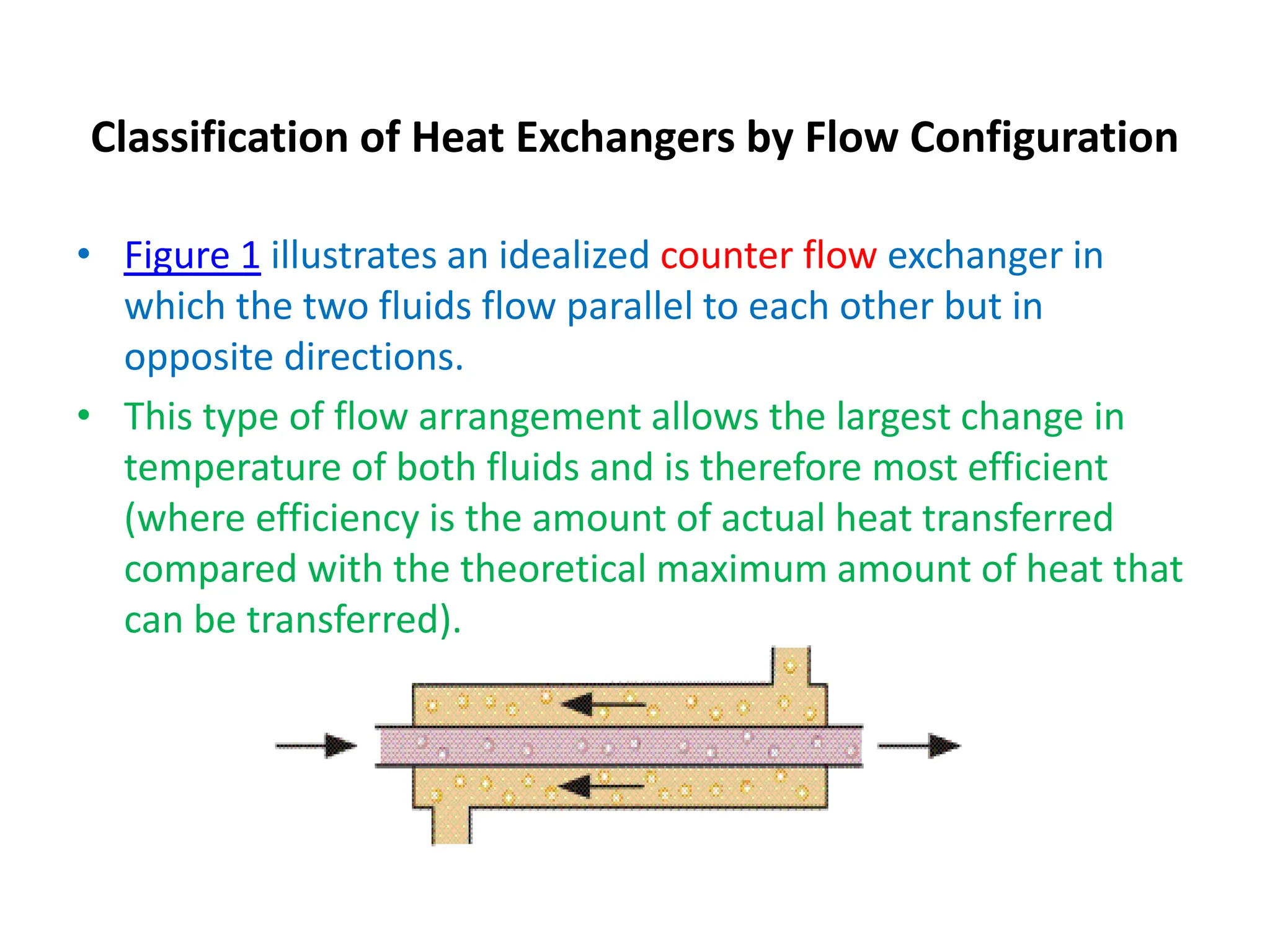

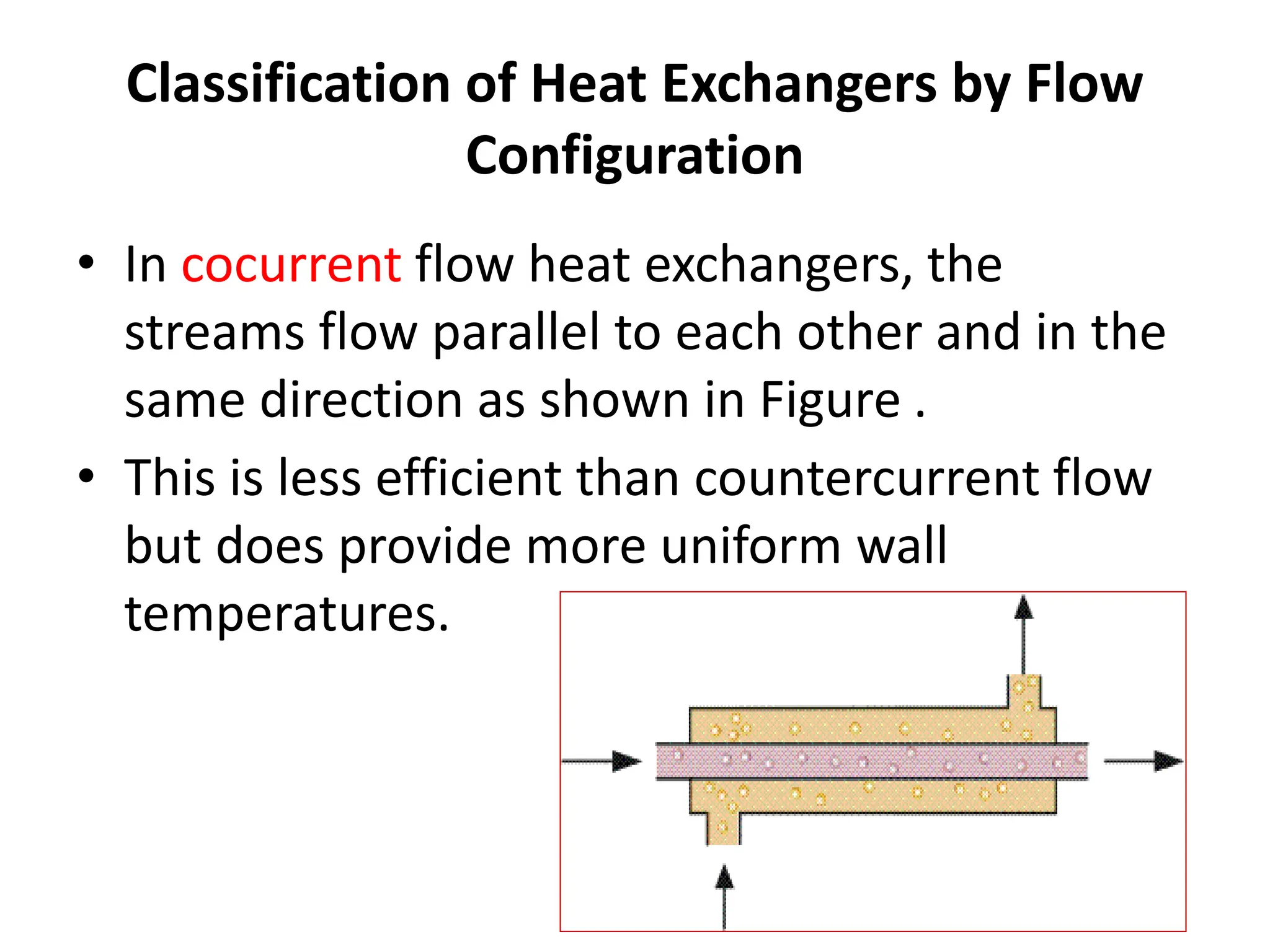

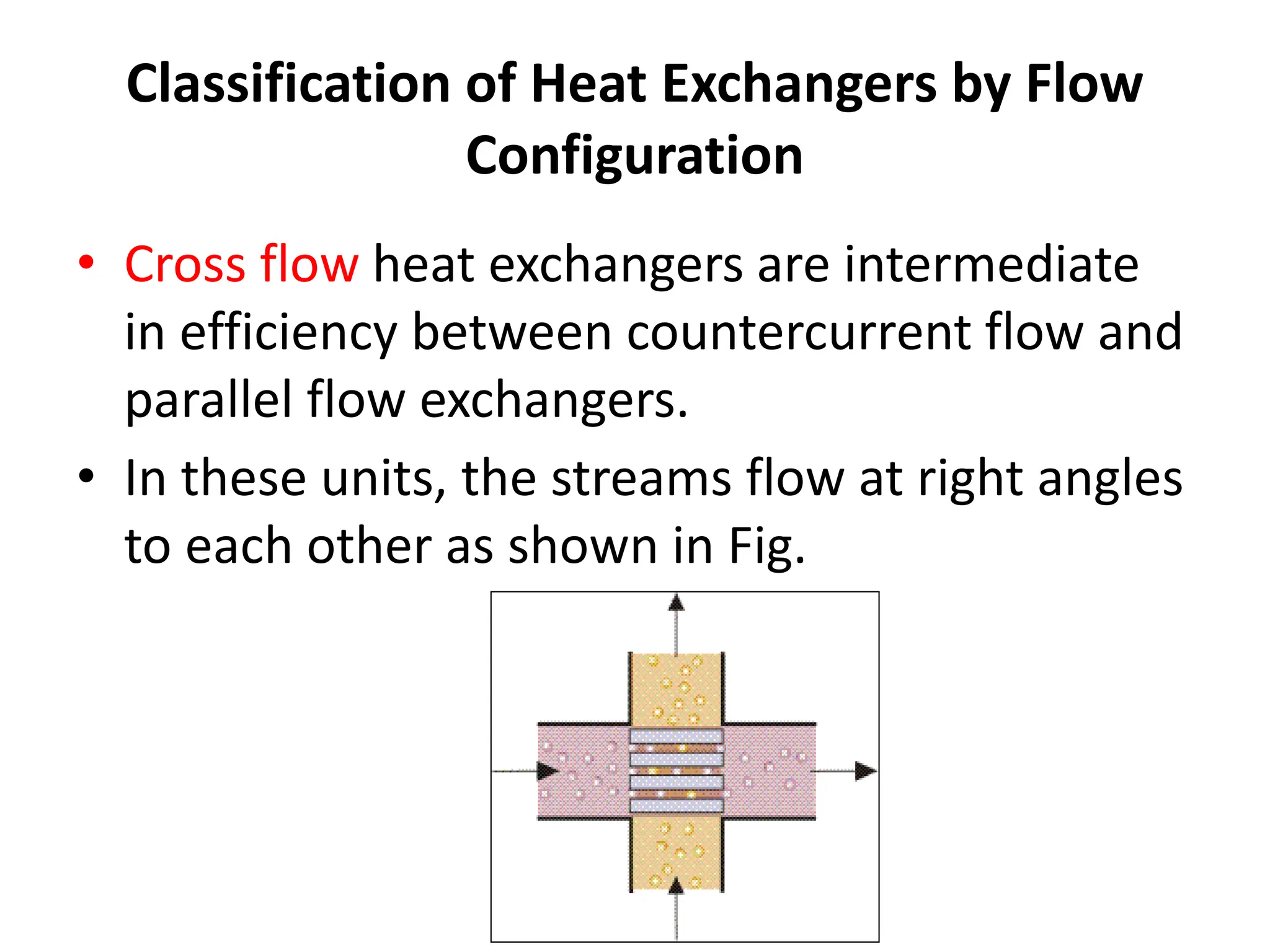

