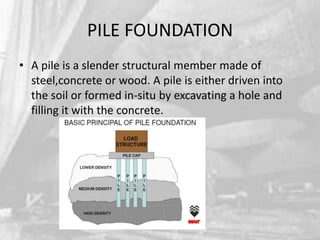

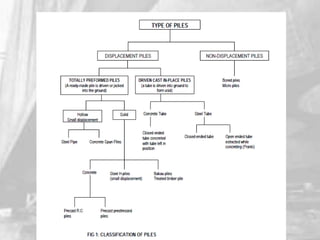

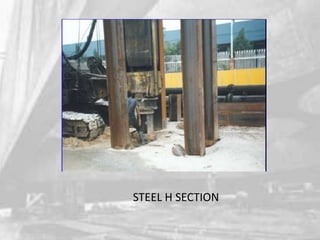

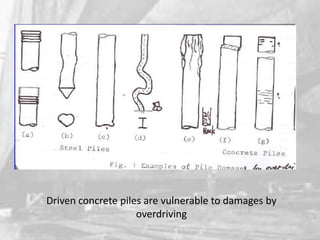

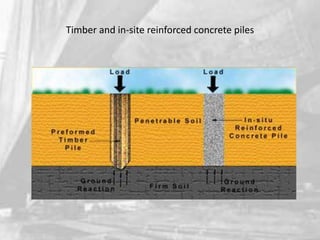

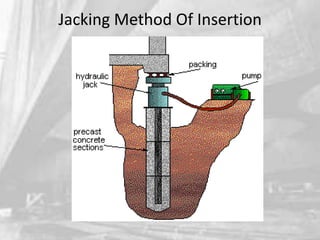

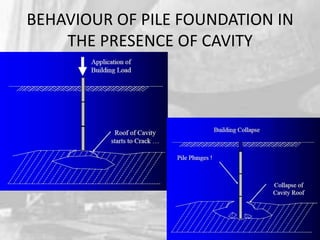

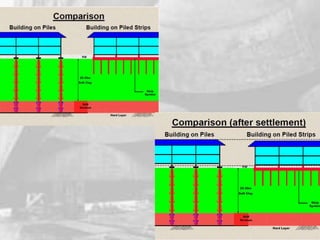

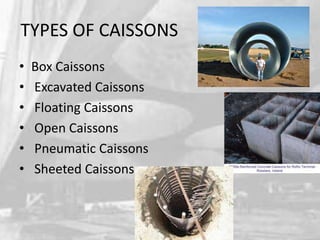

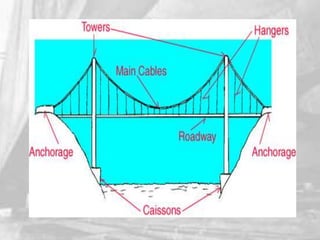

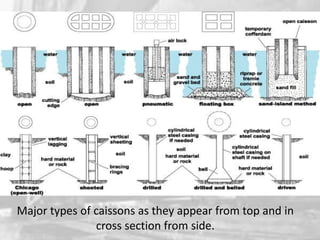

Deep foundations such as piles, piers, and caissons are required when surface soil cannot support a structure or when a firm soil layer is too deep to be reached economically by shallow foundations. Piles are slender structural members made of steel, concrete, or wood that are driven or cast in place into the ground. Piles transfer structural loads through skin friction or end bearing. Common pile installation methods include dropping weight hammers, diesel hammers, vibratory hammers, and jacking. Piers are larger diameter cast in place foundations used in dry areas. Caissons are hollow watertight structures sunk into place under bodies of water to form foundations.