Embed presentation

Downloaded 160 times

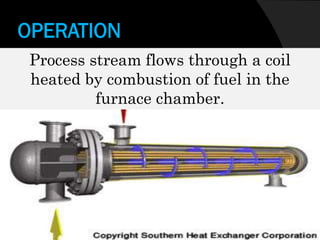

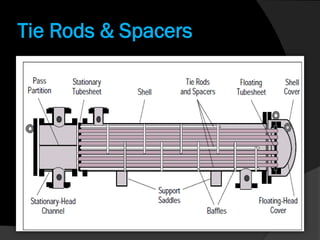

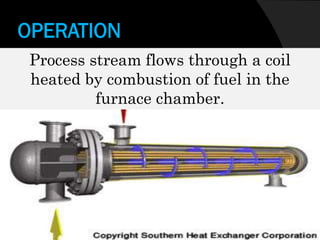

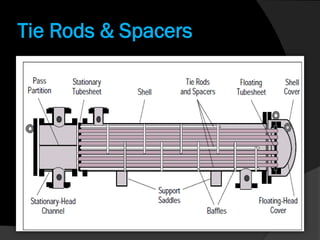

This document provides information about a shell and tube heat exchanger. It consists of a shell with a bundle of tubes inside it. Process streams flow through the tubes and are heated or cooled by another medium flowing on the outer shell side. Common applications include cooling hydraulic fluid, oil, and other mediums in engines and power systems. The simple design makes shell and tube heat exchangers suitable for a wide variety of industrial heating and cooling applications.