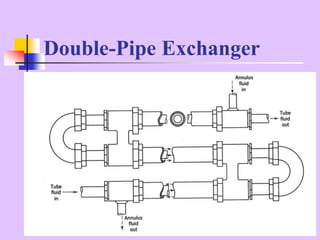

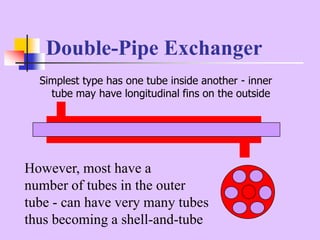

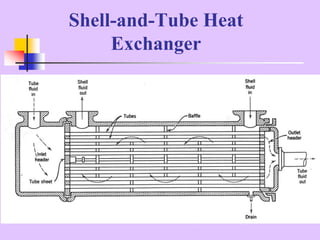

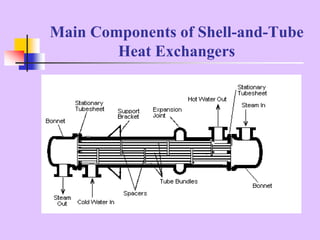

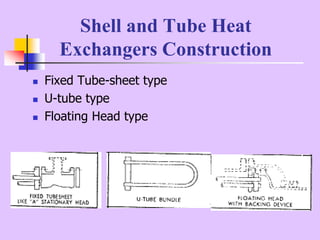

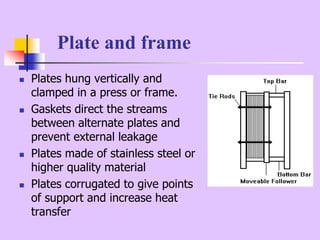

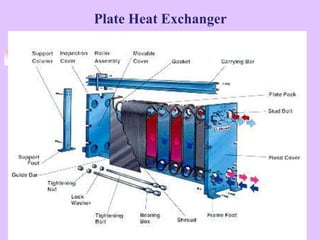

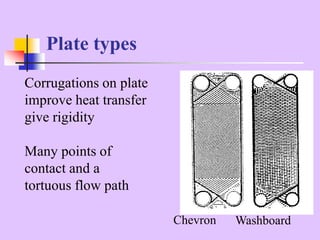

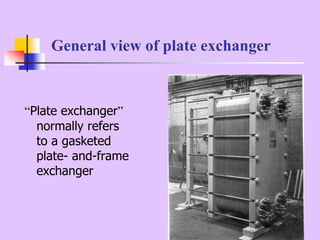

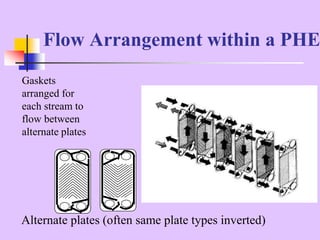

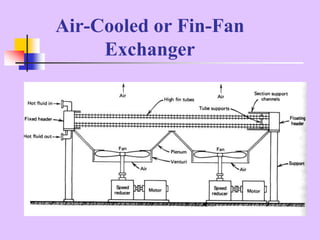

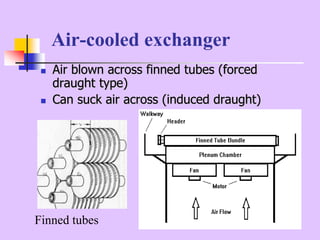

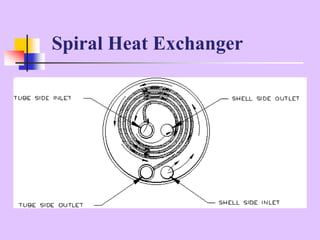

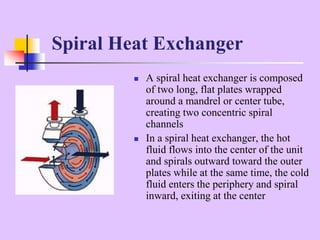

Heat exchangers transfer heat from one fluid to another without direct contact between the fluids. The most common type is the shell-and-tube heat exchanger, which consists of tubes in a shell container. Fluids flow inside the tubes and outside in the shell. Other key types include double-pipe exchangers, plate-and-frame exchangers, air-cooled exchangers, and spiral exchangers. Spiral exchangers have two fluids spiraling in opposite directions to enhance heat transfer.