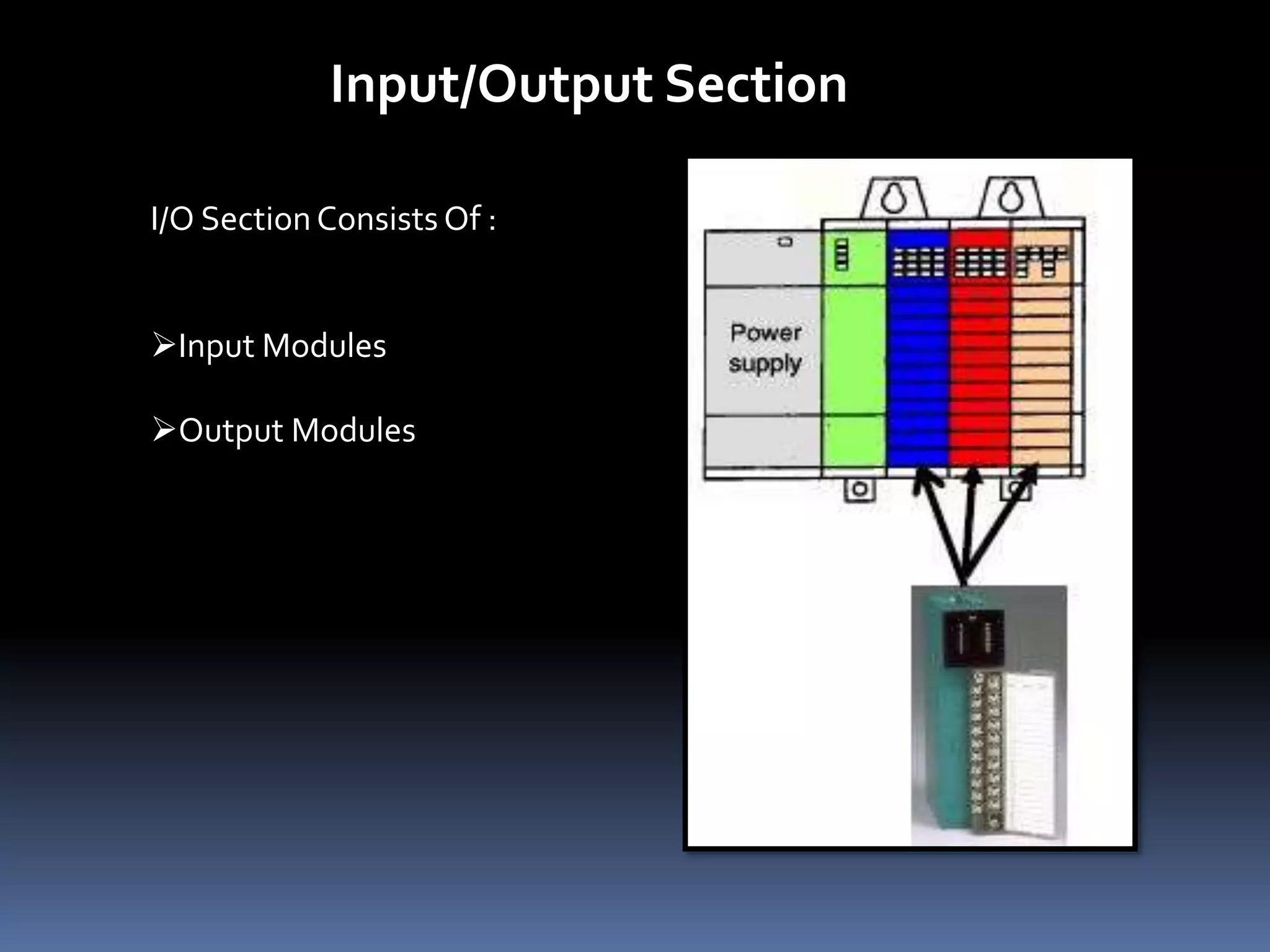

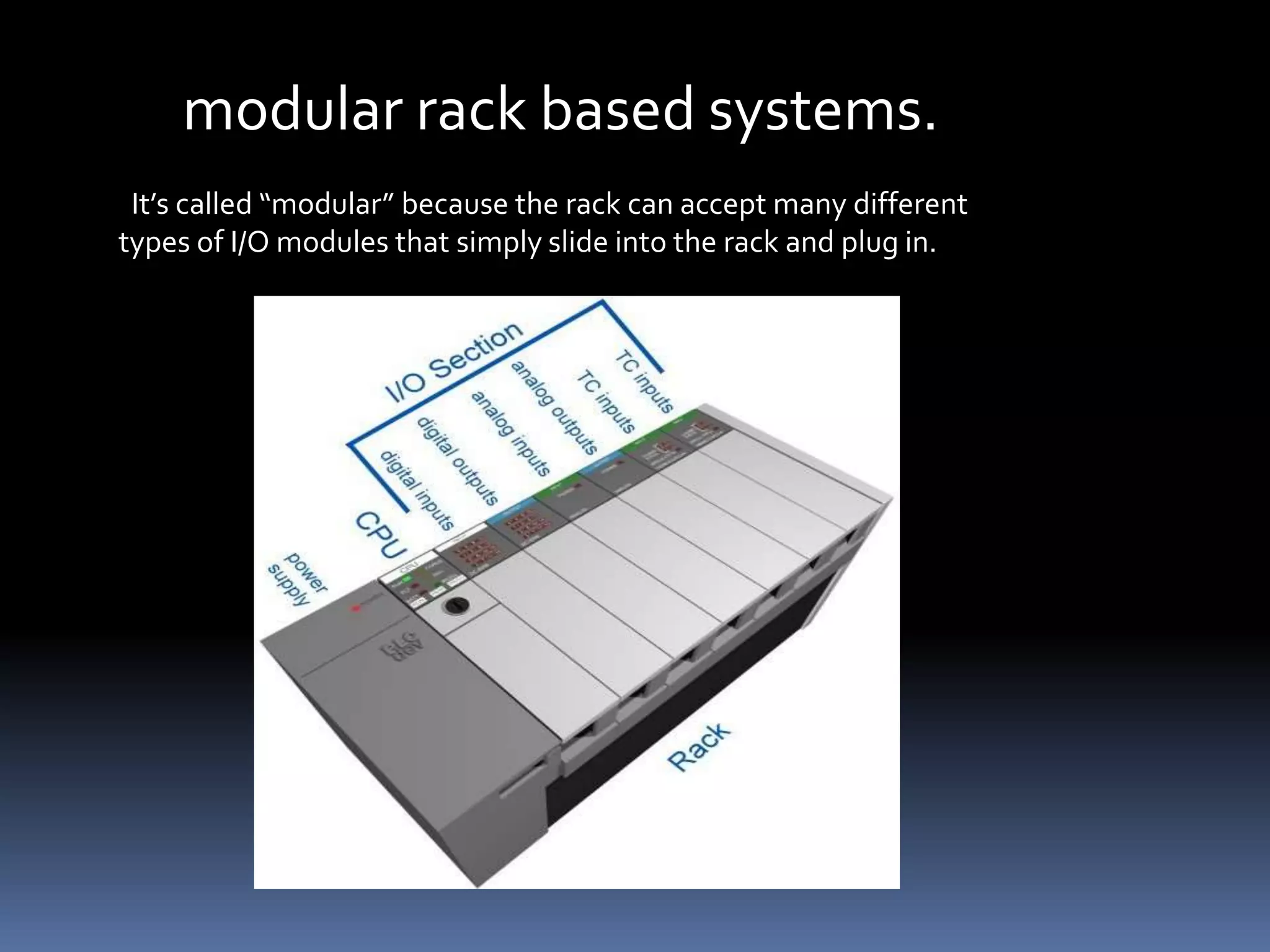

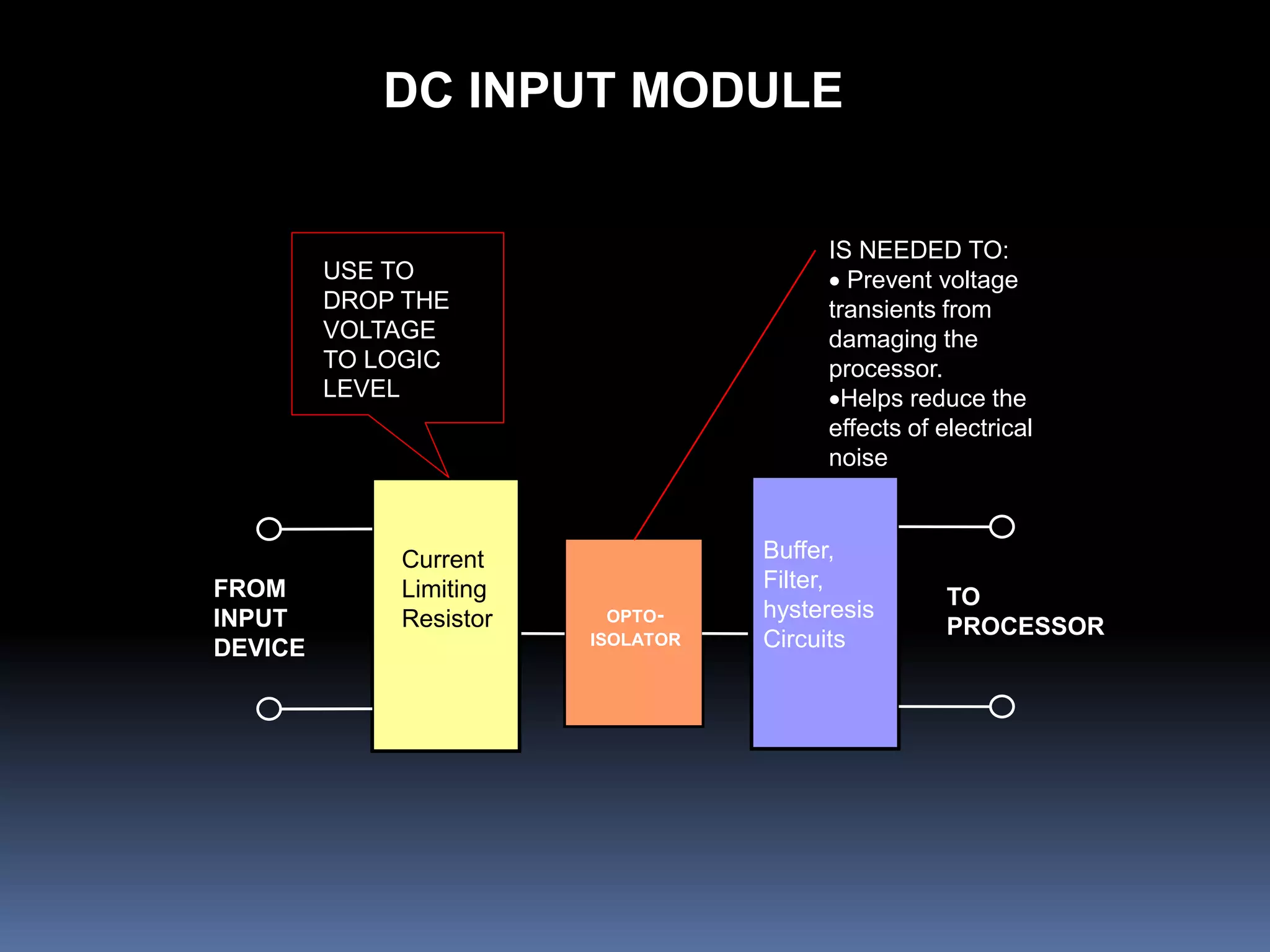

