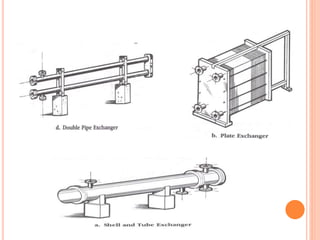

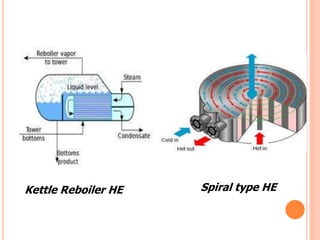

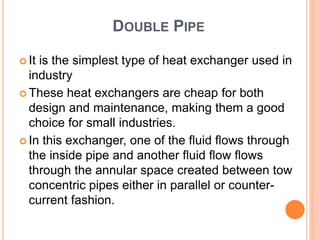

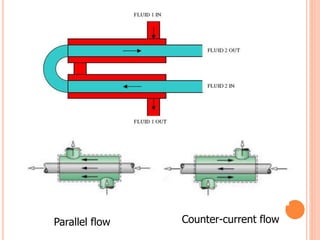

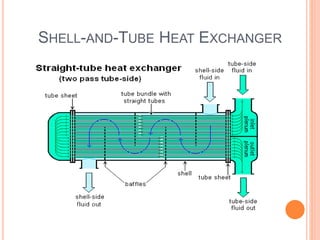

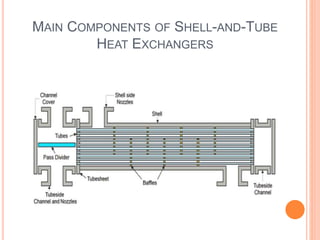

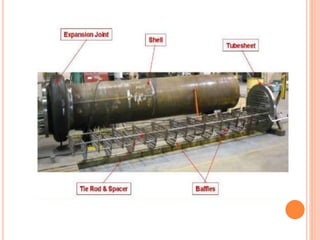

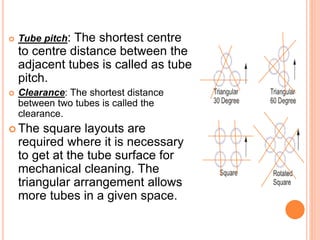

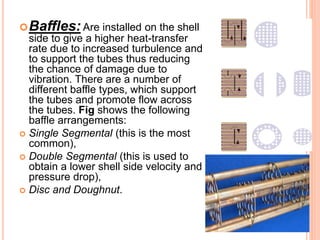

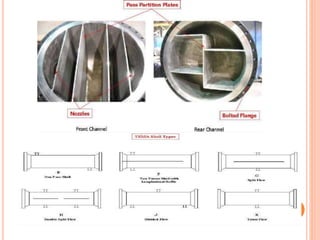

This document discusses heat exchangers, which allow the transfer of heat between two fluids without direct contact. It describes several types of heat exchangers including double pipe heat exchangers, which involve two concentric pipes, and shell and tube heat exchangers, which involve tubes inside a cylindrical shell. Shell and tube heat exchangers are widely used and involve tubes, tube sheets, baffles, and multiple passes to increase heat transfer. The document also discusses applications and advantages and disadvantages of different heat exchanger designs.