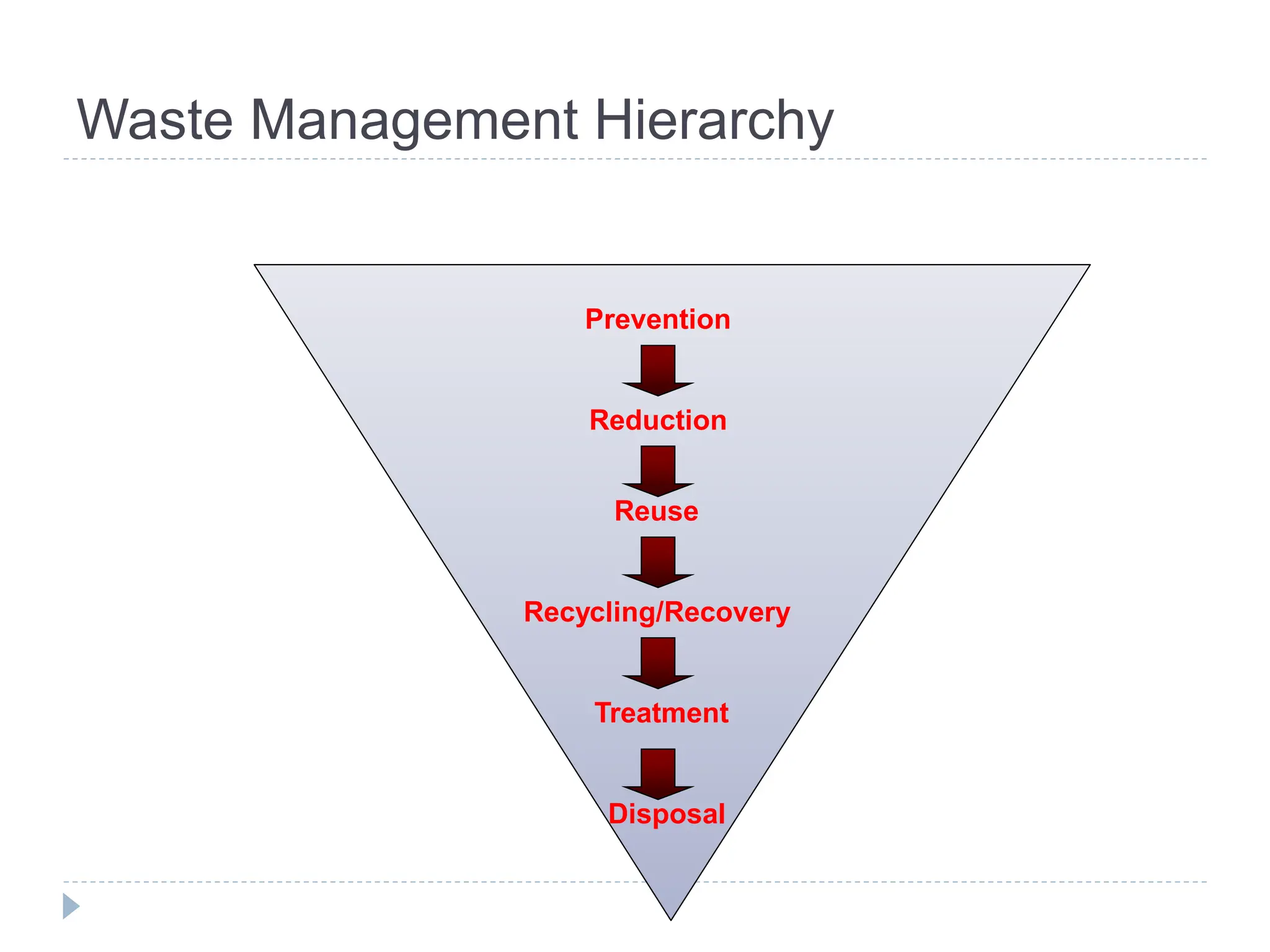

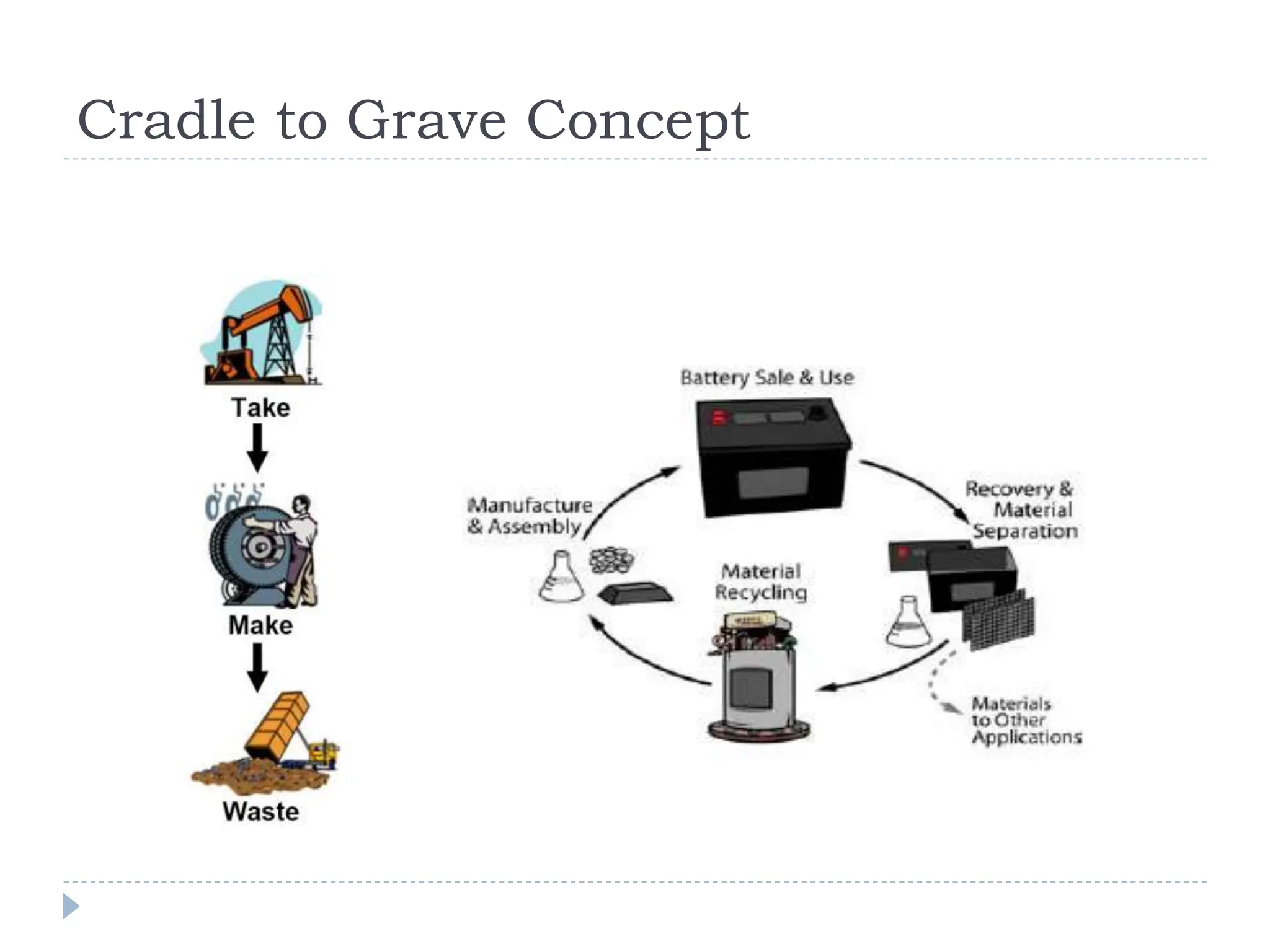

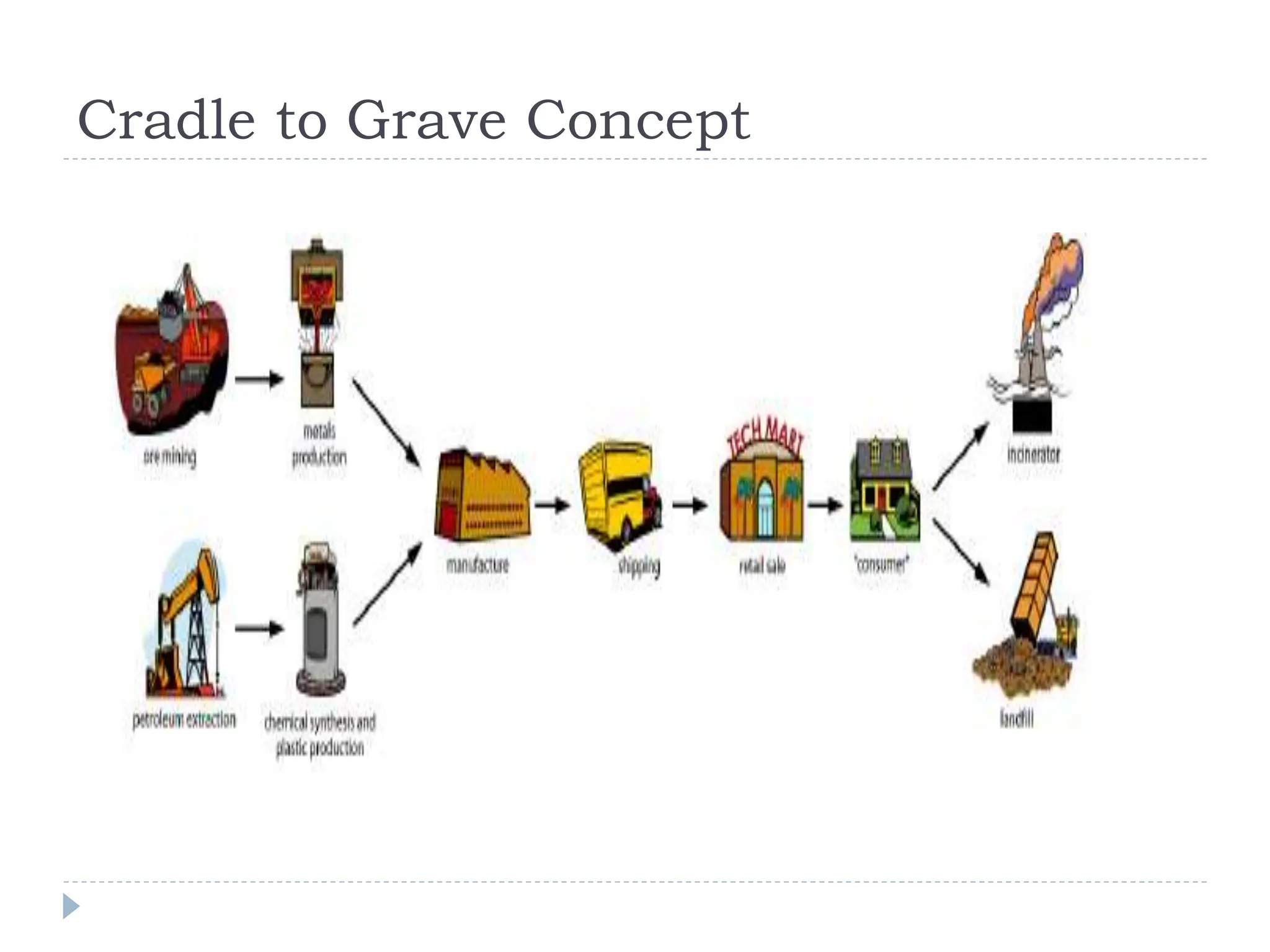

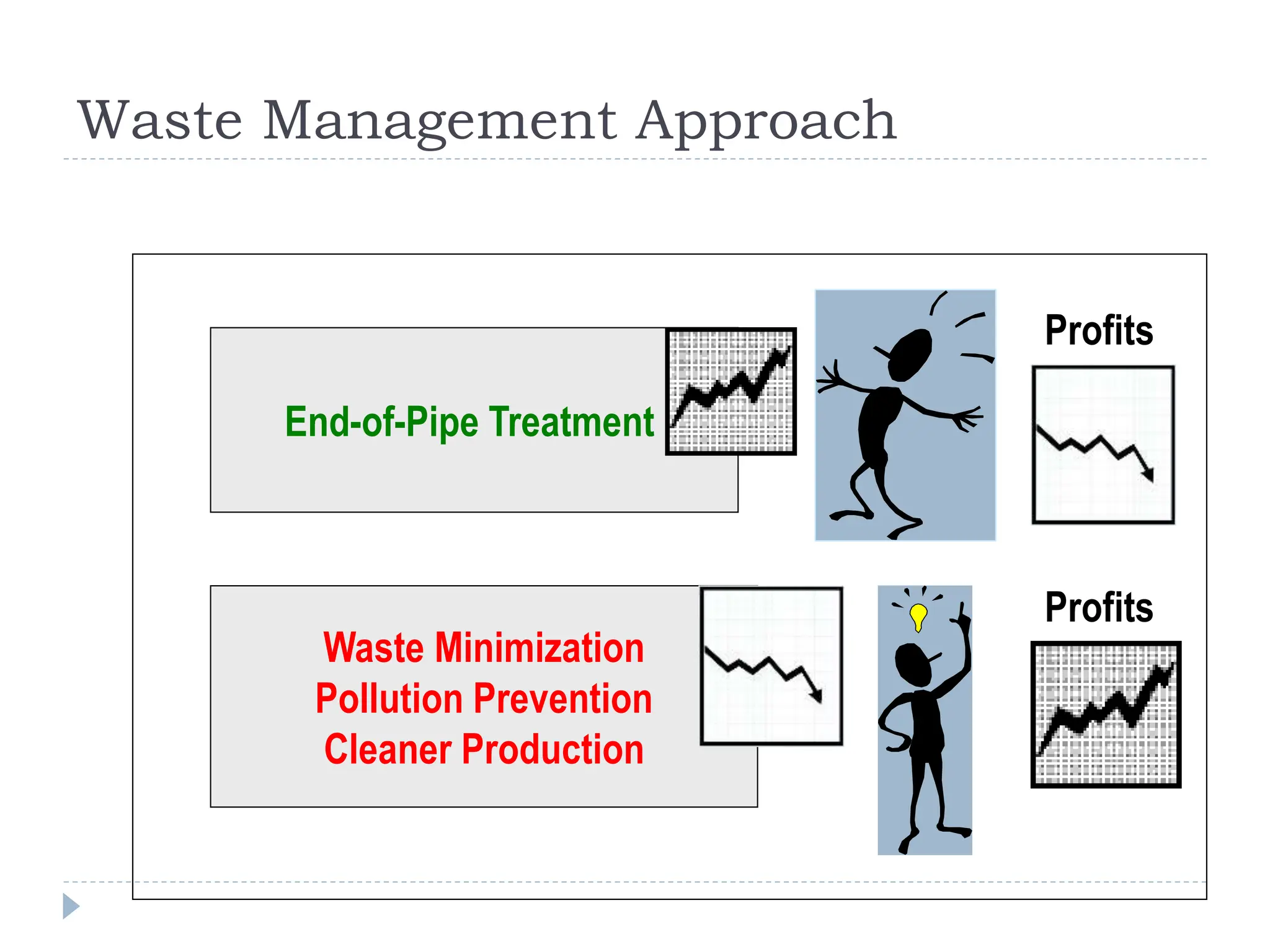

The document focuses on pollution prevention and waste minimization, outlining learning outcomes for students including concepts like cleaner production, waste management hierarchies, and recycling processes. Key strategies for source reduction are discussed, including changes in material input, technology, and procedures, aimed at enhancing efficiency and minimizing waste production. It emphasizes the importance of eco-efficiency and green productivity within the realm of sustainable development.