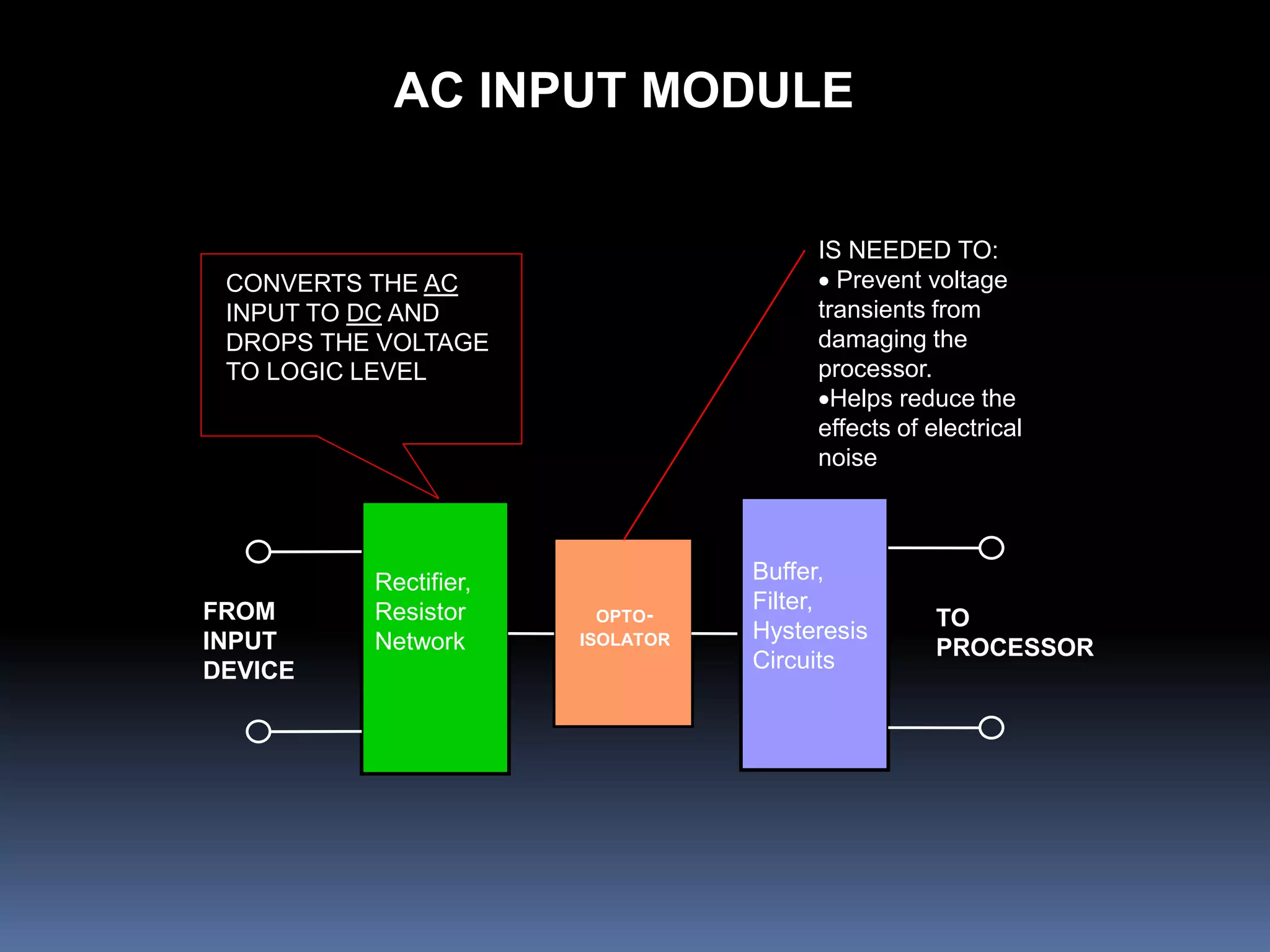

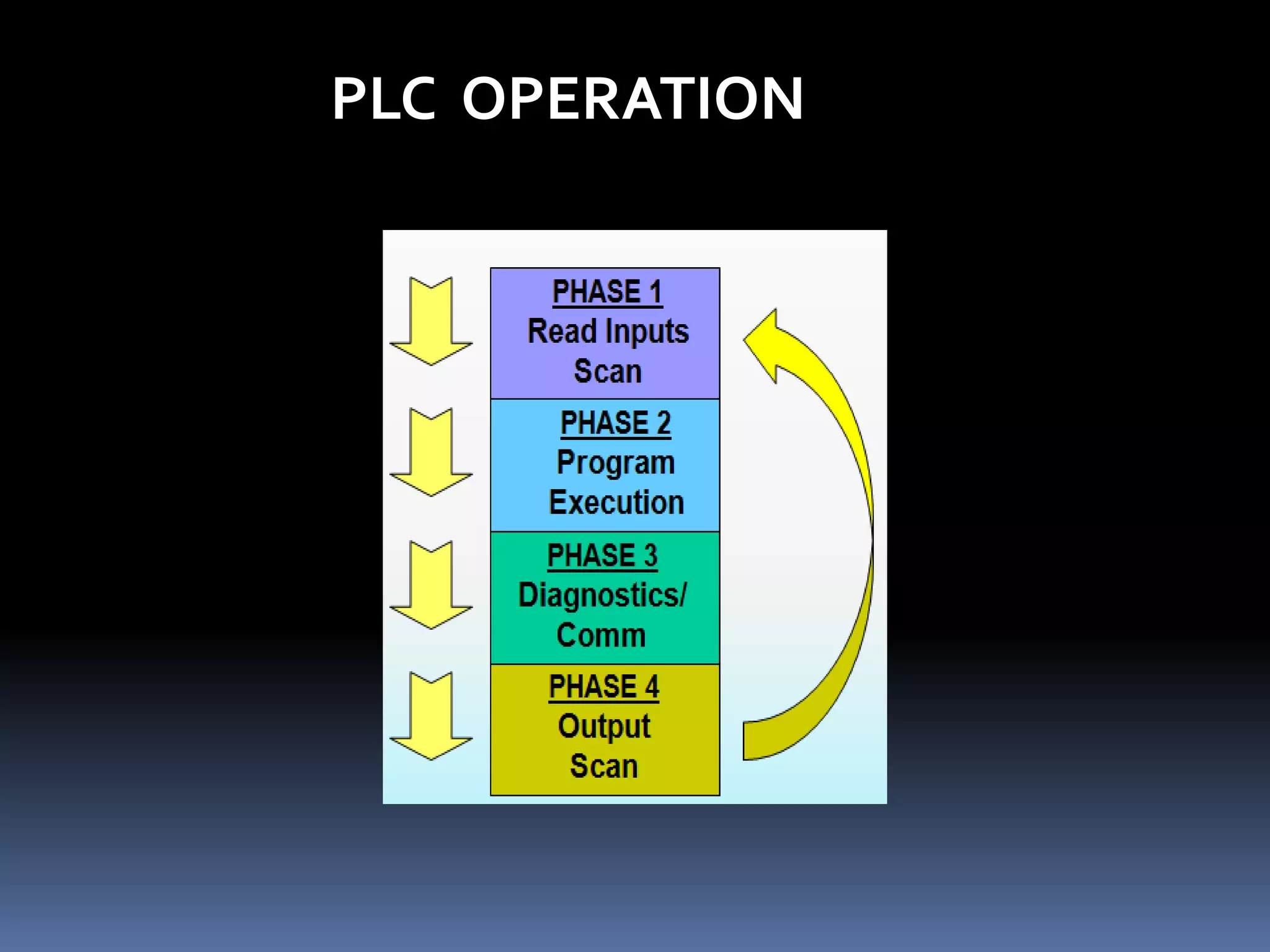

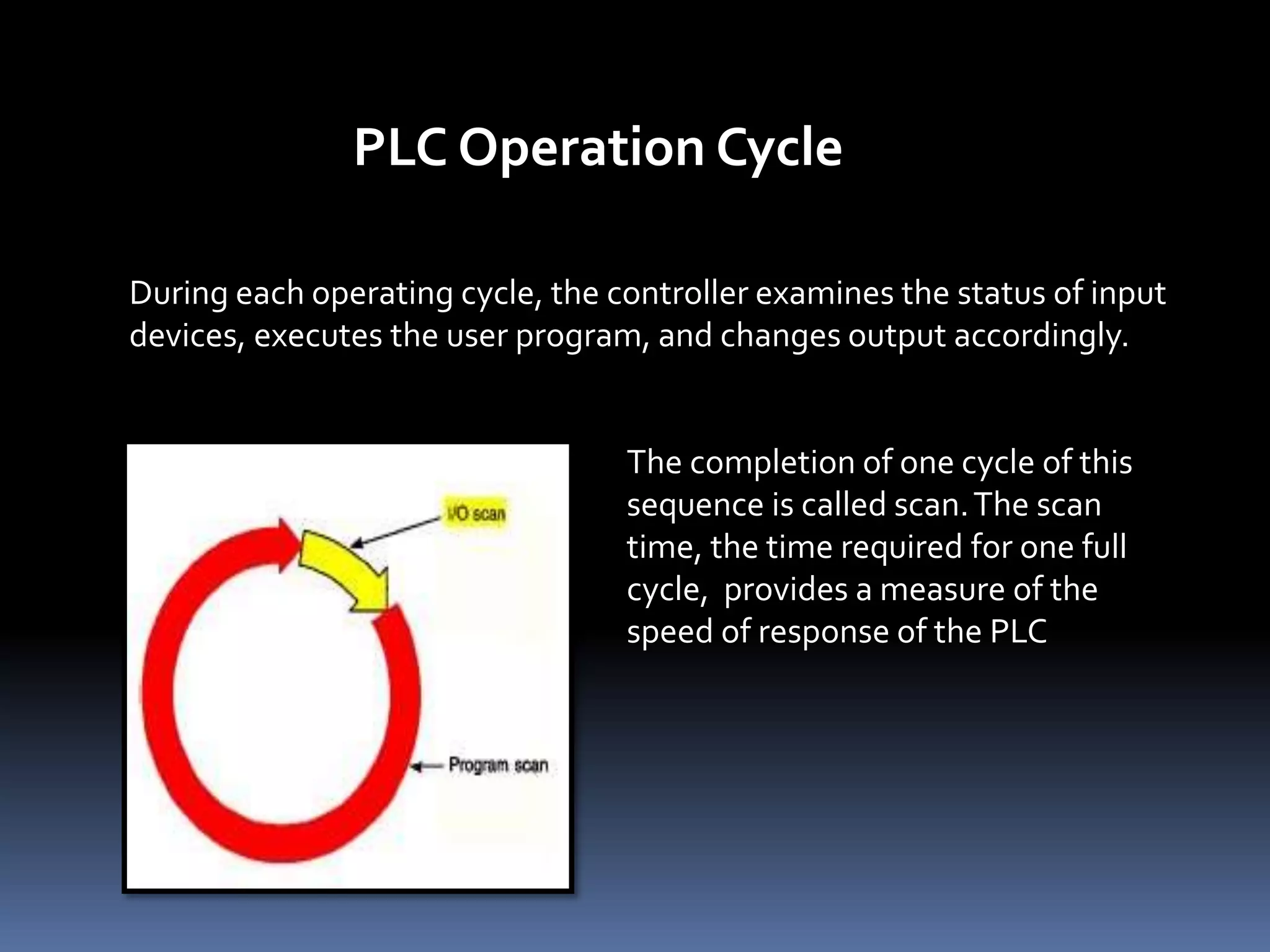

