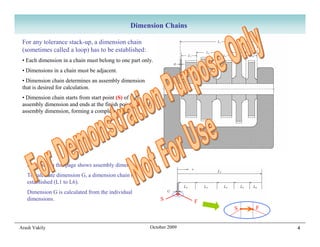

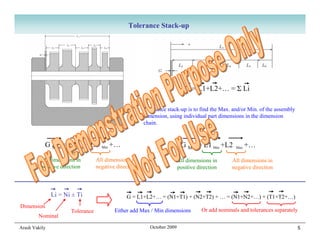

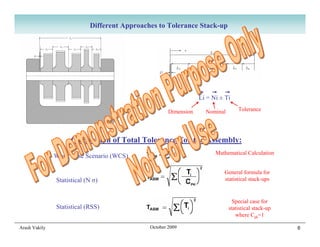

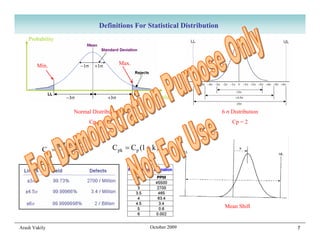

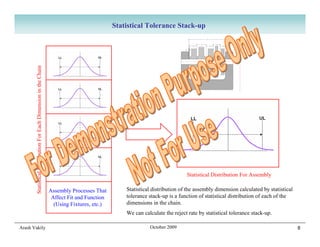

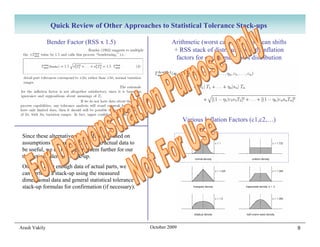

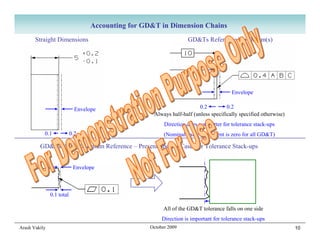

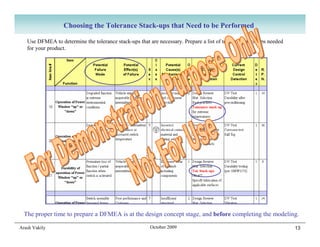

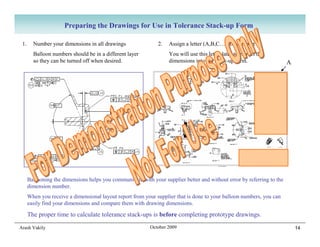

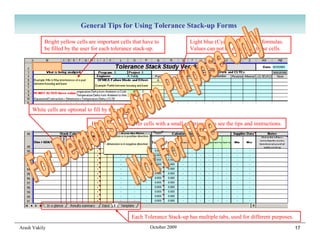

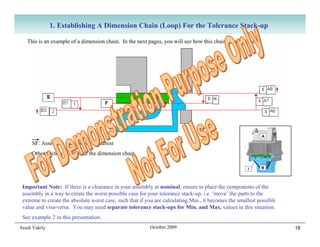

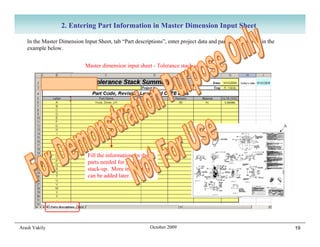

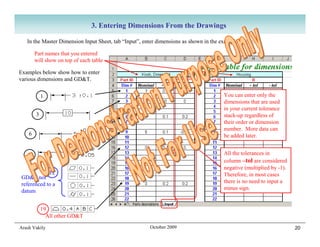

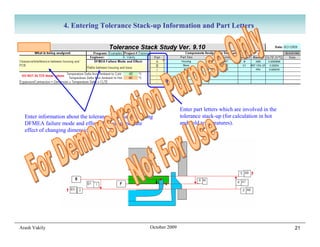

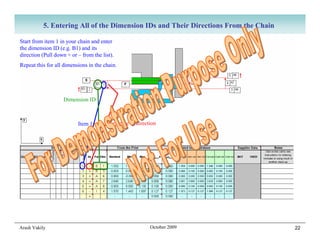

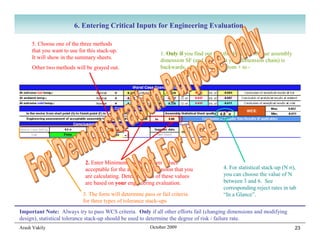

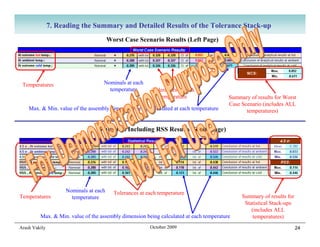

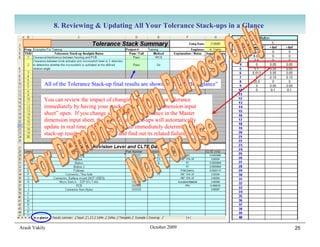

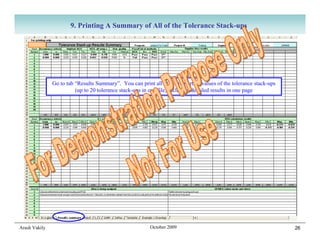

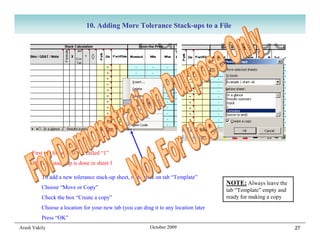

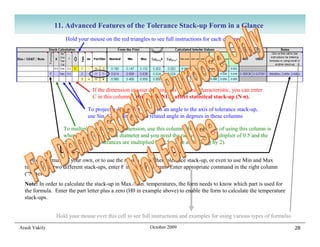

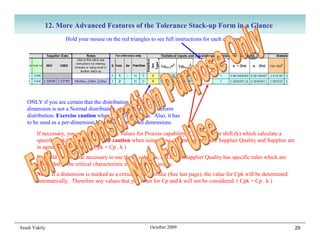

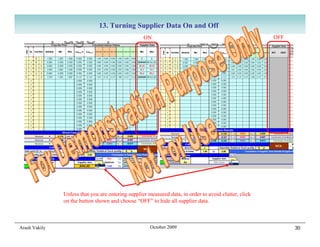

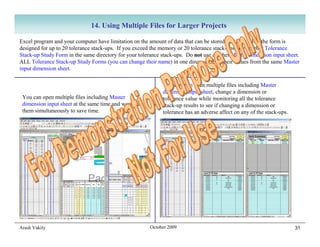

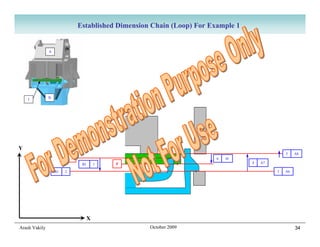

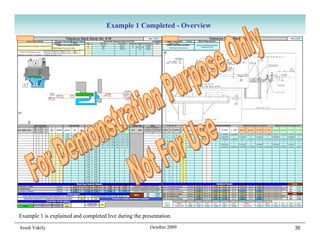