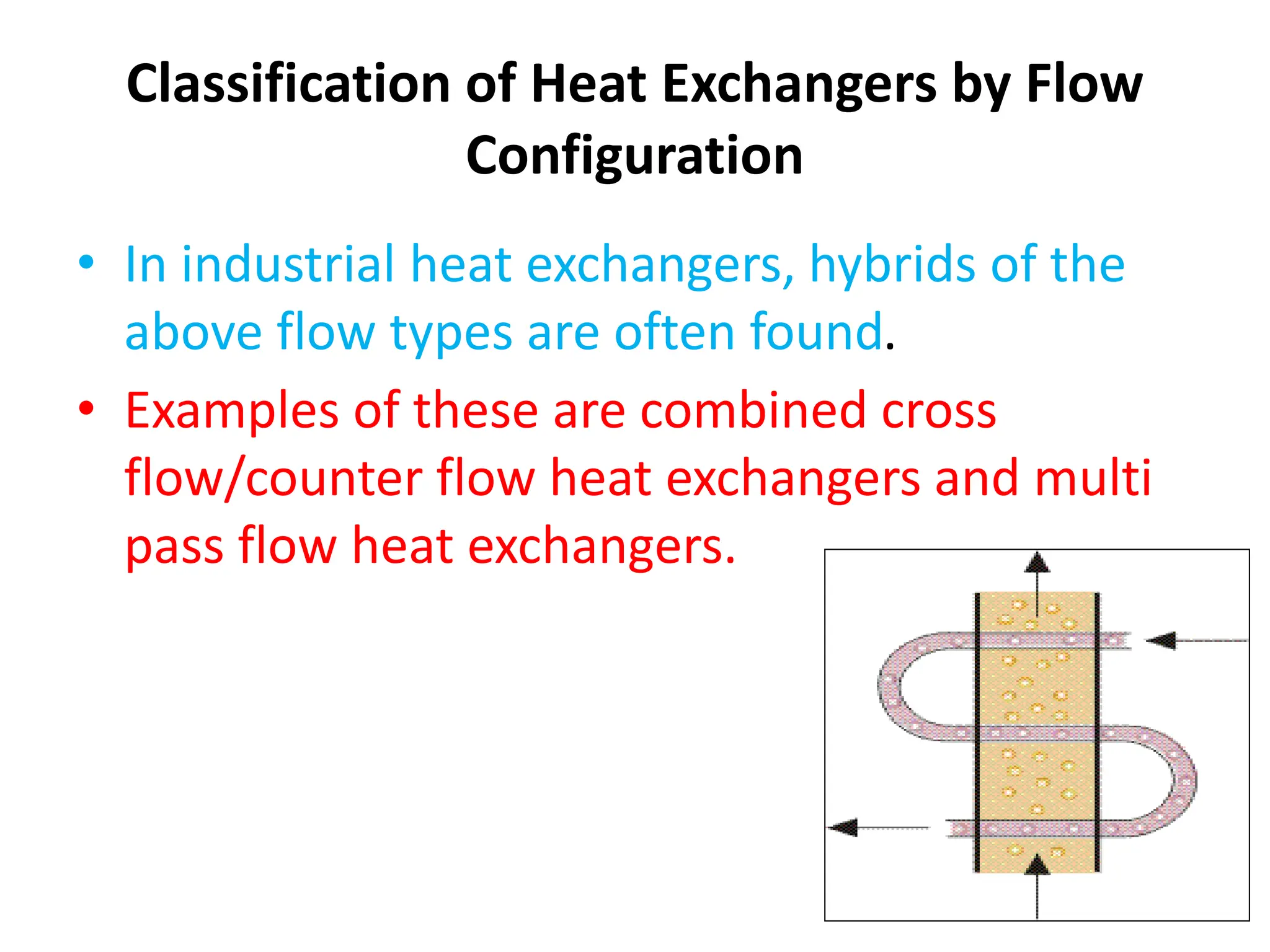

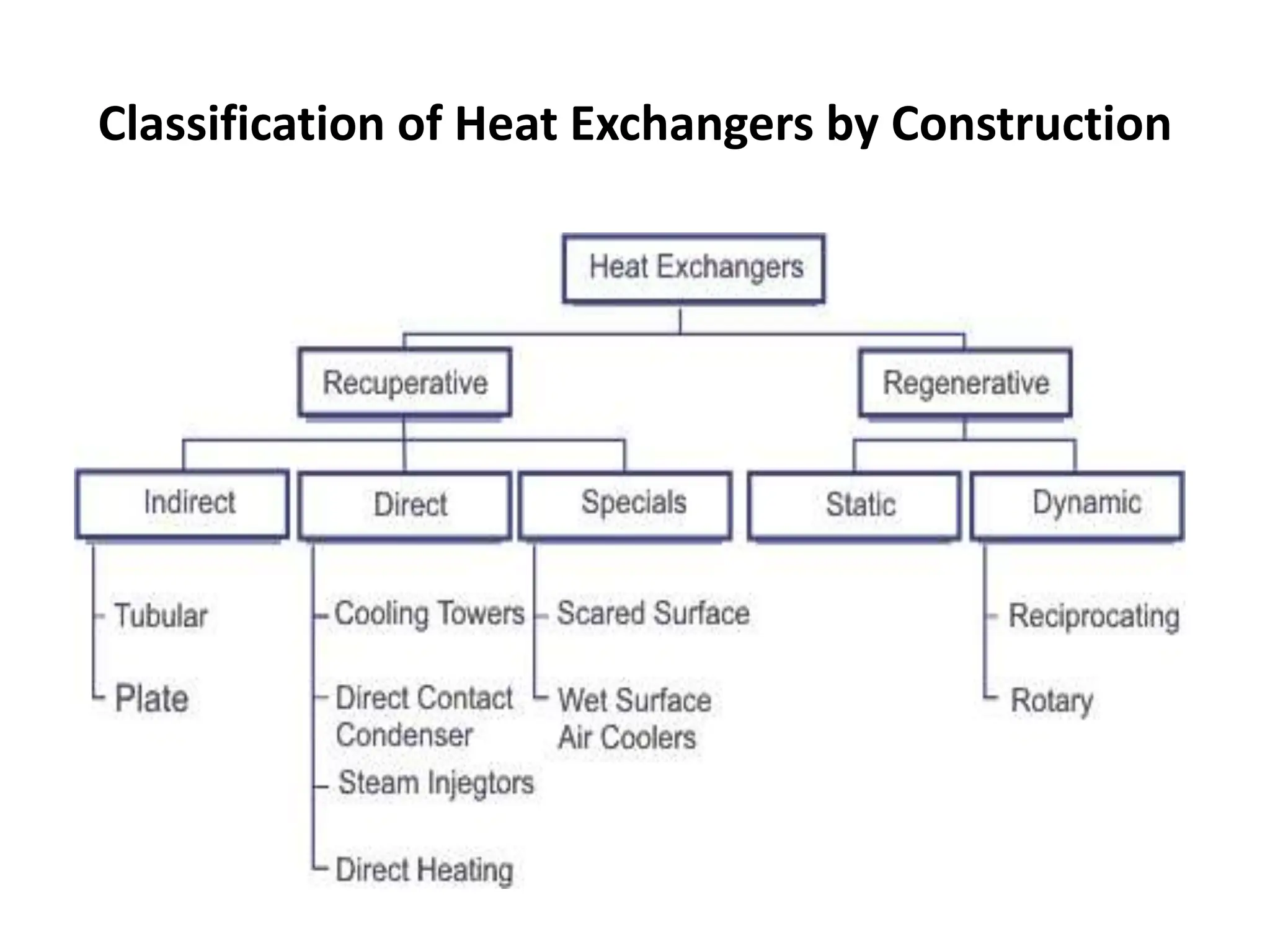

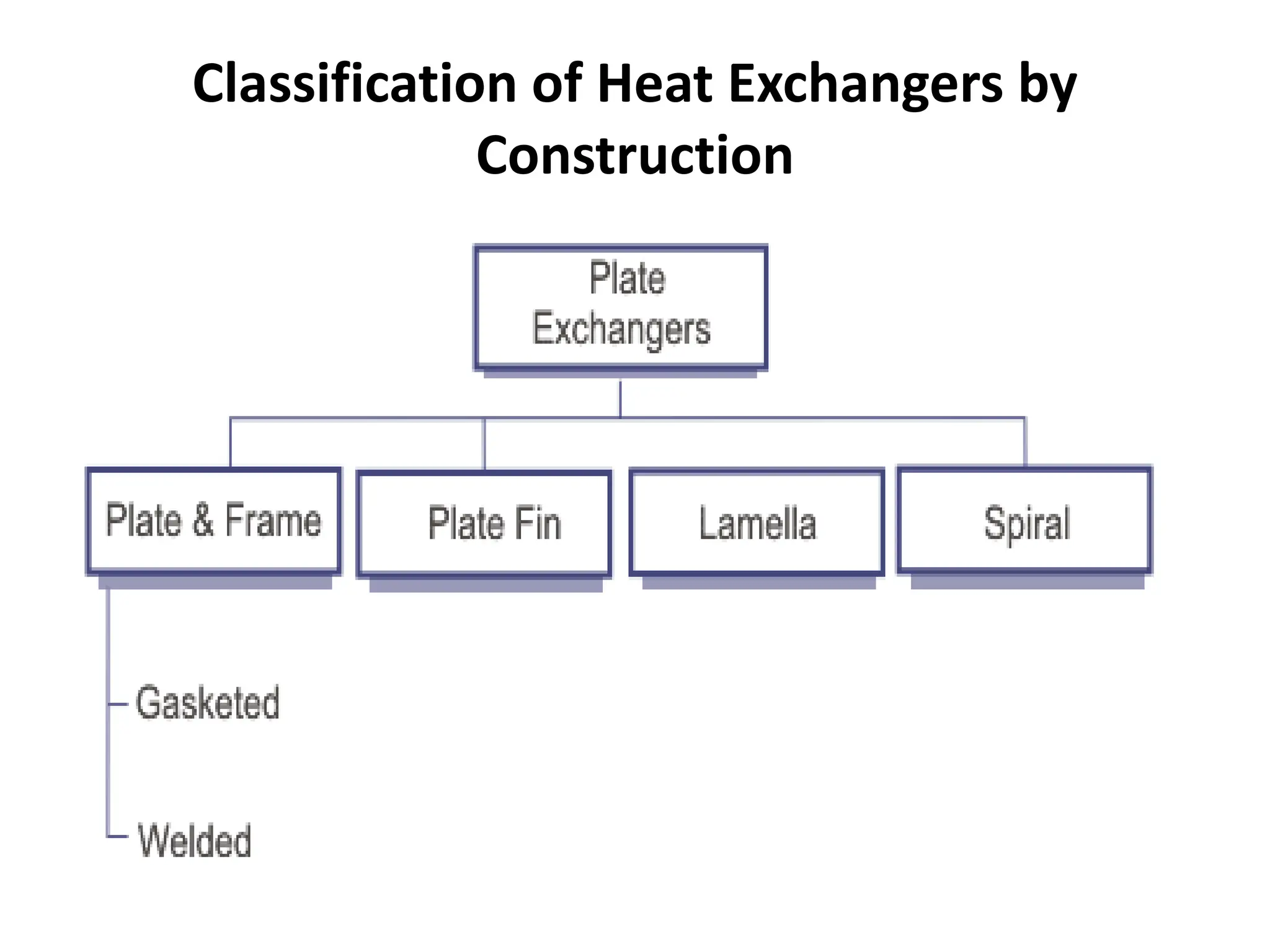

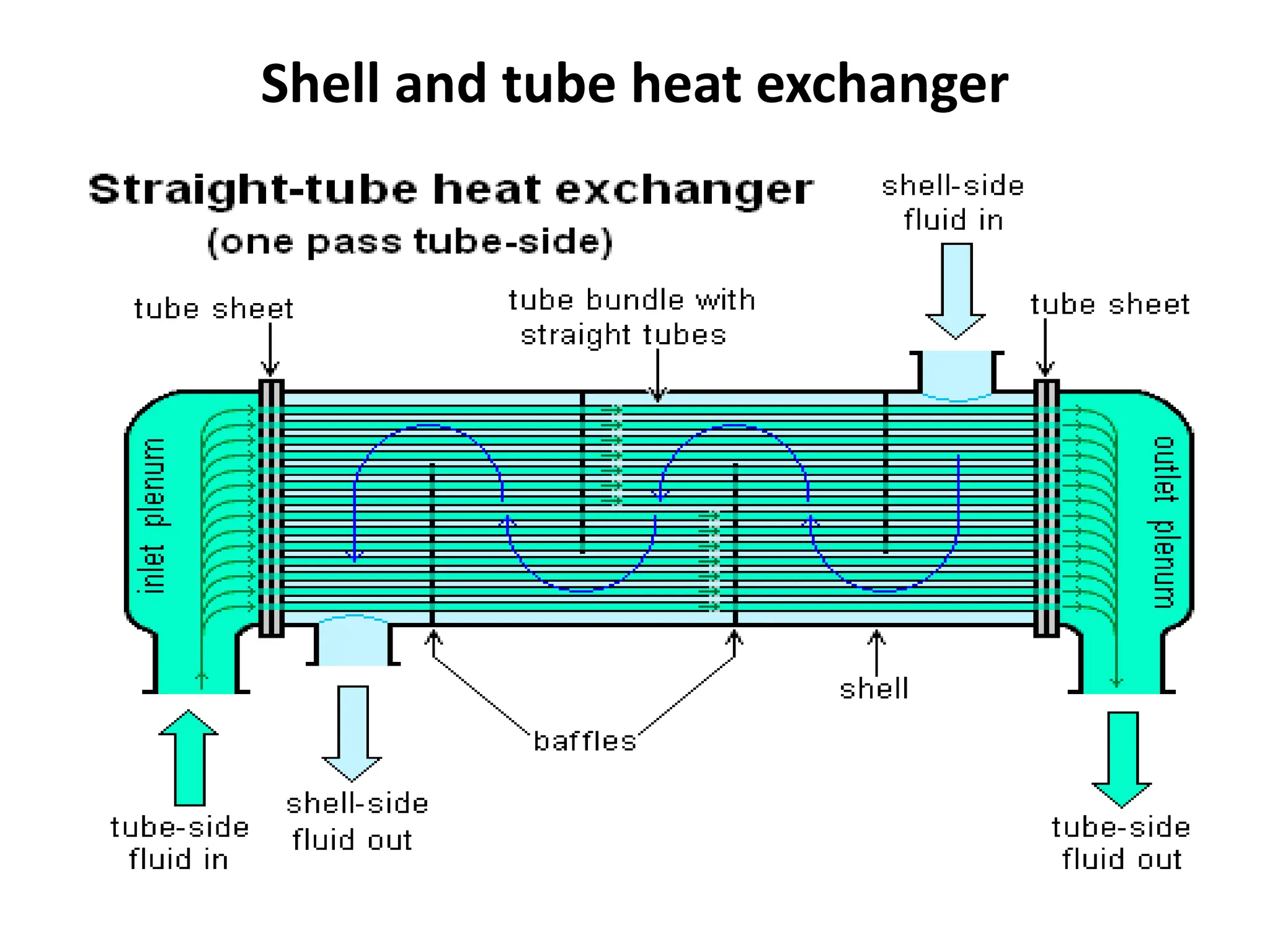