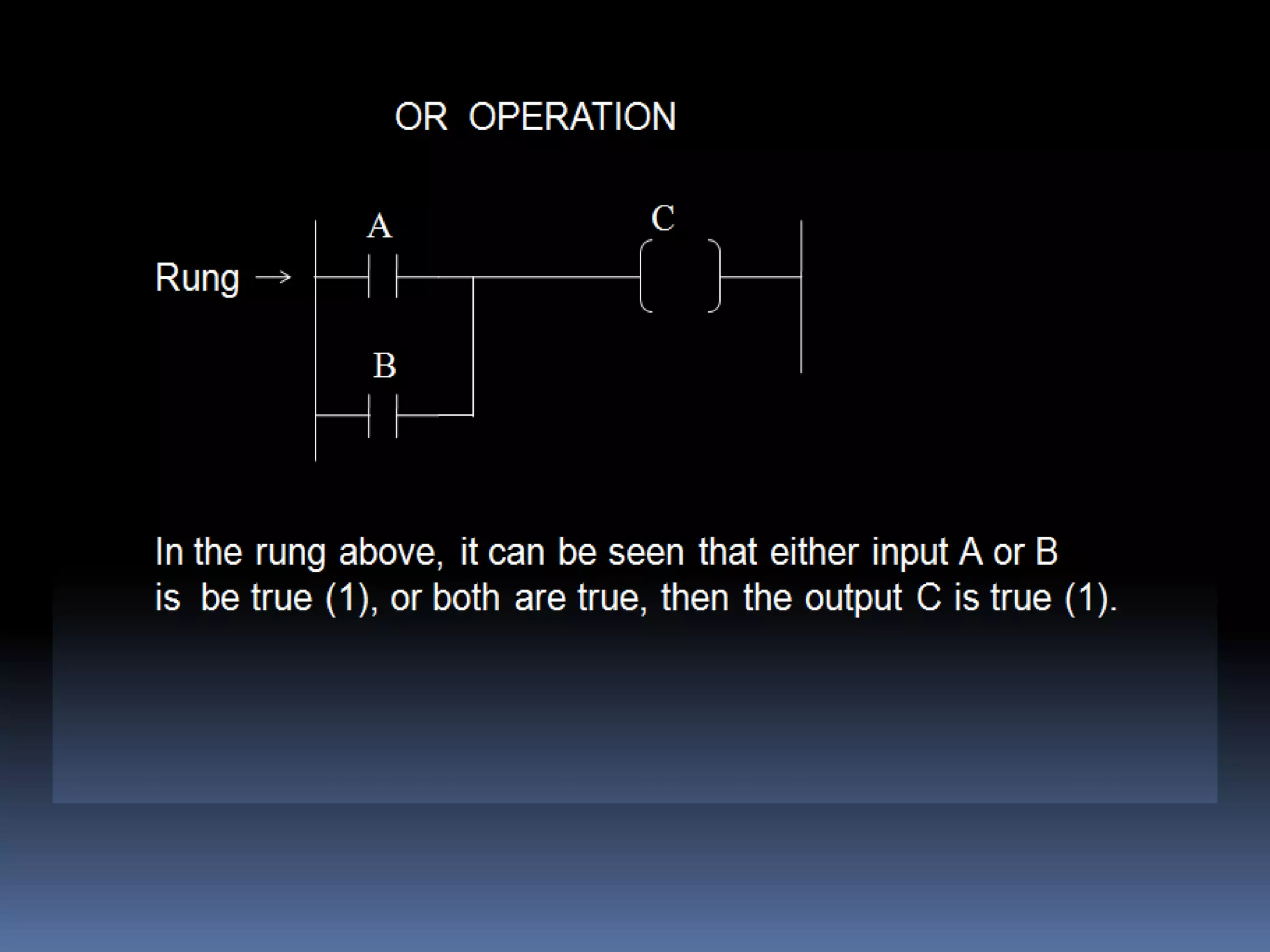

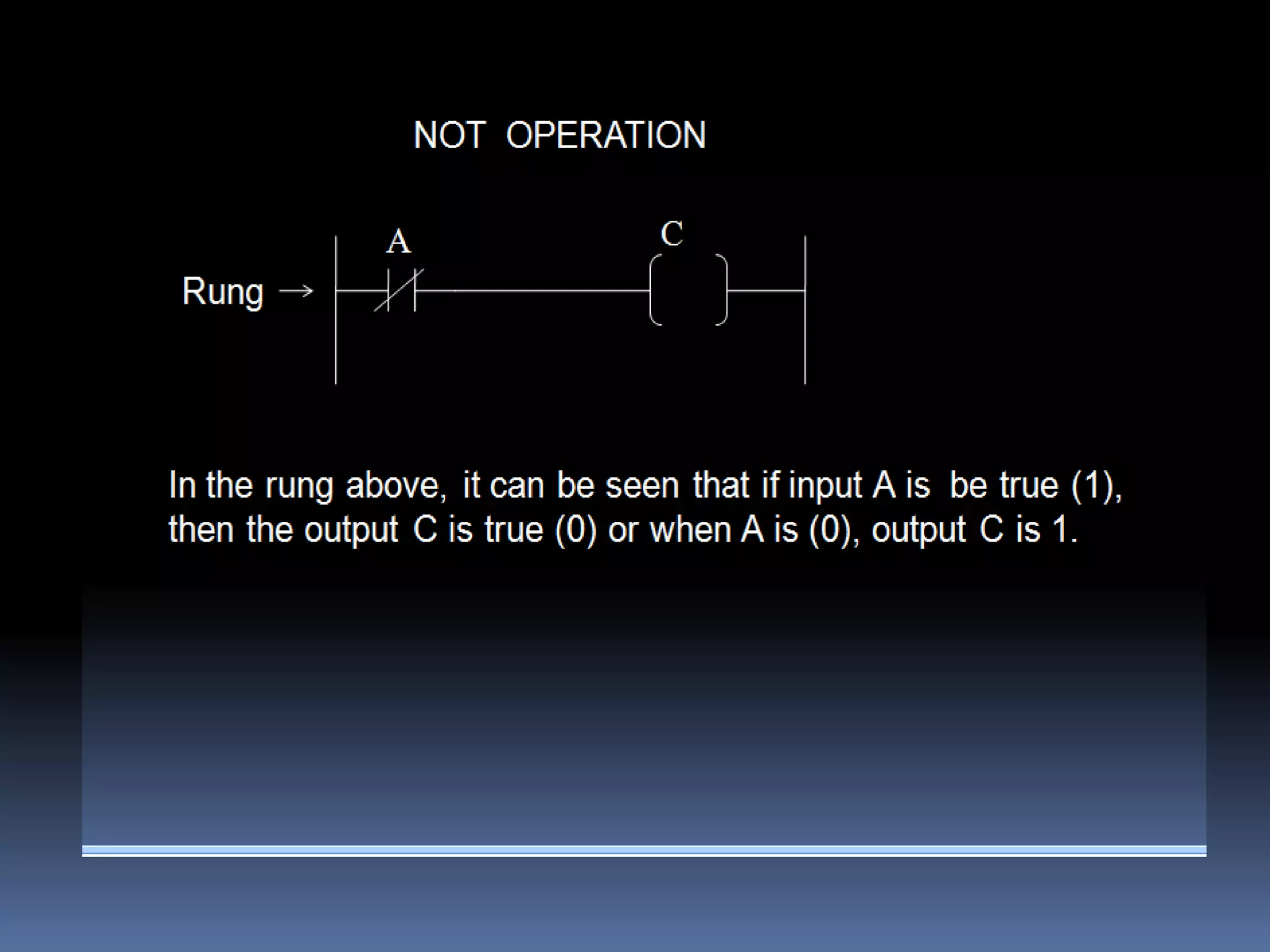

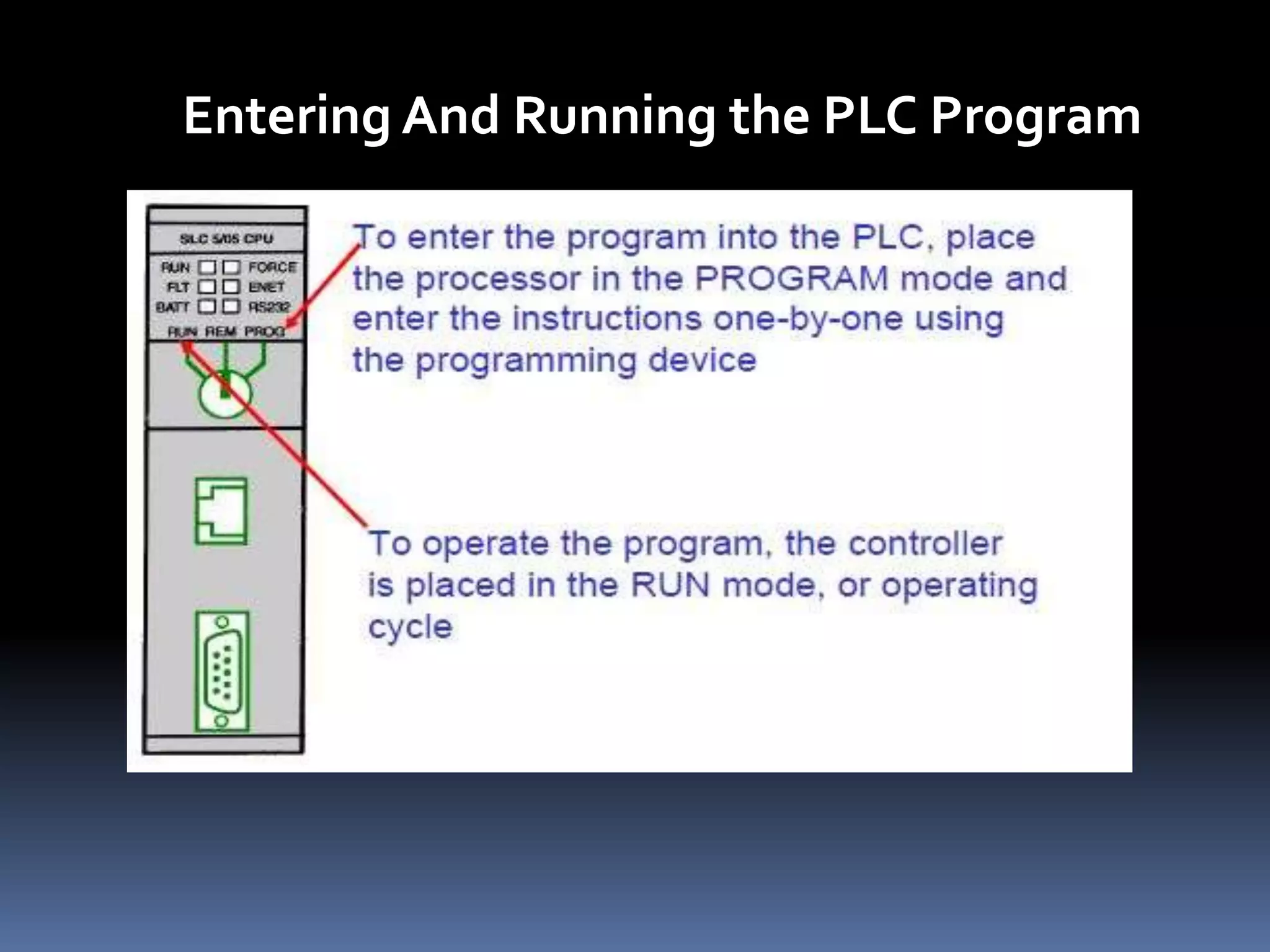

The document discusses automation and programmable logic controllers (PLCs). It describes how PLCs are used in industrial automation to control manufacturing processes and machines. The key components of a PLC system are described, including the central processing unit, memory, I/O modules, and power supply. The document outlines the basic operation of a PLC, including its scan cycle of reading inputs, executing a user program, and updating outputs. PLC programming using ladder logic is also discussed. Examples are provided of different types of inputs and outputs that can be connected to a PLC, as well as areas where PLCs are commonly applied.