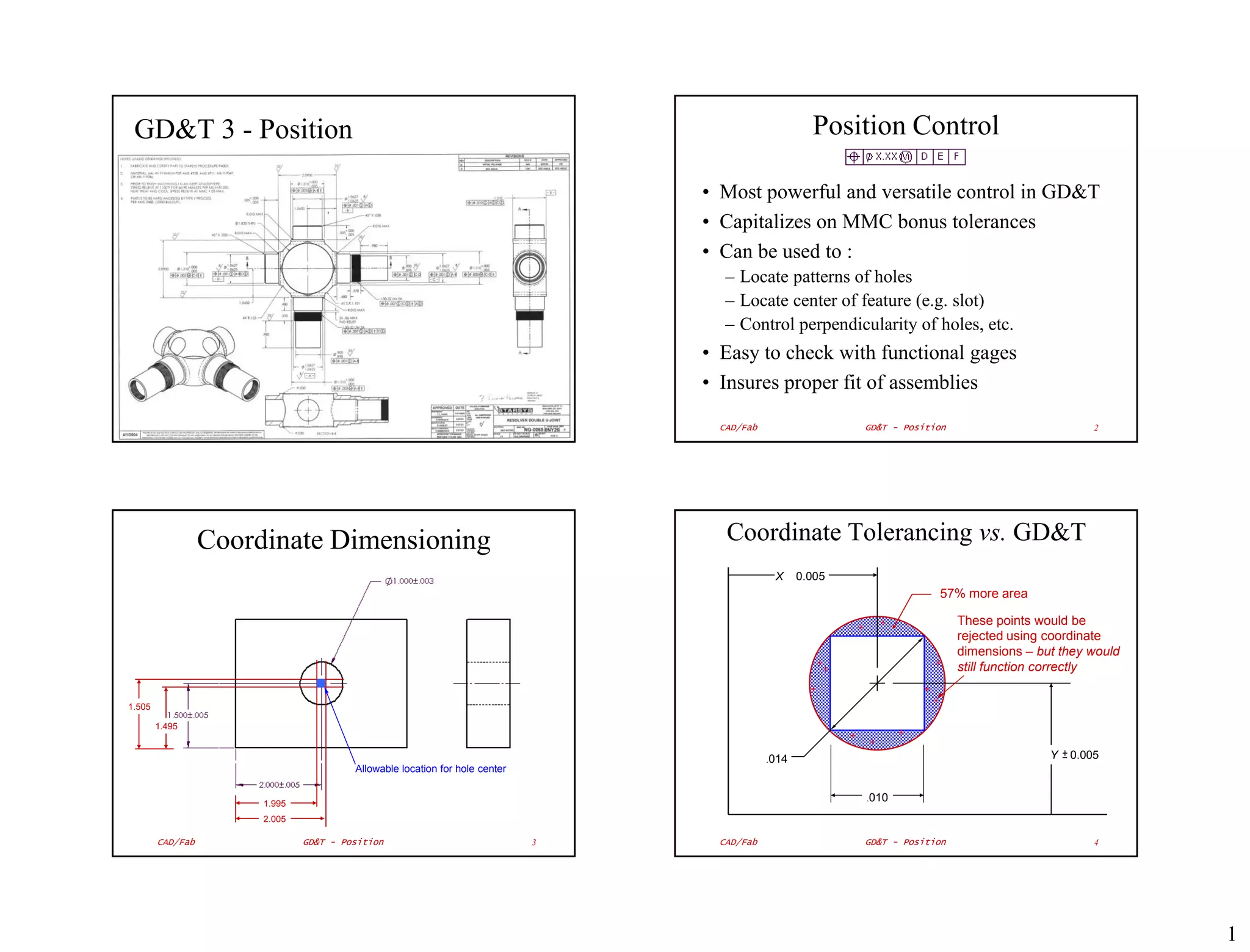

Position control is the most powerful and versatile GD&T control. It can be used to locate patterns of holes, locate the center of a feature, and control perpendicularity. Position control ensures proper assembly fit and can be easily checked with functional gages. It capitalizes on maximum material condition bonus tolerances and guarantees features are located within their tolerance zones.