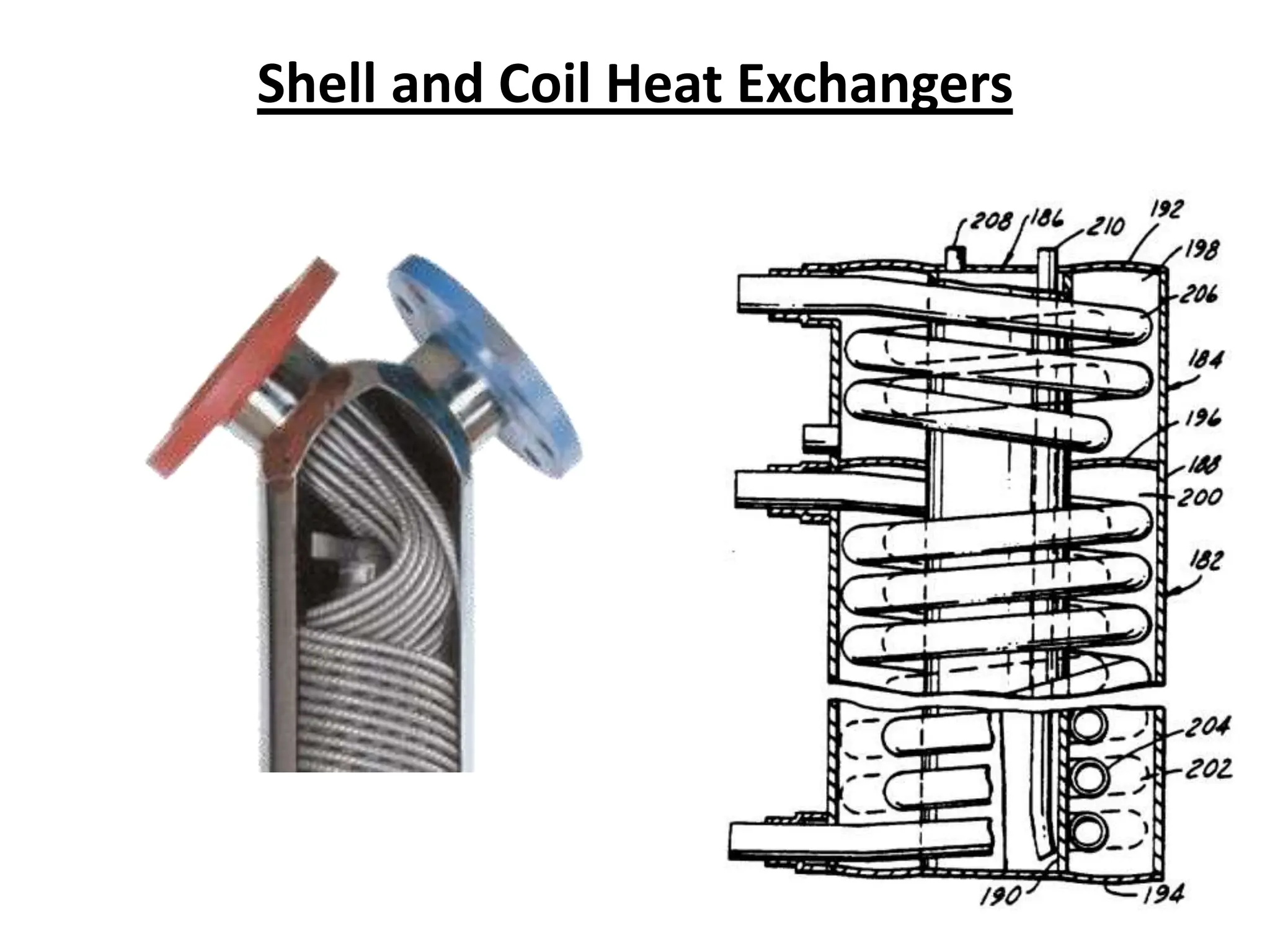

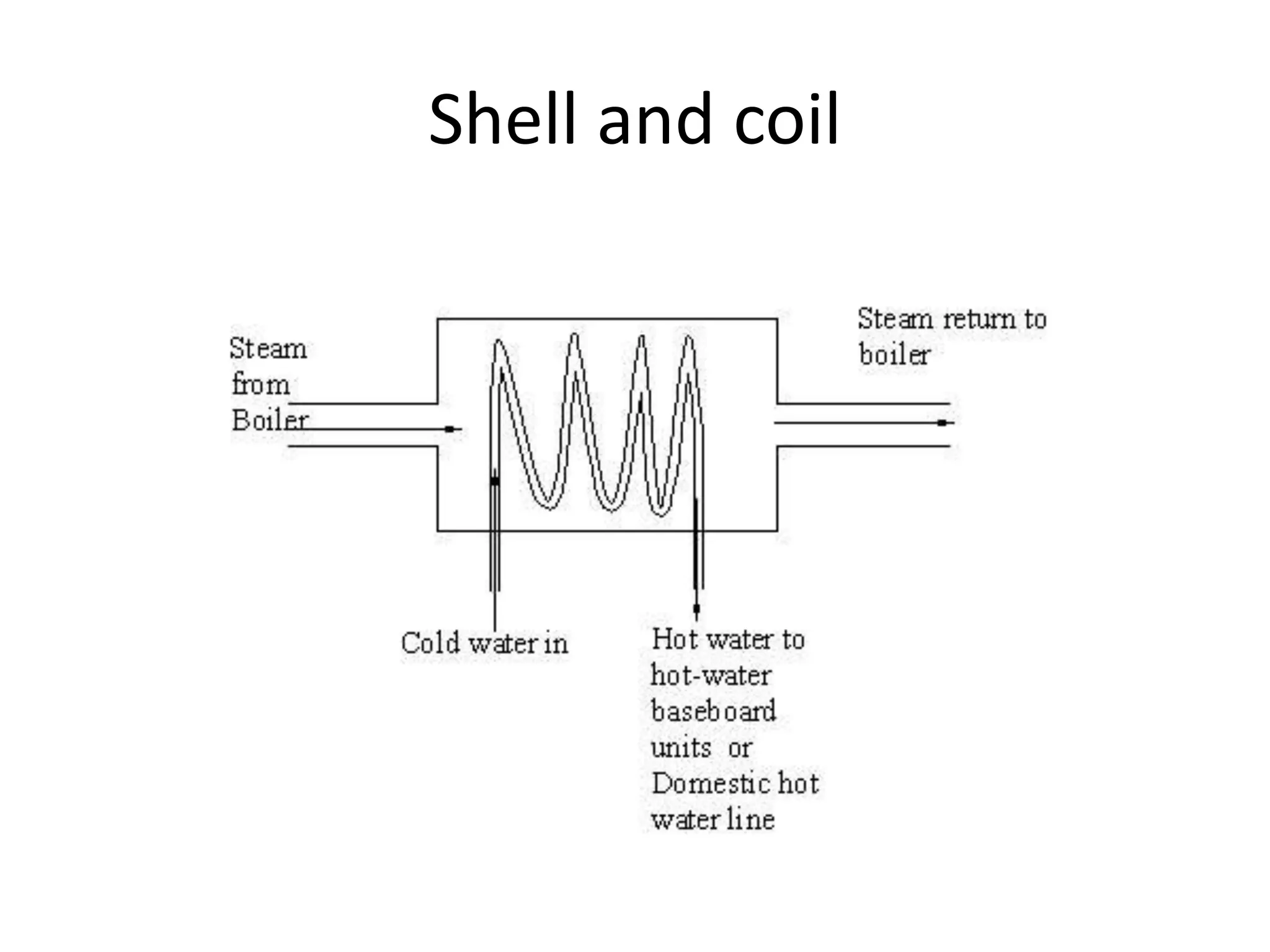

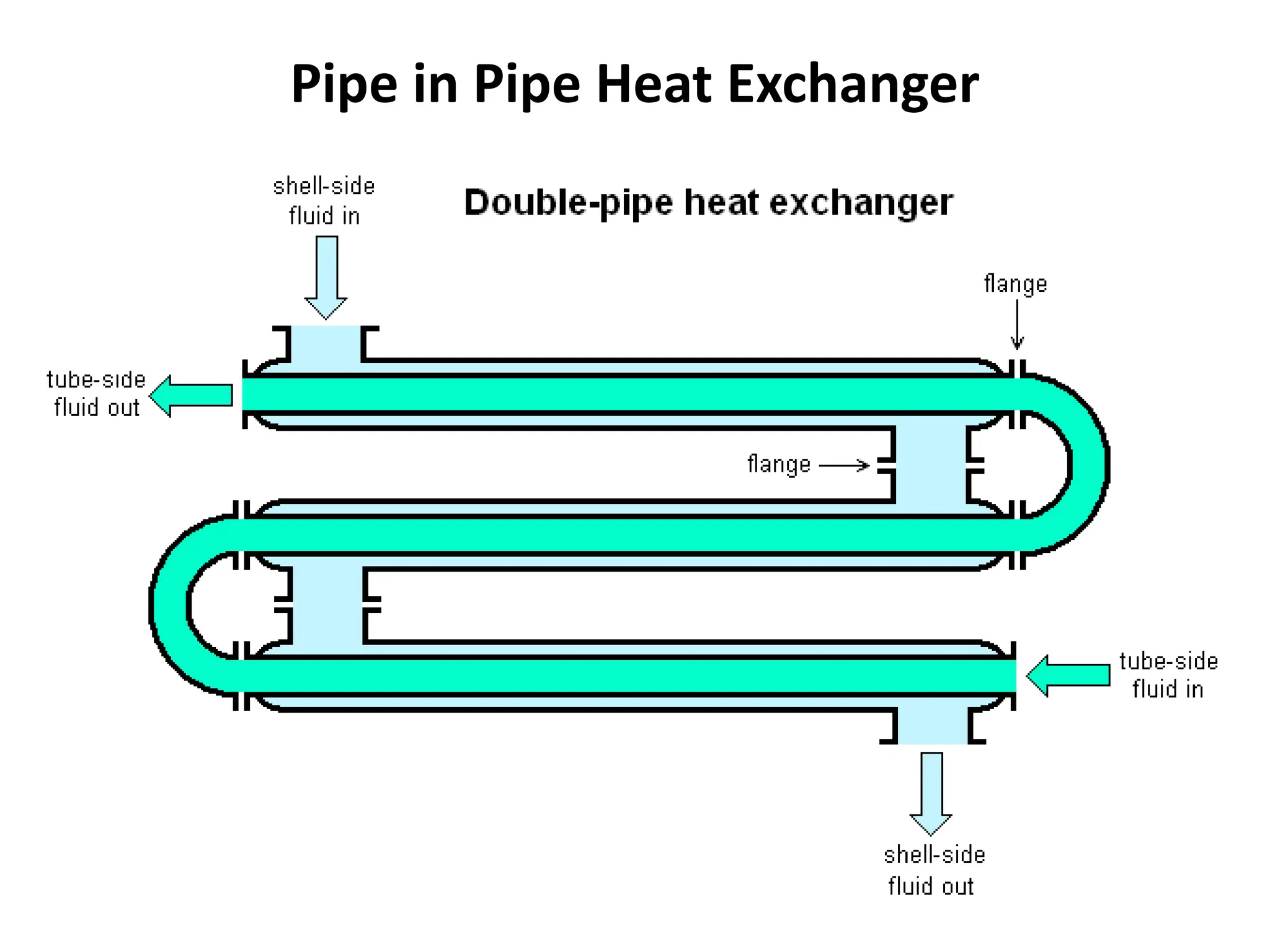

