This document outlines the key steps for setting up and implementing an effective waste management program, including:

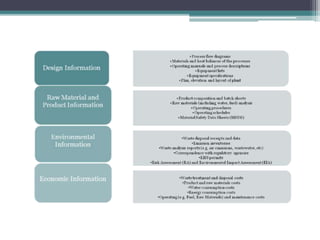

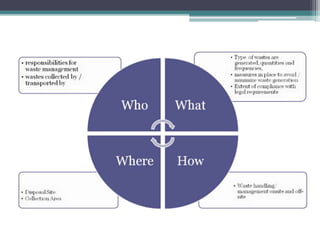

1. Conducting a preliminary waste assessment to collect baseline data on current waste generation and management practices.

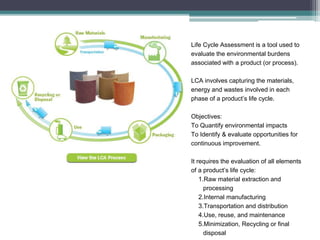

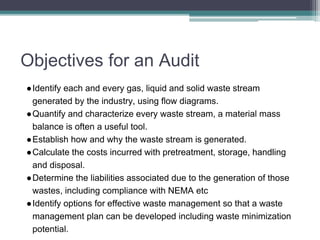

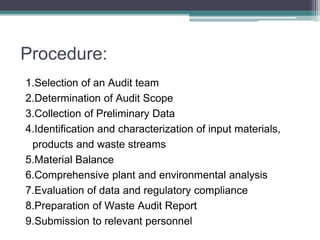

2. Using tools like life cycle assessment, best practicable environmental options, and environmental audits to analyze waste streams, identify reduction opportunities, and ensure regulatory compliance.

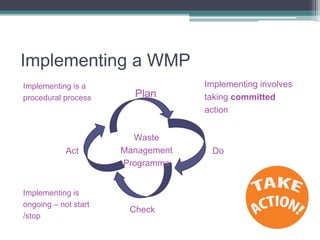

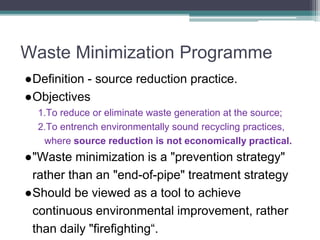

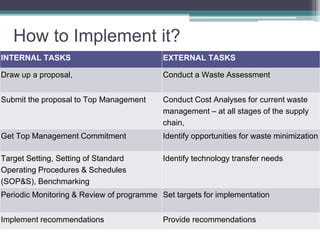

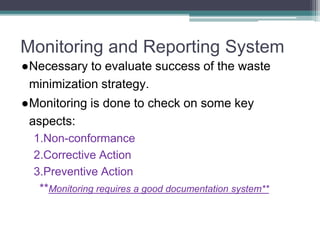

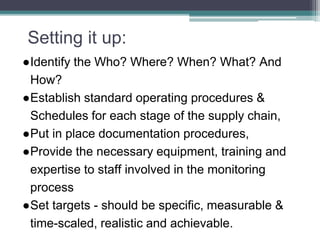

3. Developing and implementing a waste minimization program with goals, standard operating procedures, monitoring systems, and targets to continuously track waste reduction progress over time.

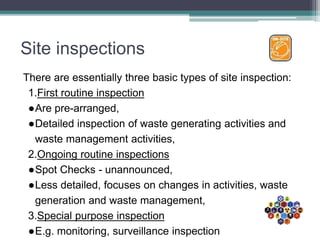

The overall waste management program aims to reduce environmental impacts and costs by analyzing an organization's full supply chain and promoting sustainable practices. Close monitoring and documentation are also essential to evaluate the program's