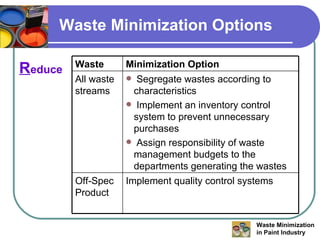

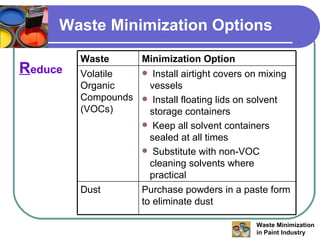

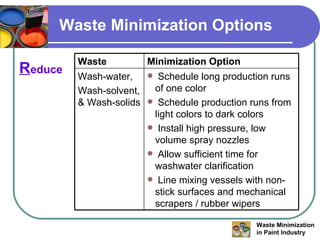

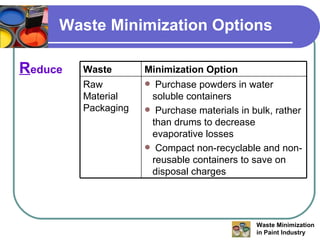

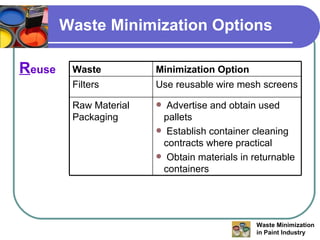

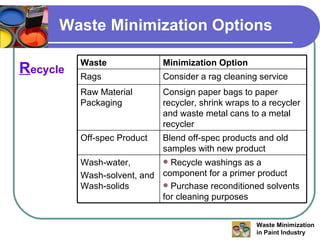

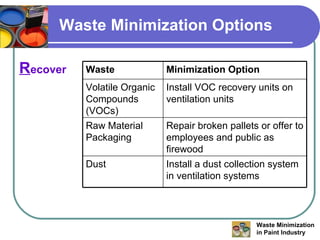

The document discusses waste minimization opportunities and reporting practices in the paint manufacturing industry. It outlines a 5-step waste minimization program that includes conducting an audit to identify waste streams, developing a plan to reduce waste, implementing the plan, and monitoring progress. Various waste reduction, reuse, recycling, and recovery options are presented, such as segregating wastes, implementing quality control, using reusable containers, and blending off-spec products. Success stories from Asian Paints are provided, where waste has been reduced by over 72% through upgraded facilities and innovative processes.