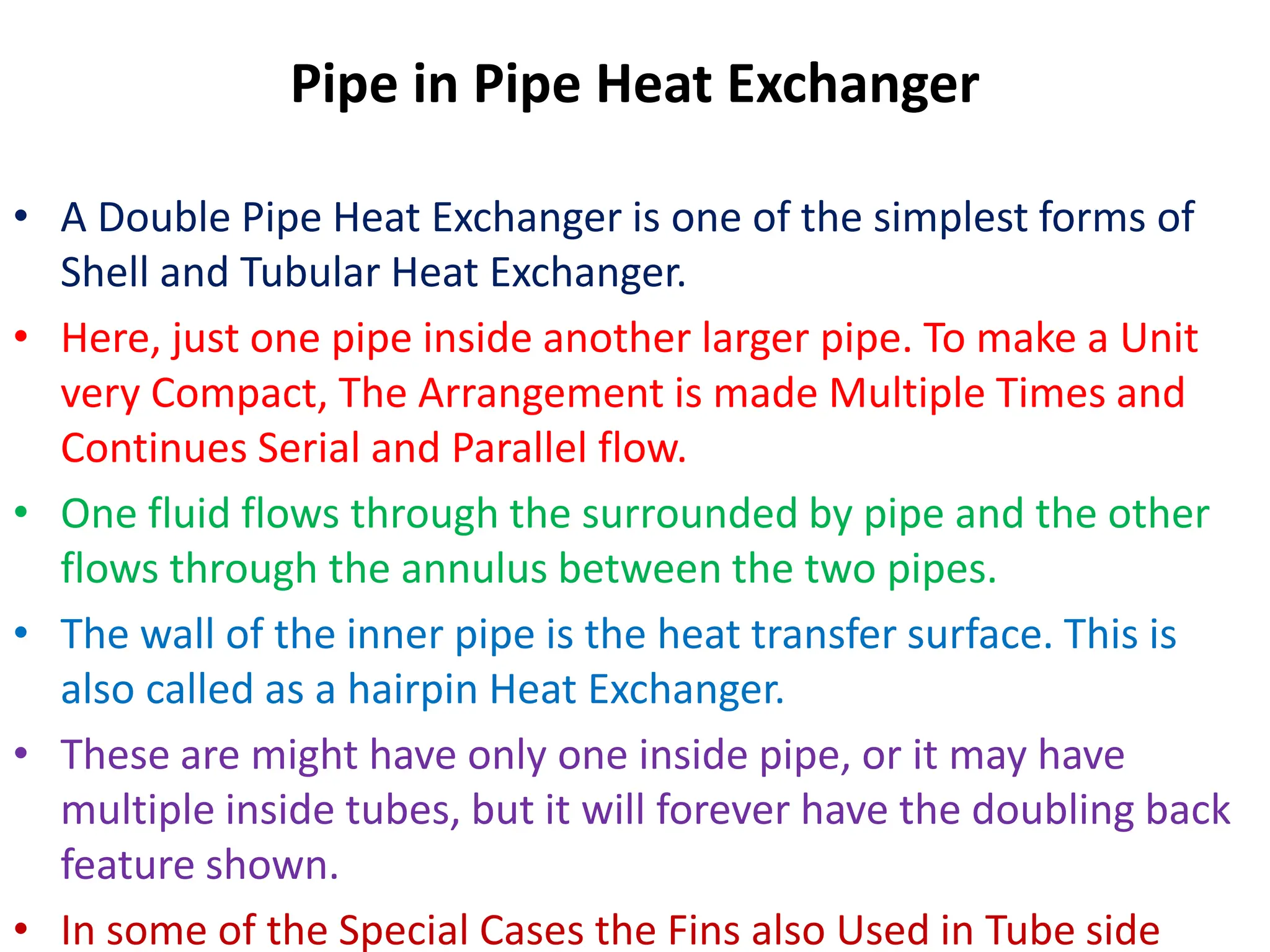

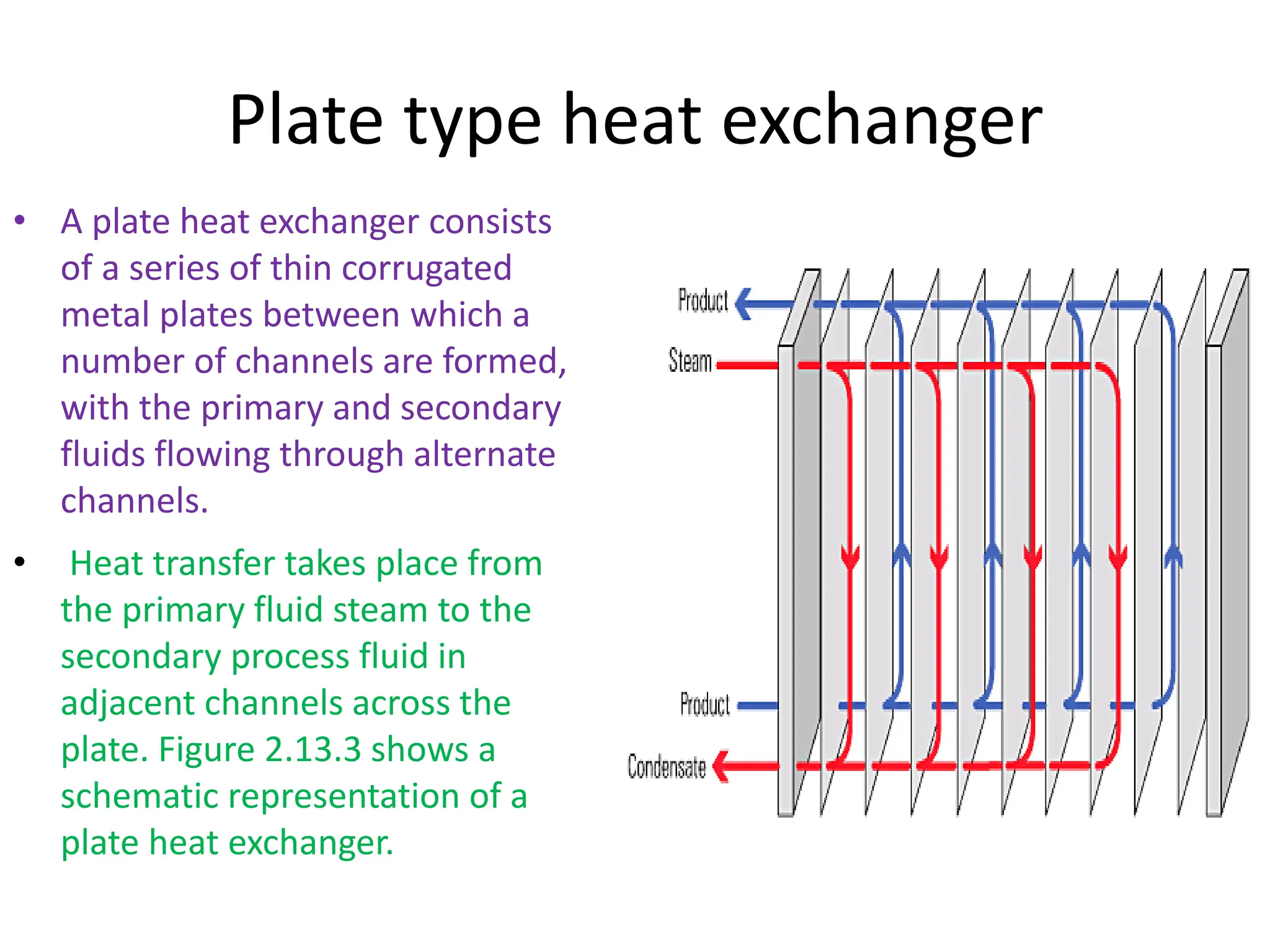

A heat exchanger facilitates efficient heat transfer between two fluids, either separated by a solid wall or in direct contact, and is utilized across various industries including power plants and refrigeration. Heat exchangers can be classified by flow configuration (counter flow, cocurrent, crossflow) and construction type (recuperative, regenerative), with shell and tube being a popular design due to its robustness and ease of maintenance. Other types include shell and coil and plate heat exchangers, each with unique advantages tailored for specific applications and performance requirements.