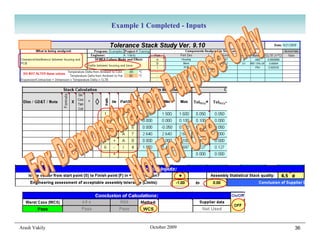

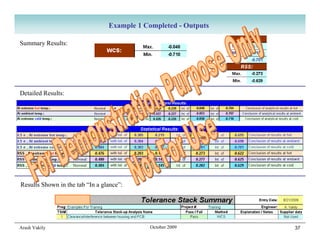

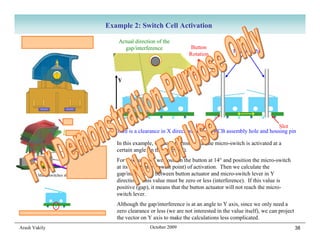

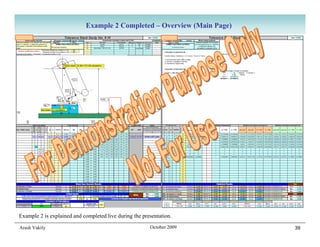

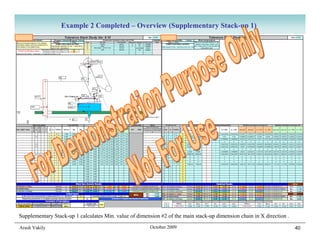

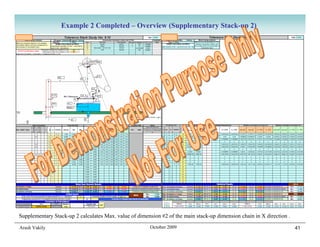

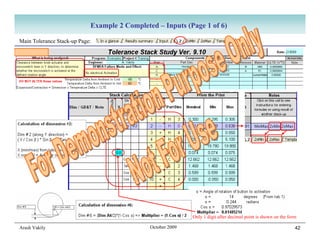

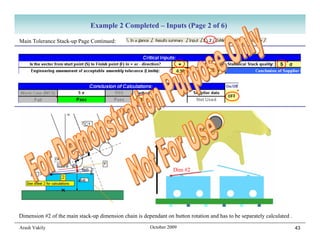

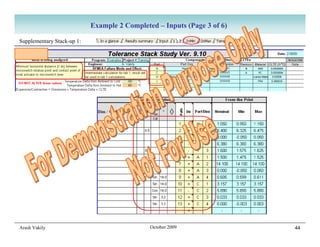

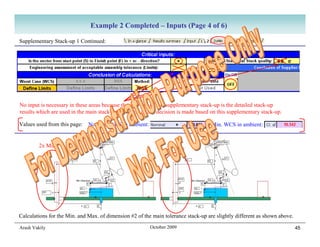

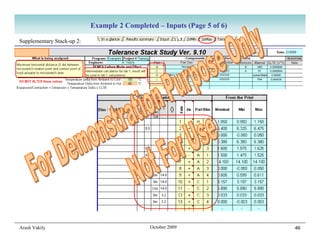

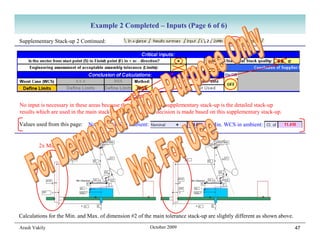

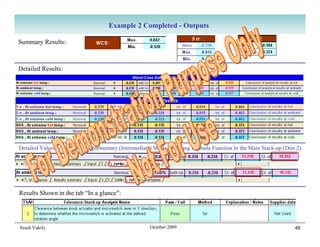

The document outlines the importance of performing tolerance stack-ups in engineering design, emphasizing the need for correct dimensions on drawings to ensure product fit and function. It describes the use of an automated Excel form to streamline the process of calculating various types of tolerance stack-ups, including worst-case and statistical methods. Additionally, it provides guidance on setting up dimension chains, inputting data, and reviewing results to ensure compliance and facilitate supplier interactions.